Vulcanized nano zero-valent iron-acid activated montmorillonite composite material, and preparation method and application thereof

A nano-zero-valent iron and composite material technology is applied in the field of soil pollution remediation, which can solve the problems of poor alkaline polluted soil effect, difficulty in meeting remediation requirements, and high sulfate content, and achieves the promotion of interlayer cation dissolution and effective adsorption sites. The effect of increasing the number of dots and increasing the specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

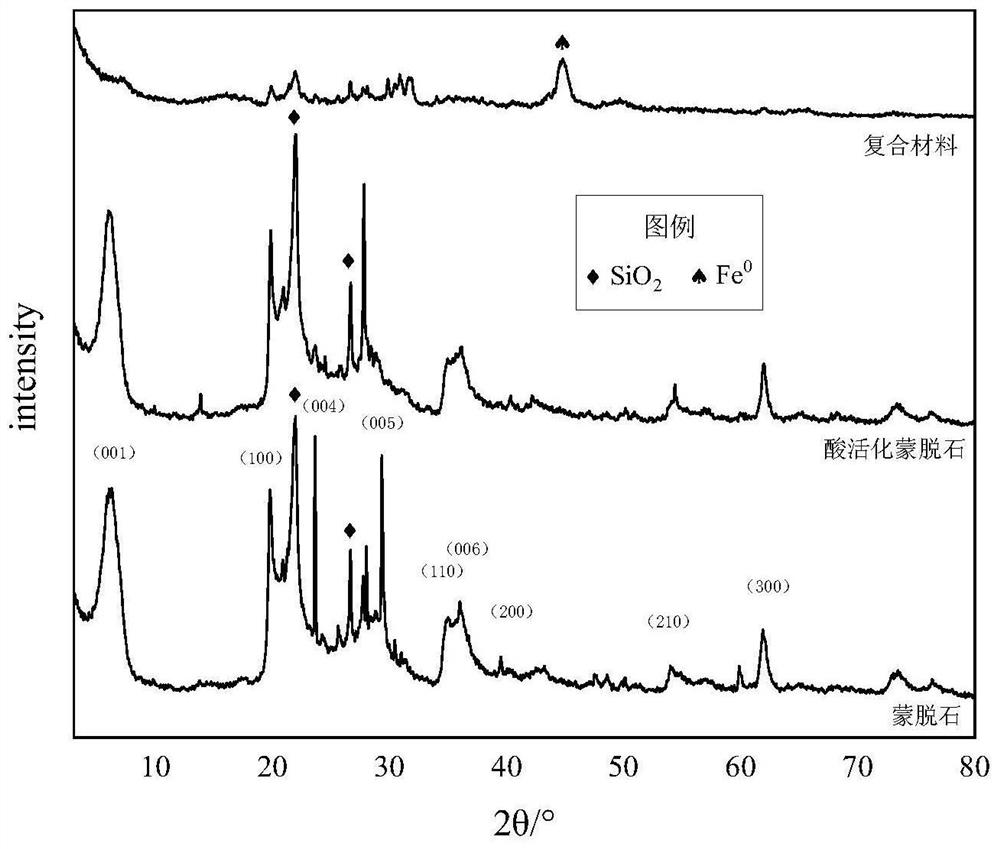

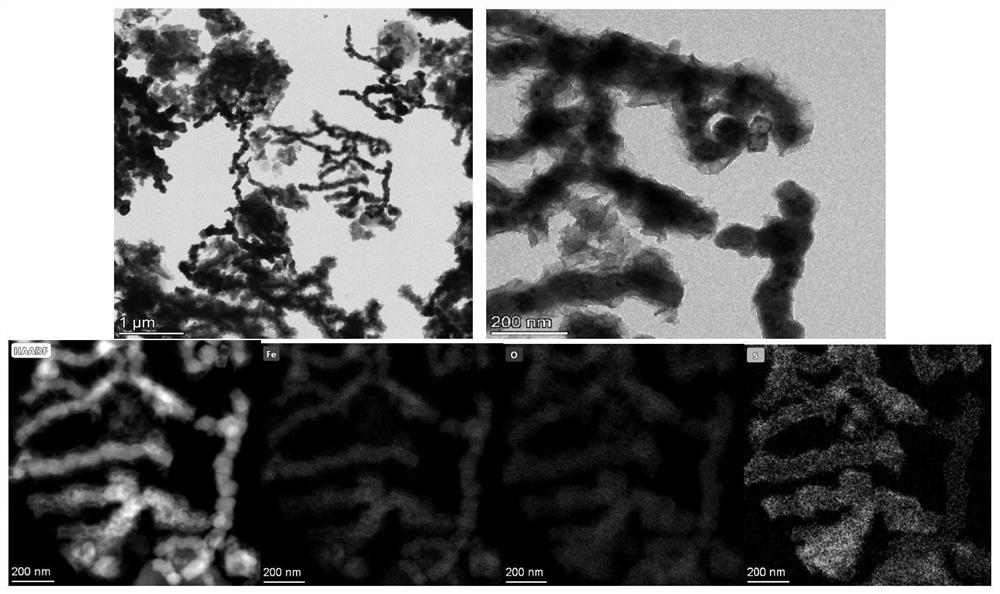

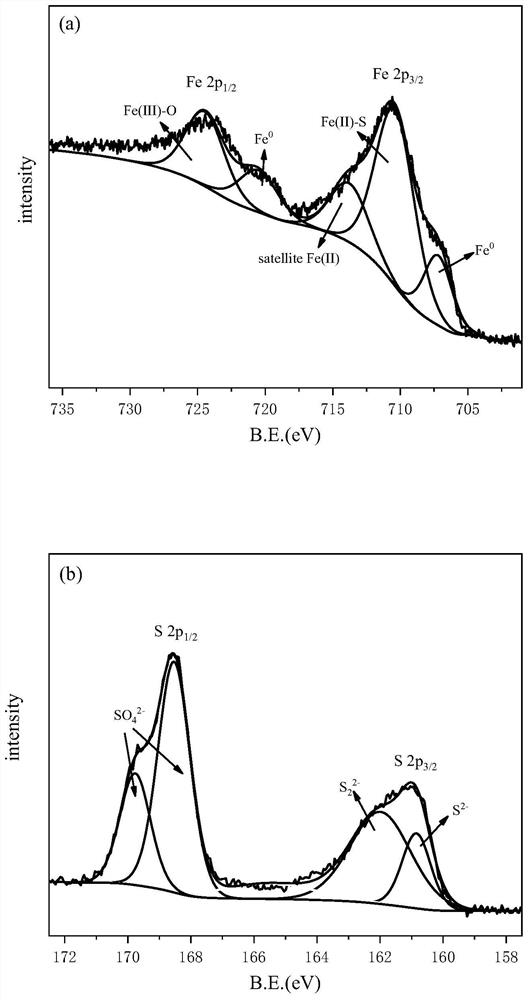

[0045] Embodiment 1: Different FeS / Fe 0 Preparation of Sulfurized Nanoscale Zero-Valent Iron-Acid-Activated Montmorillonite Composite Materials (One-Step Method)

[0046] Take 20g of calcium montmorillonite and disperse it in 100mL volume concentration of 20% sulfuric acid solution, react in a constant temperature oscillating reactor at 60°C for 8h, centrifuge after cooling, wash repeatedly with deionized water until no sulfate ion is detected in the waste liquid, After centrifugation, the solid was dried in a constant temperature drying oven at 105° C. for 12 hours to obtain an acid-activated montmorillonite product. Weigh 2.8g acid-activated montmorillonite in 100ml deoxidized deionized water, stir evenly, add 13.9g FeSO 4 ·7H 2 O, adsorb for 4 hours under nitrogen atmosphere, add 50mL sodium borohydride and 50mL Na 2 S solution. Press BH 4 - / Fe molar ratio of 2, 1.8 and 1 to control the concentration of sodium borohydride dosing is 2, 1.8 and 1mol / L; according to the...

Embodiment 2

[0047] Example 2: FeS / Fe 0 Preparation of 1 / 1 Sulfurized Nano-ZVF-Acid-Activated Montmorillonite Composite (Two-step Method)

[0048] Take 20g of calcium montmorillonite and disperse it in 100mL volume concentration of 20% sulfuric acid solution, react in a constant temperature oscillating reactor at 60°C for 8h, centrifuge after cooling, wash repeatedly with deionized water until no sulfate ion is detected in the waste liquid, After centrifugation, the solid was dried in a constant temperature drying oven at 105° C. for 12 hours to obtain an acid-activated montmorillonite product. Weigh 2.8g acid-activated montmorillonite in 100ml deoxidized deionized water, stir evenly, add 13.9g FeSO 4 ·7H 2 O, adsorbed under nitrogen atmosphere for 4h, at a rate of 0.5 ~ 3mL / min, according to BH 4 - Add 50mL of 1mol / L sodium borohydride solution at a / Fe molar ratio of 1, and then continue to react for 30min; then continue to drop 50mL of 0.5mol / L Na 2 S solution, and then continue to...

Embodiment 3

[0049] Example 3: FeS / Fe 0 Preparation of 1 / 1 sulfide nano-ZVI-montmorillonite composites (two-step method)

[0050] Weigh 2.8g calcium montmorillonite in 100ml deoxidized deionized water, stir evenly, adjust the pH value to 2, add 13.9g FeSO 4 ·7H 2 O, adsorbed under nitrogen atmosphere for 4h, at a rate of 0.5 ~ 3mL / min, according to BH 4 - Add 50mL of 1mol / L sodium borohydride solution at a / Fe molar ratio of 1, and then continue to react for 30min; then continue to drop 50mL of 0.5mol / L Na 2 S solution, and then continue to react for 30 minutes after completion. Centrifuge, rinse with deoxygenated and deionized water repeatedly, and finally dry in a freeze dryer for 24 hours to obtain FeS / Fe synthesized by two-step method 0 Sulfurized nano zero-valent-montmorillonite composite material with a ratio of 1 / 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com