Reductive iron-sulfur mixed colloid as well as preparation method and application thereof

A colloidal, iron-sulfur technology, applied in chemical instruments and methods, water pollutants, water/sludge/sewage treatment, etc., can solve the problem of reducing the reactivity and migration ability of ferrous sulfide particles, and the stabilization effect is not very ideal, Solve the problems of low passivation efficiency of heavy metals, achieve the effect of good sludge passivation of heavy metals, good practical application potential, and high economic utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

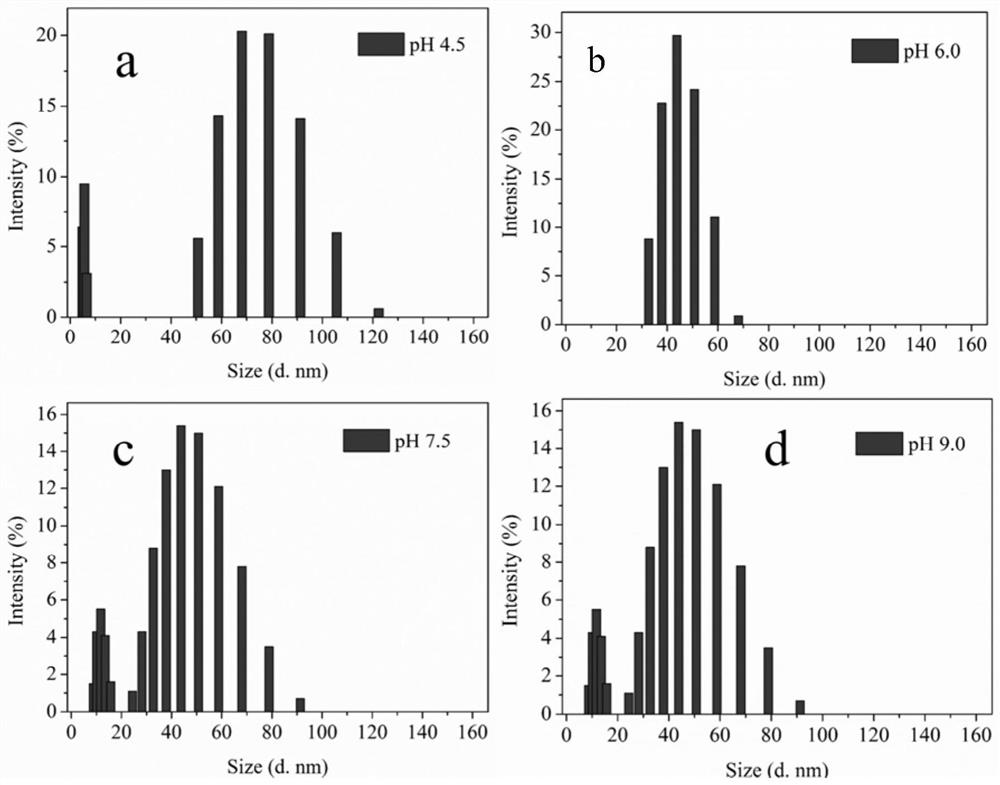

Image

Examples

Embodiment 1

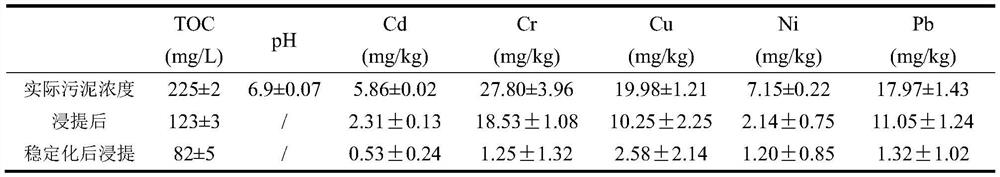

[0022] Example 1: Preparation and application of a reducing iron-sulfur mixed colloid for the stabilization and restoration of heavy metals in sludge

[0023] In this example, the water-soluble organic polymer compound is sodium polyacrylate (PAAS). Under the condition of a water bath at a temperature of 80°C, it is mechanically stirred at 400r / min for 1h, dissolved in water, and 0.1% by mass of polyacrylate is prepared. Sodium acrylate solution; ferrous sulfate (FeSO 4 ) solution concentration is 0.25mol / L; sodium sulfide (Na 2 S) The solution concentration is 0.5mol / L.

[0024] After the prepared water-soluble organic polymer solution was exposed to nitrogen for 0.5h, under normal temperature and anaerobic conditions, mechanically stirred at 400r / min, and FeSO was slowly added to the solution at a rate of less than 5mL / min. 4 Solution, obtain water-soluble organic polymer ferrous mixed colloid, wherein FeSO 4 The mass ratio to PAAS is 10:1. After the dropwise addition wa...

Embodiment 2

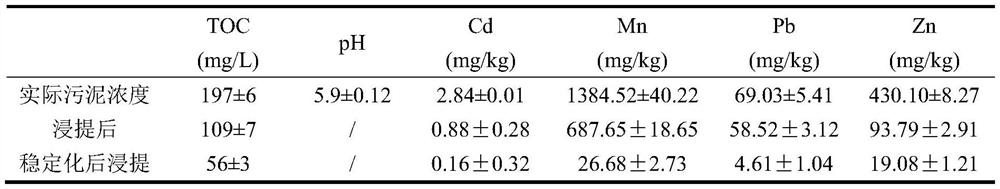

[0028] Example 2: Preparation and application of a reducing iron-sulfur mixed colloid for the stabilization and repair of heavy metals in sludge

[0029] In this example, the water-soluble organic polymer compound is polysodium methacrylate (SPMAA). Under the condition of a water bath at a temperature of 70°C, it is mechanically stirred at 350r / min for 1 hour, dissolved in water, and the mass percentage of the configuration is 0.15%. Sodium polymethacrylate solution; ferrous sulfate (FeSO 4 ) solution concentration is 0.5mol / L; sodium sulfide (Na 2 S) The solution concentration is 1.0mol / L.

[0030] After the prepared water-soluble organic polymer solution was exposed to nitrogen for 0.5h, under normal temperature and anaerobic conditions, mechanically stirred at 400r / min, and FeSO was added to the solution at a rate of 50 drops / min. 4 Solution, obtain water-soluble organic polymer ferrous mixed colloid, wherein FeSO 4 The mass ratio to SPMAA is 20:1. After the dropwise addit...

Embodiment 3

[0034] Example 3: Preparation and application of an original iron-sulfur mixed colloid for the stabilization and restoration of heavy metals in sludge

[0035] In this example, the water-soluble organic polymer compound is sodium polyacrylate (PAAS). Under the condition of a water bath at a temperature of 75° C., it is mechanically stirred at 400 r / min for 1 hour, dissolved in water, and 0.15% by mass of polyacrylate is prepared. Sodium acrylate solution; ferrous sulfate (FeSO 4 ) solution concentration is 0.5mol / L; sodium sulfide (Na 2 S) The solution concentration is 1.0mol / L.

[0036] After the prepared water-soluble organic polymer solution was exposed to nitrogen for 0.5h, under normal temperature and anaerobic conditions, mechanically stirred at 400r / min, and FeSO was slowly added to the solution at a rate of less than 5mL / min. 4 Solution, obtain water-soluble organic polymer ferrous mixed colloid, wherein FeSO 4 The mass ratio to PAAS is 12:1. After the dropwise add...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com