Method for leaching low-grade gold in high-arsenic sulfur concentrate acid-making cinder by microorganism preoxidation

A microbial and pre-oxidation technology, applied in the field of metallurgy, can solve the problems of difficult leaching and low recovery value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

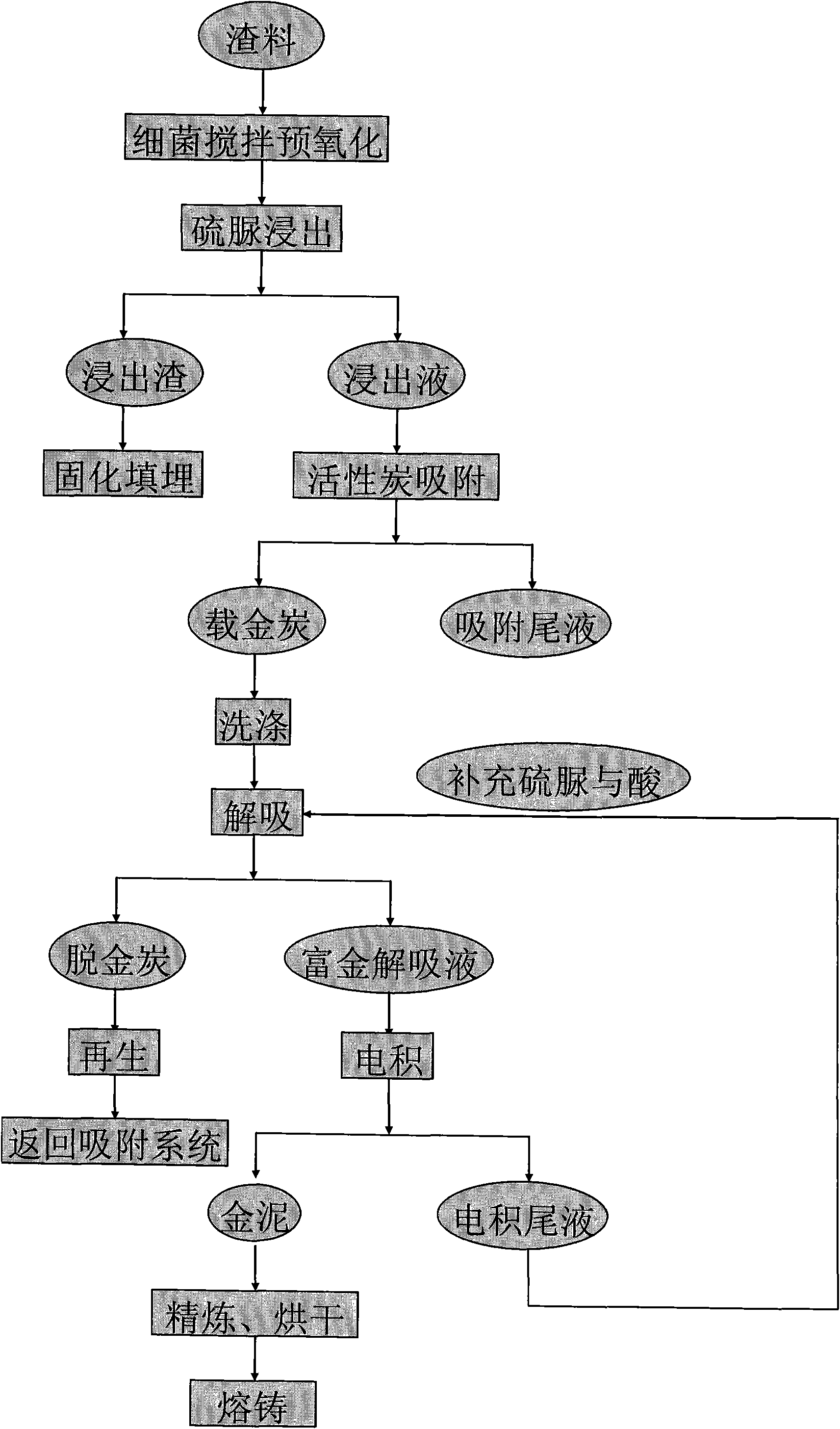

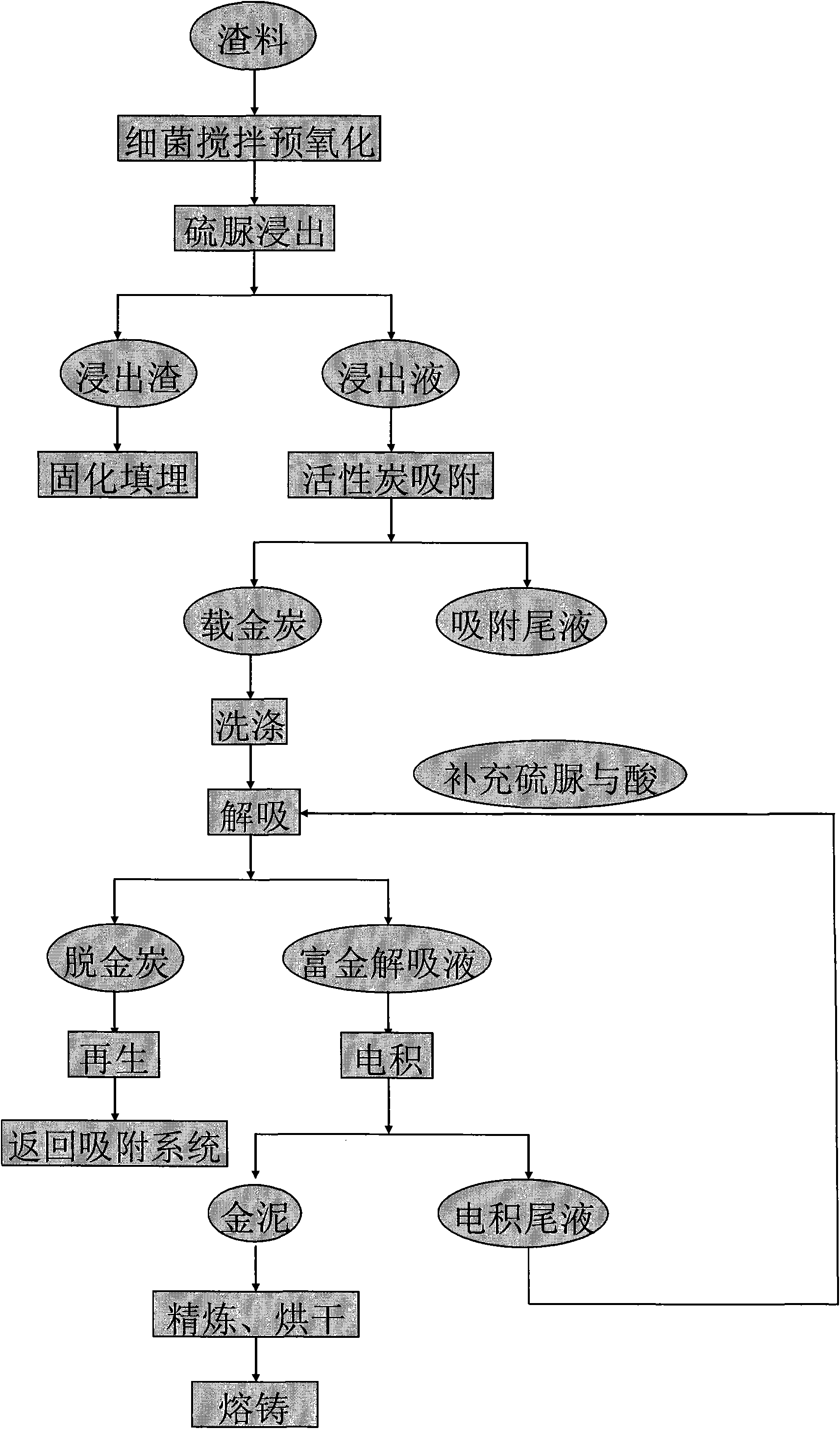

[0038] Concrete embodiment 1. containing 4.1% arsenic, gold 2.3g / ton's acid-making slag adopts bacterial preoxidation-thiourea leaching gold-activated carbon adsorption-desorption-electrowinning process, silver content 25g / ton in this slag material, copper content 0.12%, the technical process is shown in the accompanying drawing.

[0039] For relatively simple mineral composition, this process should be selected for slag with low content of silver, copper and other heavy metals except gold. Because this process adopts the activated carbon adsorption process, there are no strict requirements on the concentration of gold and oxygen in the leaching solution, so the control on the technical conditions is relatively loose and easy to master, and because the composition of the ore is simple, the content of silver and other metals in the leaching solution Less, less components competing with gold for adsorption. Therefore, the efficiency and capacity of activated carbon to adsorb go...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com