Method for detecting adsorbed-state microorganism in chalcopyrite biological leaching process

A bioleaching and detection method technology, which is applied in the direction of microorganism-based methods, microorganism measurement/inspection, biochemical equipment and methods, etc., can solve the problem of high-efficiency qualitative and quantitative detection methods for adsorbed microorganisms, extreme environment of leaching system, turbidity, etc. problems, to achieve the effect of low equipment requirements, simple and easy operation, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

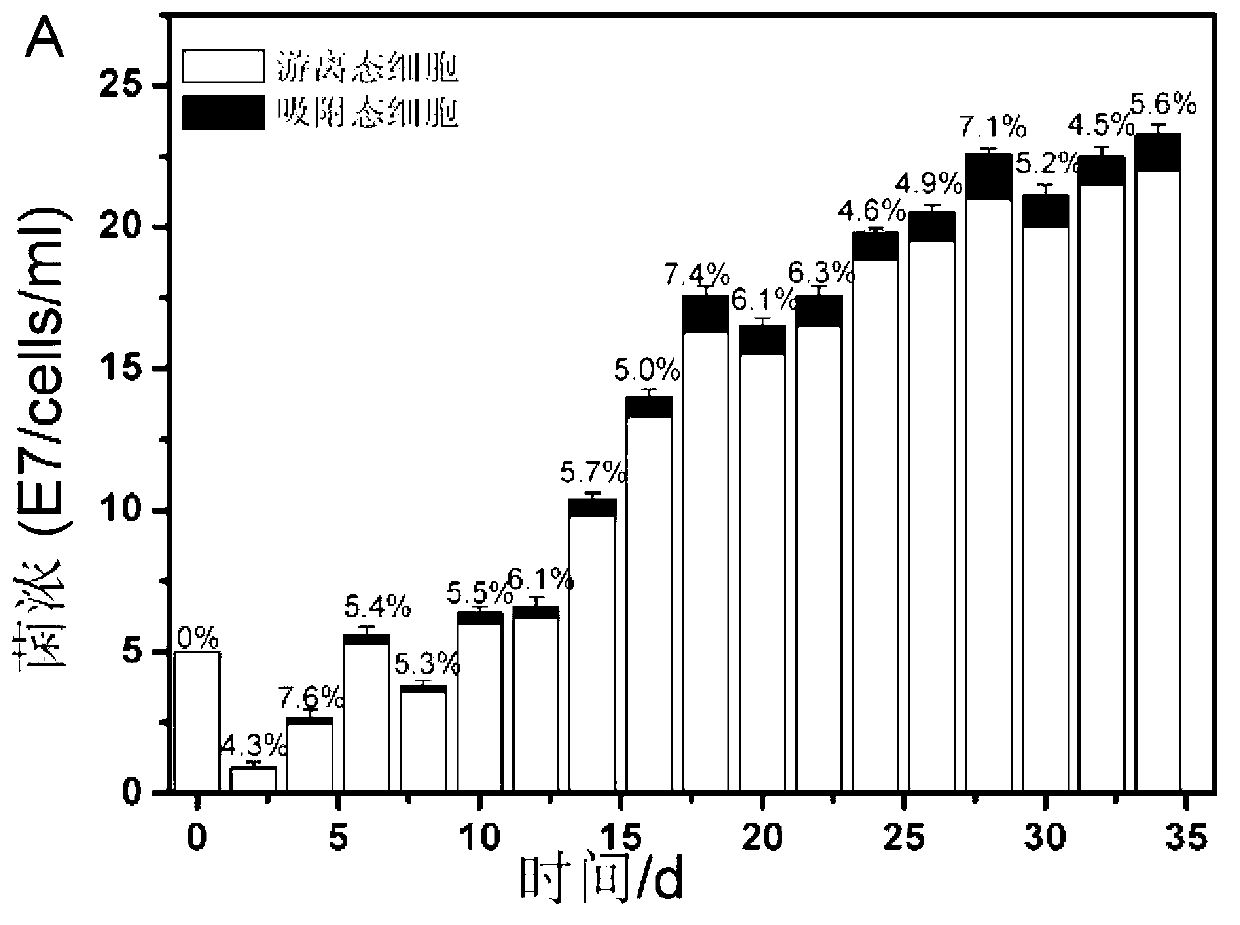

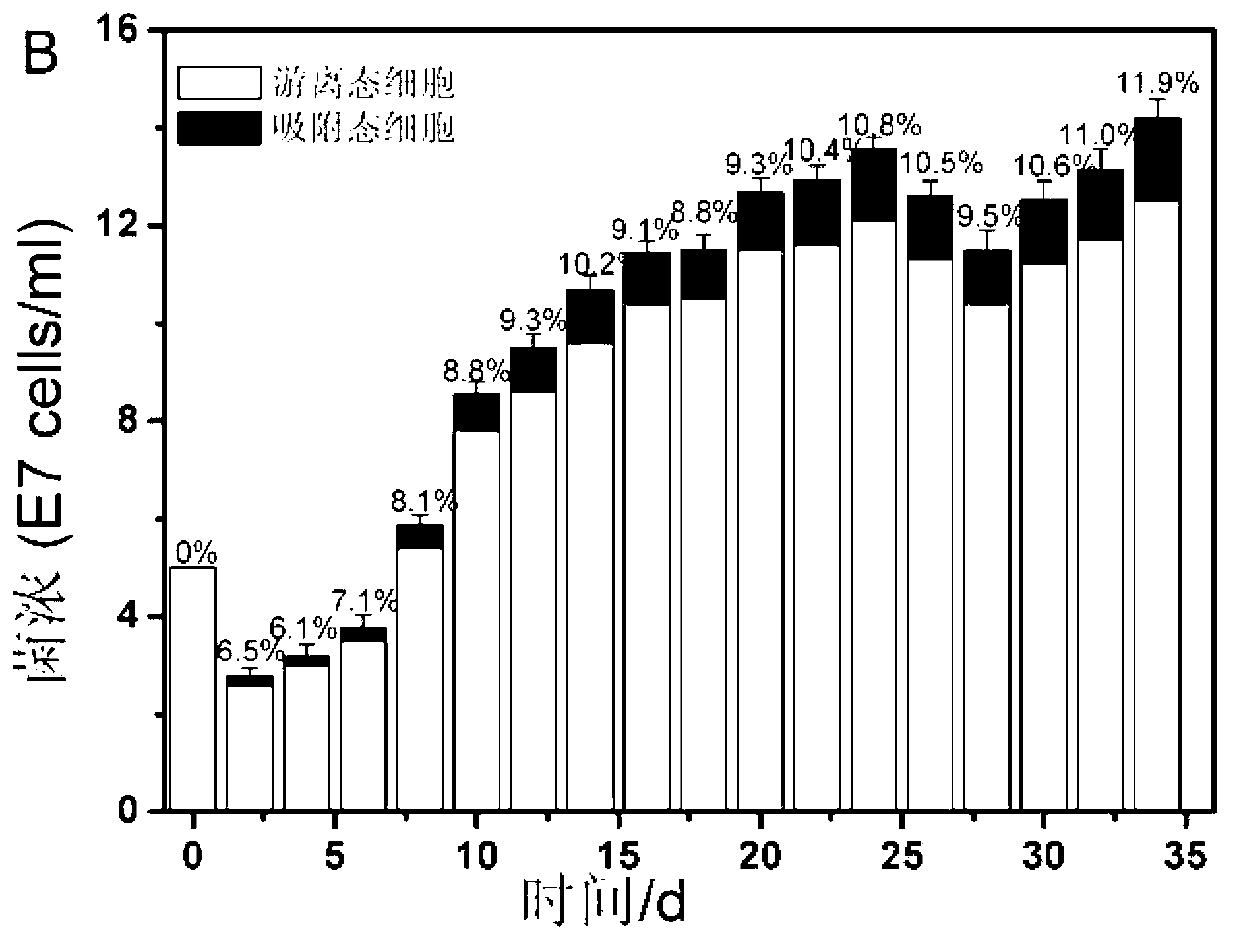

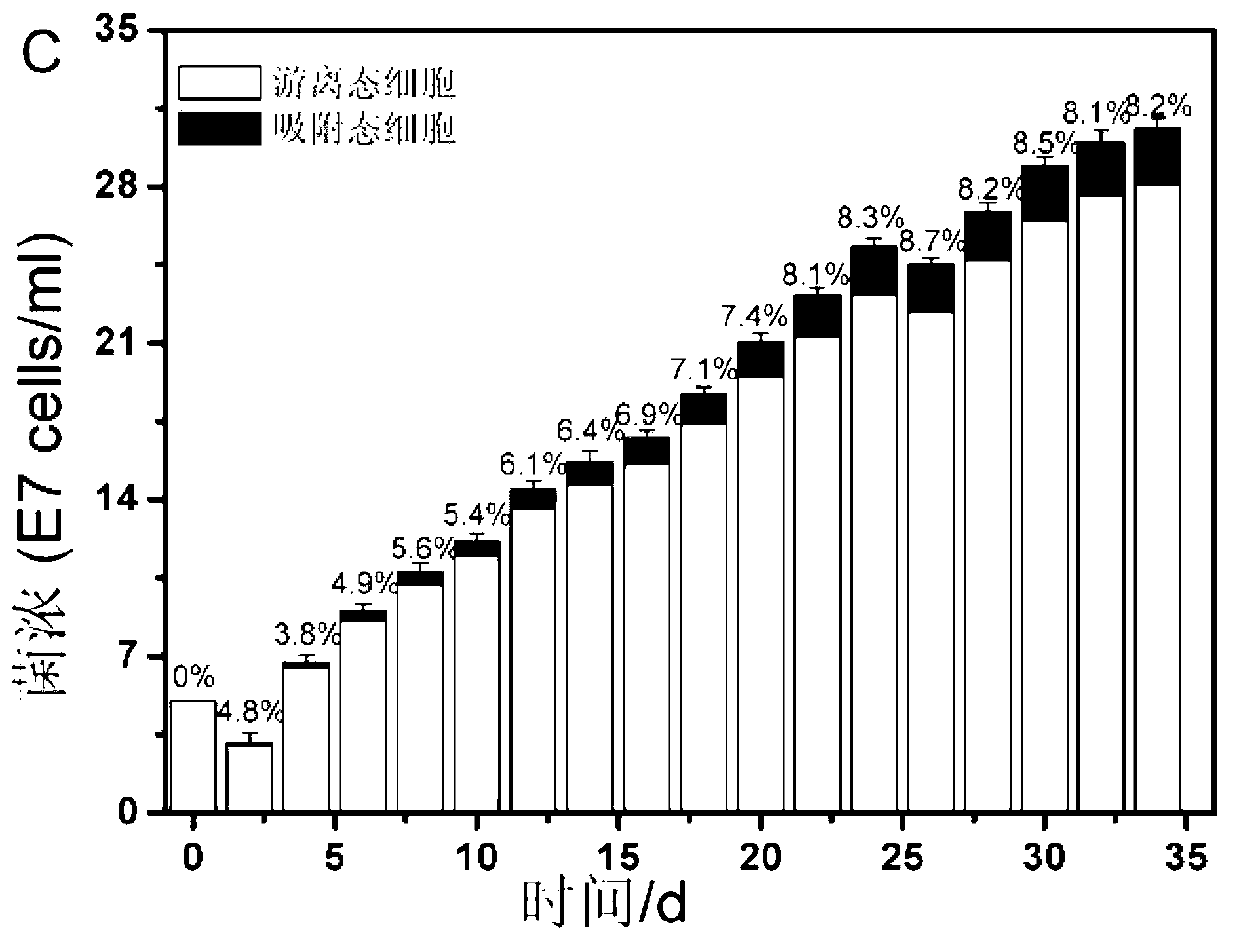

[0033] Example 1 Determination of the total bacterial concentration in the adsorbed state during the leaching process of different strains of chalcopyrite

[0034] Low-grade chalcopyrite originates from the Tonglingshan mining area in Anhui Province. The copper grade is 1.0%. The other main components are as follows: iron 31.8%, sulfur 12.9%, calcium 3.65%, magnesium 3.77%, aluminum 1.45%, and zinc 0.054%. The ore is preliminarily crushed and screened with a 100-mesh sieve to control the particle size of the ore powder to 7 individual / mL, (NH 4 ) 2 SO 4 3.0 g / L, K 2 HPO 4 0.5 g / L, MgSO 4 ·7H 2 O 0.5 g / L, KCl 0.1 g / L, Ca(NO 3 ) 2 0.01 g / L. Thiobacillus thiooxidans ZJJN-1 pure bacteria system: 100mL Starkey medium, cell concentration 5.0×10 7 individual / mL, (NH 4 ) 2 SO 4 3.0 g / L, KH 2 PO 4 3.5 g / L, MgSO 4 ·7H 2 O 0.5 g / L, CaCl 2 2H 2 O 0.25 g / L. Mixed strains of two bacteria (cell number concentration 1︰1): 50mL 9K medium + 50mL Starkey medium, the total...

Embodiment 2

[0038] Example 2 Qualitative and quantitative detection of adsorbed strains in the mixed strain system of Thiobacillus ferrooxidans CUMT-1 and Thiobacillus thiooxidans ZJJN-1

[0039] In this experiment, the Thiobacillus ferrooxidans probe set, including the main probe, capture probe and signal probe, has been applied for a patent, patent number: 201110169853.4.

[0040] According to the comparison with the close relatives of the strain, there are at least two or more base differences, indicating that the specificity is good. Using a 16S rRNA-based detection process, such as figure 2 .

[0041] (1) Preparation of streptavidin-coated plates: Streptavidin was prepared with coating solution at 5 μg / mL, and 100 μL was added to each well of the microplate, sealed with a parafilm and kept overnight at 4°C for the second time. Take out every day, wash 3 times with PBST washing solution, then use 250 μL of 0.1% BSA (solvent is 0.1mol / L PBS buffer solution with pH 7.2), block at 37°...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com