Automobile urea concentration detection system and method based on ultrasonic waves

A technology for concentration detection and automotive urea, which is applied in the direction of measuring devices, complex mathematical operations, instruments, etc., can solve problems such as changes, exhaust emission not up to standard, and inaccurate concentration of urea solution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

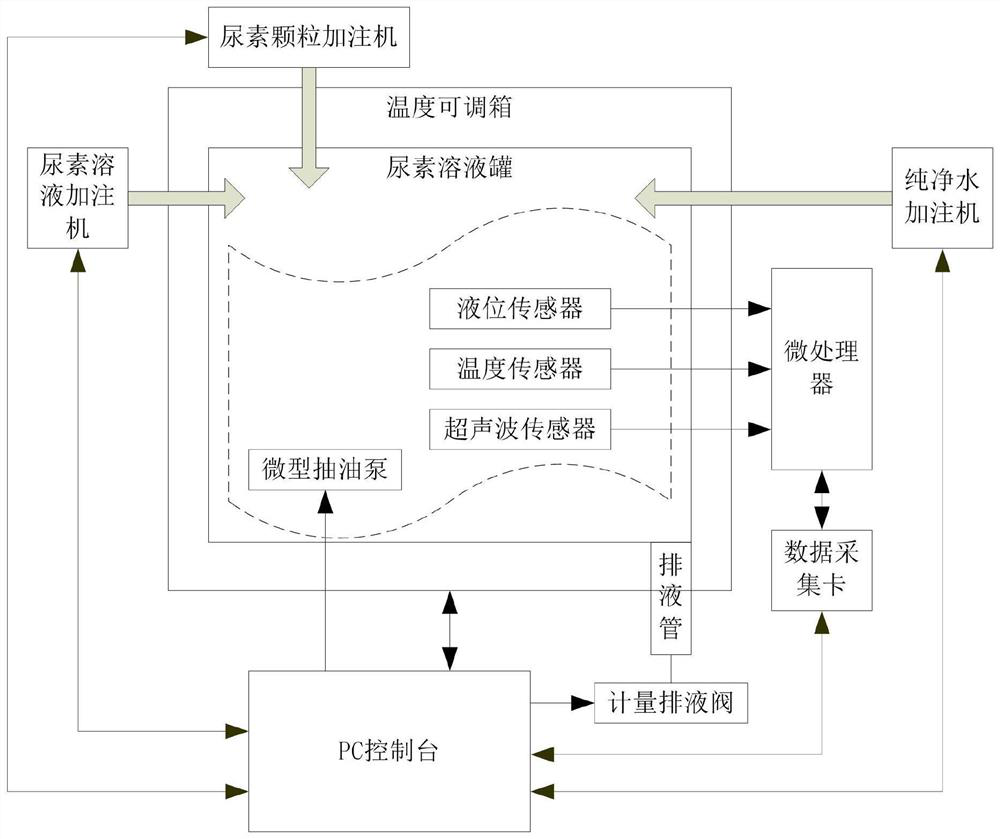

[0052] refer to figure 1 , an ultrasonic-based automotive urea concentration detection system, including:

[0053] The urea solution tank is used for the configuration, detection and storage of the urea solution; specifically, the shape of the urea solution tank is not limited, and may be in the shape of a tank, barrel, square or pool, etc.

[0054] A urea granule filling machine, the urea granule filling machine communicates with the first filling port of the urea solution tank, and is used for filling urea granules into the urea solution tank; specifically, the diameter of the urea granules ranges from 0.5 mm to 2 mm, The diameter of urea particles is preferably 1 mm; urea powder can also be used to facilitate rapid integration into the solution; small urea particles and powders are also convenient for accurate weight calculation and improve the detection accuracy of urea solution concentration.

[0055] A pure water filling machine, the pure water filling machine communica...

Embodiment 2

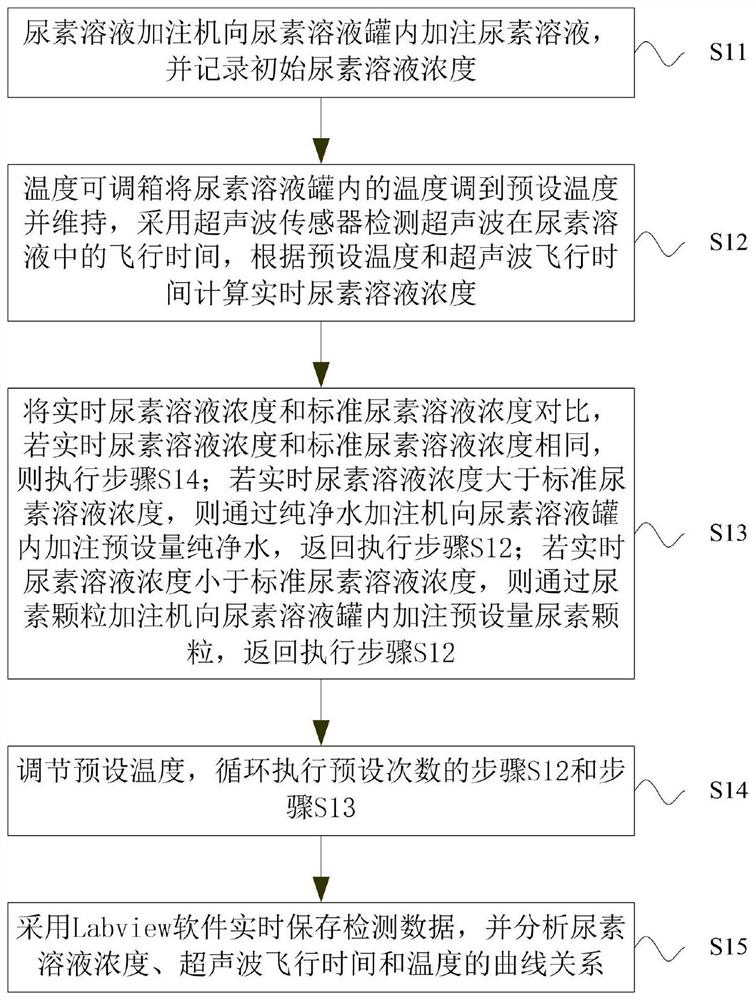

[0081] refer to figure 2 , a kind of automobile urea concentration detection method based on ultrasonic wave, comprises the following steps:

[0082] S11: Fill urea solution into the urea solution tank through the urea solution filling machine, and record the initial urea solution concentration; specifically, the urea solution in the urea solution filling machine is prepared in advance, and the concentration of urea solution can be advanced as required The setting is good; because urea itself is easy to volatilize, the solution in the urea solution filling machine needs to be replaced regularly, so as to ensure that the concentration of urea solution is within the range of volatilization error and the accuracy of urea concentration detection in the urea solution tank.

[0083] S12: Adjust the temperature in the urea solution tank to the preset temperature and maintain it through the temperature adjustable box, use the ultrasonic sensor to detect the flight time of the ultraso...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com