Method for removing heavy metal in excess activated sludge

A technology for residual activity and heavy metals, applied in biological sludge treatment, chemical instruments and methods, water/sludge/sewage treatment, etc. problem, to achieve the effect of economical feasibility, easy operation, and short removal time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

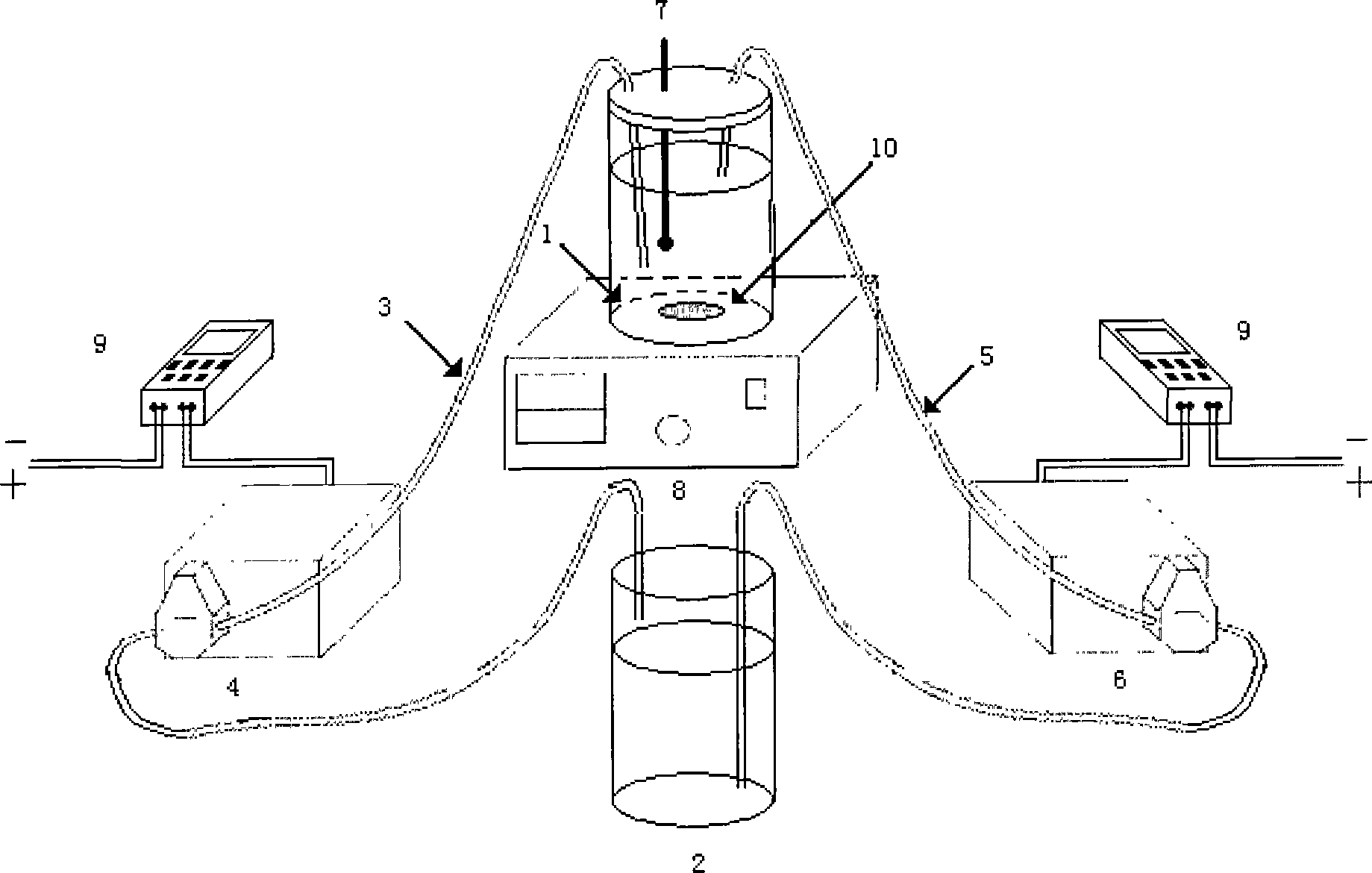

[0014] 1. Experimental equipment

[0015] 1) Reaction barrel

[0016] In this experiment, a 3-liter plexiglass bioreactor was used, with a liquid inlet, a liquid outlet, and a thermometer jack on the top. The reaction barrel was placed in a constant temperature water bath device with magnetic stirring function to ensure constant temperature and temperature during the reaction process. Stir well.

[0017] 2) Outflow and return constant flow pump

[0018] The outflow and backflow cross-flow pump can discharge or add a fixed amount of culture solution within a fixed time, and is used in conjunction with a microcomputer switch to pump a certain amount of reaction solution from the biological reaction tank within a specified time.

[0019] 1.3 microcomputer time control switch

[0020] The time can be preset, and it can be turned on and off at regular intervals to control the biological reaction, the outflow of the reaction solution and the reflux of the acidic bacteria solution...

Embodiment 2

[0036] 1. Experimental equipment

[0037] 1) Biological reaction tank

[0038] This experiment uses a 3-liter plexiglass biological reaction tank with a liquid inlet, a liquid outlet and a thermometer jack on the top. The reaction tank is placed in a constant temperature water bath device with magnetic stirring function to ensure the temperature and stirring during the reaction. .

[0039] 2) Outflow and return constant flow pump

[0040] The outflow and backflow cross-flow pump can discharge or add a fixed amount of culture solution within a fixed time, and is used in conjunction with a microcomputer switch to pump a certain amount of reaction solution from the biological reaction tank within a specified time.

[0041] 3) Microcomputer time control switch

[0042] The time can be preset, and it can be turned on and off at regular intervals to control the biological reaction, the outflow of the reaction solution and the reflux of the acidic bacteria solution, etc. The enti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com