Denitrification functional filler, and filler ball, filling method and applications thereof

A technology of functional fillers and filler balls, used in chemical instruments and methods, special compound water treatment, water/sludge/sewage treatment, etc., to achieve the effect of increasing biomass, low sludge production, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

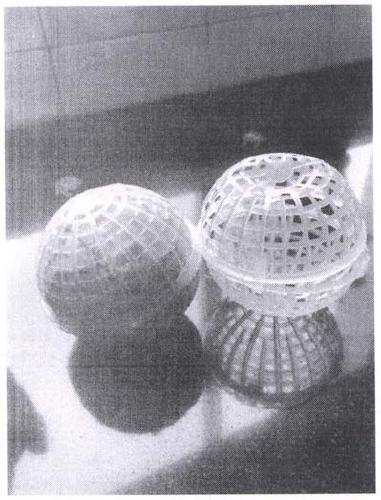

Image

Examples

Embodiment 1

[0071] Denitrification functional filler: 31.4 parts by weight of iron-carbon filler, 27.5 parts by weight of iron filings particles, 27.5 parts by weight of sulfur particles, and 7.8 parts by weight of biological activated carbon. Wherein the mass percent of each composition in the iron-carbon filler is iron: carbon: binding agent=88%: 8%: 4%, the iron-carbon filler is rugby ball shape, and its major axis radius is 8 ± 1cm, and minor axis radius is 3±0.5cm; the length and width of iron filings particles are 0.6cm, and the thickness is 0.06cm; the particle size of sulfur particles is about 0.2cm.

[0072] Filler balls: 3.9 parts by weight of anti-corrosion non-woven fabric, 2 parts by weight of filter balls.

[0073] The above-mentioned nitrogen-removing functional fillers are weighed, mixed completely, packed in anti-corrosion non-woven packing bags, and then packed into filter balls. After the packing balls are packaged, they need to be stored in a dry and low temperature p...

Embodiment 2

[0077] Denitrification functional filler: 31.4 parts by weight of iron-carbon filler, 27.5 parts by weight of iron filings particles, 27.5 parts by weight of sulfur particles, and 7.8 parts by weight of biological activated carbon. Wherein the mass percentage of each composition in the iron-carbon filler is iron: carbon: binding agent=88%: 8%: 4%, and the iron-carbon filler is rugby ball shape, and its major axis radius is 8 ± 1cm, and minor axis radius 3±0.5cm; the length and width of iron filings particles are 0.6cm, and the thickness is 0.06cm; the particle size of sulfur particles is about 0.2cm.

[0078] Filler balls: 3.9 parts by weight of anti-corrosion non-woven fabric, 2 parts by weight of filter balls.

[0079] The above-mentioned nitrogen-removing functional fillers are weighed, mixed completely, packed in anti-corrosion non-woven packing bags, and then packed into filter balls. After the packing balls are packaged, they need to be stored in a dry and low temperatu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length and width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com