Method for biologically removing hydrogen sulfide and ammonia gas by steel sulfuric acid pickling waste liquor

A technology of hydrogen sulfide and biological oxidation, which is applied in chemical instruments and methods, separation methods, air quality improvement, etc., can solve the problems of producing a large amount of waste water, biological poisoning, increasing treatment costs and engineering costs, etc., so as to save input costs and avoid Effect of secondary pollution and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

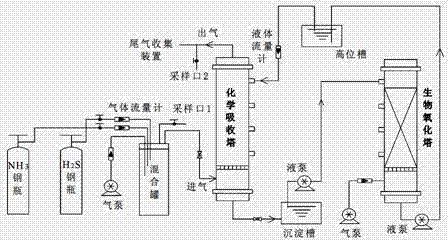

[0026] A method for biologically removing hydrogen sulfide and ammonia by using sulfuric acid washing waste liquid of iron and steel is carried out in the device shown in the accompanying drawing, wherein the chemical absorption tower and the biological oxidation tower are both made of plexiglass, the height of the chemical absorption tower is 1015mm, and the inner diameter 90mm, outer diameter 100mm, volume about 6.45L; biological tower height 1500mm, inner diameter 90mm, outer diameter 100mm, filled with 20-mesh polyurethane sponge, the effective volume of the packing layer is 10L. The bottom of the chemical absorption tower is equipped with an acid-resistant porous aeration device and a porous sieve plate to achieve uniform gas distribution and increase the total gas-liquid contact area. In the biological oxidation tower, the immobilized acidophilic Thiobacillus ferrooxidans attached to the polyurethane sponge is used as the main production body. The specific implementation...

Embodiment 2

[0032] A method for biologically removing hydrogen sulfide and ammonia by using iron and steel sulfuric acid washing waste liquid, the implementation steps are as follows:

[0033] 1) No nitrogen source is added to the culture solution used in the continuous operation of the biological oxidation tower, that is, only magnesium sulfate and potassium chloride are added to the nutrient salts when optimizing the sulfuric acid washing waste liquid of iron and steel. During operation, fresh culture fluid is continuously fed in, aeration is continuous, and biological oxidation fluid flows out from the lower part of the biological tower. Among them, the dilution rate of the culture solution is 0.09h -1 , the aeration rate is 150L / h. The concentration of soluble ferric iron in the obtained biological oxidation solution can reach 0.121-0.143mol / L under optimal conditions.

[0034]2) During the operation of the chemical absorption tower, use a peristaltic pump to pump the biological oxi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com