Preparation method and application of spherical nano iron-sulfur composite material

A composite material and nano-iron technology, which is applied in the field of preparation of spherical nano-iron-sulfur composite materials, can solve the problems of short service life and low electron utilization efficiency, and achieve the effects of improving service life, increasing electronic utilization efficiency and high efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] This embodiment provides the preparation method and application of spherical nano-iron-sulfur composite material:

[0032] Dissolve ferrous nitrate in hydrochloric acid solution with a pH value of 4.0 at room temperature, and add Na 2 S solution, reacted for 30 minutes, then added tea polyphenols, continued stirring and reacting for 60 minutes to obtain black particles, magnetically separated, washed, and vacuum freeze-dried to obtain spherical nano-iron-sulfur composite materials. Among them, Na 2 The molar ratio of S to ferrous salt is 1:1, and the molar ratio of tea polyphenols to ferrous salt is 1:1.

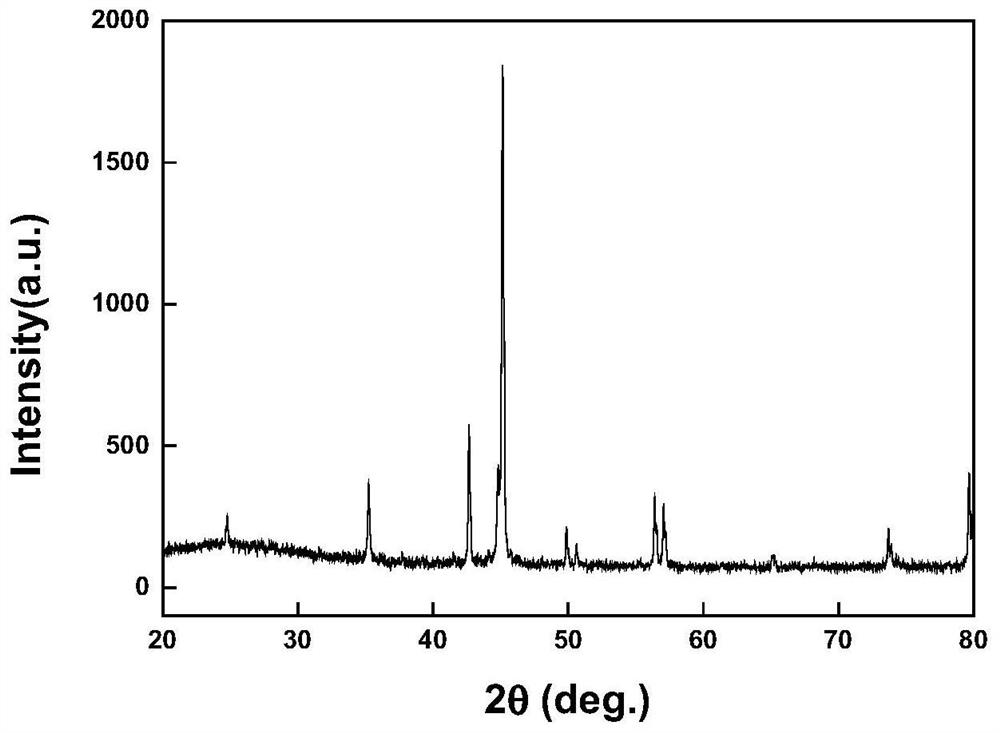

[0033] The X-ray diffraction pattern (XRD) of spherical nano-iron-sulfur composites is as follows: figure 1 shown.

[0034] This material was used to activate PS to degrade 1,2-dichlorobenzene (1,2-DCB, C 6 h 4 C l2 ), the specific degradation method is: add persulfate in the soil containing 1,2-dichlorobenzene, add the spherical nano-iron-sulfur composite mater...

Embodiment 2

[0039] This embodiment provides the preparation method and application of spherical nano-iron-sulfur composite material:

[0040] Dissolve ferrous sulfate in a hydrochloric acid solution with a pH value of 4.5 at room temperature, and add Na 2 S solution, reacted for 30 minutes, then added tea polyphenols, continued stirring and reacting for 60 minutes to obtain black particles, magnetically separated, washed, and vacuum freeze-dried to obtain spherical nano-iron-sulfur composite materials. Among them, Na 2 The molar ratio of S to ferrous salt is 2:1, and the molar ratio of tea polyphenols to ferrous salt is 1:2.

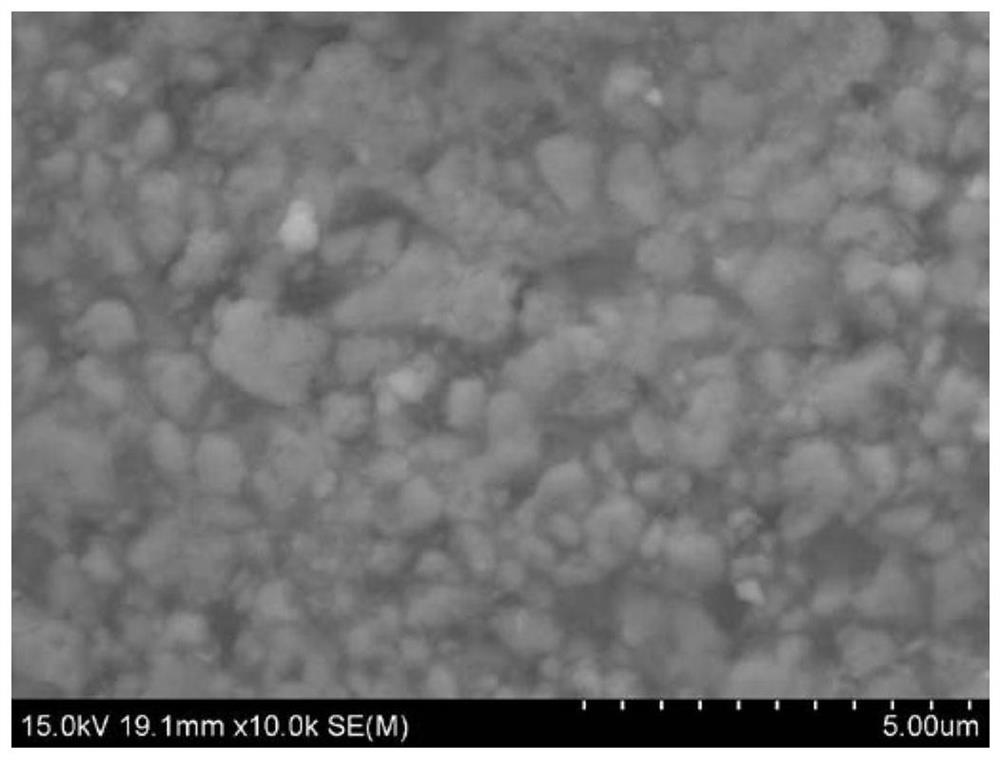

[0041] The scanning electron microscope (SEM) images of spherical nano-iron-sulfur composites are as follows: figure 2 shown.

[0042] The material was used to activate PS to degrade trichlorethylene (TCE, C 2 HCl 3 ), the specific degradation method is: add persulfate in the groundwater containing trichlorethylene, add the spherical nano-iron-sulfur composite...

Embodiment 3

[0047] This embodiment provides the preparation method and application of spherical nano-iron-sulfur composite material:

[0048] Dissolve ferrous chloride in a hydrochloric acid solution with a pH value of 4 at room temperature, and add Na 2 S solution, reacted for 30 minutes, then added tea polyphenols, continued stirring and reacting for 60 minutes to obtain black particles, magnetically separated, washed, and vacuum freeze-dried to obtain spherical nano-iron-sulfur composite materials. Among them, Na 2 The molar ratio of S to ferrous salt is 5:1, and the molar ratio of tea polyphenols to ferrous salt is 2:1.

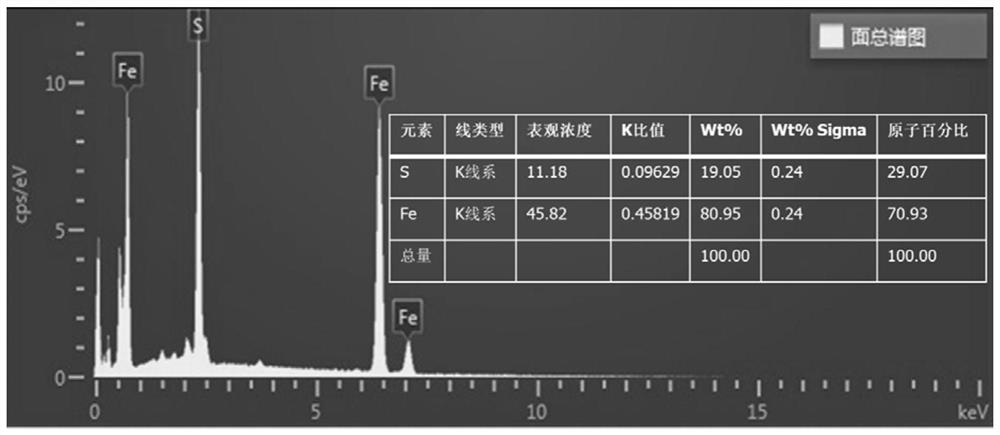

[0049] Energy dispersive spectroscopy (EDS) of spherical nano-iron-sulfur composites image 3 shown.

[0050] This material was used to activate PS to degrade sulfamethoxine sodium (SMM, C 12 h 13 N 4 NaO 4 S), the specific degradation method is: add persulfate in groundwater containing trichlorethylene, add the spherical nanometer iron-sulfur composite materi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com