Novel method for preparing iron-sulfur-titanium-based NH<3>-SCR denitrification catalyst

A technology of NH3-SCR, denitration catalyst, applied in chemical instruments and methods, physical/chemical process catalysts, separation methods, etc., can solve the problems of low experimental space velocity and low activity, and achieve wide temperature range, high activity, improved active effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Add 2.48g TiOSO4 and 0.125 g FeSO4 into 40 ml deionized water, dissolve until the solution is clear and transparent, adjust the pH to 0.8 with sulfuric acid, then put it in an oil bath at 90°C, hydrolyze and precipitate for 4h, stop heating, and cool to room temperature. The product was subjected to vacuum filtration, and the filter cake was dried at 100 °C for 12 h, and finally calcined at 500 °C for 2 h at a heating rate of 2 °C / min. After roasting and cooling, the iron-titanium-based high-temperature NH3-SCR denitration catalyst was obtained. The mass fraction of iron in the prepared catalyst was 2.5%, and the content of sulfur was 3.2%.

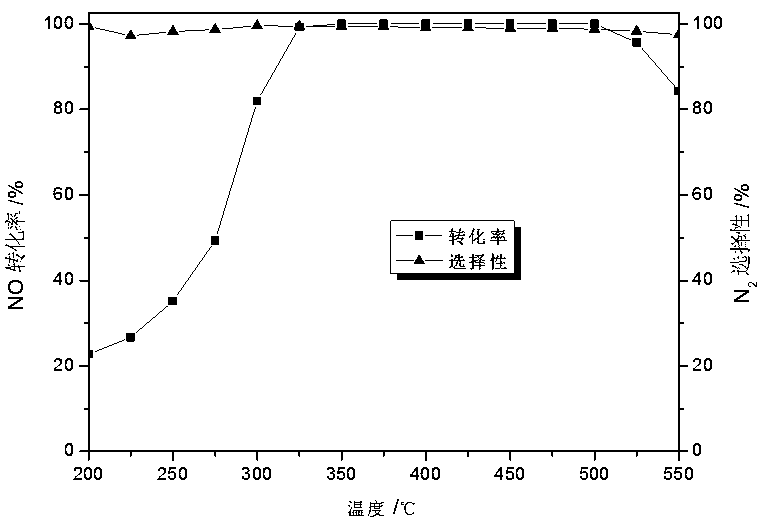

[0024] Take 0.2 g of the catalyst prepared in this example and place it in a fixed-bed reactor with an inner diameter of 0.6 mm. The volume space velocity is 60000 h-1, and the concentrations of NO and NH3 are both 800 ppm. The catalytic effect is as follows: Figure 1 , in the range of 325~525℃, the denitrification efficiency is 9...

Embodiment 2

[0026] This embodiment is to change the pH of hydrolysis precipitation on the basis of embodiment 1.

[0027] Add 2.48g TiOSO4 and 0.125 g FeSO4 into 40 ml deionized water, dissolve until the solution is clear and transparent, adjust the pH to 1.3 with sulfuric acid, then put it in an oil bath at 90°C, hydrolyze and precipitate for 4h, stop heating, and cool to room temperature. The product was subjected to vacuum filtration, and the filter cake was dried at 100 °C for 12 h, and finally calcined at 500 °C for 2 h at a heating rate of 2 °C / min. After roasting and cooling, the iron-titanium-based high-temperature NH3-SCR denitration catalyst was obtained. The mass fraction of iron element in the prepared catalyst was 3.0%, and the content of sulfur element was 3.5%.

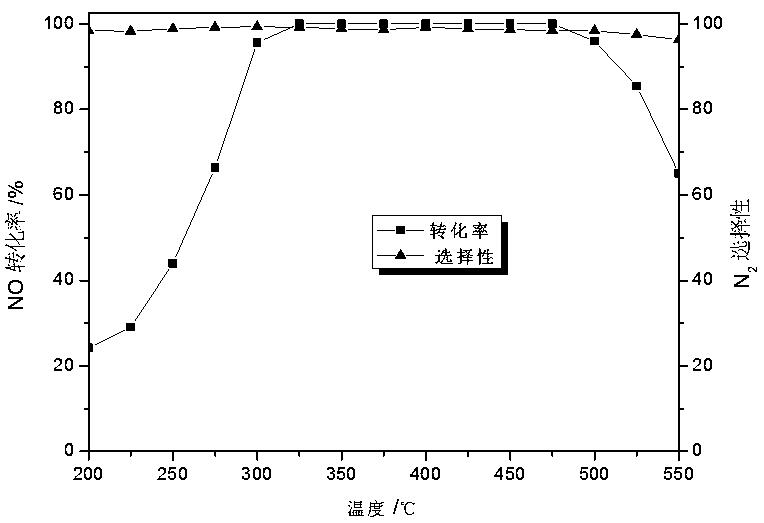

[0028] Take 0.2 g of the catalyst prepared in this example and place it in a fixed-bed reactor with an inner diameter of 0.6 mm. The volume space velocity is 60000 h-1, and the concentrations of NO and NH3 are both...

Embodiment 3

[0030] The present embodiment changes the consumption of ferric sulfate on the basis of embodiment 1.

[0031] Add 2.48g TiOSO4 and 0.250 g FeSO4 into 40 ml deionized water, dissolve until the solution is clear and transparent, adjust the pH to 0.8 with sulfuric acid, then put it in an oil bath at 90°C, hydrolyze and precipitate for 4h, stop heating, and cool to room temperature. The product was subjected to vacuum filtration, and the filter cake was dried at 100 °C for 12 h, and finally calcined at 500 °C for 2 h at a heating rate of 2 °C / min. After roasting and cooling, the iron-titanium-based high-temperature NH3-SCR denitration catalyst was obtained. The mass fraction of iron element in the prepared catalyst was 4%, and the content of sulfur element was 3.9%.

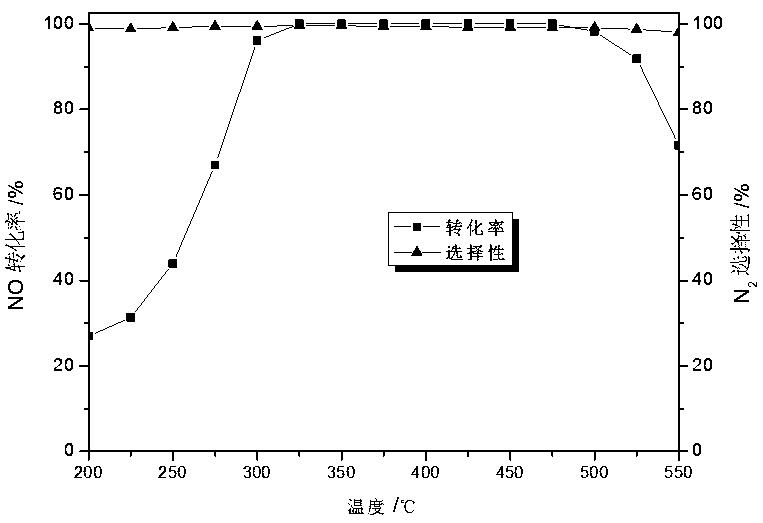

[0032] Take 0.2 g of the catalyst prepared in this example and place it in a fixed-bed reactor with an inner diameter of 0.6 mm. The volume space velocity is 60000 h-1, and the concentrations of NO and NH3 are both ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com