Iron-sulfur cluster and apoferritin complex and preparation method and application thereof

A technology of apoferritin and iron-sulfur clusters, which is applied in chemical instruments and methods, organic compound/hydride/coordination complex catalysts, chemical/physical processes, etc. Poor water solubility and other problems, to achieve the effect of enhancing catalytic hydrogen production efficiency, good biocompatibility, and strong stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

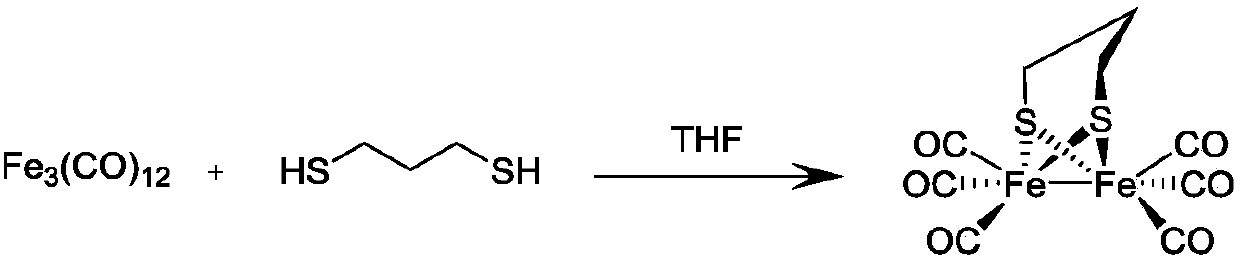

Method used

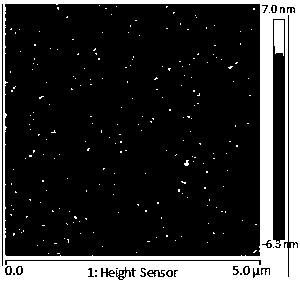

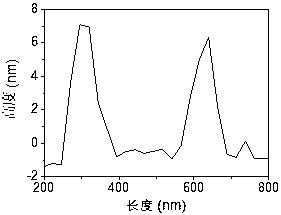

Image

Examples

preparation example Construction

[0072] The preparation method comprises the following steps:

[0073] (1) Synthesis of 1,10-phenanthroline-5,6-dione:

[0074] First synthesize 1,10-phenanthroline-5,6-dione, prepare a mixed acid solution containing 20mL of concentrated sulfuric acid and 10mL of concentrated nitric acid, and add 2.0g of 1,10-phenanthroline and potassium bromide 2.0 in the mixture of g. Heat in an oil bath at 130°C for 3 hours. After cooling to room temperature, it was added to 250 mL of deionized water at 4 °C, and the pH was neutralized to 6-7 with 80 mL of 10 M NaOH. Then use CHCl 3 Extracted 3 times, 100 mL each time, finally treated with anhydrous sodium sulfate and dried in a vacuum oven to obtain 1.8 g of a bright yellow solid product.

[0075] (2) Synthesis of ruthenium complex ligand (dpqp):

[0076] Weigh 0.084g of 1,10-phenanthroline-5,6-dione and dissolve it in 20mL of methanol. After boiling, quickly add 0.044g of 2,3-diaminopiperazine and reflux for 3 hours. The resulting so...

Embodiment 1

[0085] Adjust the pH of the apoferritin aqueous solution to be 2, add the ruthenium complex to the apoferritin solution, the feeding ratio of the ruthenium complex to the apoferritin nanoparticles is 300:1, after stirring, for example, using a magnetic stirrer, the The pH of the solution was adjusted to 10, so that the apoferritin was assembled back into a complete protein cage, and allowed to stand for a period of time. Dialyze with PBS aqueous solution (1mM) containing 10% acetonitrile solvent by volume for 48 hours, and use PBS aqueous solution without acetonitrile for the last dialysis; filter the sample obtained after the above dialysis with a 0.22 μm water filter head, and then use PD-10 After post-processing the desalting column, the apoferritin complex loaded with ruthenium complexes can be obtained; subsequently, the complex obtained above is blended with the iron-sulfur cluster catalyst, wherein the feed of the iron-sulfur cluster catalyst and the apoferritin nanopart...

Embodiment 2

[0088] Adjust the pH of the apoferritin aqueous solution to be 2, add the ruthenium complex to the apoferritin solution, the feeding ratio of the ruthenium complex to the apoferritin nanoparticles is 300:1, and after stirring with a magnetic stirrer, adjust the pH of the solution to 10. Allow the apoferritin to assemble back into a complete protein cage and let it stand for a period of time. Dialyze with PBS aqueous solution (1mM) containing 5% acetonitrile solvent by volume for 48h; filter the sample obtained after the above dialysis with a 0.22μm water filter head, and then use a PD-10 desalting column for post-treatment to obtain the loaded ruthenium complex apoferritin complex; then, the complex obtained above was blended with an iron-sulfur cluster catalyst, wherein the feeding ratio of the iron-sulfur cluster catalyst to apoferritin nanoparticles was 400:1, and after standing still, a 0.22 μm Filter the water system filter head, and then use the PD-10 desalting column fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Optical power density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com