Carbon dot modified graphite-phase carbon nitride hollow sphere photocatalyst as well as preparation method and application thereof

A graphite-phase carbon nitride and photocatalyst technology, applied in the direction of physical/chemical process catalysts, chemical instruments and methods, hydrogen production, etc., to achieve improved hydrogen production performance by splitting water, high practical value, and increased specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

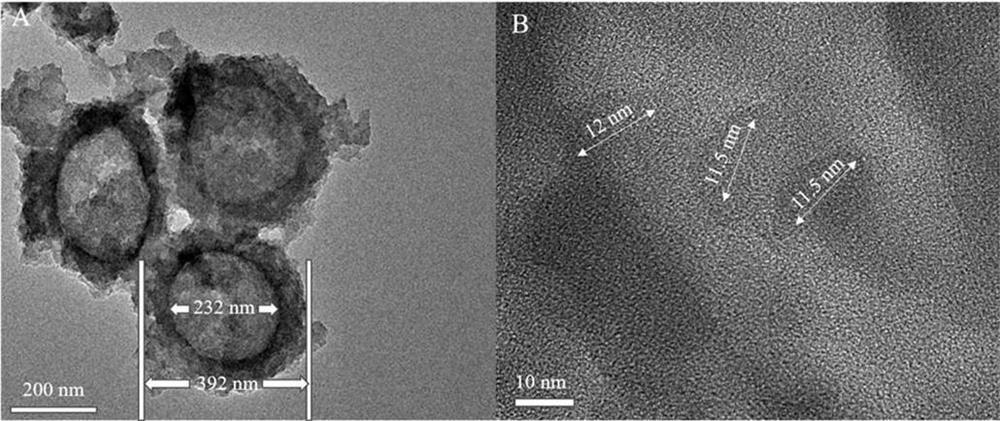

[0030] A carbon dot-modified graphite-phase carbon nitride hollow sphere photocatalyst, the photocatalyst is prepared from a graphite-like phase carbon nitride precursor and a carbon-dot precursor mixture as a product precursor through a hard template method; the graphite-like The precursor of phase carbon nitride is cyanamide; the precursor of carbon dots is glucose.

[0031] Its preparation method comprises the following steps:

[0032] (1) Weigh 5 g of cyanamide and 5 mg of glucose into an aqueous solution in which 1 g of silica sol is dissolved, and obtain a white powder after ultrasonication, stirring at 60°C, centrifugation, washing, and drying;

[0033] (2) The white powder was kept in a tube furnace at 550°C for 4 h, and argon gas was continuously introduced as a protective gas during the heat preservation process, and then naturally cooled to room temperature to obtain a yellow powder;

[0034] (3) Add the yellow powder to 4 mol / L NH 4 HF 2 Stir in the aqueous solu...

Embodiment 2

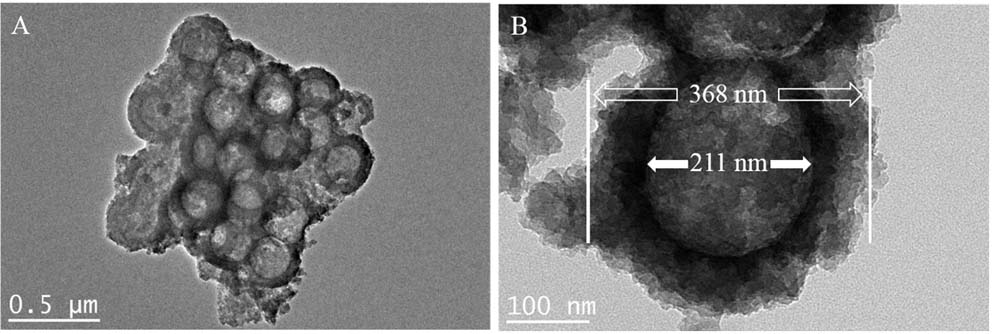

[0036] A carbon dot-modified graphite-phase carbon nitride hollow sphere photocatalyst, the photocatalyst is prepared from a graphite-like phase carbon nitride precursor and a carbon-dot precursor mixture as a product precursor through a hard template method; the graphite-like The precursor of phase carbon nitride is cyanamide; the precursor of carbon dots is glucose.

[0037] Its preparation method comprises the following steps:

[0038](1) Weigh 5 g of cyanamide and 10 mg of glucose into an aqueous solution in which 1 g of silica sol is dissolved, and obtain a white powder after ultrasonication, stirring at 60°C, centrifugation, washing, and drying;

[0039] (2) The white powder was kept in a tube furnace at 550°C for 4 h, and argon gas was continuously introduced as a protective gas during the heat preservation process, and then naturally cooled to room temperature to obtain a yellow powder;

[0040] (3) Add the yellow powder to 4 mol / L NH 4 HF 2 Stir in the aqueous solu...

Embodiment 3

[0042] A carbon dot-modified graphite-phase carbon nitride hollow sphere photocatalyst, the photocatalyst is prepared from a graphite-like phase carbon nitride precursor and a carbon-dot precursor mixture as a product precursor through a hard template method; the graphite-like The precursor of phase carbon nitride is cyanamide; the precursor of carbon dots is maltose.

[0043] Its preparation method comprises the following steps:

[0044] (1) Weigh 5 g of cyanamide and 5 mg of maltose into an aqueous solution in which 1 g of silica sol is dissolved, and obtain a white powder after operations such as ultrasonication, stirring at 60°C, centrifugation, washing, and drying;

[0045] (2) The white powder was kept in a tube furnace at 550°C for 4 h, and argon gas was continuously introduced as a protective gas during the heat preservation process, and then naturally cooled to room temperature to obtain a yellow powder;

[0046] (3) Add the yellow powder to 4 mol / L NH 4 HF 2 Stir ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com