A method for effectively removing oil from aqueous solution

An aqueous solution and removal technology, applied in separation methods, liquid separation, grease/oily substance/float removal devices, etc., can solve the problems of high operating cost, high price, uneven use effect, etc., to promote aggregation The effect of growing up, good degreasing effect and low operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

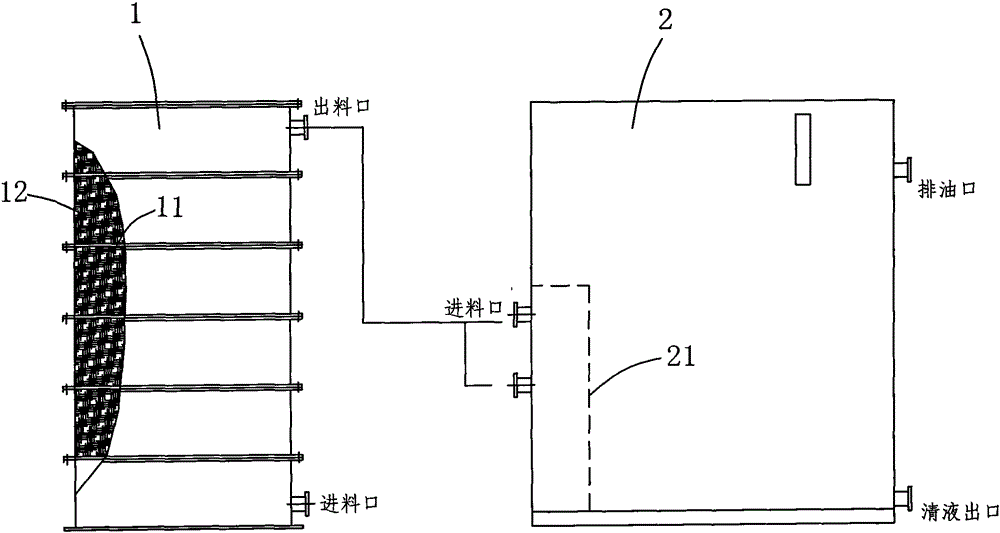

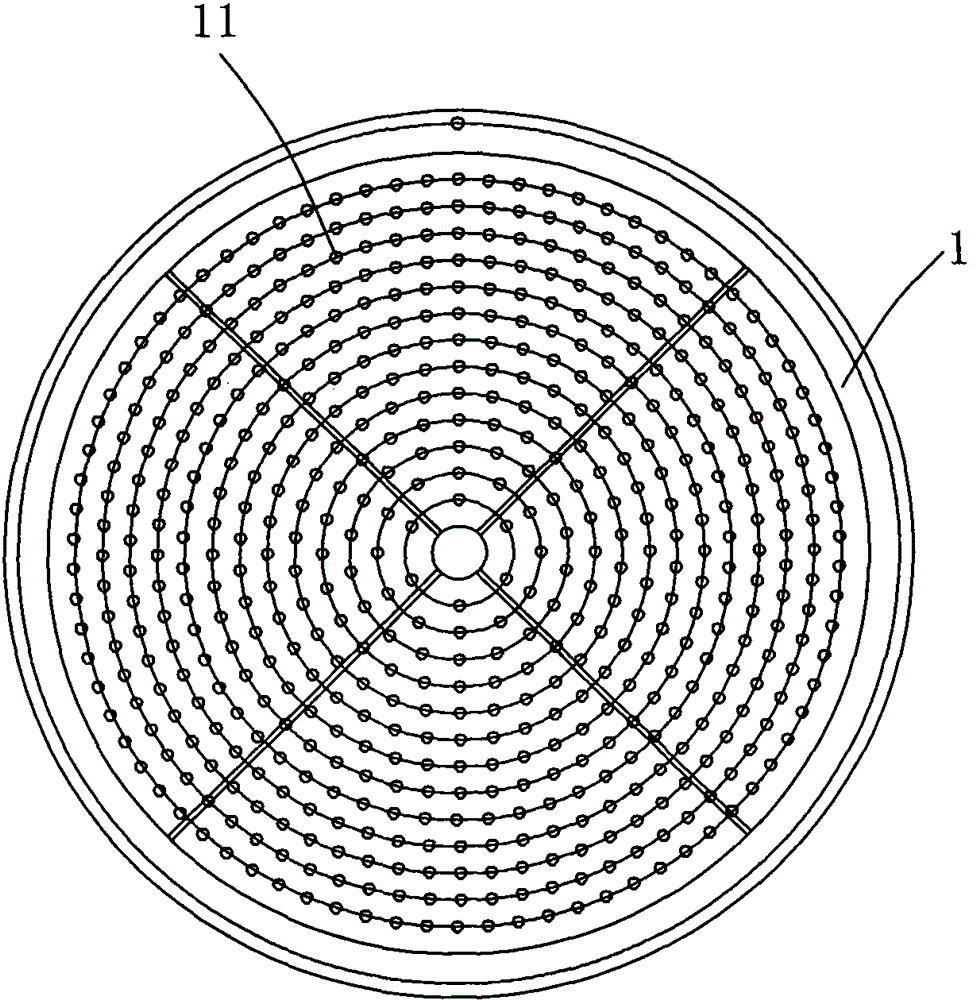

[0018] According to a kind of method that the present invention effectively removes oil content in aqueous solution, comprise the steps: (1) metal fiber or alloy fiber or inorganic material fiber or any one (i.e. selected fiber) in above-mentioned fiber and inert powder The mixture is filled in the holding container with a porosity of not less than 50%; (2) The oil-containing aqueous solution to be treated flows through the holding container at a certain flow rate, so that the water-in-oil or oil-in-water in the oil-containing aqueous solution The emulsified phase is destroyed under the action of the filling material, and promotes the aggregation and growth of oil particles; (3) The oily aqueous solution after the deoiling treatment of the bearing container is passed into the oil-water clarification separation tank, so that the oil in the oily aqueous solution passes through Clarify and float on the aqueous solution, and then separate from the aqueous solution; (4) The clean aq...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com