A kind of preparation method of acid-soluble titanium slag

A technology of acid-soluble titanium slag and titanium slag, which is applied in furnaces, electric furnaces, furnace types, etc., can solve the problems of poor raw material applicability, long reaction time, and separation of titanium and iron, and achieve pollution reduction, short reaction time, and reduced reaction time. the effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

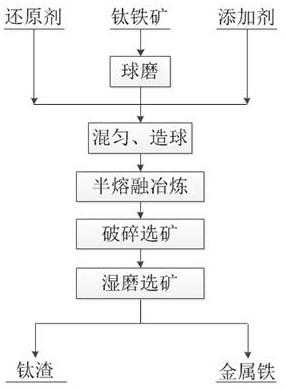

[0036] Embodiment 1: a kind of preparation method of acid-soluble titanium slag comprises the following steps:

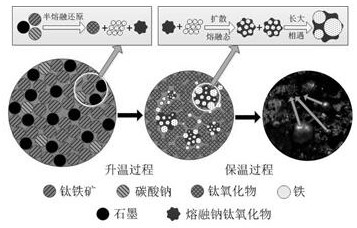

[0037] (1) Ball mill ilmenite and magnesium-containing slag to about 50 μm, and then mix with graphite, additive Na 2 CO 3 Send them together into a mixer for mixing, make pellets and dry at 120°C; wherein, the mass ratio of ilmenite, reducing agent, additive and modifier is: 100:12:6:3.

[0038] (2) Put the pellets in step (1) into an electric furnace for semi-molten smelting, and at the same time pass in argon gas to obtain semi-molten pellets; the conditions for the reduction are: control the reaction temperature to 1380°C, and keep the temperature constant Treat for 90min.

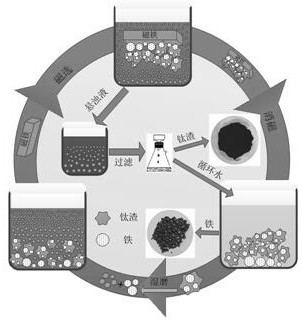

[0039] (3) The semi-molten pellets in step (2) are crushed by a crusher until the particle size is -50 mesh, accounting for 70-100%, to obtain a mixture of slag and iron, and the metal iron particles are screened out during the coarse grinding process; to obtain metal iron:

[0040] (4) ...

Embodiment 2

[0042] Embodiment 2: a kind of preparation method of acid-soluble titanium slag comprises the following steps:

[0043] (1) Ball mill ilmenite and magnesium-containing slag to about 125 μm, and then mix with graphite, additive Na 2 CO 3 Send them together into a mixer and mix them evenly to form pellets and dry them at 120°C; the mass ratio of ilmenite, reducing agent, additive and modifier is: 100:12:7:4.

[0044] (2) Put the pellets in step (1) into an electric furnace for semi-melting smelting, and at the same time pass in argon (containing 5% CO) to obtain semi-molten pellets; the conditions for the reduction are: control the reaction The temperature is 1400°C, and it is treated at constant temperature for 80 minutes.

[0045](3) The semi-molten pellets in step (2) are crushed by a crusher until the particle size is -50 mesh, accounting for 70-100%, to obtain a mixture of slag and iron, and the metal iron particles are screened out during the coarse grinding process; to ...

Embodiment 3

[0048] Embodiment 3: a kind of preparation method of acid-soluble titanium slag comprises the following steps:

[0049] (1) Ball mill ilmenite and magnesium-containing slag to about 200 μm, then mix with graphite, additive Na 2 CO 3 Send them together into a mixer to mix evenly, make pellets and dry at 120°C; wherein, the mass ratio of ilmenite, reducing agent, additive and modifier is: 100:12:8:5.

[0050] (2) Put the pellets in step (1) into an electric furnace for semi-melt smelting, and at the same time pass in argon (containing 10% CO) to obtain semi-molten pellets; the conditions for the reduction are: control the reaction The temperature is 1420°C, and it is treated at constant temperature for 70 minutes.

[0051] (3) The semi-molten pellets in step (2) are crushed by a crusher until the particle size is -50 mesh, accounting for 70-100%, to obtain a mixture of slag and iron, and the metal iron particles are screened out during the coarse grinding process; to obtain me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com