High temperature high pressure acoustic emission electrochemistry simulation experiment apparatus capable of loading stress

A simulation experiment device, high temperature and high pressure technology, applied in the direction of material analysis, measurement device, scientific instrument, etc. using the acoustic emission technology, can solve the problem of the electrochemical corrosion rate of the acoustic emission signal, etc., to achieve practical design, avoid attenuation, Guaranteed reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

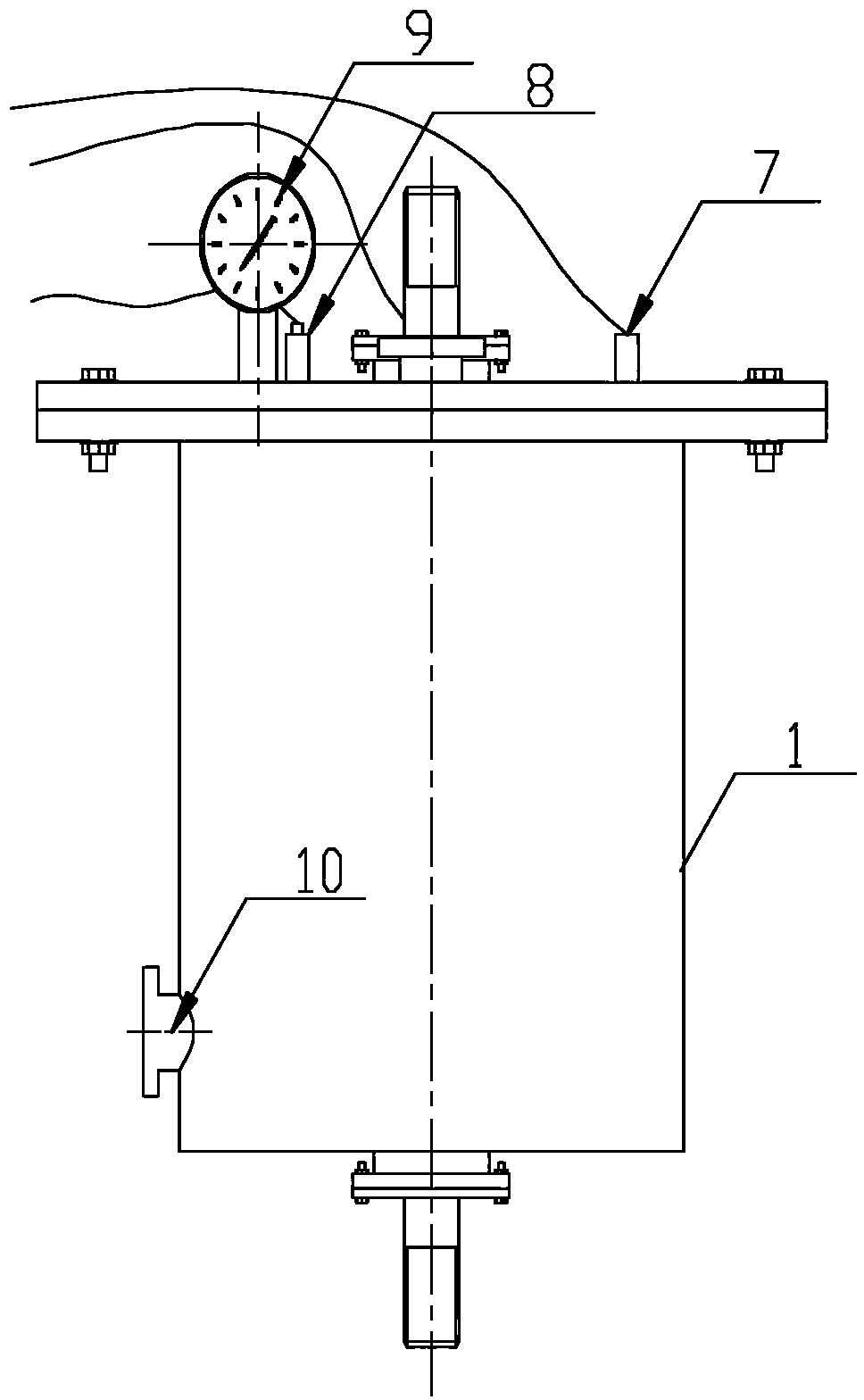

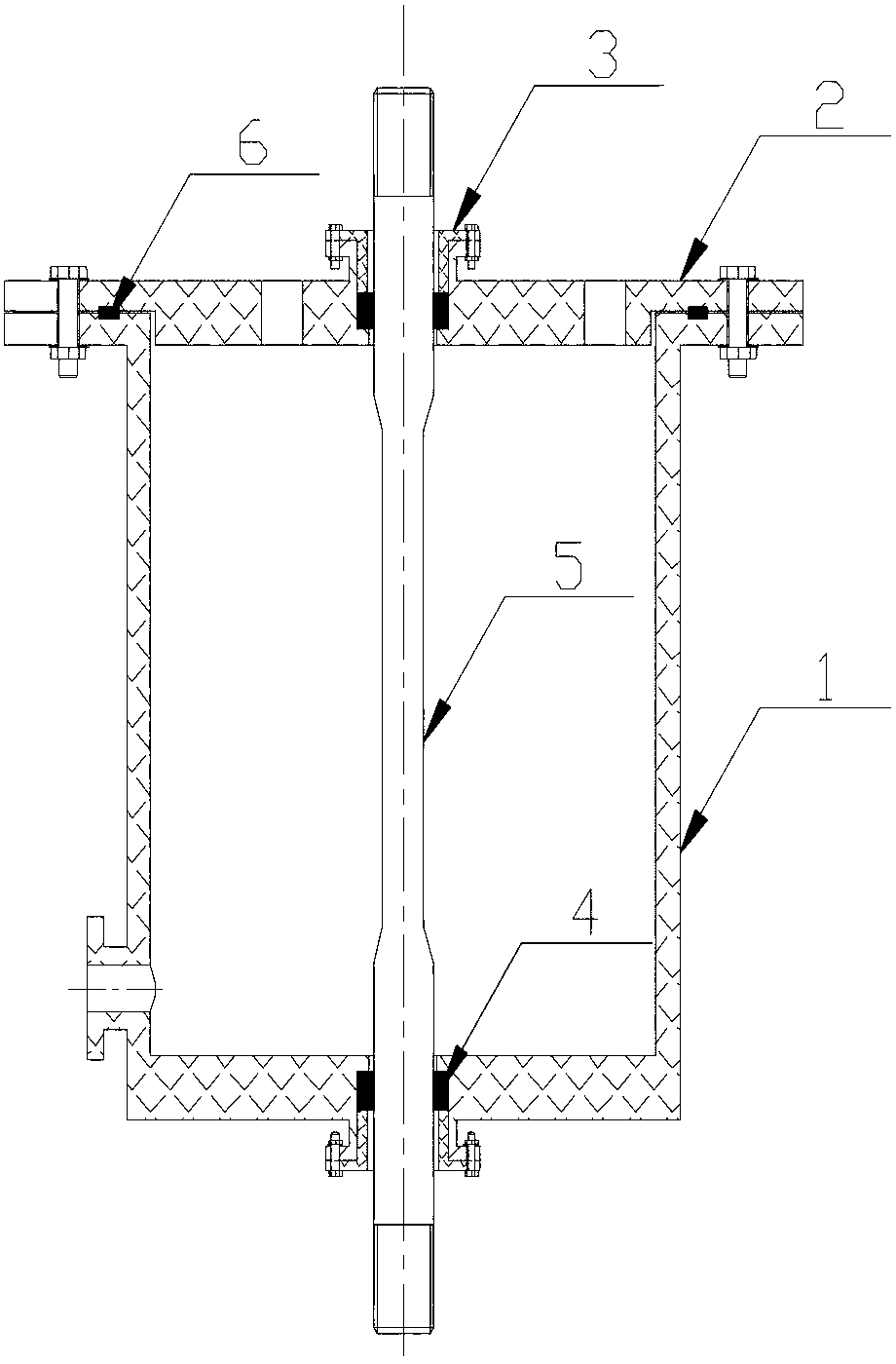

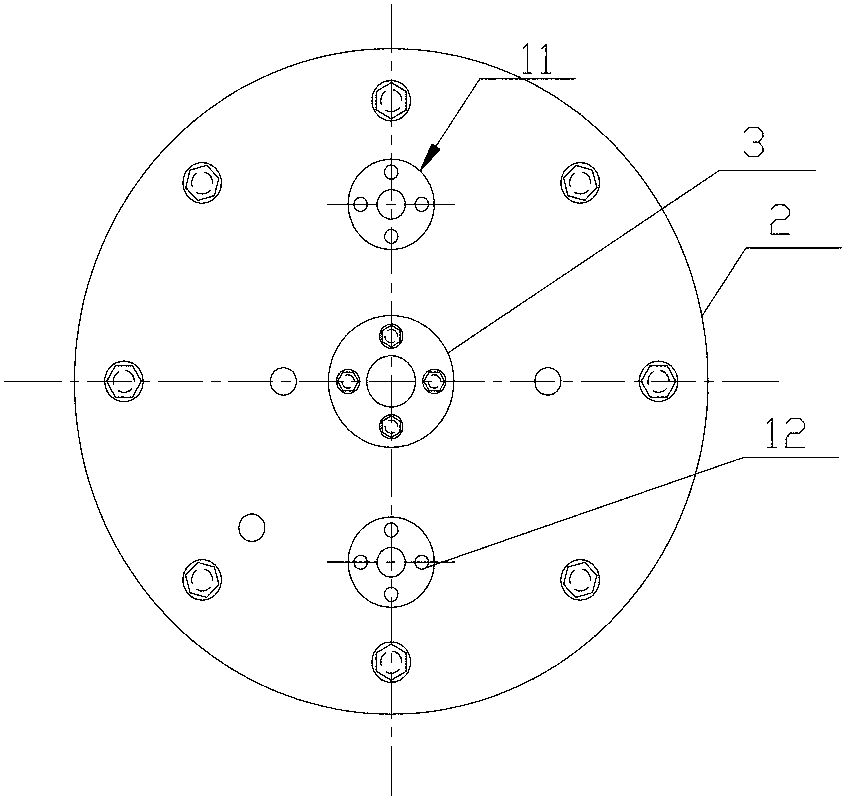

[0042] like Figure 5 As shown, the high-temperature and high-pressure acoustic emission electrochemical simulation experimental device capable of loading stress according to an embodiment of the present invention includes:

[0043]An autoclave, the autoclave has an inner cavity, and a test piece 5 is arranged in the inner cavity. The autoclave uses high-temperature-resistant glass fiber reinforced plastics with high strength, corrosion resistance, light weight, electrical insulation, and low thermal conductivity, and can be heated at 150 ° C. The following long-term use can not only meet the strength requirements of high-voltage resistance, but also realize the electrical insulation between the test piece and the surrounding con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com