Patents

Literature

56results about How to "Offset loss" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

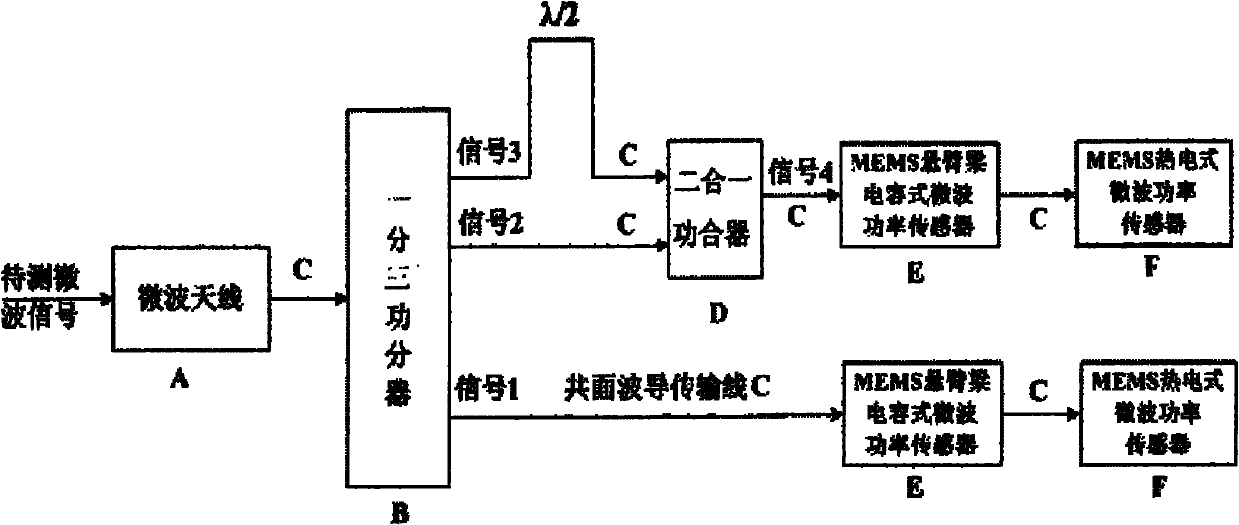

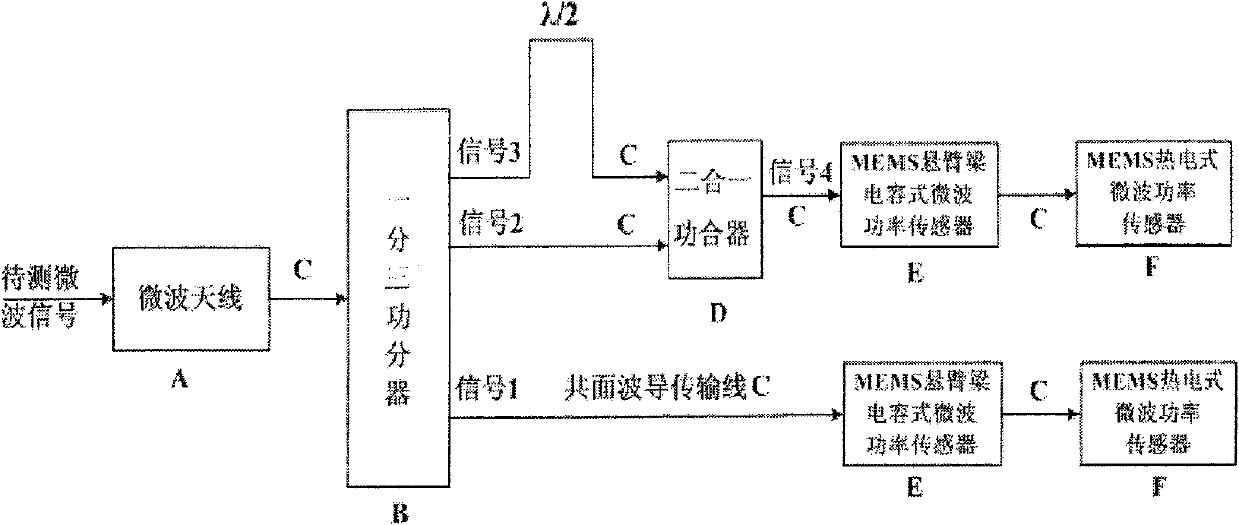

Wireless-receiving system for detecting microelectronic mechanical microwave frequency and preparation method thereof

InactiveCN101788605ARealize wireless receptionTo achieve the purpose of wireless detectionTelevision system detailsPiezoelectric/electrostriction/magnetostriction machinesPower combinerPhase difference

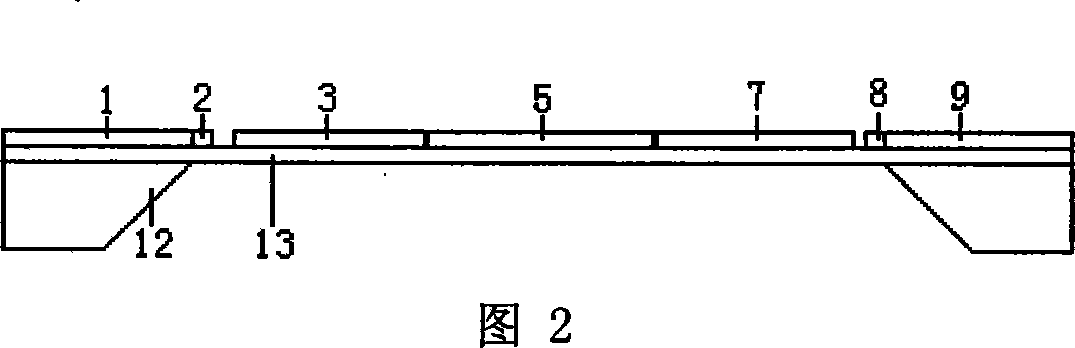

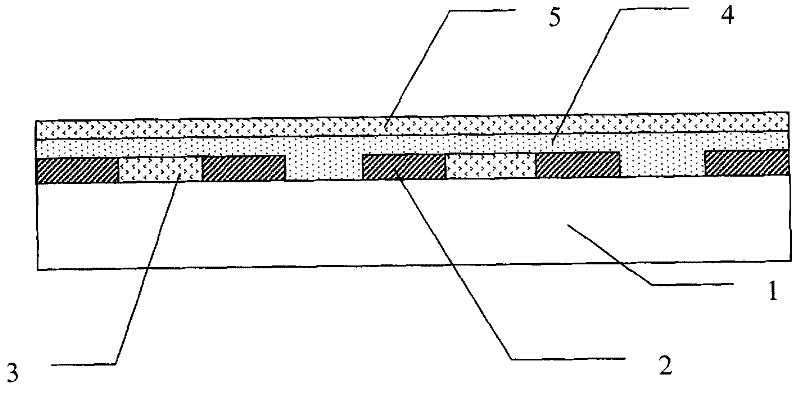

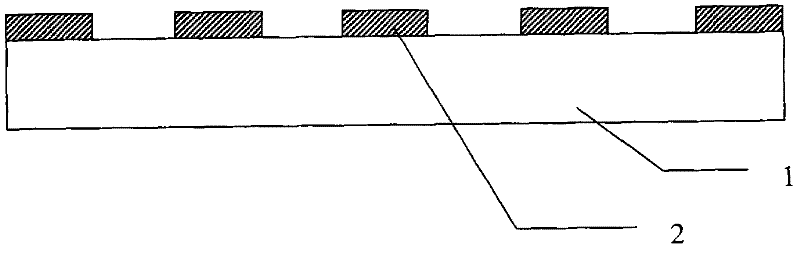

The invention relates to a wireless-receiving system for detecting microelectronic mechanical microwave frequency and a preparation method thereof. The wireless-receiving system for detecting the microelectronic mechanical microwave frequency has quite simple structure, large measurement magnitude range, no direct-current power consumption and easy integration. In the system for detecting the microelectronic mechanical microwave frequency, gallium arsenide is used as a substrate, wherein a microwave antenna (A), a one-three power splitter (B), a coplanar waveguide transmission line (C), a two-in-one power combiner (D), an MEMS cantilever capacitive microwave power sensor (E) and an MEMS thermoelectric microwave power sensor (F) are designed on the substrate; and then a phase difference between a signal 3 and a signal 2 after the signal 3 passes through the coplanar waveguide transmission line with the length of lambda / 2 can be determined according to a law of cosines. Because the phase difference corresponds to the frequency of the signal, the frequency of the signal can be measured.

Owner:SOUTHEAST UNIV

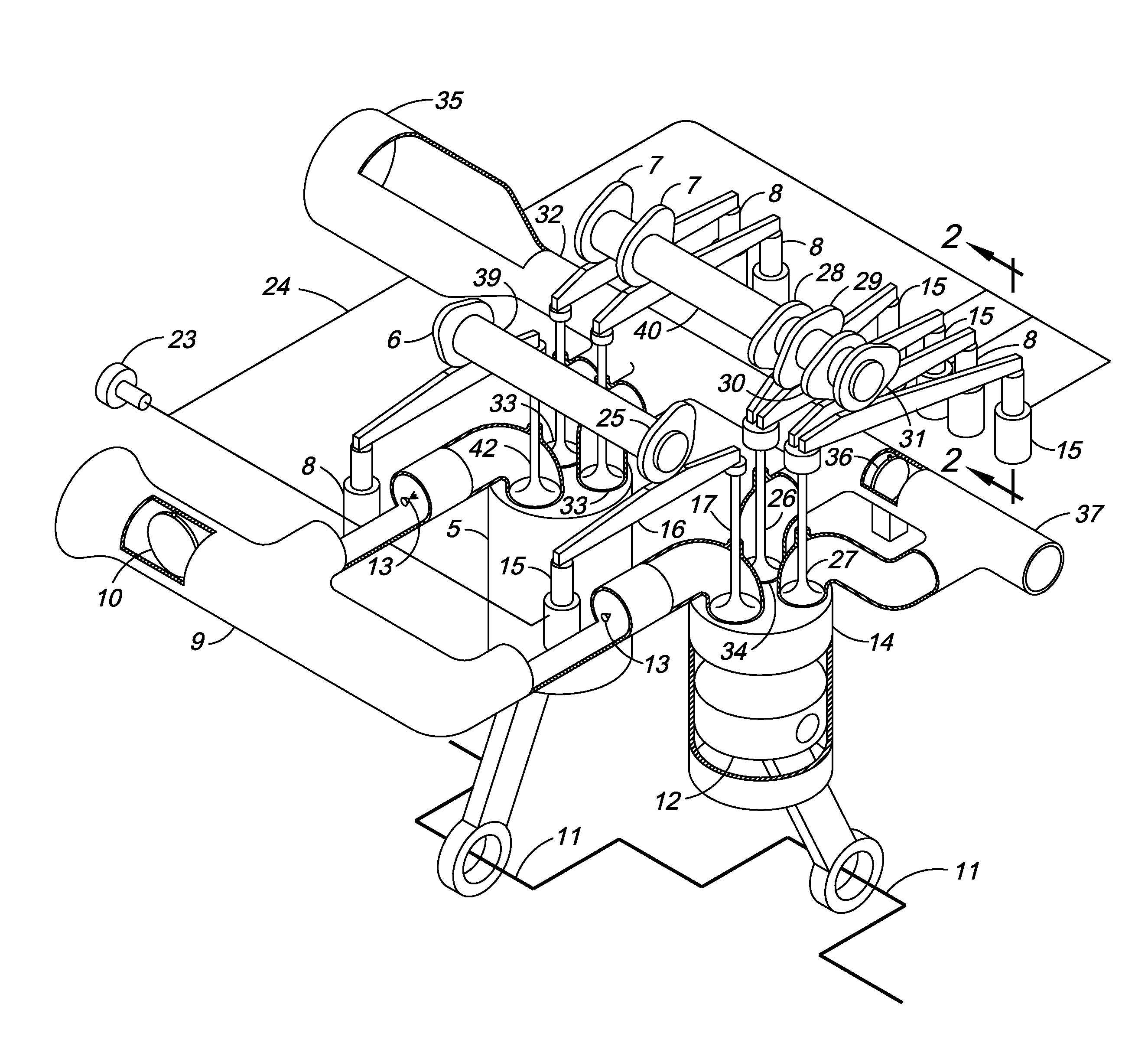

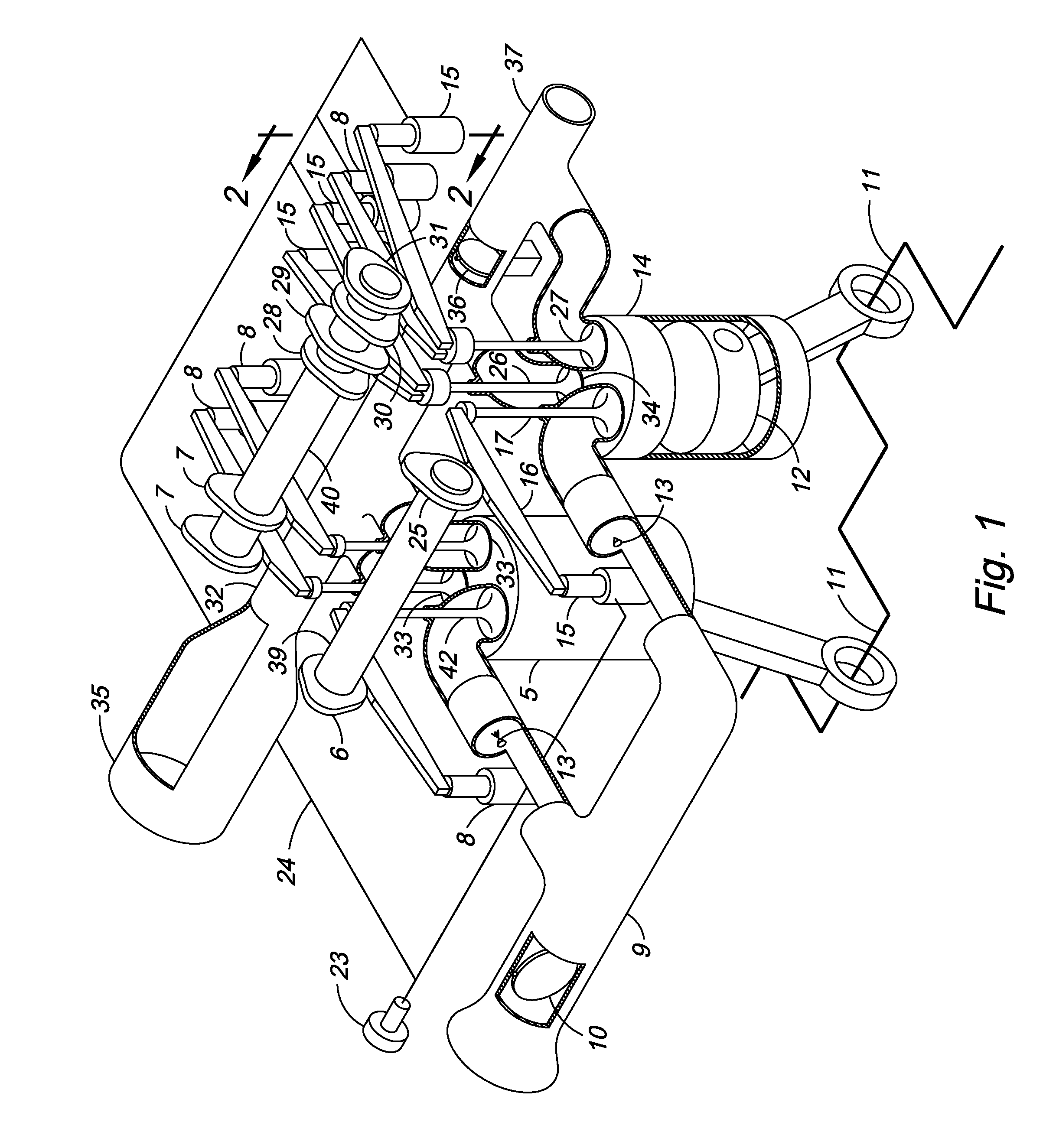

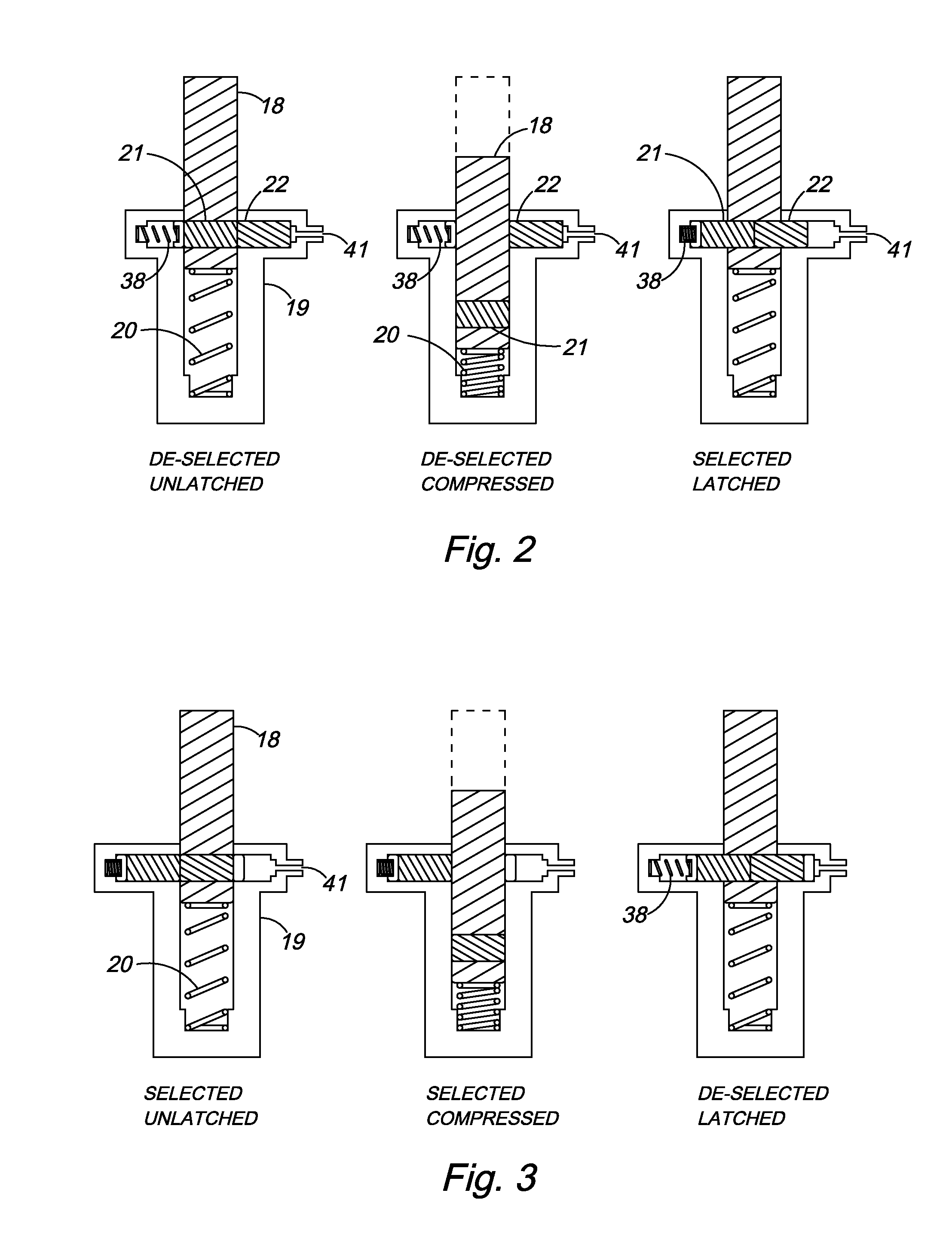

Selective Compound Engine

InactiveUS20090301086A1Improve fuel efficiencyReduce cylinder compression ratioCombustion enginesHot gas positive displacement engine plantsExhaust valveFuel efficiency

The fuel efficiency of an internal combustion reciprocating piston engine may be increased through selective secondary expansion of exhaust gas in the engine cylinders in order to recover exhaust gas energy which is otherwise wasted by cylinder blow-down at the end of the power stroke. Exhaust valve cam switching, intake valve deactivation, multiple exhaust valves, a specialized exhaust manifold arrangement and an exhaust gas diverter valve can be configured to enable a reciprocating engine to selectively operate in efficient eight stroke cycle compound mode when moderate engine power is demanded, then revert to conventional four stroke cycle non-compound mode operation when high engine power is demanded, without stopping the engine. For a road vehicle application, the benefit is substantially reduced highway cruising fuel consumption, while incurring minimal impact on engine weight, minimal impact on engine manufacturing cost, and no adverse impact on vehicle acceleration performance, hill climbing performance or trailer towing performance.

Owner:RALSTON MARK DIXON

Wireless-receiving system for detecting microelectronic mechanical microwave frequency and preparation method thereof

InactiveCN101788605BRealize wireless receptionTo achieve the purpose of wireless detectionTelevision system detailsImpedence networksPower combinerPhase difference

The invention relates to a wireless-receiving system for detecting microelectronic mechanical microwave frequency and a preparation method thereof. The wireless-receiving system for detecting the microelectronic mechanical microwave frequency has quite simple structure, large measurement magnitude range, no direct-current power consumption and easy integration. In the system for detecting the microelectronic mechanical microwave frequency, gallium arsenide is used as a substrate, wherein a microwave antenna (A), a one-three power splitter (B), a coplanar waveguide transmission line (C), a two-in-one power combiner (D), an MEMS cantilever capacitive microwave power sensor (E) and an MEMS thermoelectric microwave power sensor (F) are designed on the substrate; and then a phase difference between a signal 3 and a signal 2 after the signal 3 passes through the coplanar waveguide transmission line with the length of lambda / 2 can be determined according to a law of cosines. Because the phase difference corresponds to the frequency of the signal, the frequency of the signal can be measured.

Owner:SOUTHEAST UNIV

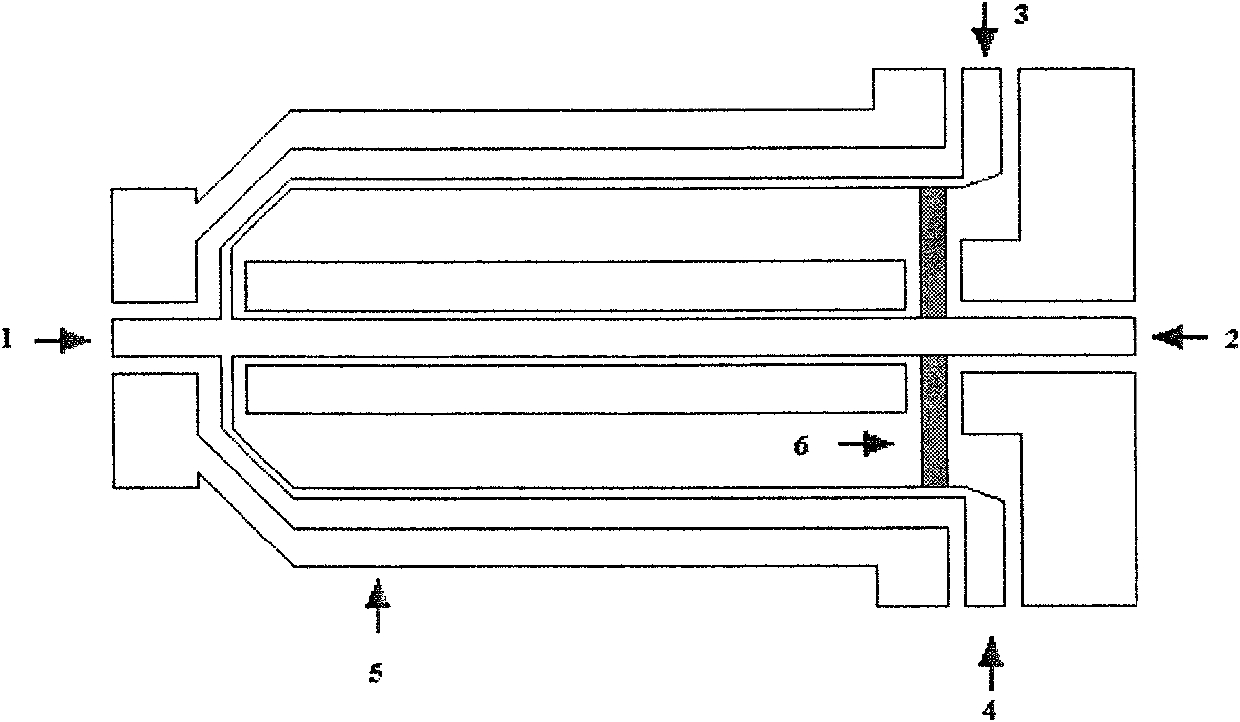

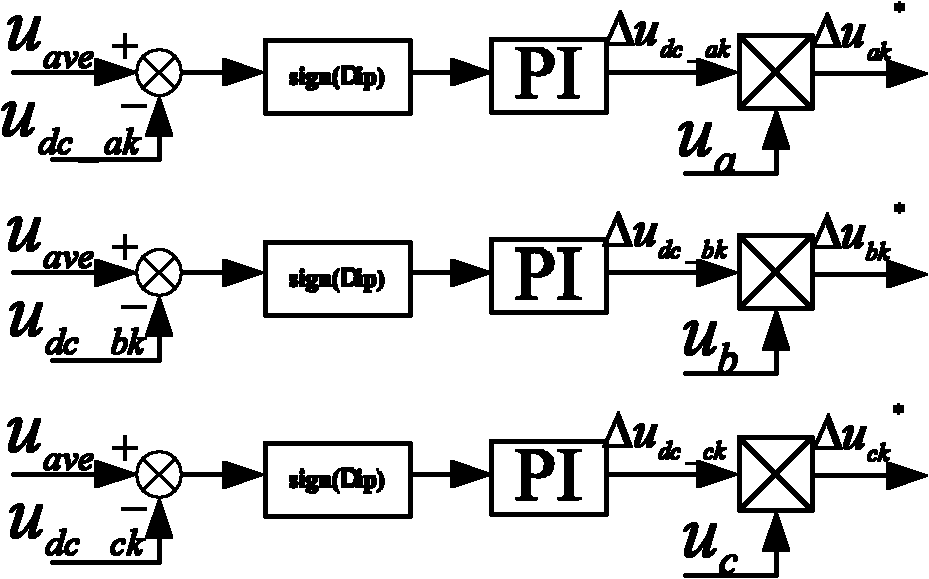

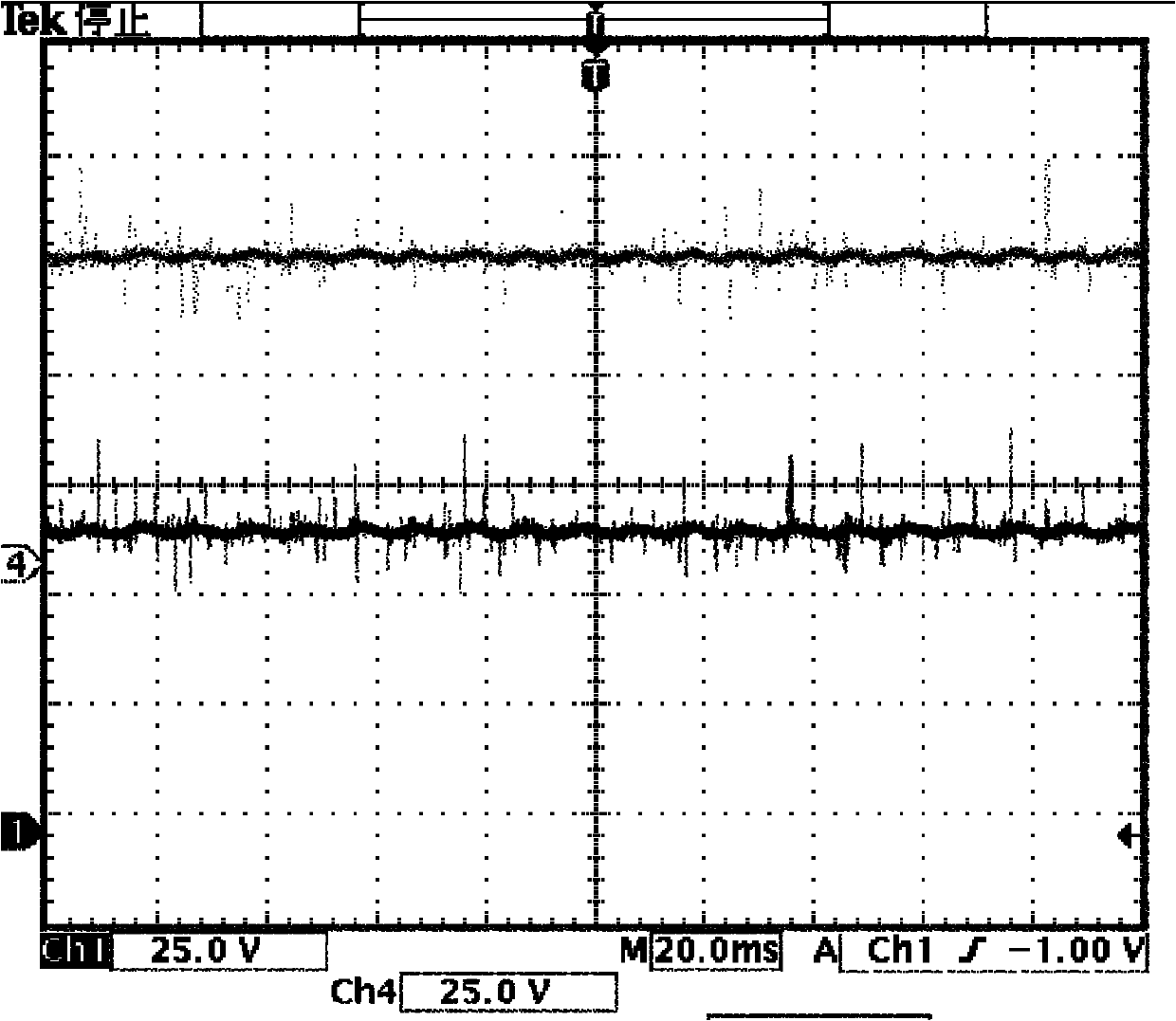

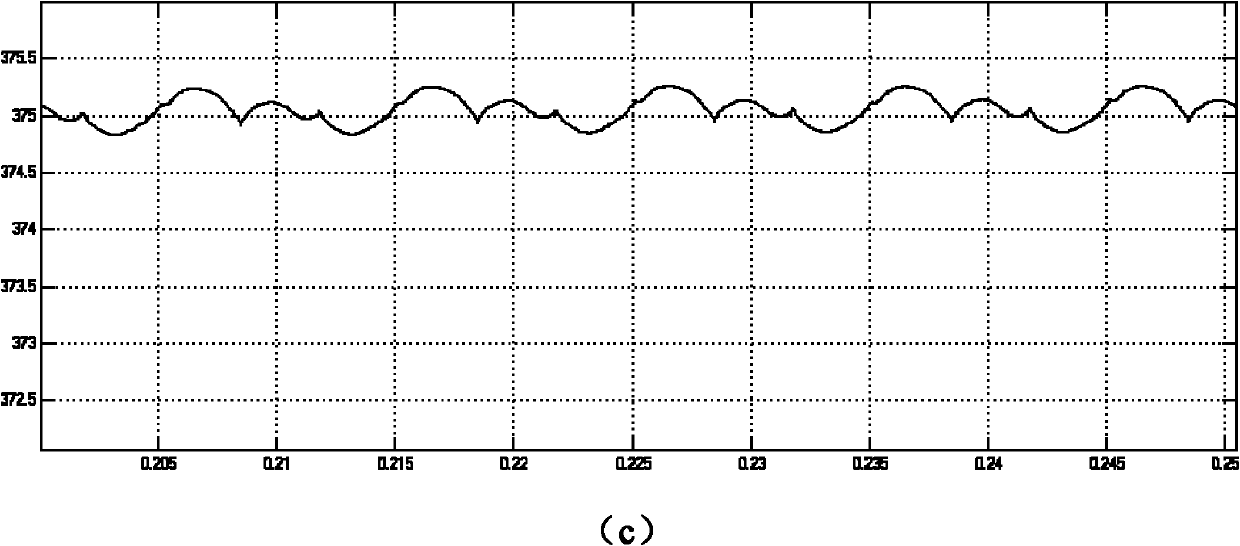

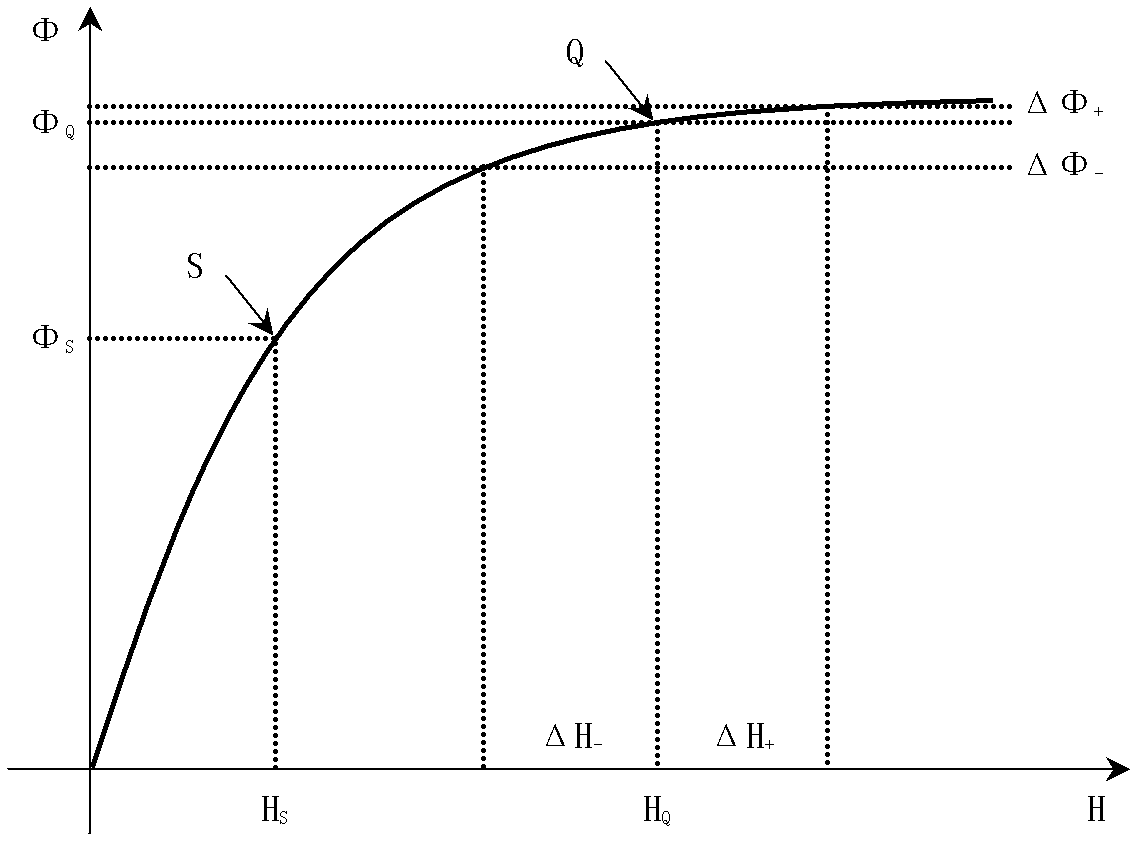

Control method of DC bus voltage of cascading multi-level power quality conditioners

InactiveCN101950960AControl DC side voltageOffset lossThree-or-more-wire dc circuitsPower qualityFull bridge

The invention discloses a control method of the DC bus voltage of cascading multi-level power quality conditioners. The control method is verified by simulation through a simulink module in a MATLAB (Matrix Laboratory), meanwhile, a small experimental prototype with the capacity of 30 kVA and formed by connecting two single-phase full bridge unit modules in series is set up in the laboratory, and the control method is verified by experiments. Both simulation results and experiment results can verify that the control method can well stabilize the DC side voltage of the single-phase full bridge unit modules to equal to a given value, increase the utilization rate of the DC bus voltage and provide a good reference value for engineering application.

Owner:XI AN JIAOTONG UNIV

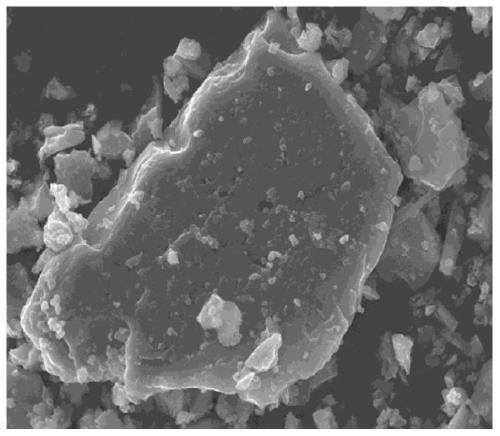

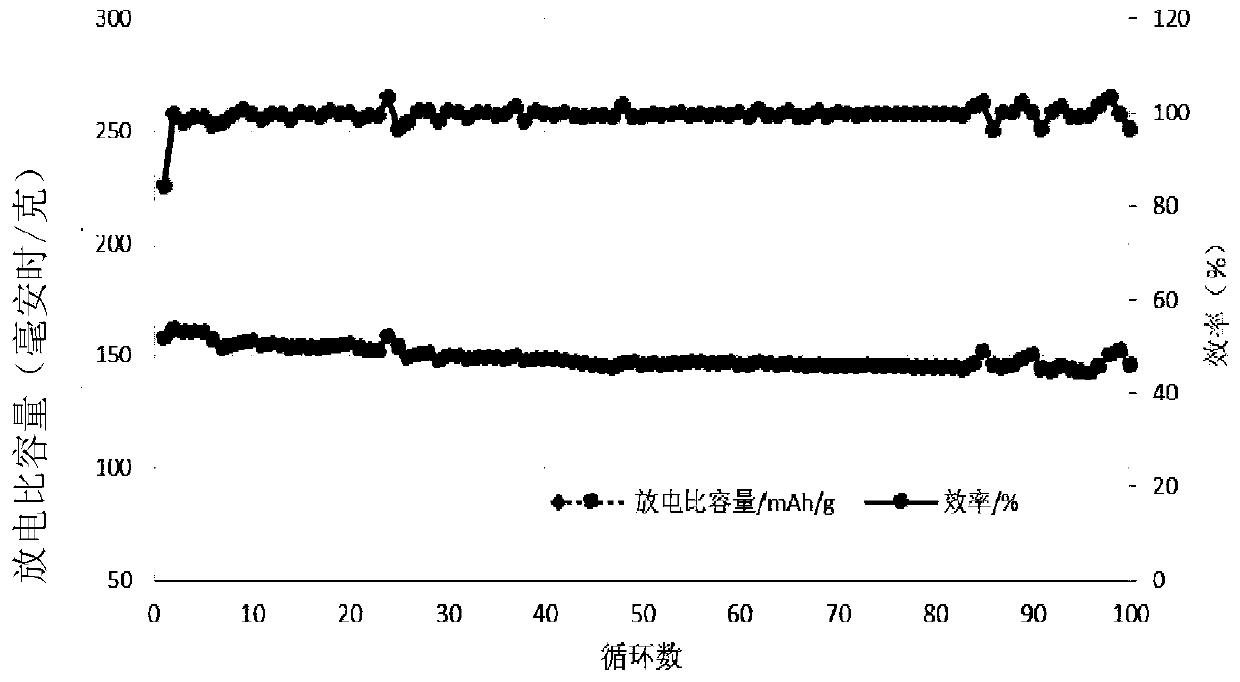

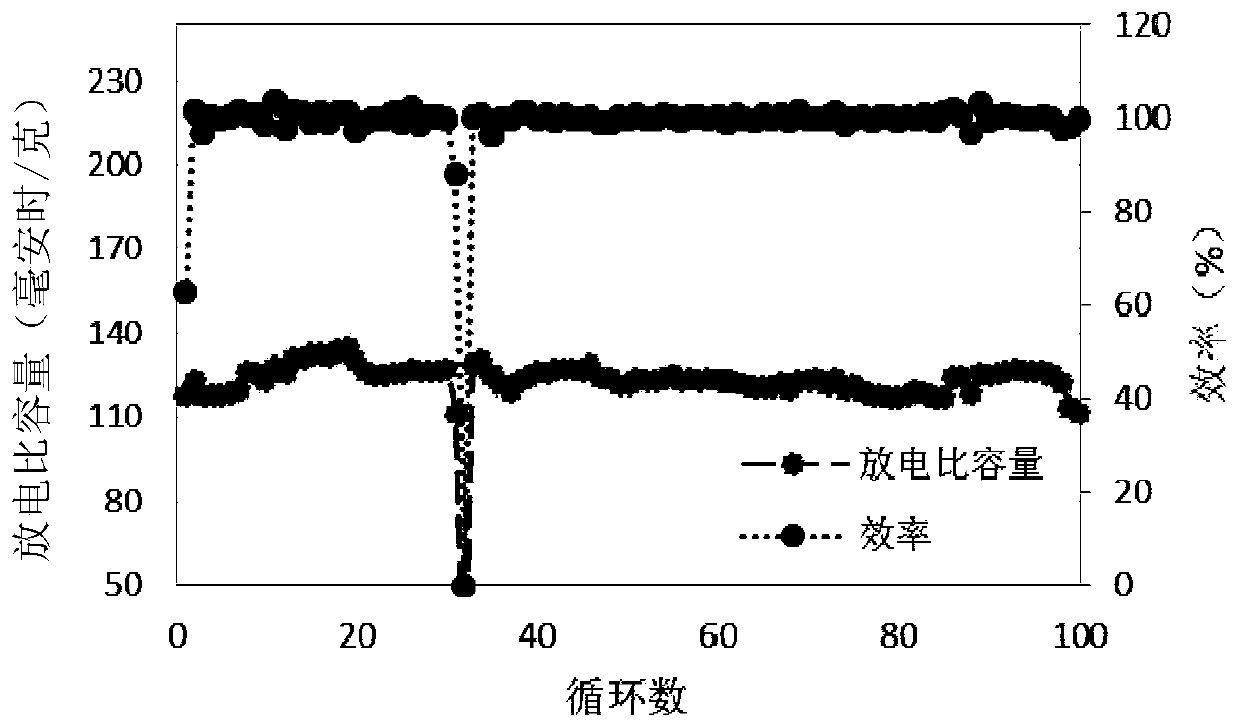

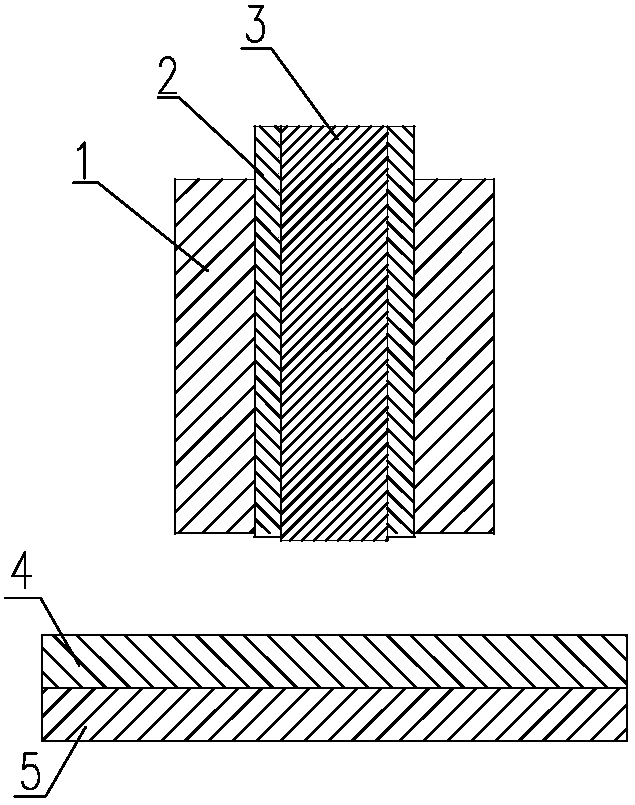

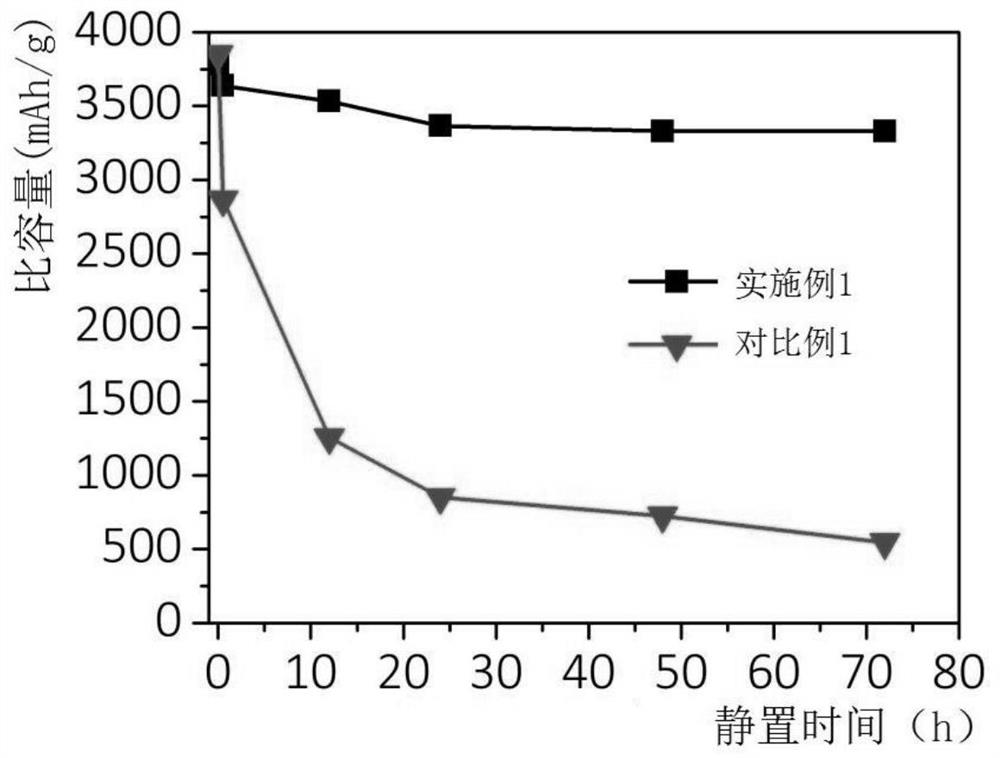

Negative electrode material, negative electrode plate, preparation method of negative electrode plate and all-solid-state lithium ion battery

ActiveCN111430681AImprove the first Coulombic efficiencyHigh activityNegative electrodesSecondary cellsSolid state electrolyteAll solid state

The invention provides a negative electrode material, a negative electrode plate, a preparation method of the negative electrode plate and an all-solid-state lithium ion battery. The negative electrode material comprises coated lithium powder; silicon carbon powder; a conductive agent; and a solid electrolyte, wherein the coated lithium powder comprises lithium powder and a lithium-conducting coating layer coating at least one part of the outer surface of the lithium powder. In the negative electrode material, on one hand, the coated lithium powder is adopted, so that the activity of the coated lithium powder is greatly reduced compared with that of the lithium powder while the lithium can be effectively supplemented, no strict requirements for environment and equipment exist, the compatibility compared with the prior art is high, the production cost is lower, and meanwhile, the operation safety is greatly improved; and on the other hand, the solid electrolyte is added into the negative electrode material, so that the side reaction of the lithium powder and the solid electrolyte can be greatly reduced, the first coulombic efficiency can be effectively improved, and meanwhile, a lithium battery system has higher safety.

Owner:SVOLT ENERGY TECHNOLOGY CO LTD

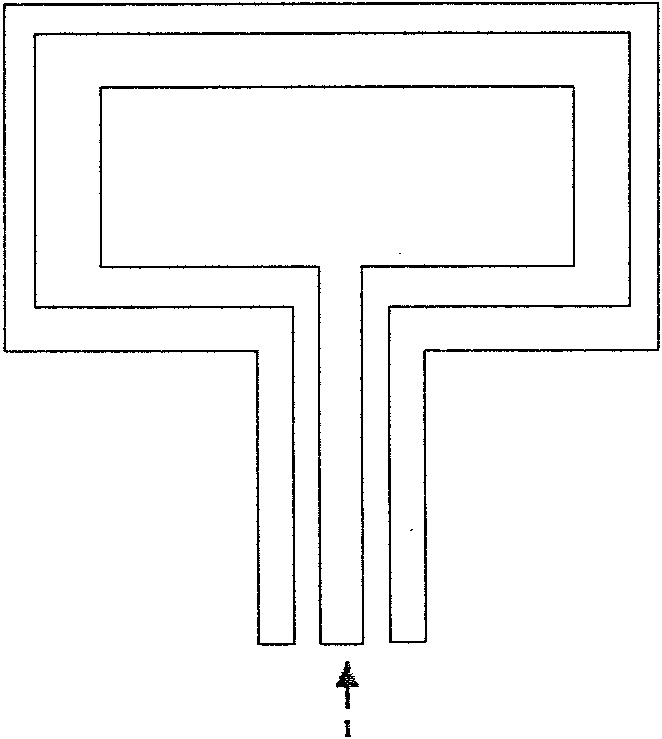

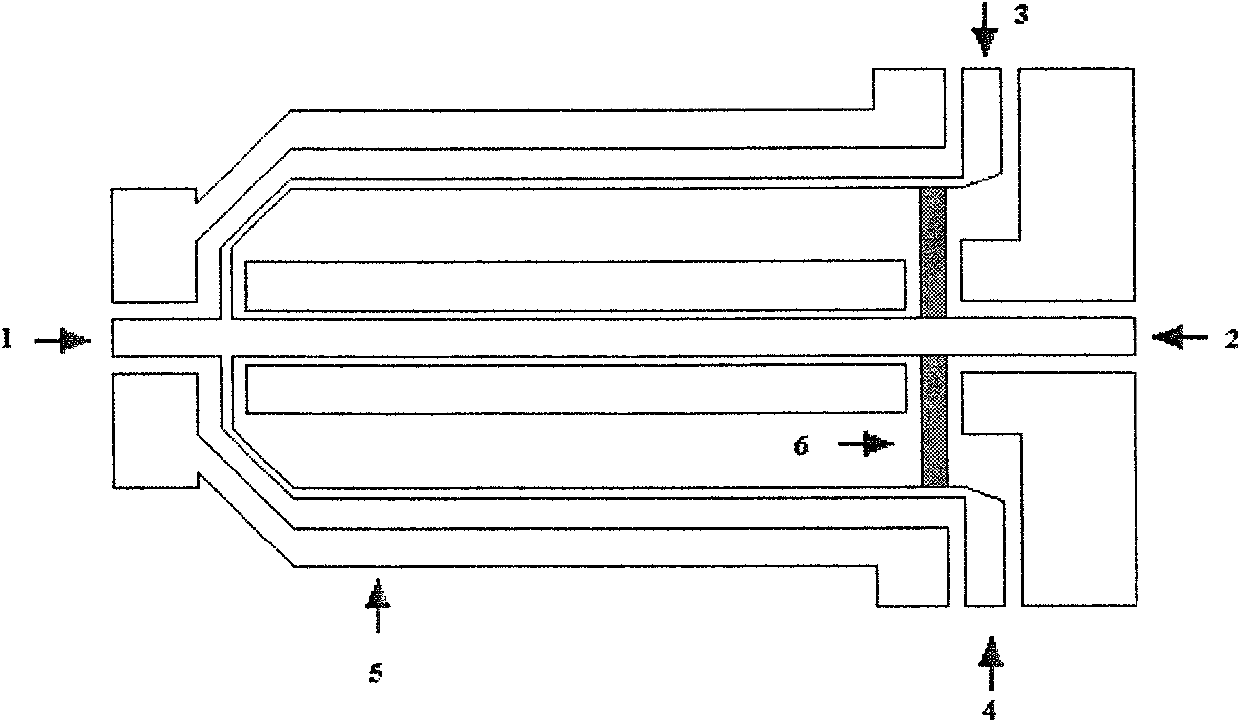

Microelectromechanical microwave powersensor with two balanced thermopiles and its prepn process

InactiveCN101046487ALower cold junction temperatureSame cold junction temperatureTelevision system detailsImpedence networksThermopileCoplanar waveguide

The balanced microwave power sensor with two thermopiles based on microelectromechanical technology is used in measuring microwave power by means of thermal balance. The microwave power sensor has the first coplane waveguide transmission line to receive the measured microwave signal, the first load resistor to absorb the signal power and convert it into heat and the first thermopile to receive the heat to generate potential difference; the second coplane waveguide transmission line, the first press welded block to output the potential difference, the second load resistor, the second thermopile, the second press welded block in the same structure and action with the first ones; and one power source. Through regulating the power source to make the second press welded block output the same voltage as the first one, the DC power consumed in the second load resistor will be equal to the microwave power, realizing the microwave power measurement.

Owner:SOUTHEAST UNIV

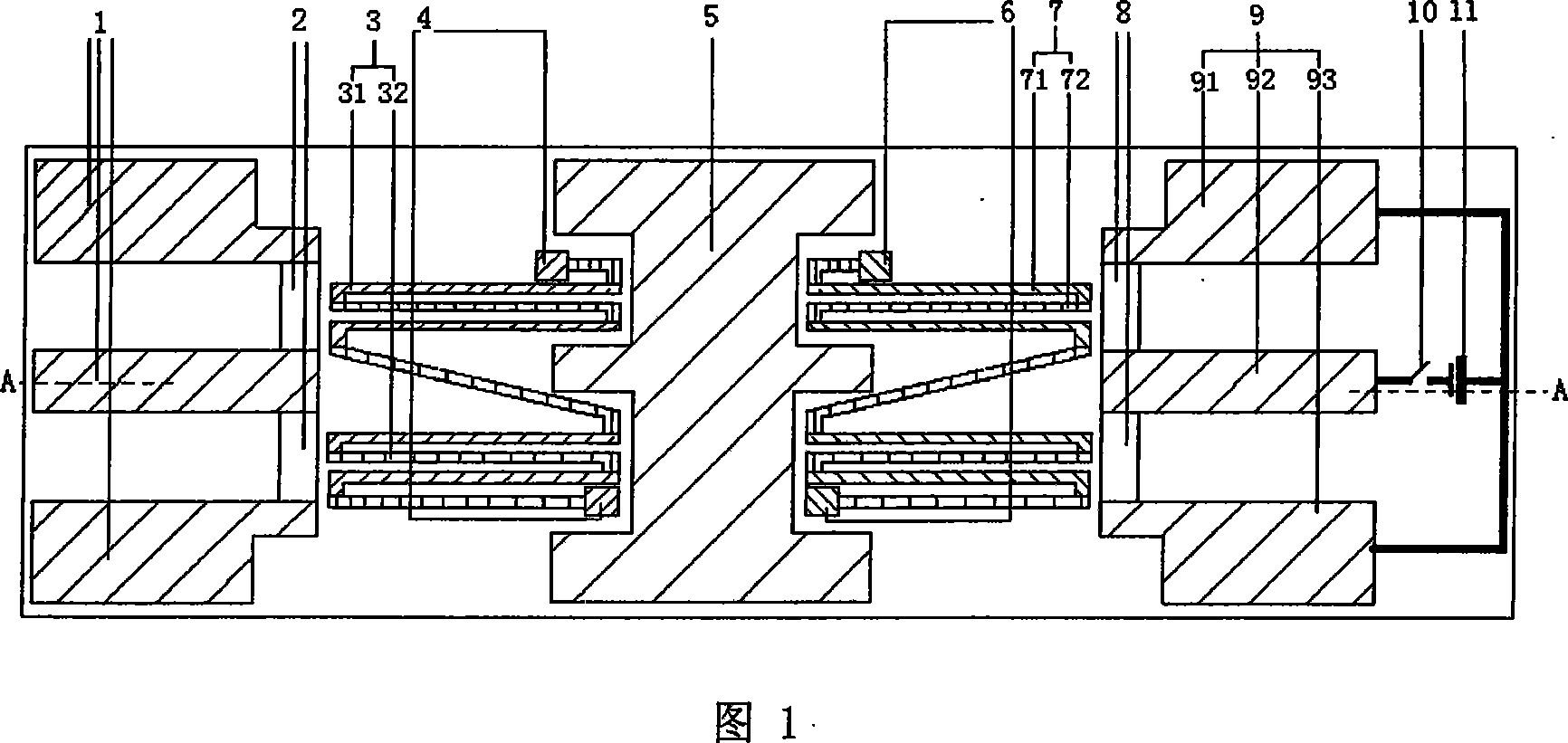

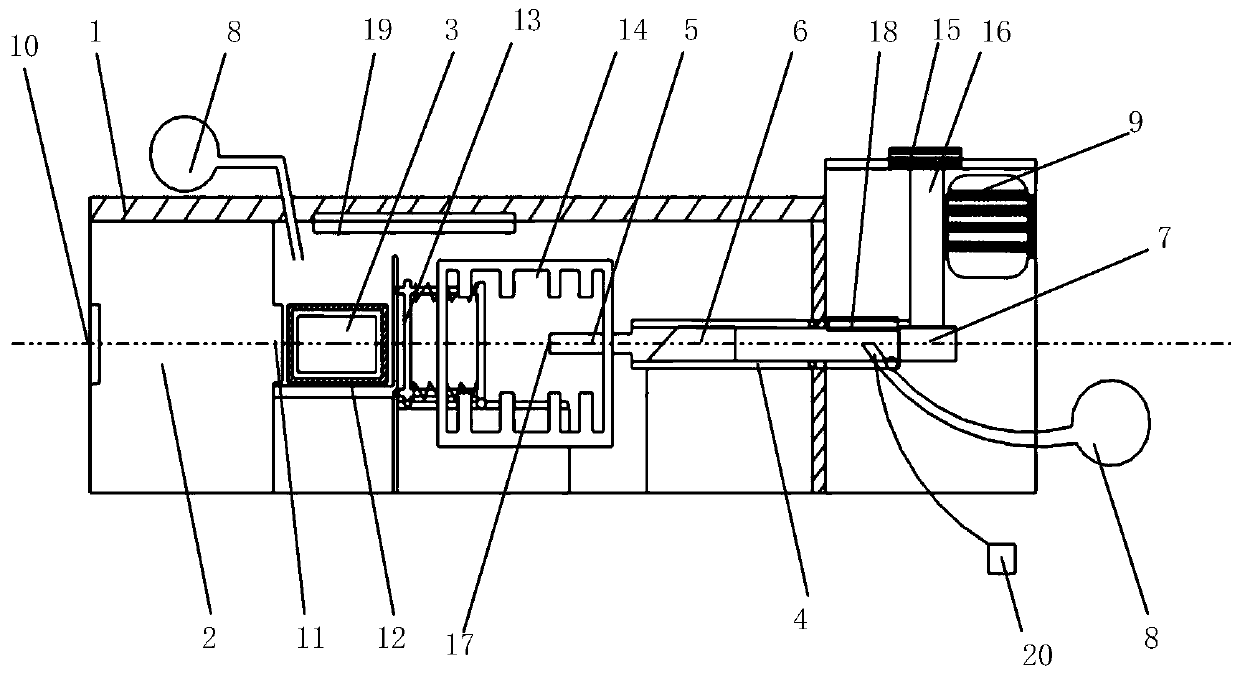

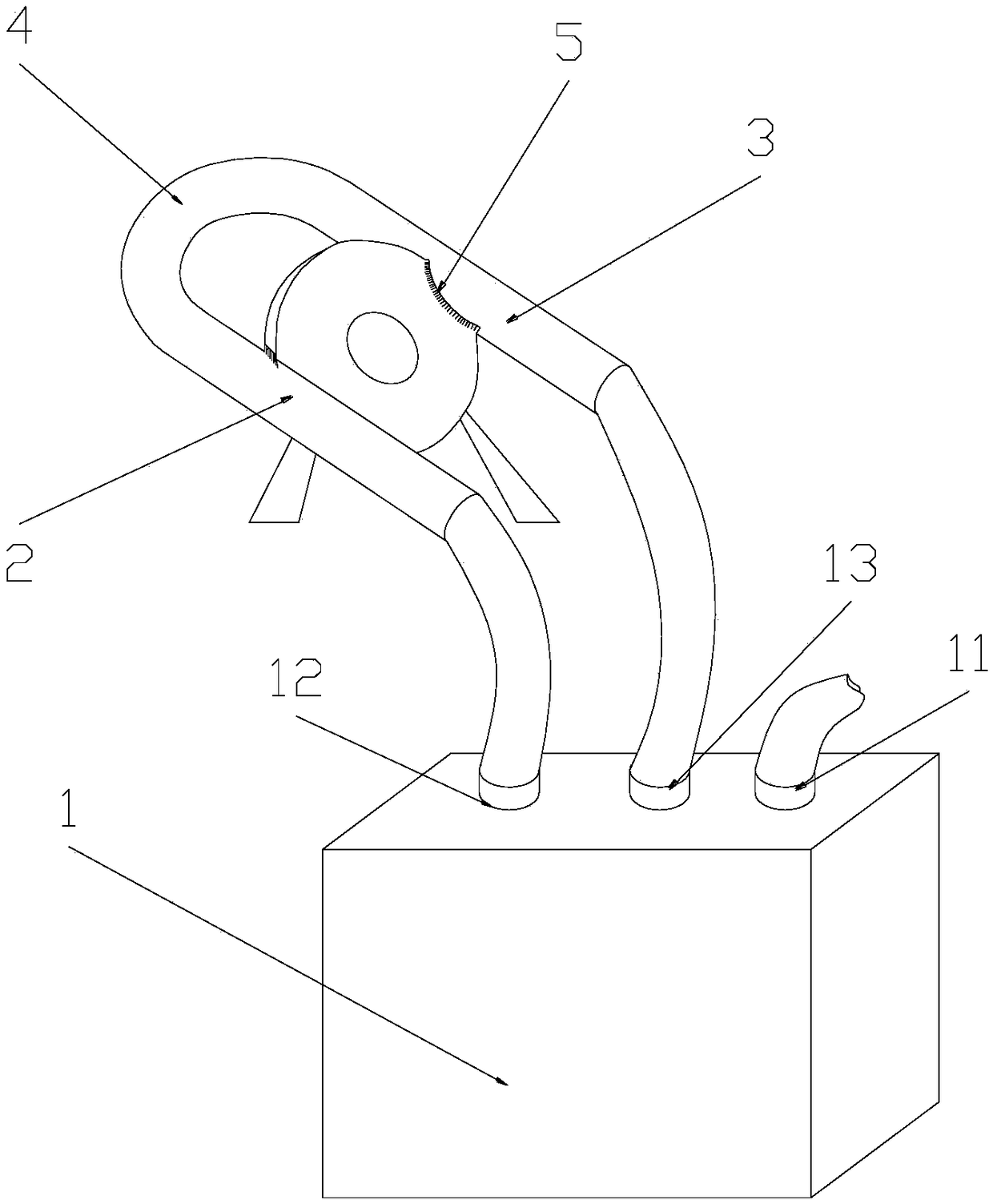

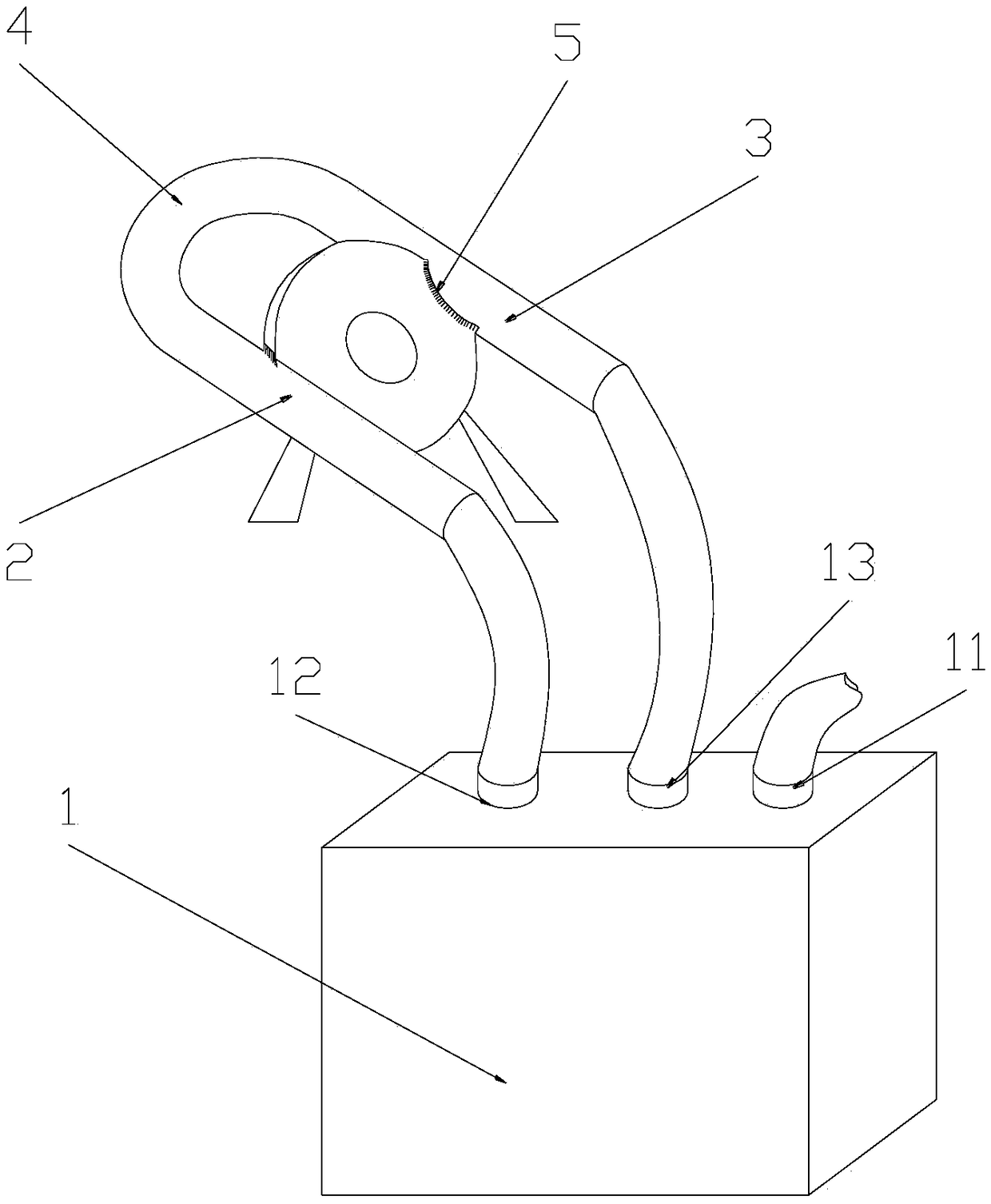

Horizontal ejection-impact type blade bird cutting test device and test method

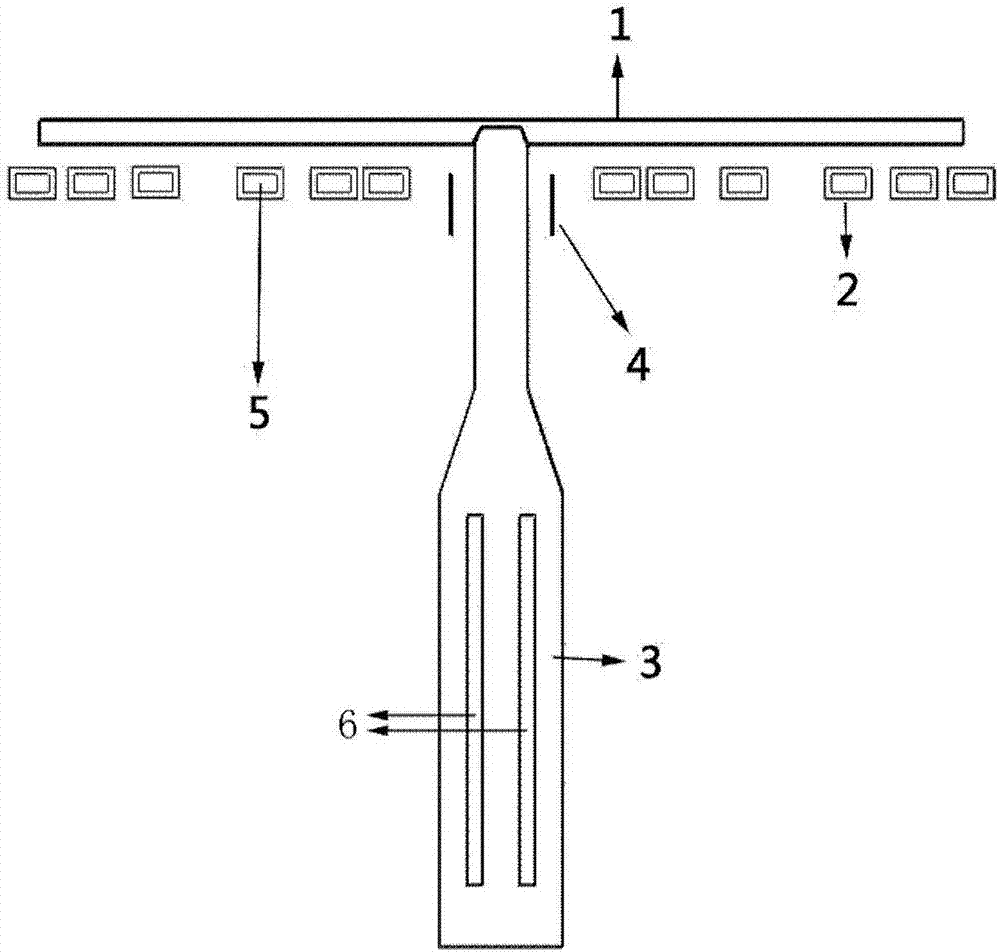

ActiveCN111579190AImprove convenienceImprove accuracyAircraft components testingShock testingMarine engineeringStructural engineering

The invention discloses a horizontal ejection-impact type blade bird cutting test device. The device comprises an air cannon, projectiles launched by the air cannon, a slideway, an impulse conversiondevice, a test blade and a test bird body, wherein the impulse conversion device serves as an impulse conversion medium, the impulse of the shots launched by the air cannon is transferred into the test blade, and the process that the test blade impacts the test bird body is used for simulating blade bird cutting. As the projectile does not directly impact the test blade and does not need to directly hit the test blade from a gun barrel, different types of bird impact blades are simulated by impacting the test bird body with the test blade, and convenience and accuracy of the bird impact resistance blade test method are improved. The invention further provides a test method using the test device.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

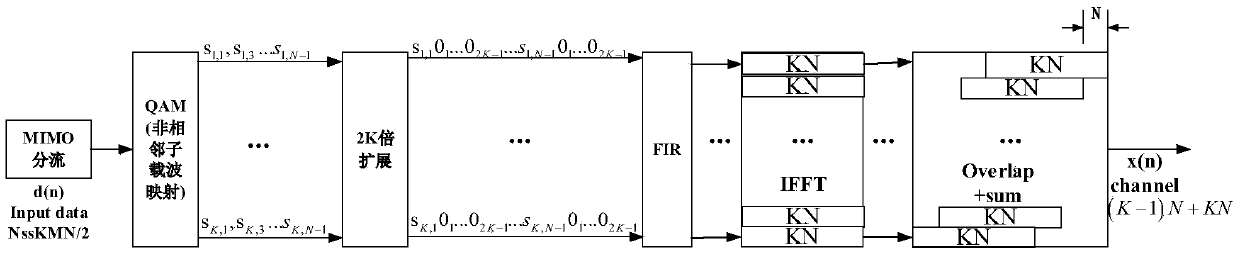

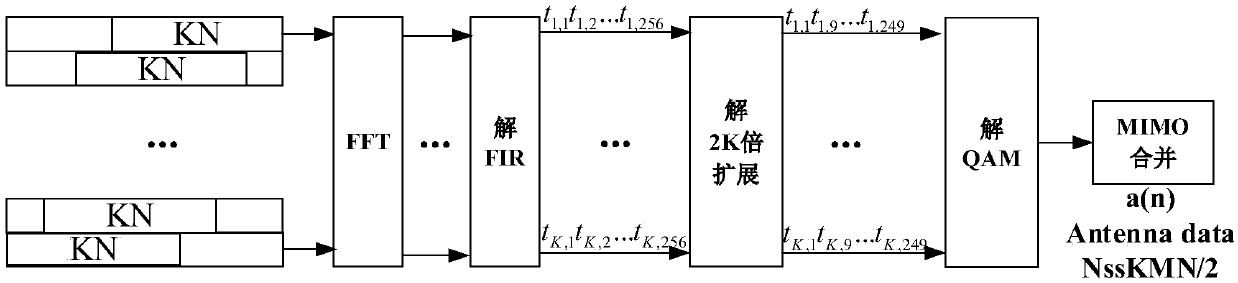

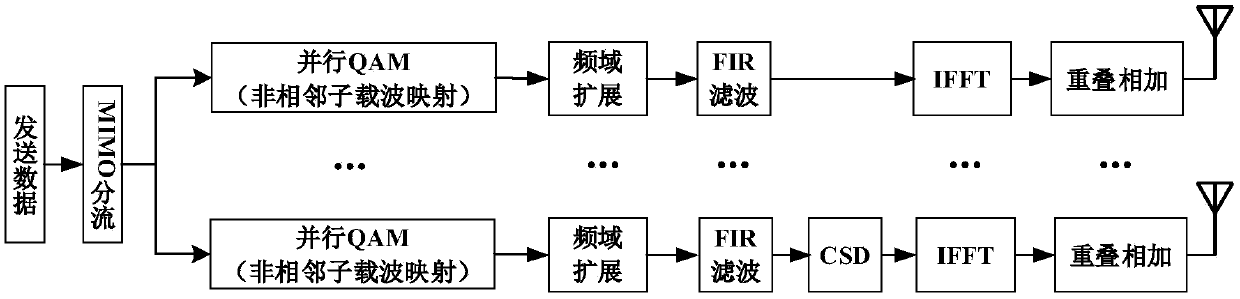

Less complex MIMO-FBMC system data transceiving method and device

ActiveCN108809880ASimplify the demodulation processReduce complexityRadio transmissionMulti-frequency code systemsQam modulationCarrier signal

The invention discloses a less complex MIMO-FBMC system data transceiving method and device. According to the method, QAM modulation is performed on a signal of each antenna in a parallel manner at asending end and the signal is modulated on an odd number of carrier or an even number of subcarrier only; a QAM symbol is filtered through a frequency domain extension manner, and signal correlation is eliminated through cyclic shift; and finally, time domain data is overlap-added so as to mix wave forms and send out the mixed wave forms, wave forms are separated at a receiving end, a series of corresponding demodulation steps are performed so as to recover original sent data. In the method, signals are modulated by using the odd number or even number of subcarrier only, complex overlap-addedwave forms in the FBMC system are mixed and are processed parallelly through multiple paths, therefore, interference between subcarriers and interference between symbols are prevented, further, lowered efficiency due to frequency domain extension and lowered rate due to delayed waiting are prevented, the data processing process is simplified effectively, and hardware is realized less complexly.

Owner:SOUTHEAST UNIV

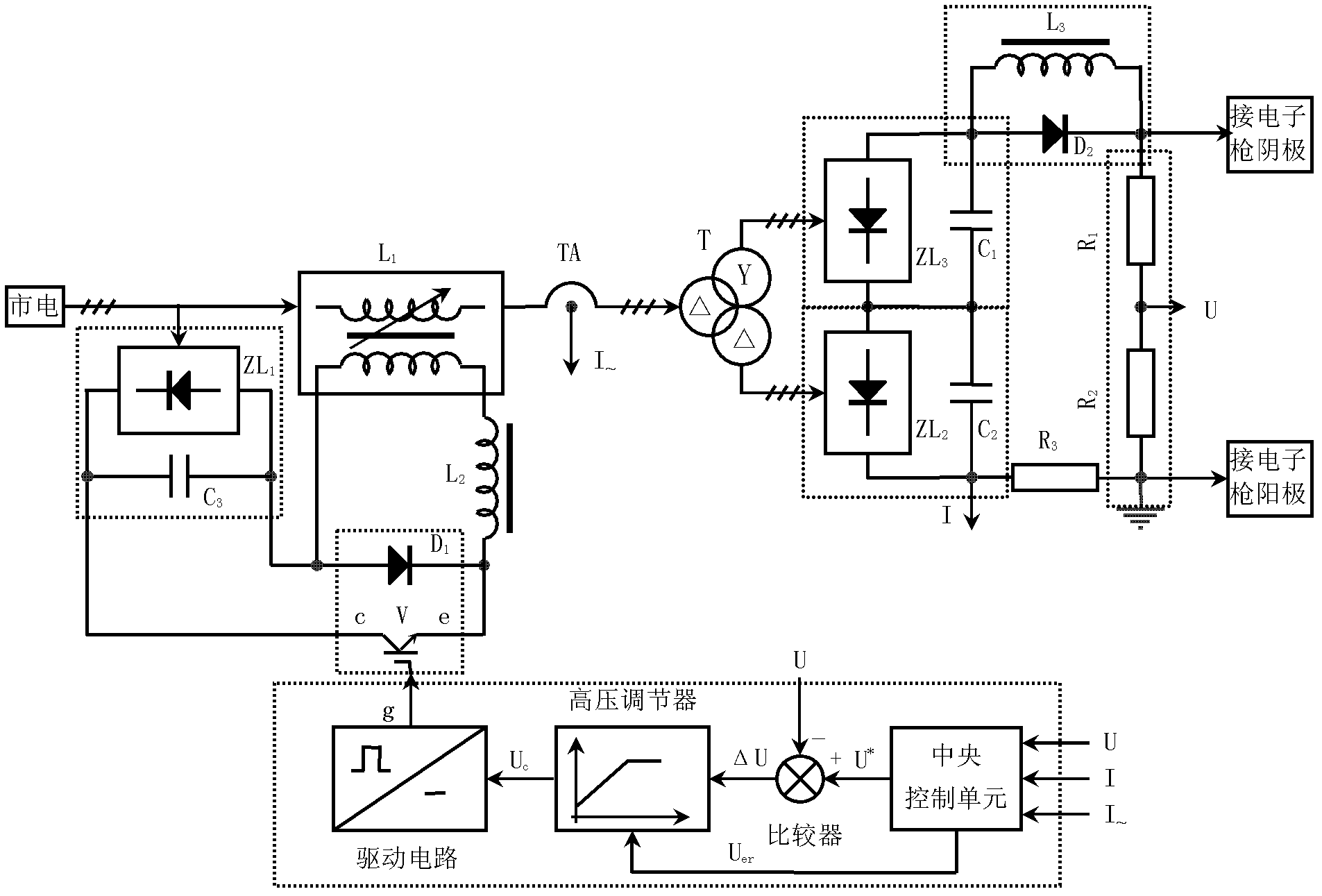

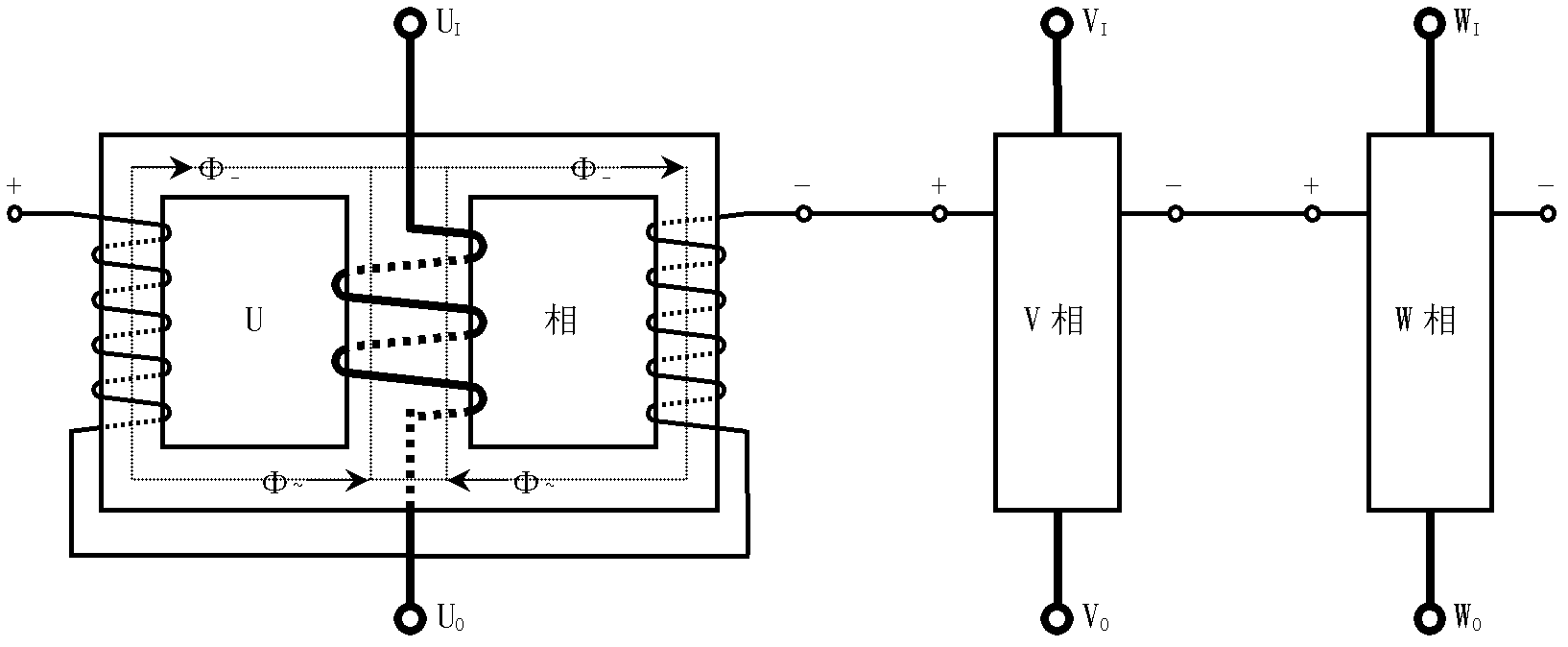

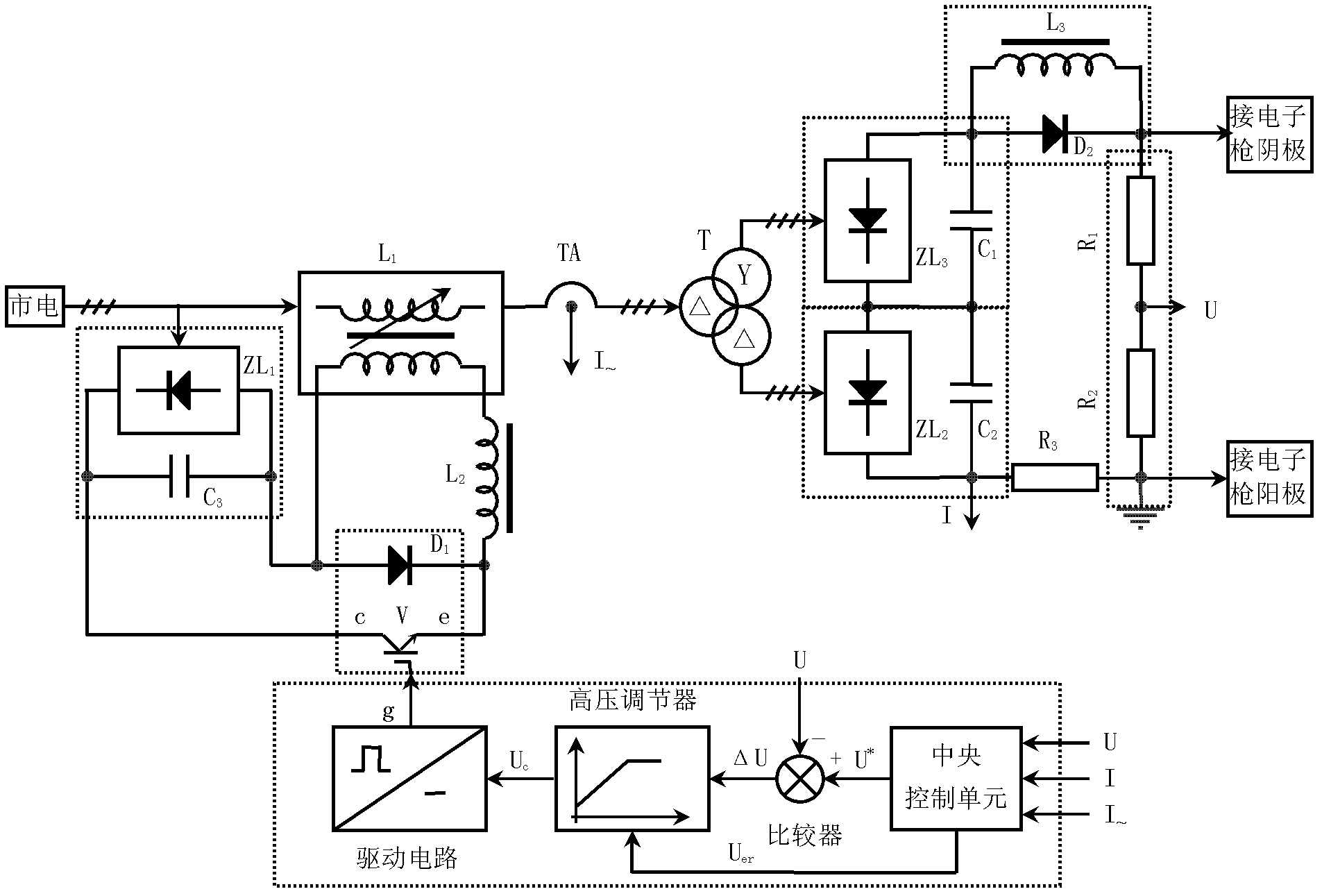

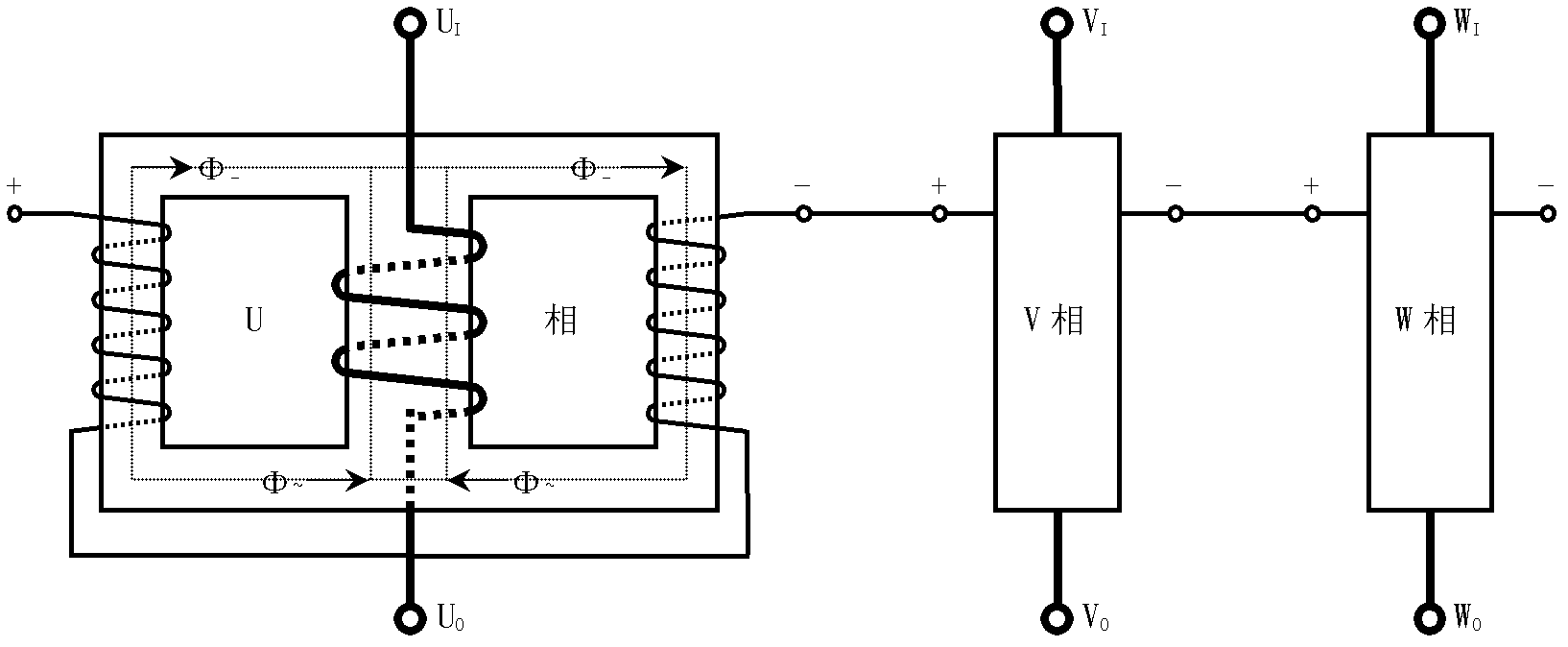

Control method of high-voltage power supply of electron beam melting furnace and power supply device

InactiveCN102573163AIncrease powerImprove efficiencyElectric discharge heatingIncreasing energy efficiencyFiltrationTransformer

The invention discloses a high-voltage power supply device of an electron beam melting furnace. According to the power supply disclosed by the invention, a current transformation way including power frequency alternating current input, voltage regulation by a three-phase adjustable reactor, boosting by a three-phase boosting transformer and high-voltage rectification and filtration is adopted for output; and output high-voltage sampled signals are taken as negative feedback signals, current of a direct current control winding of the three-phase adjustable reactor is controlled by a voltage regulator, and automatic voltage regulation is performed for keeping an output voltage value of the high-voltage power supply of the electron beam melting furnace stable. The power supply disclosed by the invention is based on the control of the controllable reactor and has the characteristics of high efficiency, small public nuisance and capability of fast and effectively suppressing discharge current during discharge of the high-voltage power supply.

Owner:GUILIN UNIV OF ELECTRONIC TECH

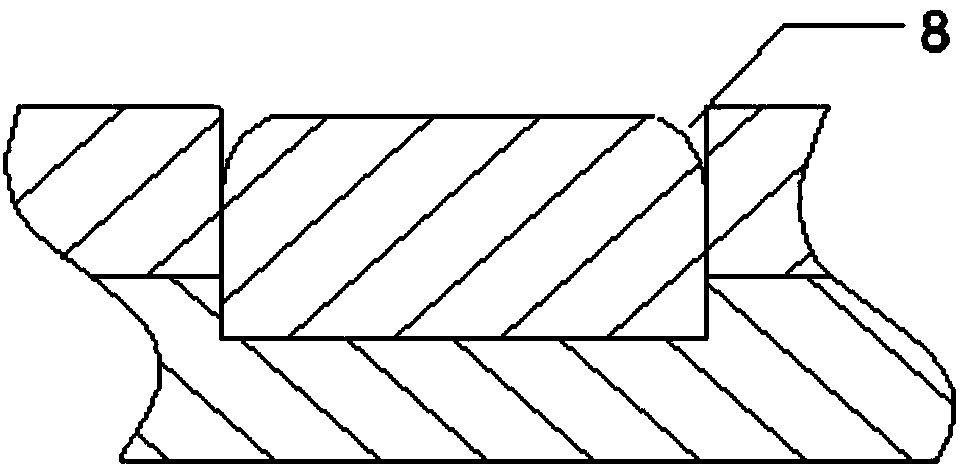

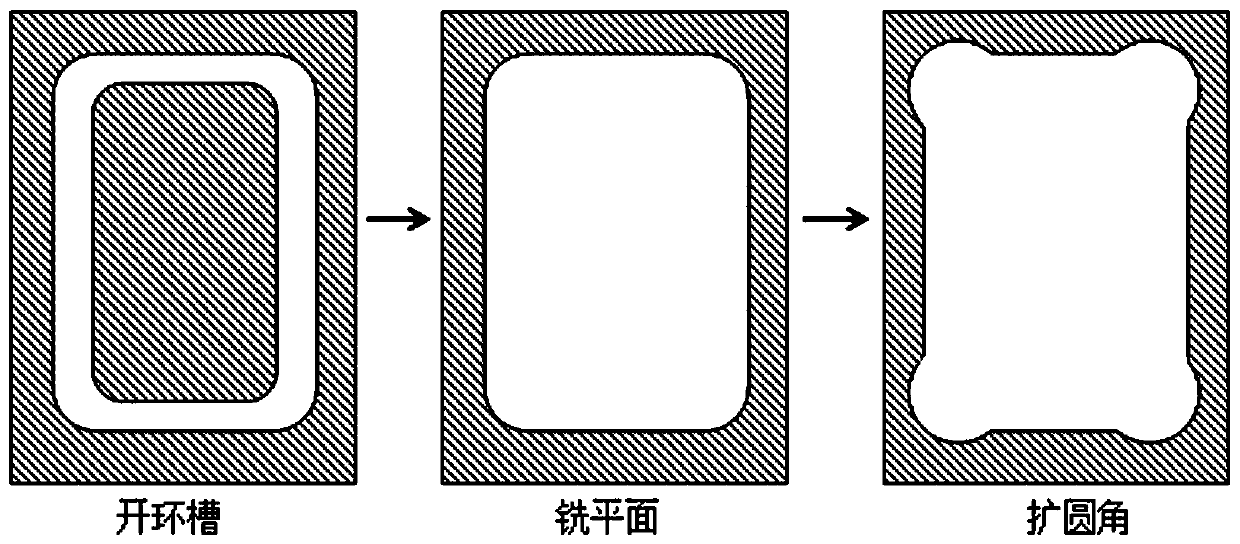

Method for eliminating keyhole-free friction stir spot welding ring groove

InactiveCN107855639AOffset lossSolve the hidden danger of compression sleeveWelding/soldering/cutting articlesNon-electric welding apparatusMolten stateEngineering

The invention provides a method for eliminating a keyhole-free friction stir spot welding ring groove. According to the method, through zero point setting before welding, the length of the part, stretching out of a datum plane, of a stirring pin is 10% of the thickness of a to-be-welded base material, the length of the part, stretching out of the datum plane, of a stirring sleeve is 80% of the stretching length of the stirring pin, and at this moment, the positions of the stirring pin and the stirring sleeve are set as zero points, that is, the zero points are determined by a numerical controlsystem; and before a stirring tool moves downwards, the stirring pin and the stirring sleeve are drawn back at the same time. After the stirring pin and the stirring sleeve are welded and return to the original point, the stirring pin continues to move downwards; and when the quantity that the stirring pin continues to move downwards is 20% of the thickness of the base material, the stirring pinis kept at the position to rotate for 1 s to 2 s, aluminum metal in a molten state is fully backfilled to the position around the welding point, the stirring pin and the stirring sleeve return to theoriginal point and rotate for 1 s to 5 s, the periphery of the welding point is fully filled with the aluminum metal in the molten state, and the aim of eliminating the welding defect ring groove is achieved. The method is used for welding of aluminum plates of 1 mm, 2 mm, 3 mm, 4 mm and 5 mm, and the welding ring groove defect is eliminated.

Owner:HUBEI SANJIANG AEROSPACE WANFENG TECH DEV

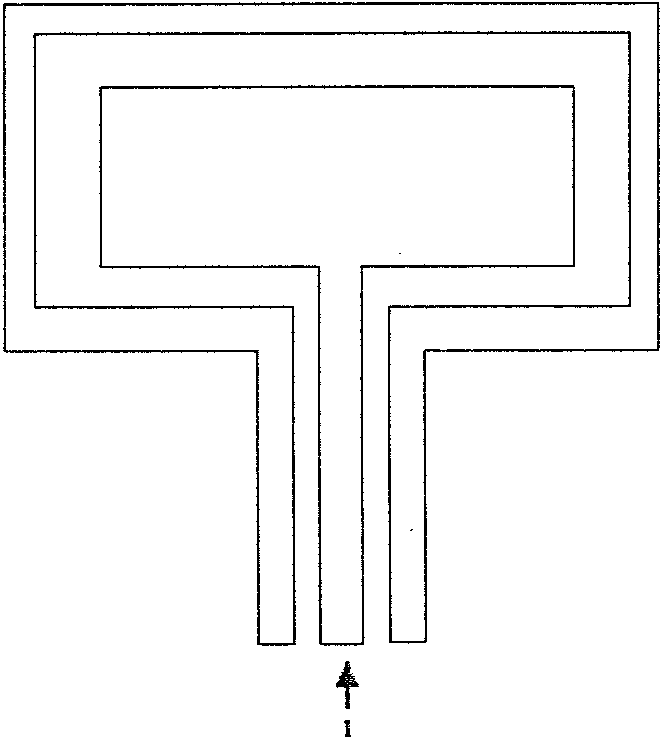

Reconfigurable antenna and manufacturing method therefor

InactiveCN107546484APromote polarizationHigh frequencyRadiating elements structural formsAntenna earthingsReconfigurable antennaCommunications system

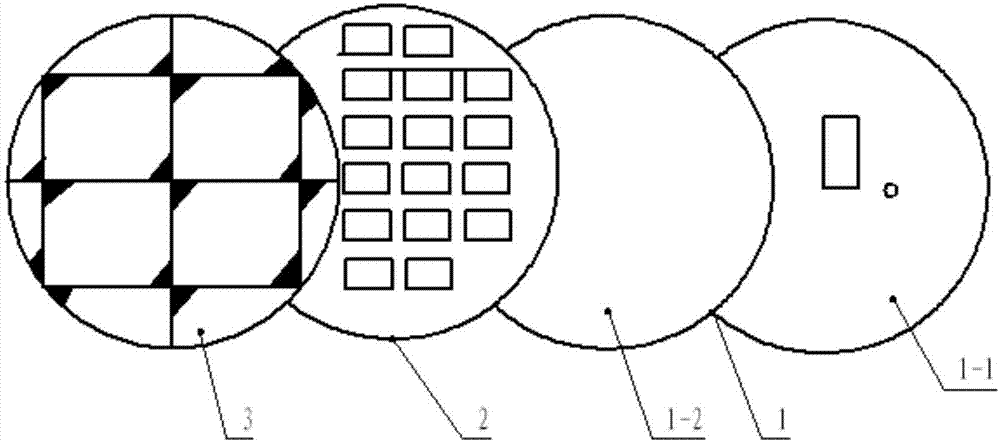

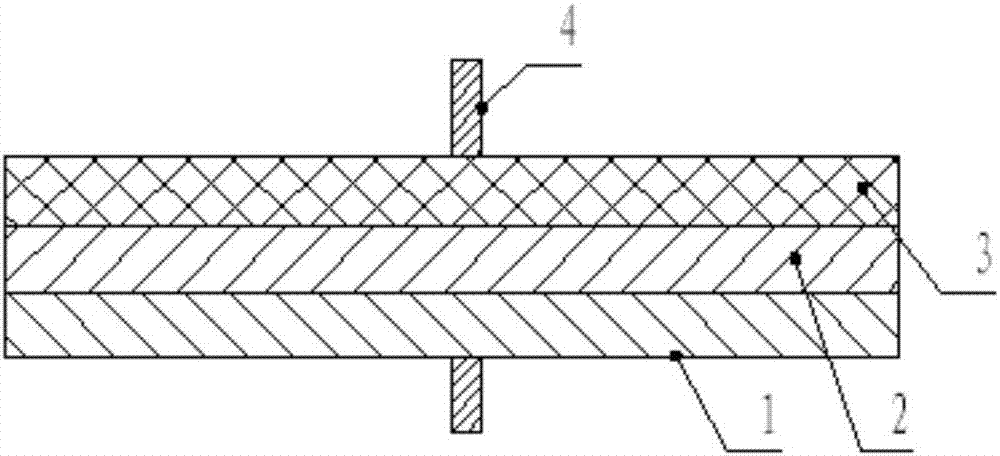

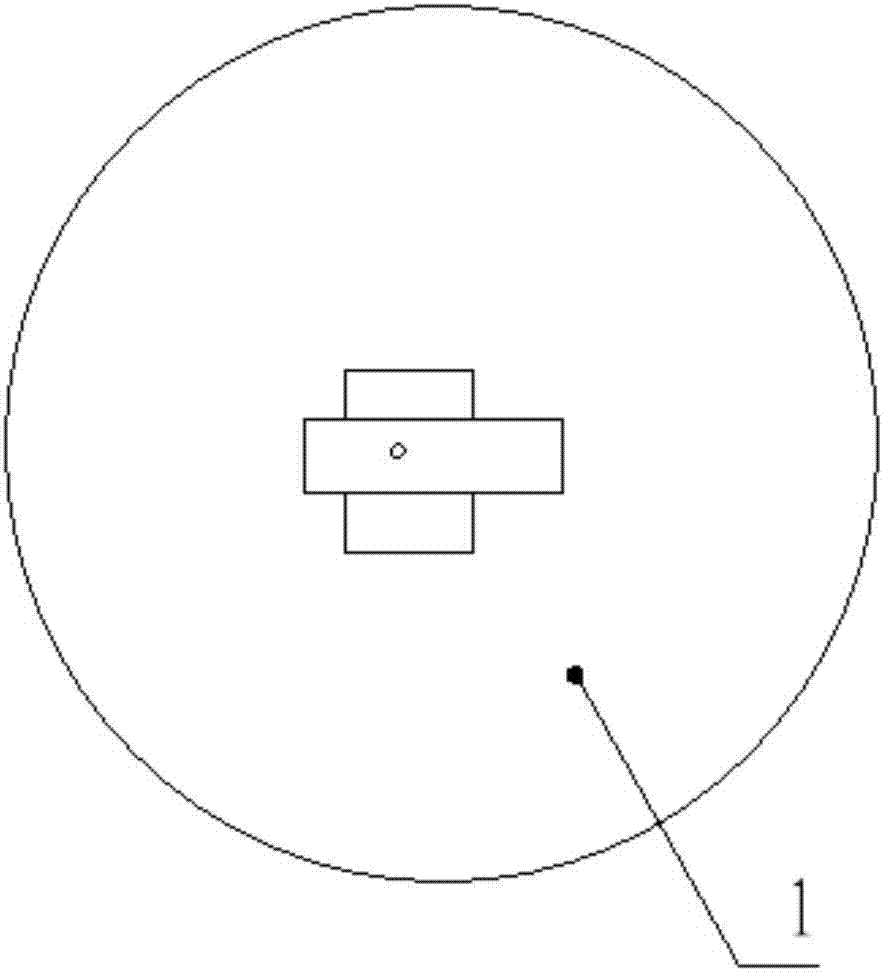

The invention relates to a reconfigurable antenna and a manufacturing method therefor, and mainly aims to solve the problems of small tuning range, single re-configurability and high loss of the reconfigurable antenna in the prior art. A technical scheme is adopted as follows: the reconfigurable antenna comprises a source antenna layer, a metal ring structural layer and a metal cut corner structural layer arranged from the bottom up; the source antenna layer adopts a slit microstrip antenna structure, and comprises a floor with rectangular coupling slits and a dielectric plate with rectangularmetal radiation patches; the metal ring structural layer comprises rectangular metal ring units periodically arranged in the directions of X axis and Y axis; the metal cut corner structural layer comprises square metal cut corner units periodically arranged in the directions of X axis and Y axis; the metal ring structural layer performs clockwise rotation to form an included angle <theta>1 with the X axis; and the metal cut corner structural layer performs clockwise rotation to form an included angle <theta>2 with the X axis. By virtue of the method, the problems are well solved, and the reconfigurable antenna can be used for an intelligent communication system.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

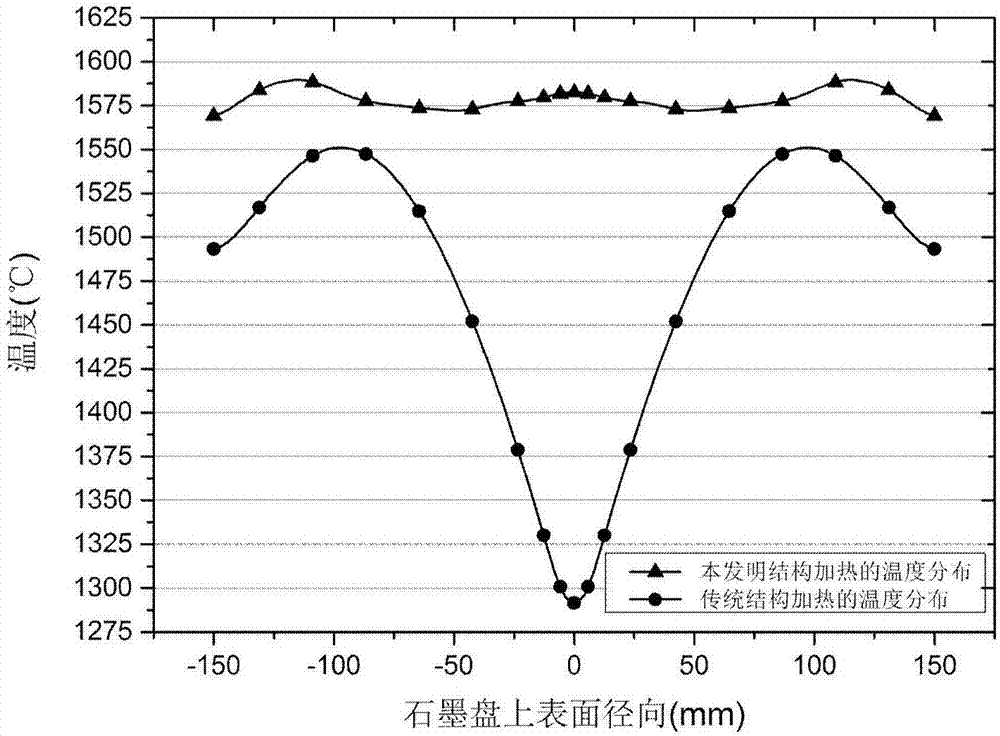

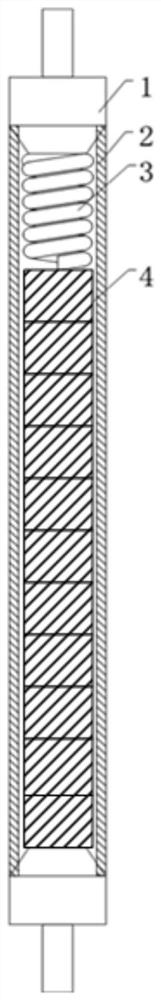

Induction heating device for thin film materials

ActiveCN107326343AImprove temperature uniformityOffset lossChemical vapor deposition coatingEngineeringLarge size

The invention provides an induction heating device for thin film materials. The induction heating device comprises a tray and an induction coil. The induction coil is arranged below the tray and used for heating the tray. The induction coil is in a plane spiral shape and comprises p turns of coils. The first turn of coil is the innermost turn of coil of the induction coil, the pth turn of coil is the outermost turn of coil, the mth turn of coil and the nth turn of coil are located between the first turn of coil and the pth turn of coil, and 1<m<n<p. The distance between any two adjacent turns of coils from the first turn of coil to the mth turn of coil and the distance between any two adjacent turns of coils from the nth turn of coil to the pth turn of coil are smaller than the turn-to-turn distance between any two adjacent turns of coils from the mth turn of coil to the nth turn of coil. According to the induction heating device, the overall temperature uniformity of the tray and the temperature of a center area of the tray are improved, the requirements of the large-size multi-piece thin film materials for growth at the high temperature are met, and the growing efficiency and quality of the thin film materials are improved.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

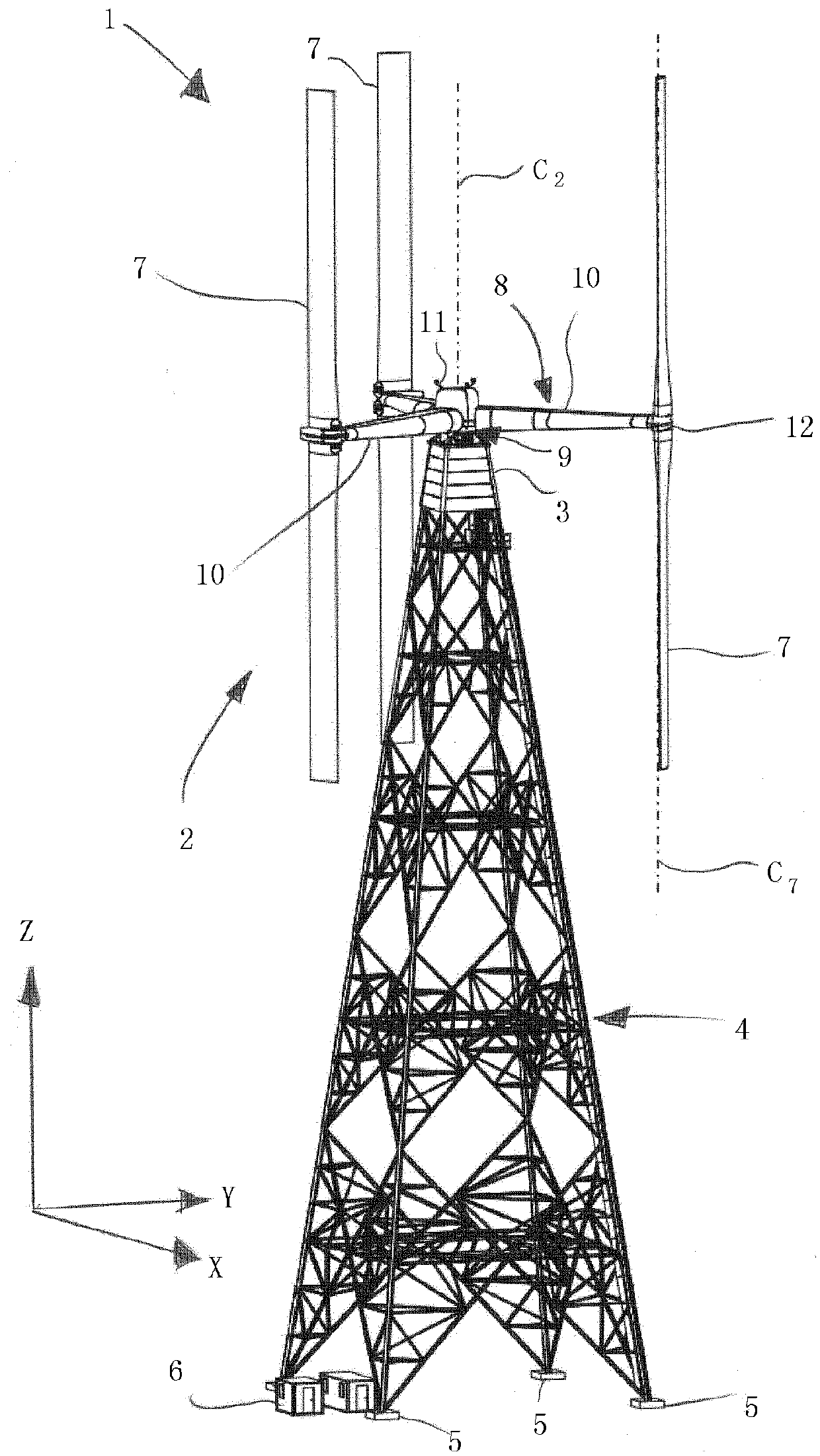

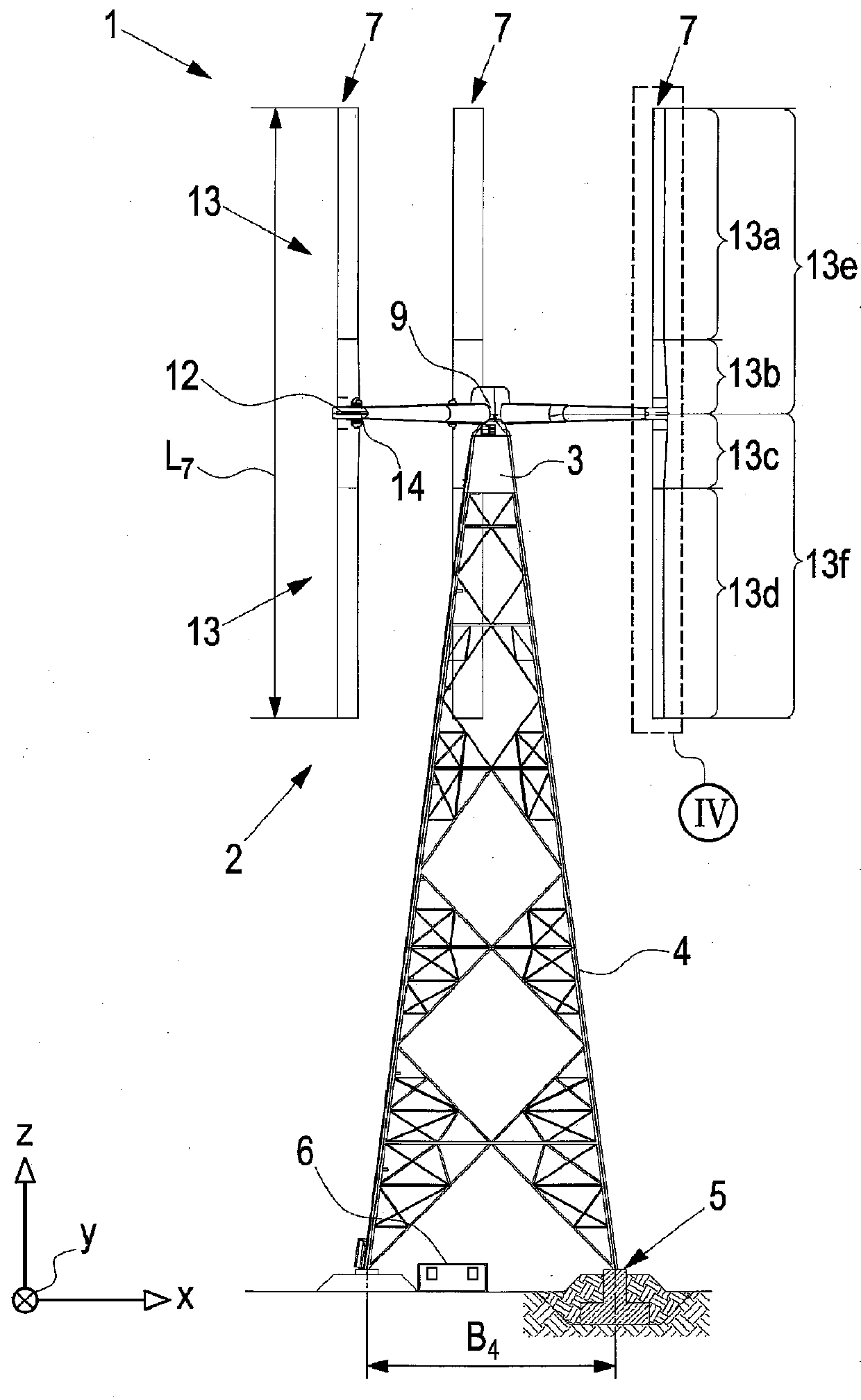

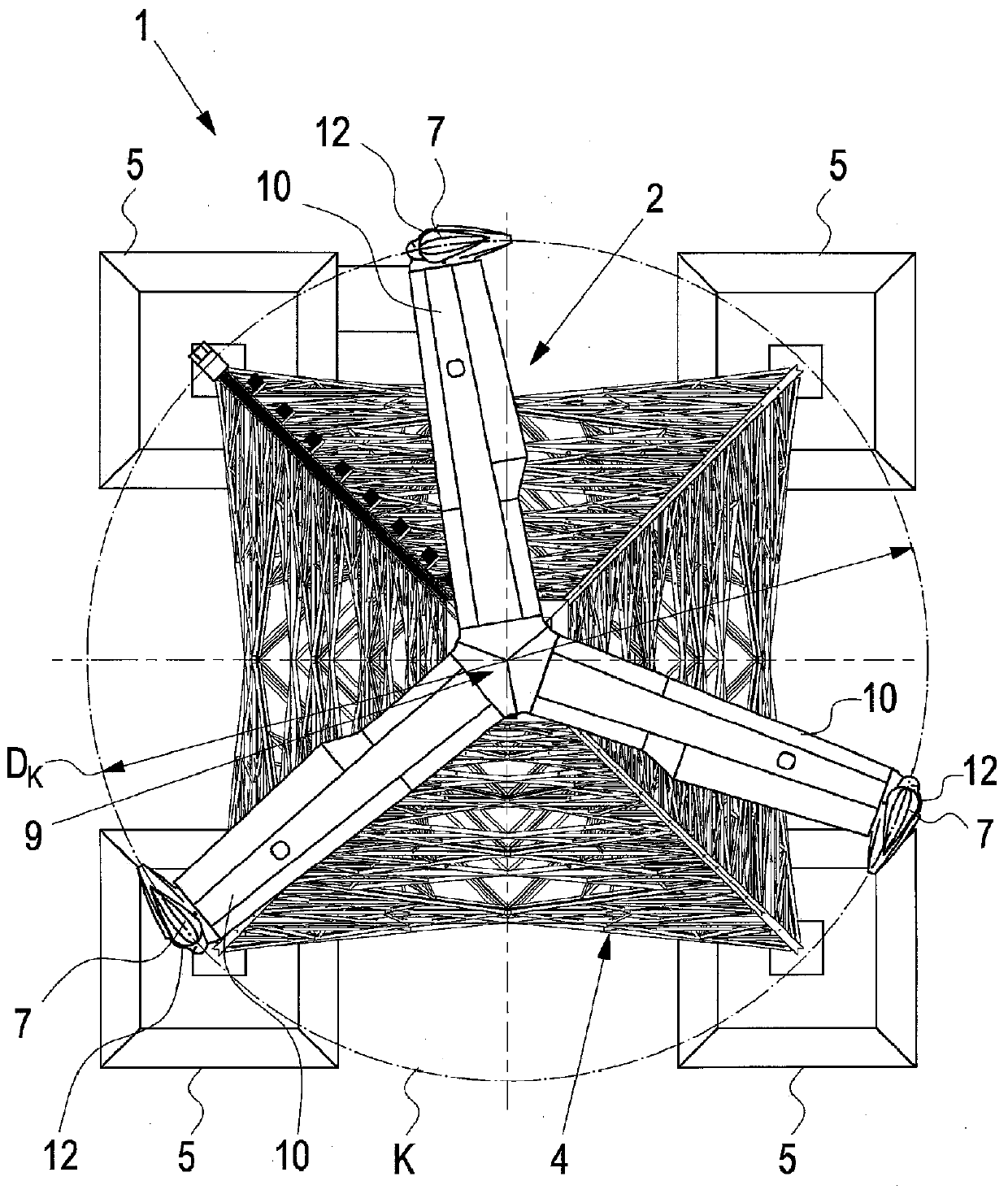

Vertical wind turbine comprising pitch motor with protruding rotor blades, kit for same, and method for operating same

PendingCN110892154APrecise and energy-efficient drivesEasy to adjustWind motor controlEngine fuctionsRotational axisClassical mechanics

Owner:AGILE WIND POWER

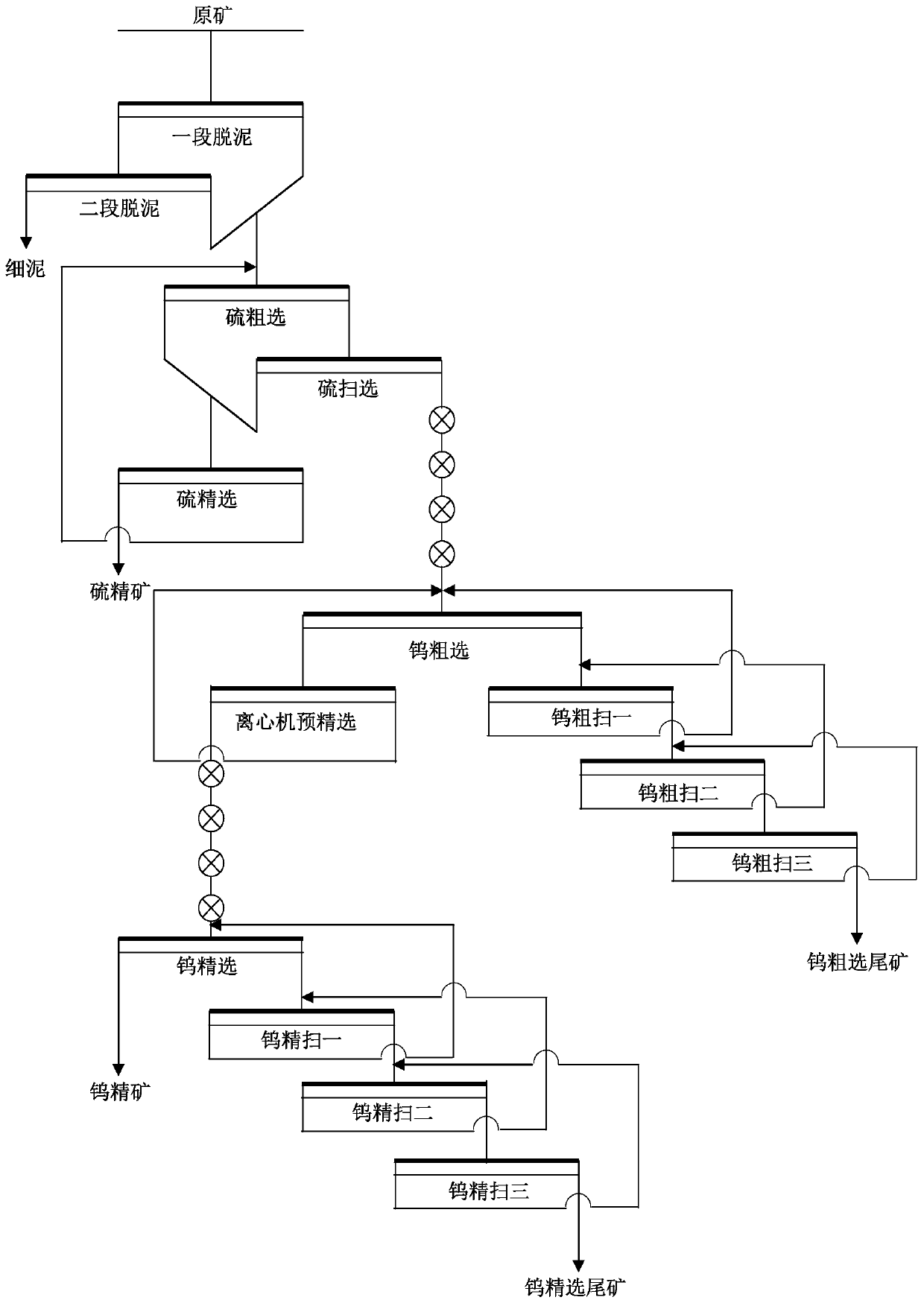

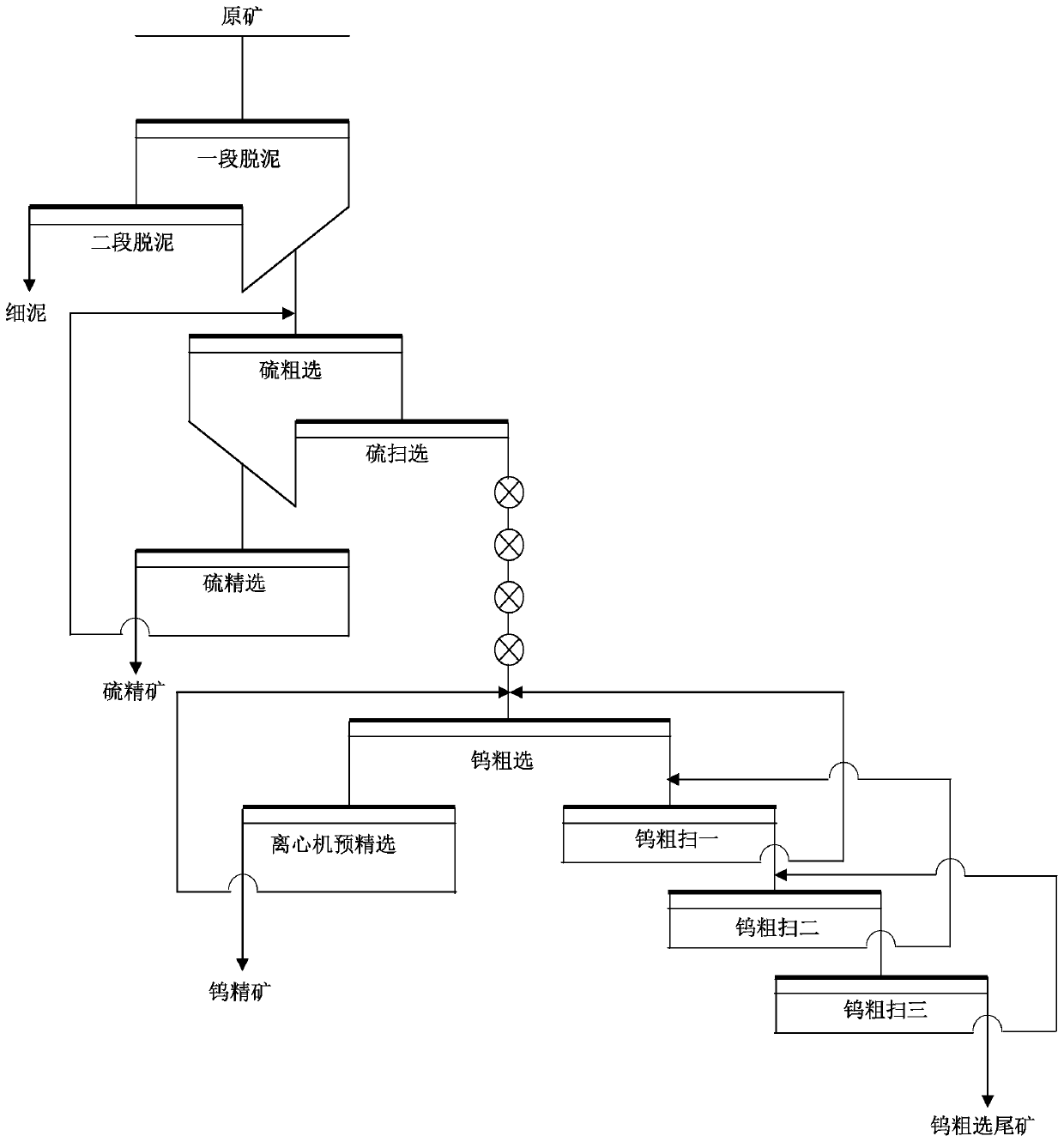

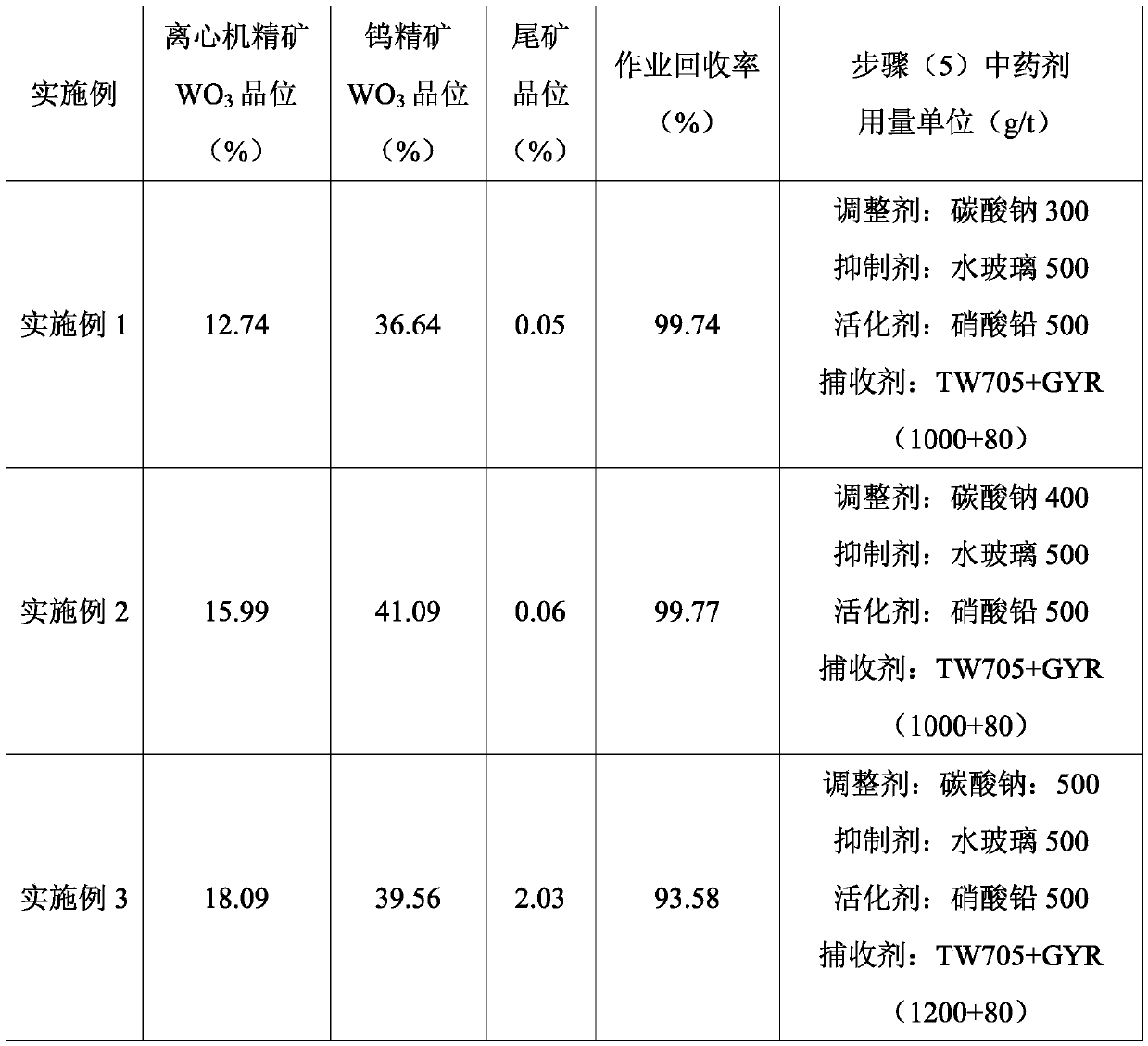

Sorting method of low-grade black and white tungsten fine clay

InactiveCN110918247ALarge circulationImprove concentrate gradeWet separationOre concentrateProcess engineering

The invention discloses a sorting method of low-grade black and white tungsten fine clay. A buoyancy-gravity-buoyancy combined process is adopted, the complex fine clay mineral recycling and grade increasing requirement is satisfied, and the overall advantage of the process is given. The process has the advantages of simplicity, convenience in operation and management, strong suitability and no need of heating, the technical problem that the grade of the tungsten fine clay concentrate does not meet the smelting requirement all the time is solved, and the purpose of directly producing qualified-grade black and white tungsten fine clay concentrate by floatation at normal temperature is realized. Because the concentrate grade of the product meets the requirement for sale, the cost of flotation reagents and the loss of the amount of metal due to the decrease of the recovery rate are enough to offset by economic benefits obtained by the increase of the selling price, more importantly, the product marketing is expanded, so that the requirement of environmental protection of a smelting plant is met, and good social benefits are generated.

Owner:宁化行洛坑钨矿有限公司

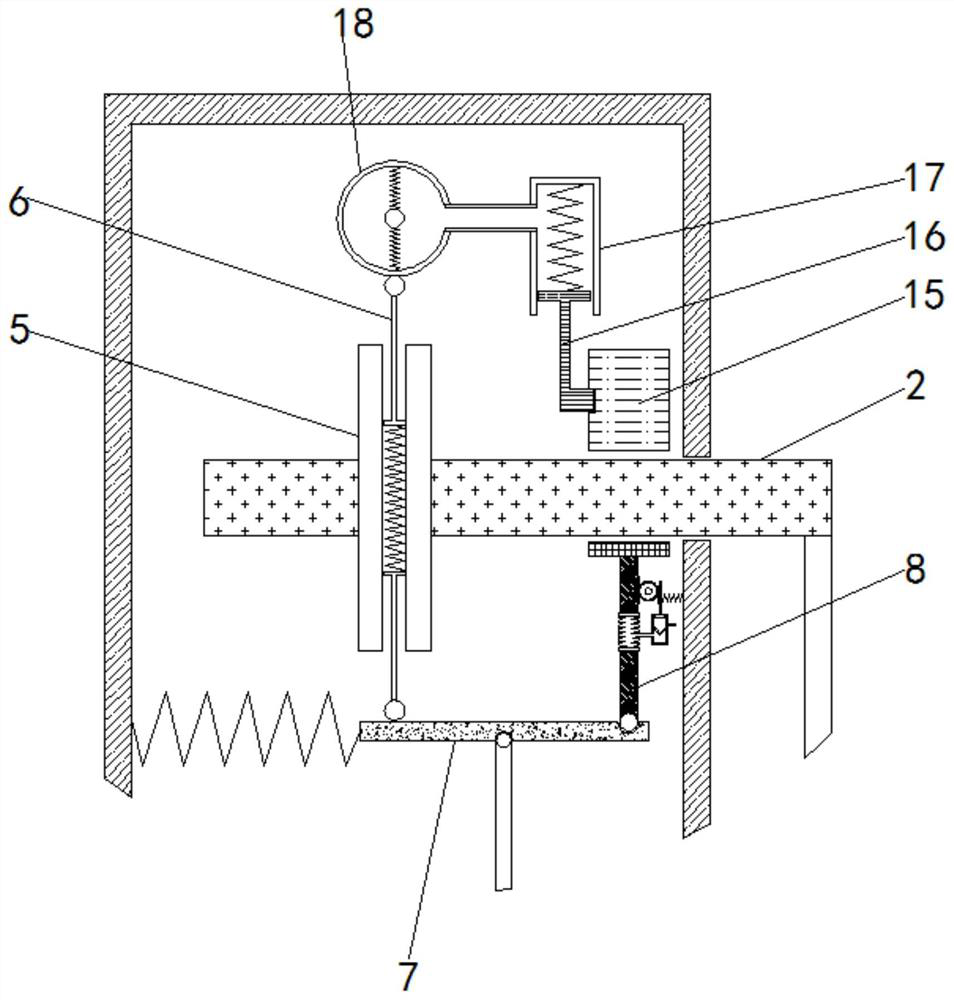

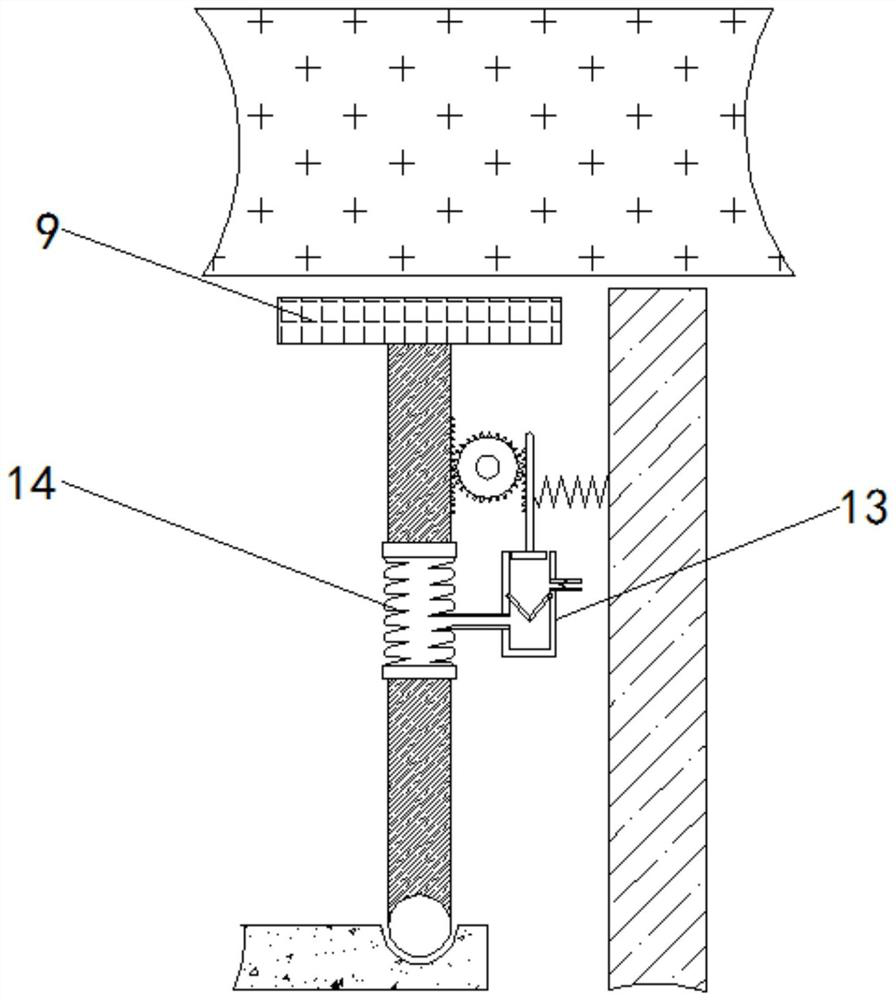

Special stretching equipment for preventing old people from being strained

ActiveCN111773617AAchieve the purpose of stretchingYaw speed limitMovement coordination devicesCardiovascular exercising devicesOlder peopleEngineering

The invention relates to the technical field of elderly care equipment. The invention discloses special stretching equipment special for preventing old people from being strained. The stretching equipment comprises a supporting column; a rotating shaft is inserted into the side surface of the supporting column; the side, away from the supporting column, of the rotating shaft is fixedly connected with a deflection rod; the bottom of the deflection rod is fixedly connected with a pedal; the side surface of the rotating shaft is fixedly connected with a centrifugal wheel; a centrifugal rod is arranged on the side face of the centrifugal wheel in a penetrating and inserting mode, a lever is arranged below the centrifugal wheel, a friction block is fixedly connected to the top of an ejector rod, a bearing wheel is connected to the side face of an inflation toothed rod in a meshed mode, an air bag is arranged above the centrifugal wheel, and an extrusion air box is fixedly connected to the side face of the air bag through a guide pipe. According to the special stretching equipment for preventing the old people from being strained, through cooperative use of the rotating shaft and the centrifugal wheel, the effects of preventing excessive stretching of legs and protecting the legs when the old people use a stretching machine are achieved.

Owner:SHANDONG XIEHE UNIV

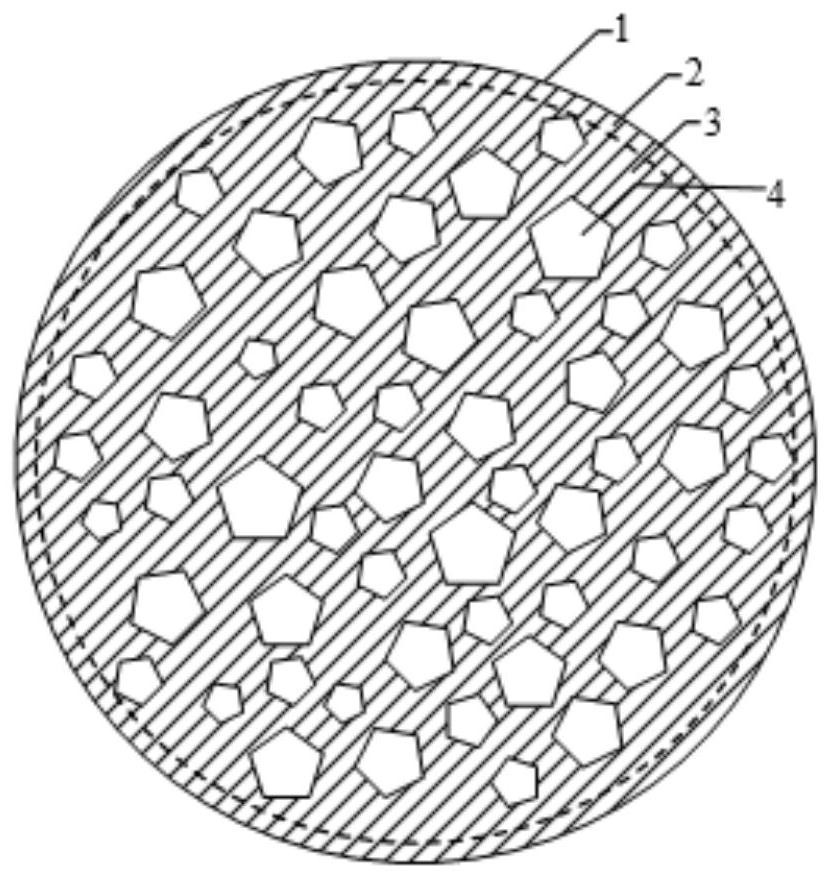

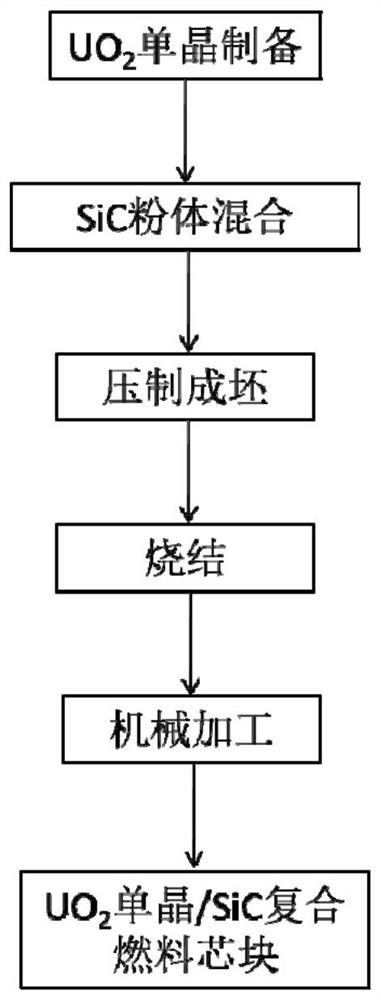

High-thermal-conductivity uranium dioxide single crystal composite fuel pellet and preparation method thereof

ActiveCN111933310AImprove thermal conductivityLow chemical activityNuclear energy generationReactors manufactureUranium oxidePhysical chemistry

The invention discloses a high-thermal-conductivity uranium dioxide single crystal composite fuel pellet and a preparation method thereof. The pellet takes UO2 single crystals as fuel particles, the fuel particles take SiC, Zr and other high-thermal-conductivity metal or ceramic material powder as a connecting medium, and the fuel particles and the connecting medium are wrapped with fuel-free areas reserved on the outer surfaces. The novel UO2 single crystal composite fuel researched and developed by the invention effectively counteracts self-obstruction and loss caused by the heat conductiondirectivity of UO2. According to the scheme, the thermal conductivity of the material is improved under the condition that the chemical activity of the fuel pellet is reduced, and the binary compositepellet fuel is excellent.

Owner:SHANGHAI NUCLEAR ENG RES & DESIGN INST CO LTD

Online surfacing welding repair method for large grinding roller sleeve

The invention belongs to the technical field of surfacing welding methods, in particular to an online surfacing welding repair method for a large grinding roller sleeve. Compared with the prior art, the invention provides continuous, long-time heating effects for the large grinding roller sleeve by the use of pre-heating air and cooling air and effectively solves the various problems in the existing online surfacing welding repair. The weld bead is closely connected with the outer surface of the large grinding roller sleeve to be repaired and does not fall off easily. In addition, the weld bead has no crack and is resistant to wear, which conforms to the repair requirements.

Owner:湖北秦鸿新材料有限公司

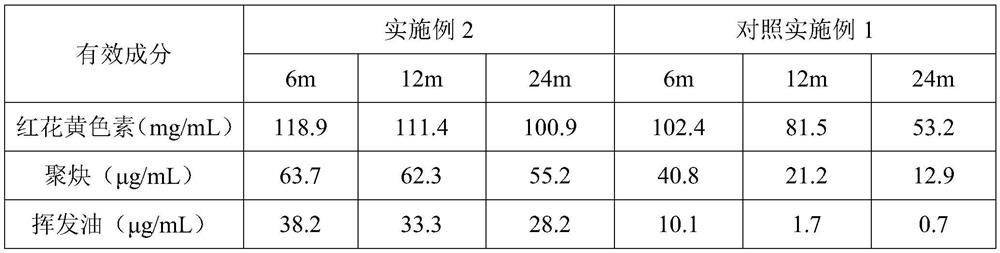

Processing technology of high-quality safflower decoction pieces

ActiveCN111920841AIncrease the content of active ingredients for promoting blood circulationQuality improvementAntipyreticAnalgesicsProcess engineeringAqueous solution

The invention discloses a processing technology of high-quality safflower decoction pieces. The invention relates to the technical field of safflower decoction piece preparation. The method comprisesthe following steps of: drying, moistening with a reinforcing liquid, freeze-drying, stir-frying with vinegar, wax-sealing and the like. According to the invention, the safflower dry product is moistened by the reinforcing liquid; the content of blood-activating effective components in the safflower semi-finished product is effectively improved; the loss in the processing process is partially counteracted, the content of effective components in the safflower decoction piece finished product is increased, the beewax is used for encapsulating the safflower decoction piece, thereby fixing the effective components and isolating the air, reducing the loss of the effective components of the safflower decoction piece in the storage process and improving the quality of the stored safflower decoction piece. T he step of stir-frying with vinegar can reduce the pH value of the safflower decoction piece aqueous solution, effectively improve the dissolution rate of carthamin yellow and improve thedrug effect.

Owner:安徽鑫泰药业有限公司

Online surfacing welding repair method for large vertical mill grinding roller

The invention belongs to the technical field of surfacing welding methods, in particular to an online surfacing welding repair method for a large vertical mill grinding roller. Compared with the priorart, the invention provides continuous, long-time heating effects for the large vertical mill grinding roller by the use of pre-heating air and cooling air and effectively solves the various problemsin the existing online surfacing welding repair. The weld bead is closely connected with the outer surface of the large vertical mill grinding roller to be repaired and does not fall off easily. In addition, the weld bead has no crack and is resistant to wear, which conforms to the repair requirements.

Owner:湖北秦鸿新材料有限公司

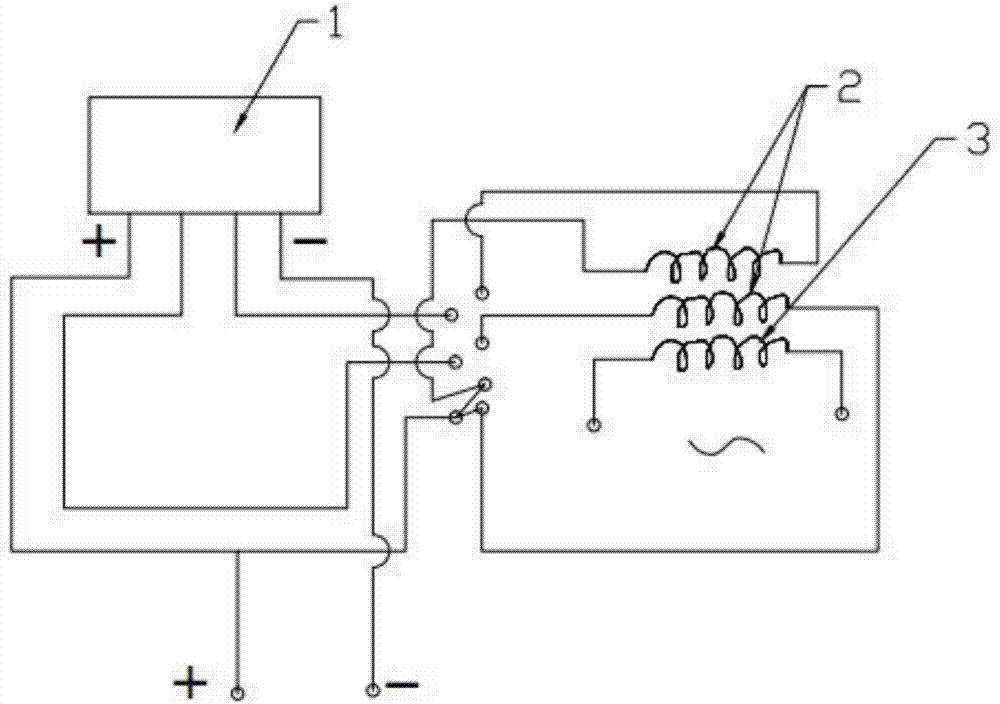

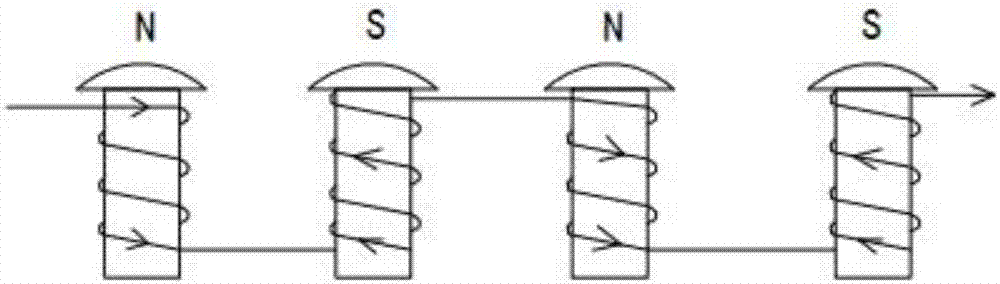

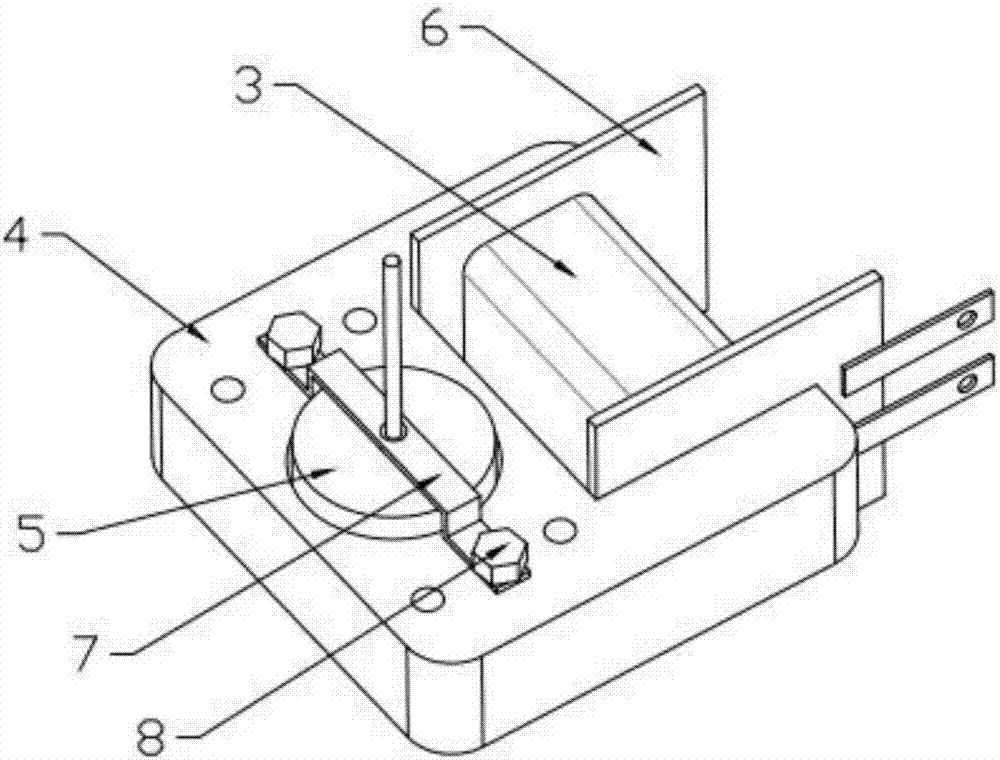

Low energy consumption AC/DC universal electric motor

InactiveCN107959396AOffset lossReduce energy consumptionWindingsDC commutatorElectricityElectric machine

The invention relates to a low-energy-consumption AC-DC universal motor, which includes a motor body, in which a plurality of sets of stator excitation coils are arranged, and at least one set of induction coils are added to the motor body, the induction coils are connected to a power supply through wires, and the induction coils induce the stator The magnetic field of the excitation coil generates current and charges the power supply to form a cycle of electrical energy. The motor body of the present invention adds a group of induction coils, and the magnetic field generated by the excitation coil forms a current in the induction coil, that is, generates electricity. This part of the current is charged into the power supply to form a circular conversion of electric energy, offsetting part of the loss of the motor, thereby To achieve the purpose of low energy consumption.

Owner:宋质繁

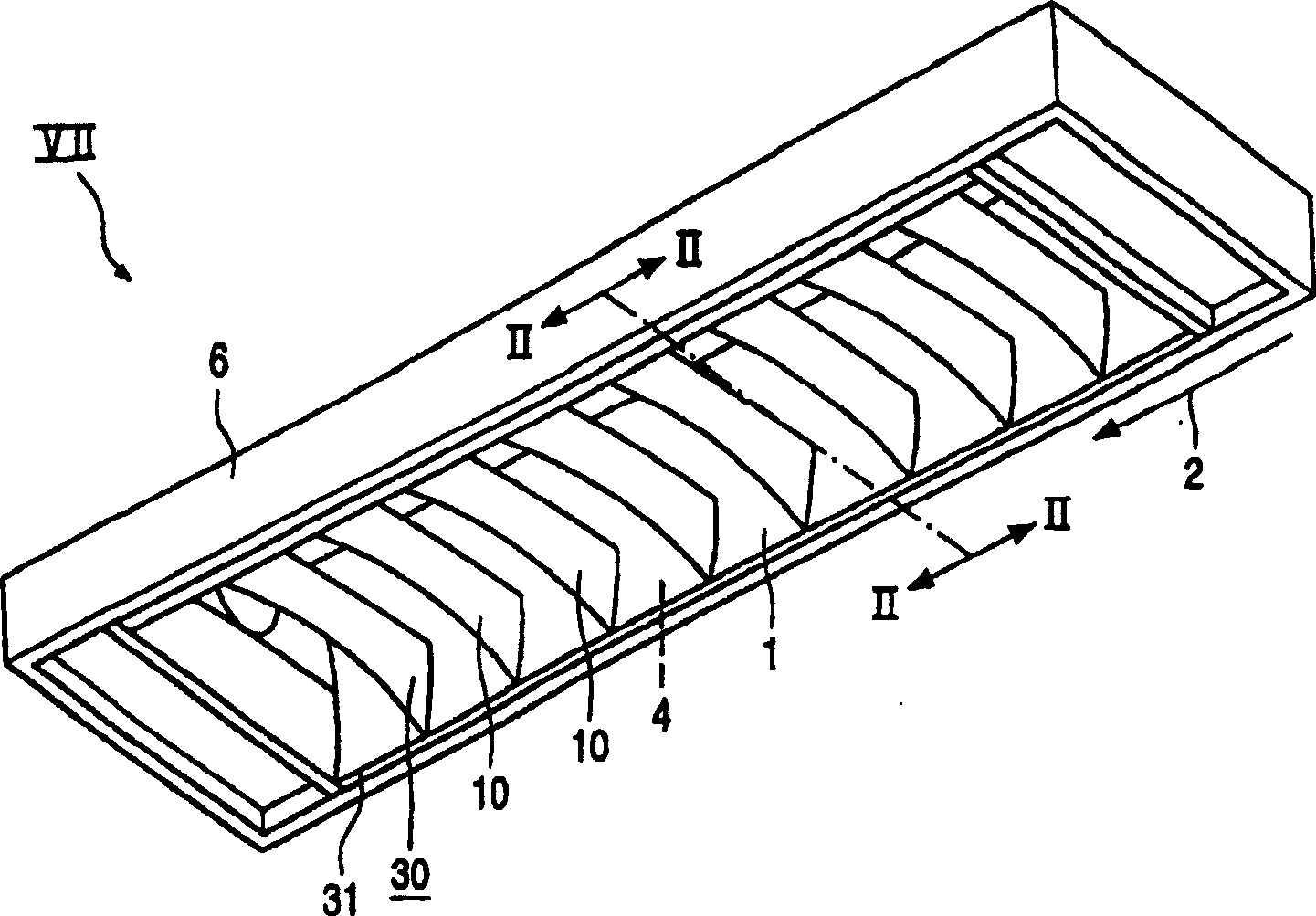

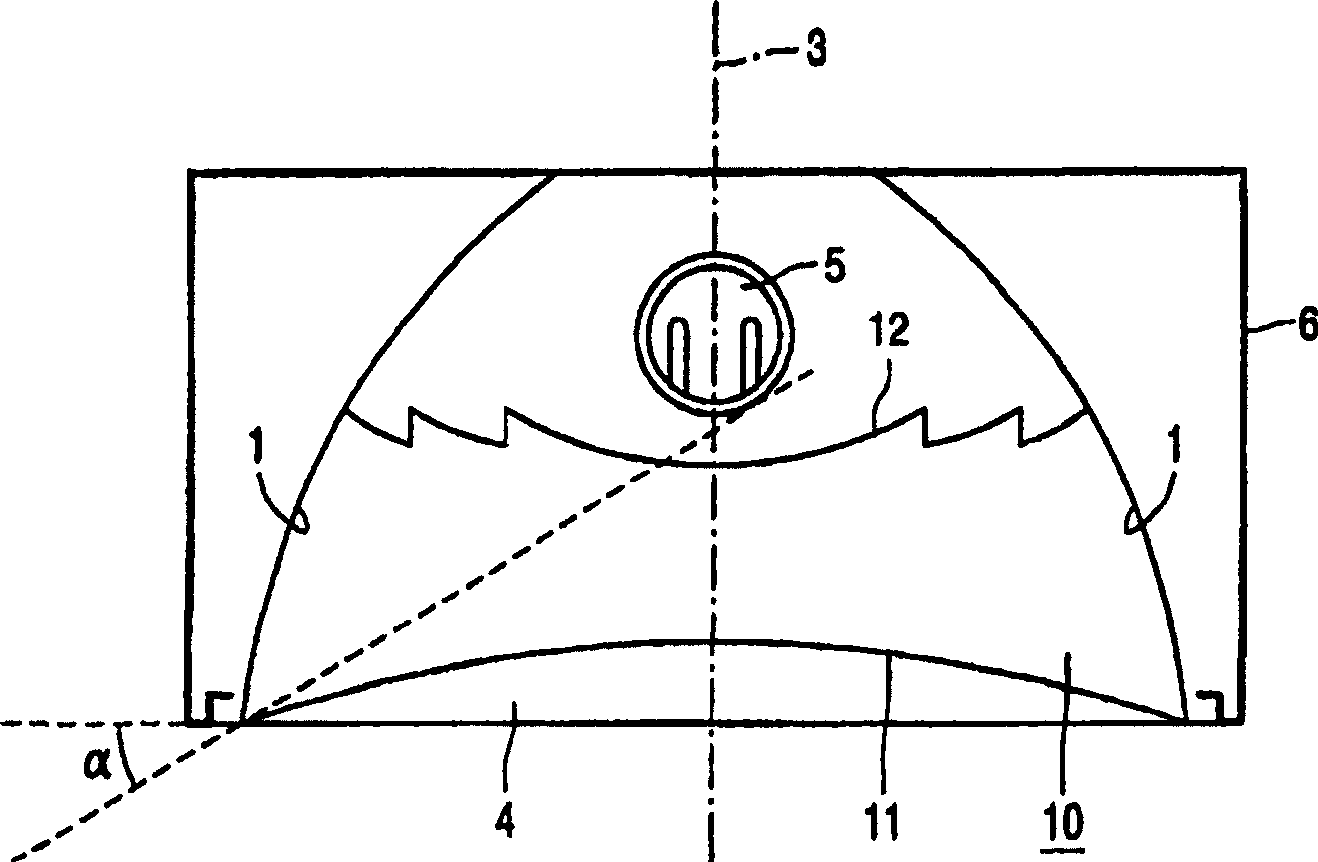

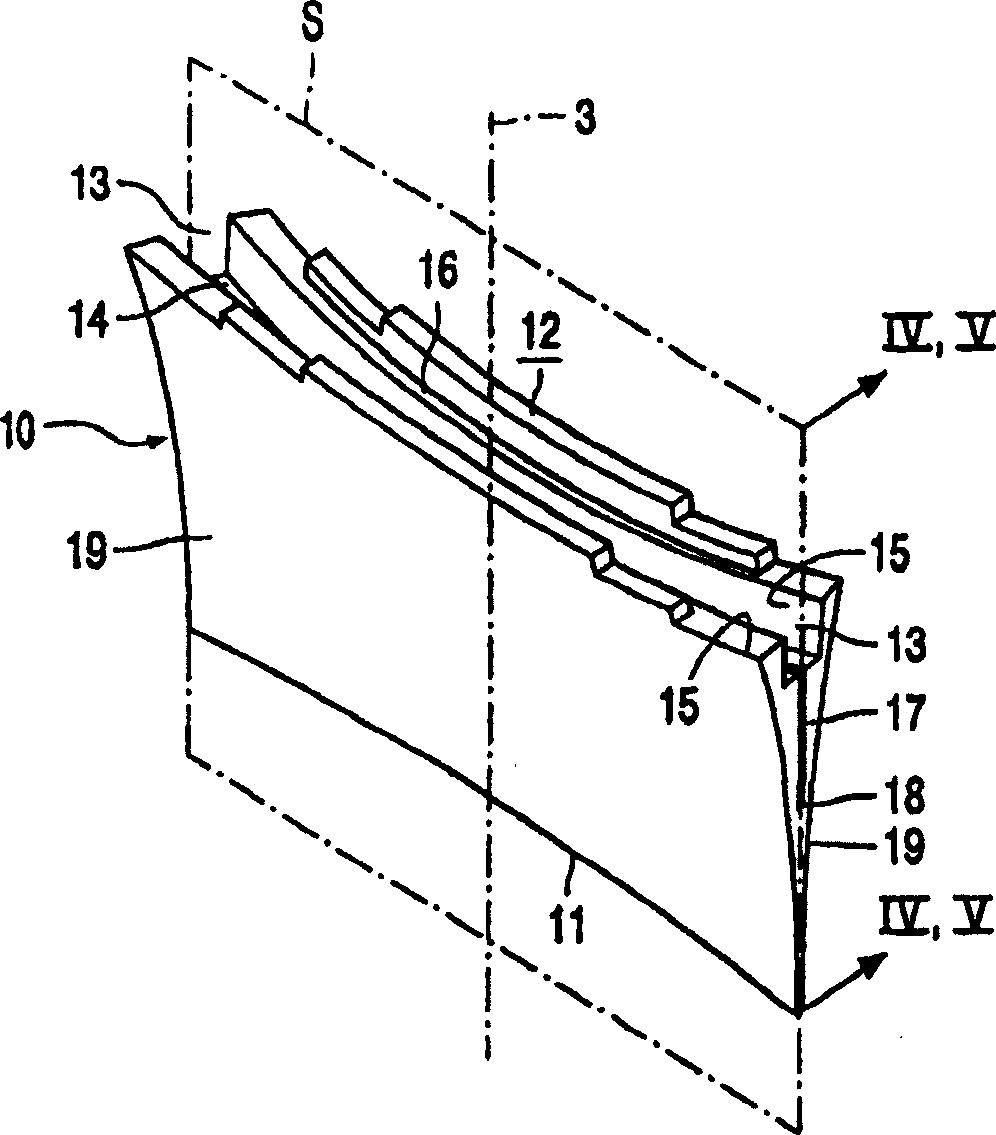

Luminaire and lamellae grid for this

InactiveCN100473896CShorten operation timeOffset lossElongate light sourcesReflectorsClassical mechanicsBright spot

The luminaire has a plurality of reflecting lamellae (10) between side reflectors (1). The lamellae (10) each have an outer edge (11), an inner surface (12) facing away from said edge (11), and a plane of symmetry (S) through the outer edge (11) and the inner surface (12). The lamellae (10) have a resin body and a recess (13) in the inner surface (12), in the plane of symmetry (S). The recess (13) has a bottom surface (14) transverse to the plane of symmetry (S) and substantially parallel walls (15) along said plane. The recess (13) may widen stepwise from the bottom plane (14) towards the inner surface (12). The lamellae (10), as compared with metal lamellae, provide a greater freedom to choose their shape and are less expensive. They nevertheless avoid the occurrence of reflections on the side reflectors, which cause unpleasant bright spots within the cut-off angle of the luminaire. The lamellae grid (30) has strips (31) interconnecting, and integral with, the lamellae (10) and is suitable for use in the luminaire.

Owner:SIGNIFY HLDG BV

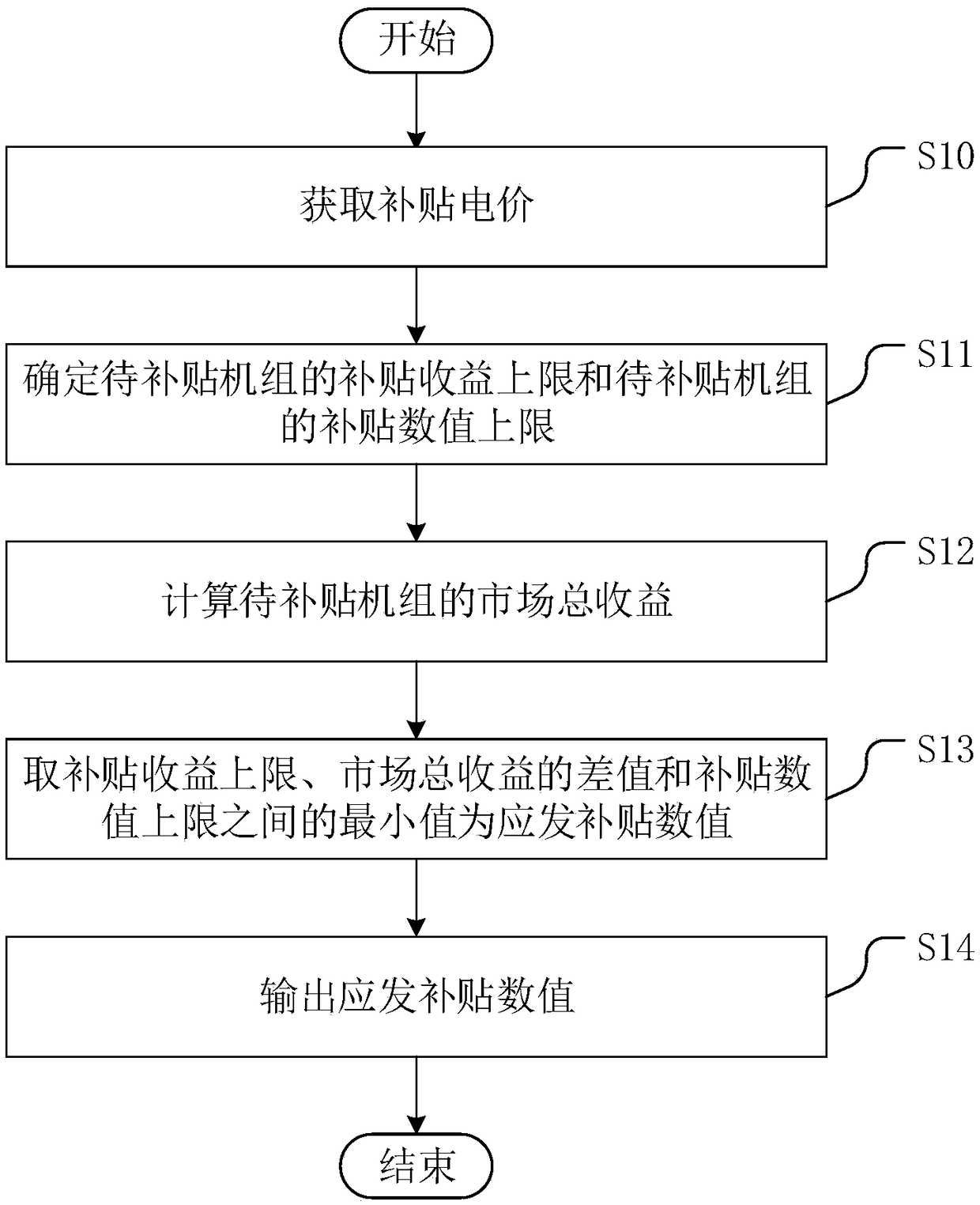

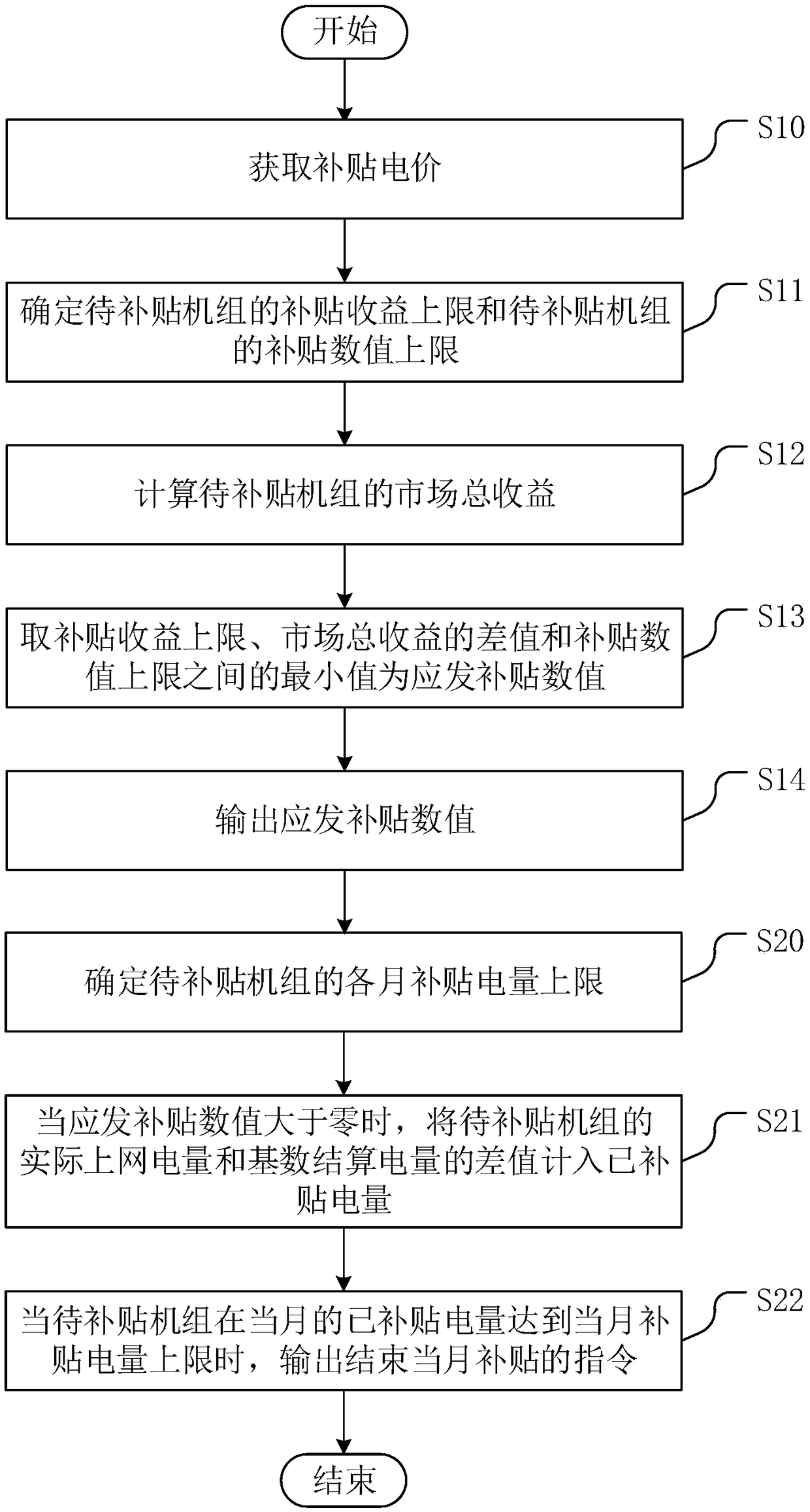

Subsidy method, apparatus and device for high-cost unit to participate in spot market

InactiveCN109409725AAvoid excessive subsidiesOffset lossMarket predictionsResourcesElectricity priceEngineering

The invention discloses a subsidy method for a high-cost unit to participate in a spot market. Through access to subsidized electricity tariffs, the upper limit of the subsidy income and the upper limit of the subsidy value of the subsidy units to be subsidised are determined, calculating the total market income of the units to be subsidized, subsidise the ceiling on earnings. The minimum betweenthe difference in total market earnings and the ceiling on the value of the subsidy is the value of the subsidy payable. Provided is a method of targeted subsidization according to the actual situation of a high-cost unit, and by capping the benefits of subsidies, the upper limit of the subsidy value. At that same time, the value of the subsidy payable is obtain by taking a small amount of the subsidy. As excessive subsidy to that high-cost generating unit are avoided, the value of subsidies should be exported for staff reference, and the value of subsidies should be issued to the units to besubsidized according to the value of subsidies, which can offset the losses of high-cost units in the competition of spot market to a certain extent, pave the way for the improvement of the mechanismof the power market, and ensure the stable start of the spot market.

Owner:GUANGDONG POWER GRID CO LTD +1

Nonlinear wireless electric energy transmission system and method with variable coupling coefficient stability

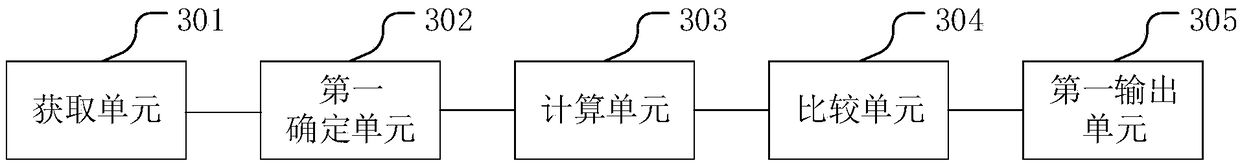

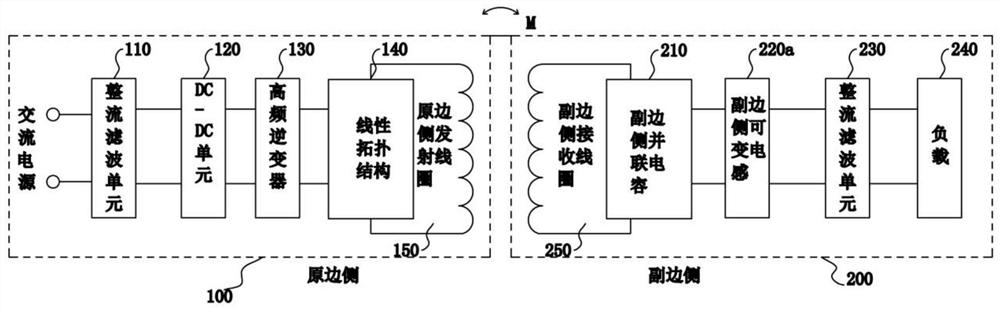

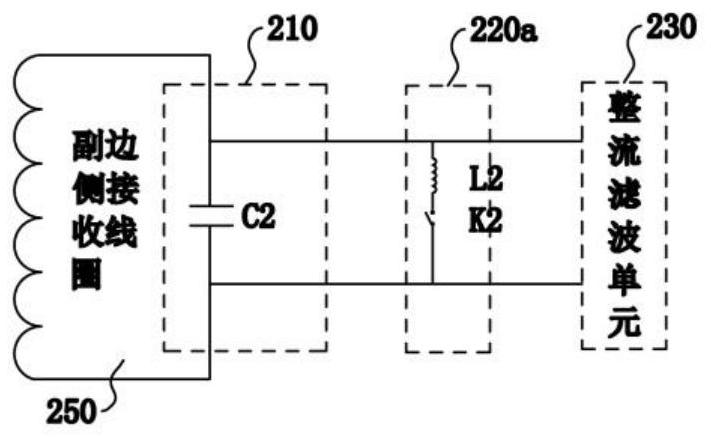

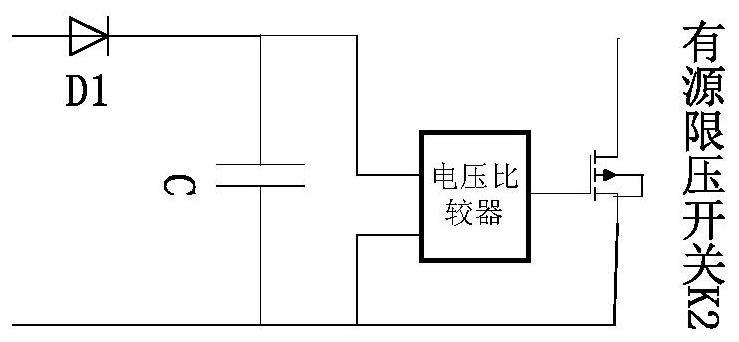

PendingCN112701804AConstant output voltageSave voltage regulatorCircuit arrangementsTransmitter coilSquare waveform

The invention discloses a wireless power transmission method and device with variable coupling coefficient stability. The system comprises a primary side rectifying and filtering unit, a primary side high-frequency inverter, a primary side DC / DC unit, a primary side linear topological structure, a primary side transmitting coil, a secondary side receiving coil, a secondary side parallel capacitor, a secondary side variable inductor or capacitor structure, a secondary side rectifying and filtering unit and the like; the secondary side variable inductor or capacitor structure comprises at least one linear inductor L2 or linear capacitor C3 working in a switching state. The output voltage waveform is between a sine wave and a square wave, automatic voltage stabilization and spectrum spreading under the condition of a variable coupling coefficient can be achieved, and participation of an active control device is not needed. The stability of the system does not depend on communication feedback, and therefore, the reliability of the system is high, and the cost of the system is low; high efficiency and stability of wireless power transmission can be maintained when the coupling coefficient changes.

Owner:NANYANG INST OF TECH

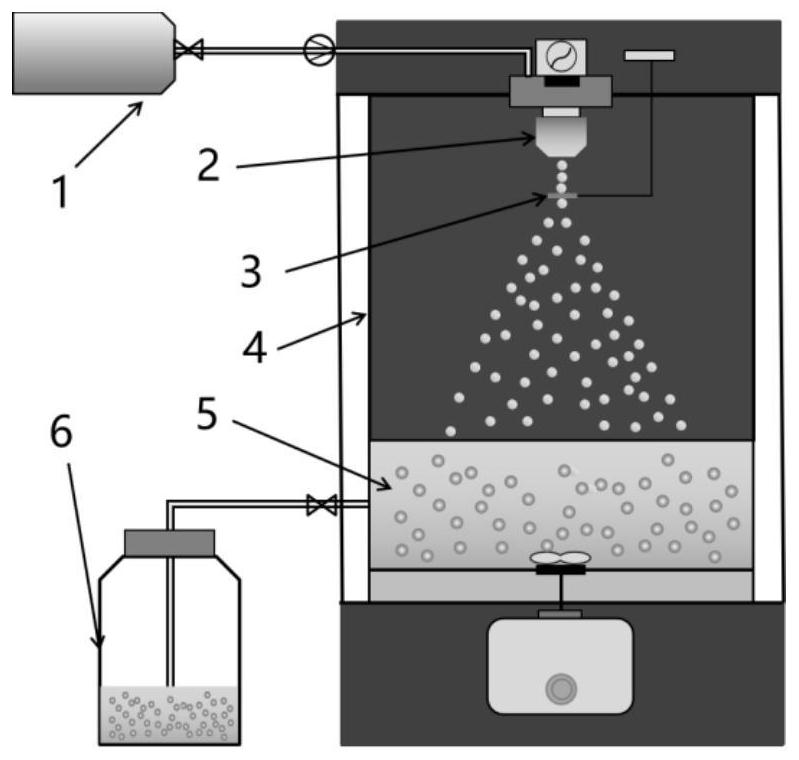

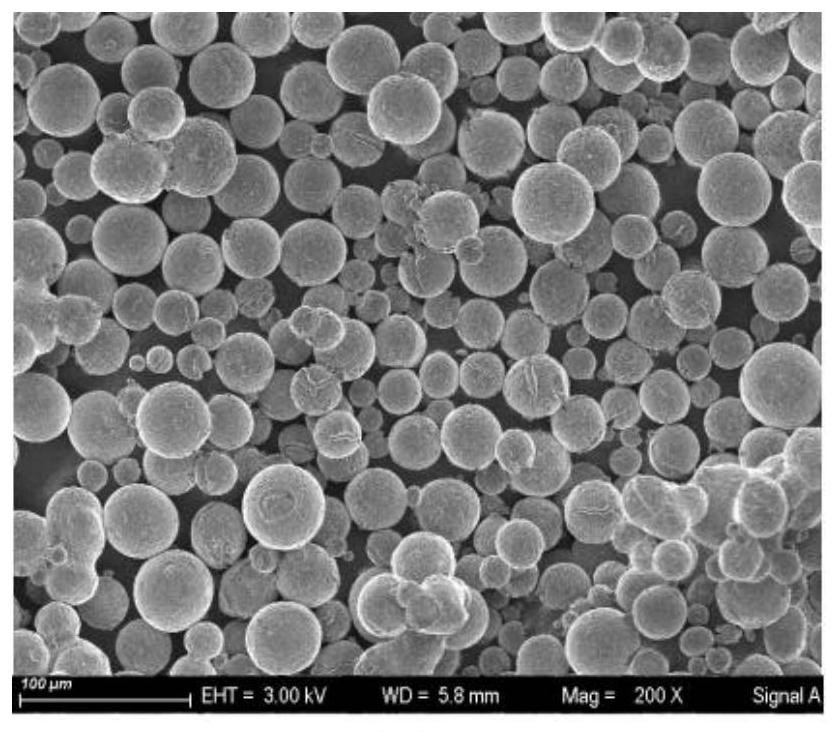

Preparation method and device of passivated lithium microspheres and application

InactiveCN113059167AIncrease coverageSmall sizeTransportation and packagingMetal-working apparatusMetallic lithiumMolten state

The invention provides a preparation method and device of passivated lithium microspheres and an application of the passivated lithium microspheres. The preparation method of the passivated lithium microspheres comprises the following steps: 1) carrying out dispersion treatment on molten-state metal lithium jet flow by utilizing a fluid vibration nozzle to obtain metal lithium liquid drops; 2) applying static electricity to the metal lithium liquid drops to obtain metal lithium microspheres; and 3) placing the metal lithium microspheres in a passivation solution, and stirring to obtain the passivated lithium microspheres. According to the preparation method of the invention, a microcapsule granulation technology is adopted, the superposition vibration principle and the specific passivation technology are utilized, and the passivated lithium microspheres which are small in size, adjustable in size, narrow in particle size distribution, adjustable in passivation layer composition and thickness and high in coating rate can be prepared.

Owner:KUNSHAN BAOTRON NEW ENERGY TECH CO LTD

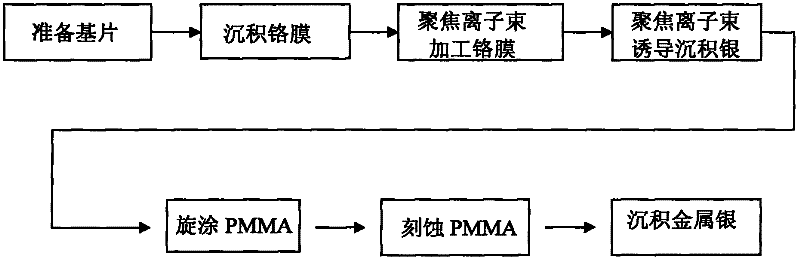

Super-diffraction imaging device for improving resolution based on phase shifting principle and manufacturing method thereof

ActiveCN102096334BImprove modulation efficiencyIncrease profitPhotomechanical exposure apparatusMicrolithography exposure apparatusNanolithographyPhase shifted

The invention discloses a super-diffraction imaging device for improving resolution based on a phase shifting principle and a manufacturing method thereof. Adjacent light transmission areas of the super-diffraction imaging device realize phase delay and phase advance respectively by alternately filling two materials with a positive dielectric coefficient and a negative dielectric coefficient and the phase difference modulation of the material thicknesses is enhanced greatly, so that the device is easier to realize a pi phase difference; therefore, the imaging resolution of the device is further improved. The scheme solves the technical difficult problem that a conventional super-diffraction imaging device is difficult to realize the resolution below the line width of 40 nm and has a broadapplication prospect in super-diffraction imaging and nano-lithography technologies.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

Spraying method for pack rolled sheet parting agent

The invention discloses a spraying method for a pack rolled sheet parting agent. The spraying method includes the steps that after a blank to be subjected to pack rolling is subjected to cogging to reach the size of 60 mm to 80 mm, the thickness of a lower blank which is milled after sizing is larger than that of an upper blank by 1 mm to 2 mm; then ring groove forming, plane milling and fillet expanding are conducted on the lower blank, and therefore a parting agent spraying groove is machined; after machining is completed, the mixed parting agent is sprayed into the parting agent spraying groove, and the whole spraying groove is filled with the thickness of the parting agent; then the lower blank obtained after the parting agent is sprayed is conveyed into a baking oven to be dried, thebaking temperature is 450 DEG C to 650 DEG C, and the baking time is 50 min to 75 min; and finally, after the parting agent is dried, the lower blank is taken out of the baking oven, the lower blank is cooled to be below 100 DEG C, and therefore the spraying work of the parting agent is completed. The spraying method has the beneficial effects that yield losses caused by head and tail arc deformation of steel sheets obtained after rolling are counteracted, the edge shearing amount is reduced, the yield and the qualification rate of the pack rolled sheets are increased, and the quality of the sheets obtained after pack rolling is effectively ensured.

Owner:NANJING IRON & STEEL CO LTD

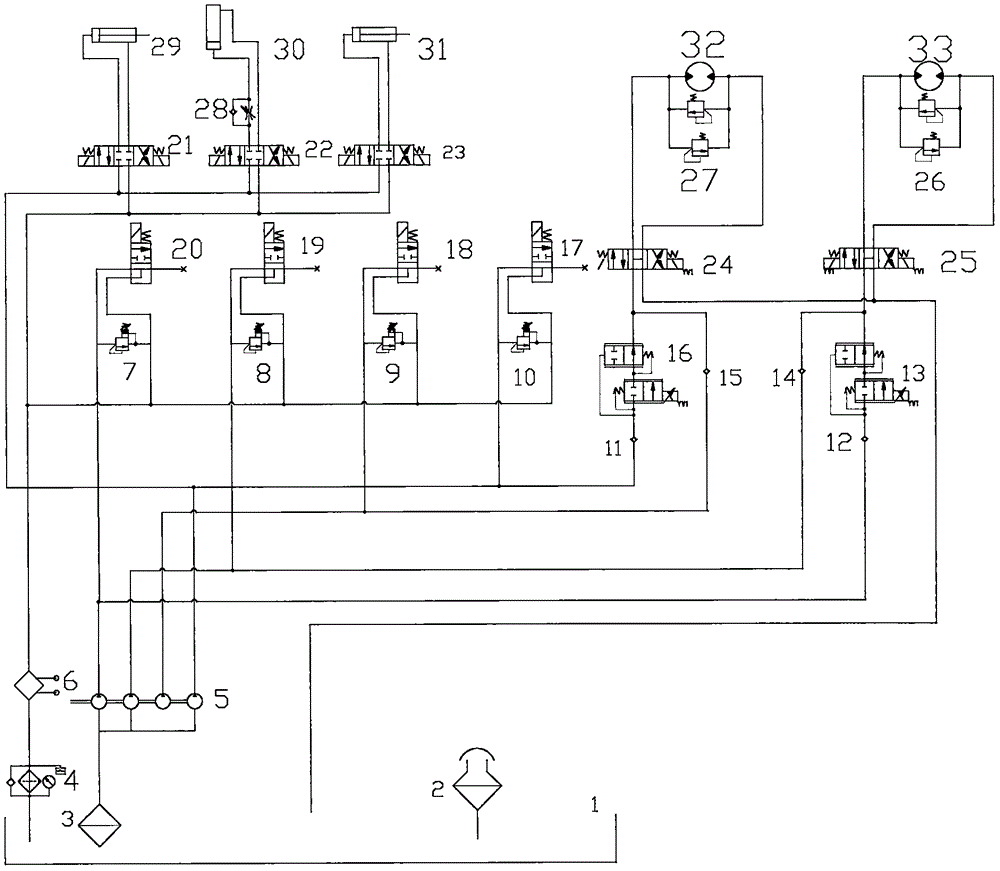

Hydraulic system of novel multifunctional orchard work vehicle

InactiveCN106402065AReduce hydraulic shockImprove work efficiencyServomotor componentsServomotorsHydraulic motorElectricity

A hydraulic system of a novel multifunctional orchard work vehicle comprises an oil tank, a quadruple gear pump, electromagnetic reversing valves, proportional flow valves, electromagnetic overflow valves, an adjusting one-way throttle valve, hydraulic oil cylinders and hydraulic motors. According to the hydraulic system of the novel multifunctional orchard work vehicle, on the basis of achieving traveling of a vehicle and lifting of an operating platform, overflow loss and throttle loss u are counteracted while throttle speed regulation is adopted, and work requirements can be well met; an electric-drive fan and a return oil filter are additionally arranged at an oil return opening, and the cooling effect is enhanced; and the hydraulic system is simple in overall structure, high in flow, sufficient in rotating and correcting power, good in cooling effect and convenient to use.

Owner:NORTHWEST A & F UNIV

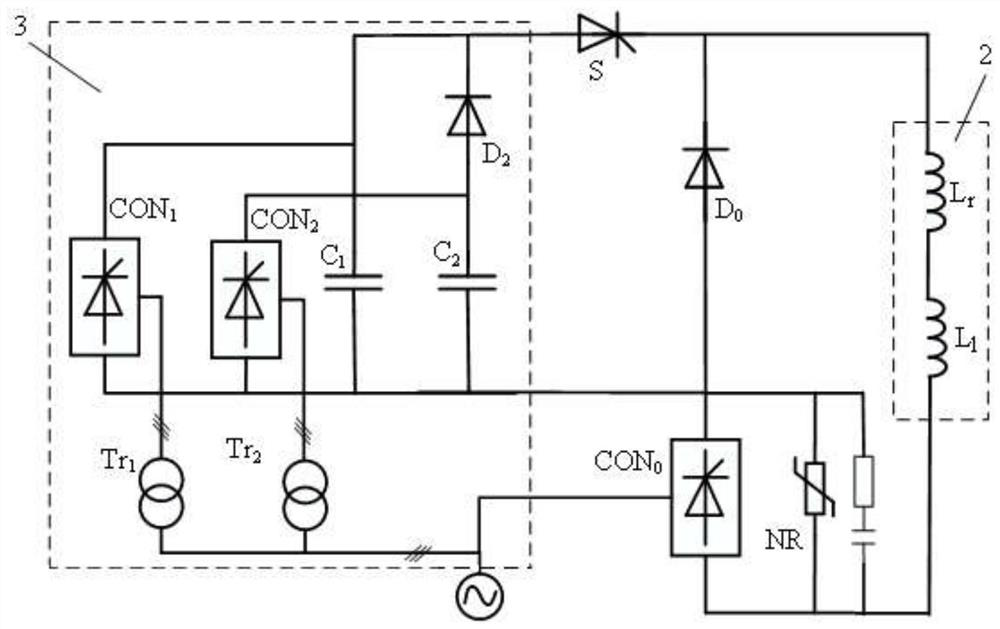

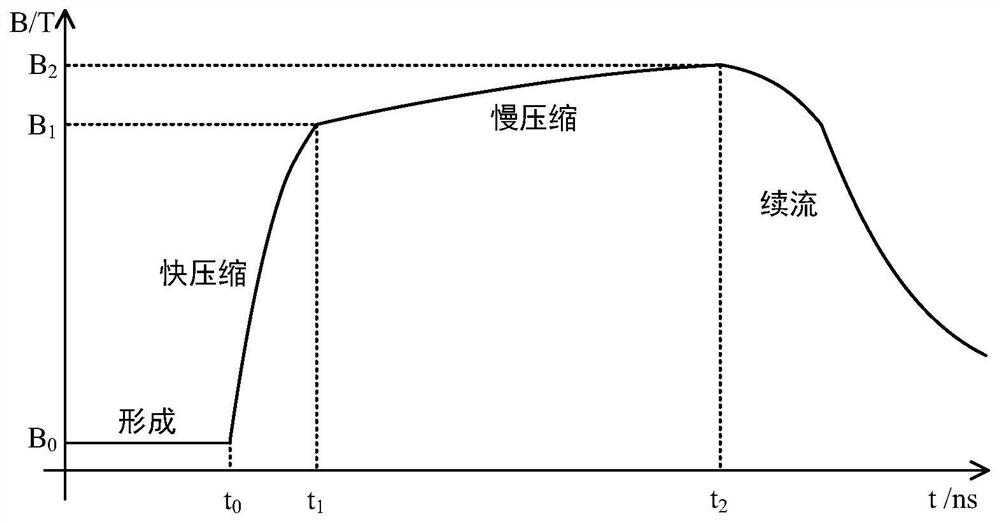

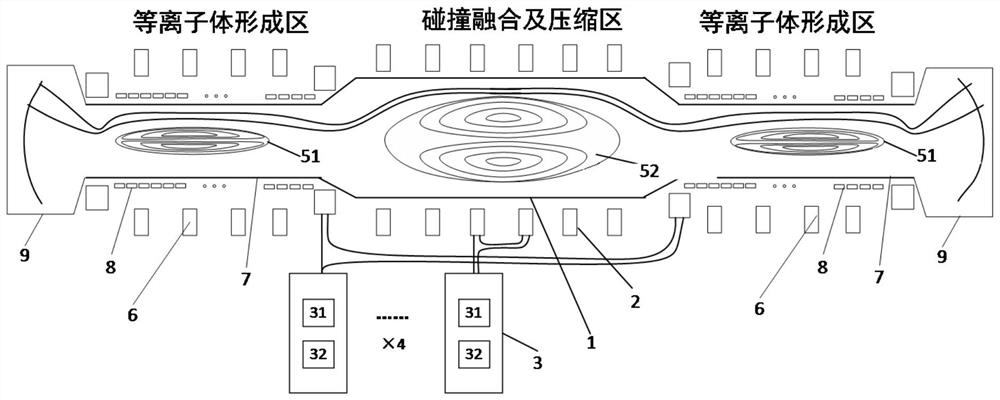

Field anti-plasma magnetic compression device and method

ActiveCN112397206AAchieve recyclingImprove energy conversion efficiencyNuclear energy generationThermonuclear fusion reactorNuclear engineeringMagnetic energy

The invention discloses a field anti-plasma magnetic compression device and method, and belongs to the field of magnetic confinement nuclear fusion, and the device comprises a vacuum chamber, a compression coil surrounding the vacuum chamber, and a power module. A first power supply module in the power supply module generates a first compressed magnetic field in the vacuum chamber through a compression coil, and when the first compressed magnetic field rises to the maximum value, the second power supply module is connected and generates a second compressed magnetic field in the vacuum chamberthrough the compression coil, so that the magnetic field in the vacuum chamber continuously rises to perform cascade magnetic compression on the field anti-plasma in the vacuum chamber. After the plasma is rapidly heated to a high-temperature state, another power supply module is switched on to ensure that the current of the coil continuously rises, so that certain heating power is maintained to counteract transportation and radiation loss in the plasma, and the service life and fusion reaction time of the plasma are greatly prolonged, when coil current rises to the maximum value, coil magnetic energy can be fed back to a power grid or a power module, energy recovery is achieved, and compression efficiency is improved.

Owner:HUAZHONG UNIV OF SCI & TECH

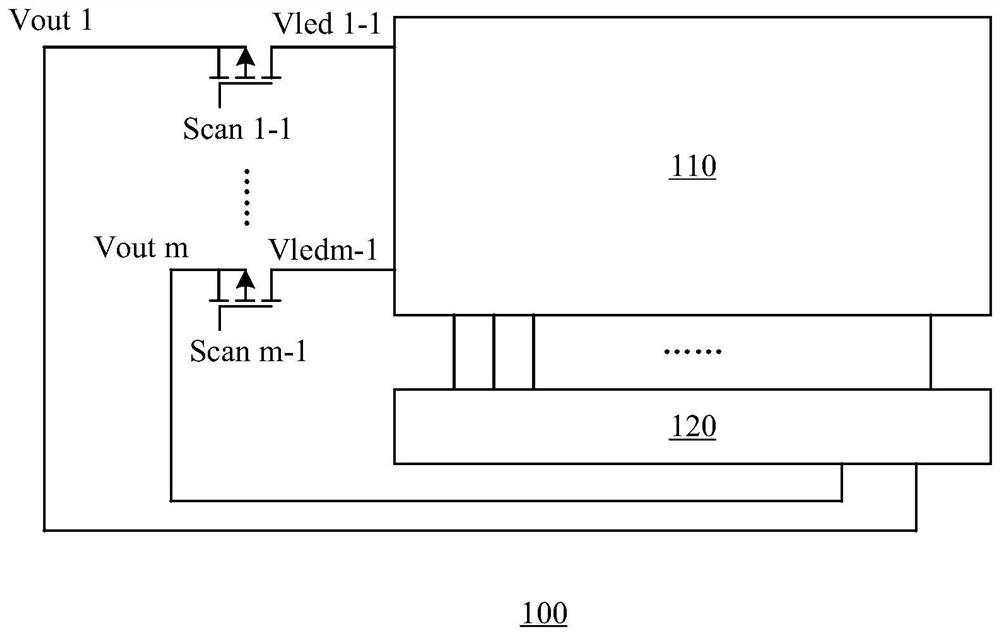

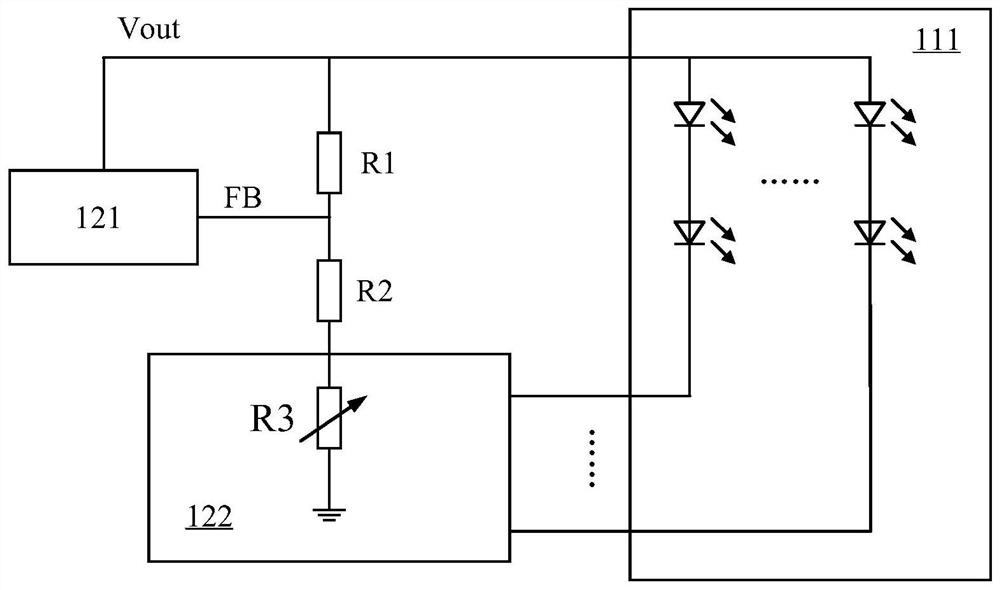

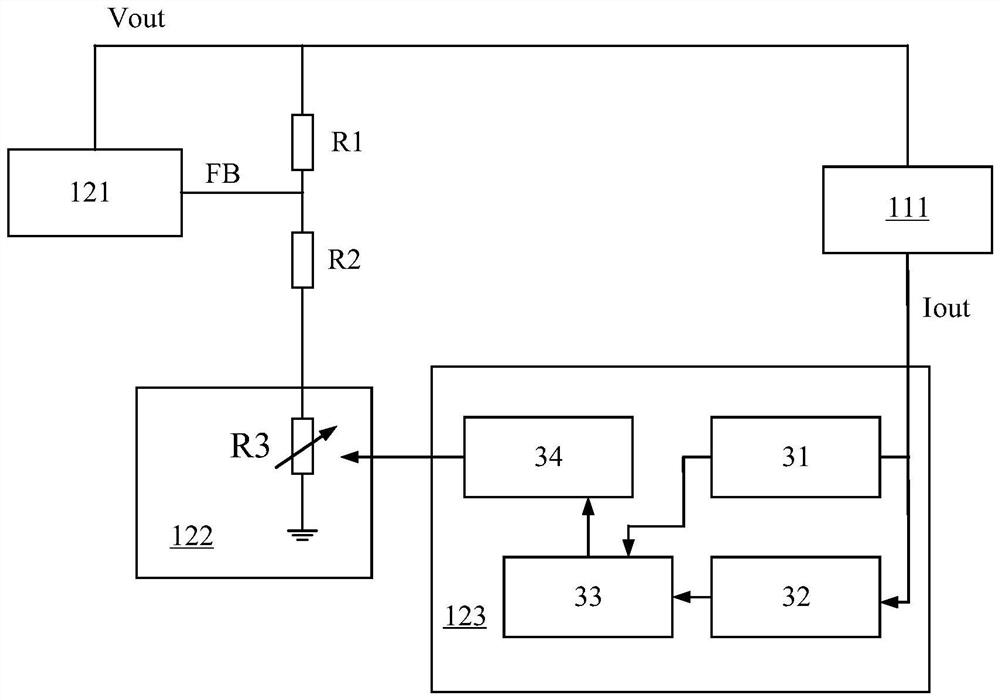

Backlight driving circuit and display device

ActiveCN114038431AImprove luminous brightnessOffset lossStatic indicating devicesEngineeringHemt circuits

The invention relates to the technical field of display, and discloses a backlight driving circuit and a display device.The display device comprises the backlight driving circuit, the backlight driving circuit is provided with a control unit to compare working current of a backlight plate with set current, and when the working current is smaller than the set current, the ratio of the sampling voltage to the backlight driving voltage output by a power supply module is controlled to be reduced, so that the backlight driving voltage output by the power supply module can be improved through a feedback output loop of the power supply module, the driving capability to the backlight plate is improved, the working current of the backlight plate is improved to a set value, and the backlight brightness is adjusted to be consistent with an ideal set value; the display effect is improved.

Owner:KUSN INFOVISION OPTOELECTRONICS

High-voltage power supply of electron beam melting furnace

InactiveCN102573163BIncrease powerImprove efficiencyIncreasing energy efficiencySemiconductor devicesFiltrationTransformer

The invention discloses a high-voltage power supply device of an electron beam melting furnace. According to the power supply disclosed by the invention, a current transformation way including power frequency alternating current input, voltage regulation by a three-phase adjustable reactor, boosting by a three-phase boosting transformer and high-voltage rectification and filtration is adopted for output; and output high-voltage sampled signals are taken as negative feedback signals, current of a direct current control winding of the three-phase adjustable reactor is controlled by a voltage regulator, and automatic voltage regulation is performed for keeping an output voltage value of the high-voltage power supply of the electron beam melting furnace stable. The power supply disclosed by the invention is based on the control of the controllable reactor and has the characteristics of high efficiency, small public nuisance and capability of fast and effectively suppressing discharge current during discharge of the high-voltage power supply.

Owner:GUILIN UNIV OF ELECTRONIC TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com