Wireless-receiving system for detecting microelectronic mechanical microwave frequency and preparation method thereof

A micro-electromechanical, microwave frequency technology, applied in the direction of frequency measurement devices, TV system components, frequency to amplitude conversion, etc., can solve the problems of small signal amplitude, DC power consumption, etc., to improve accuracy, offset loss, The effect of a large dynamic range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

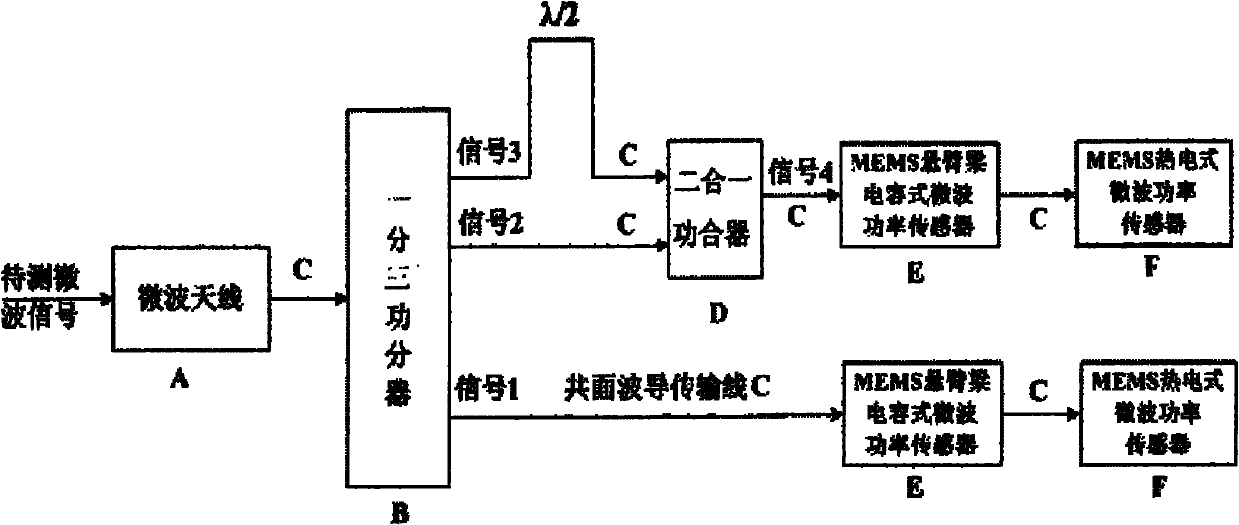

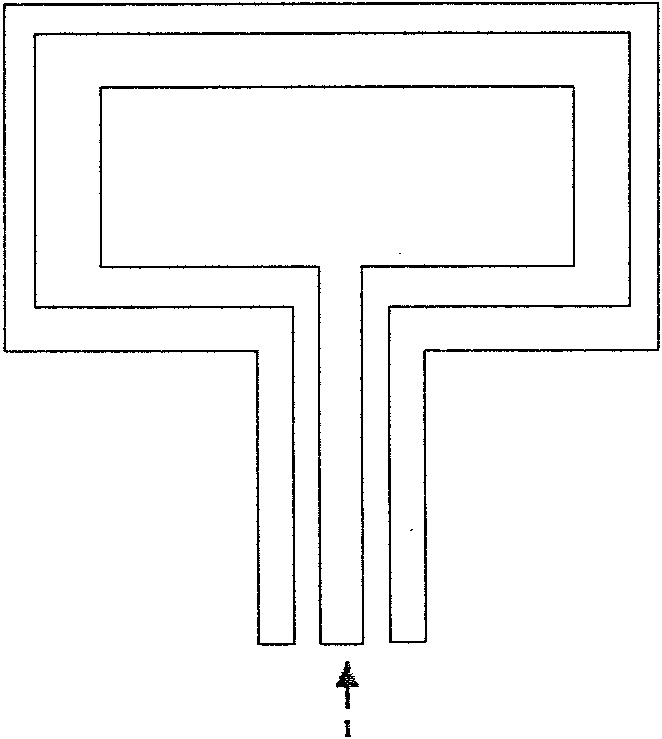

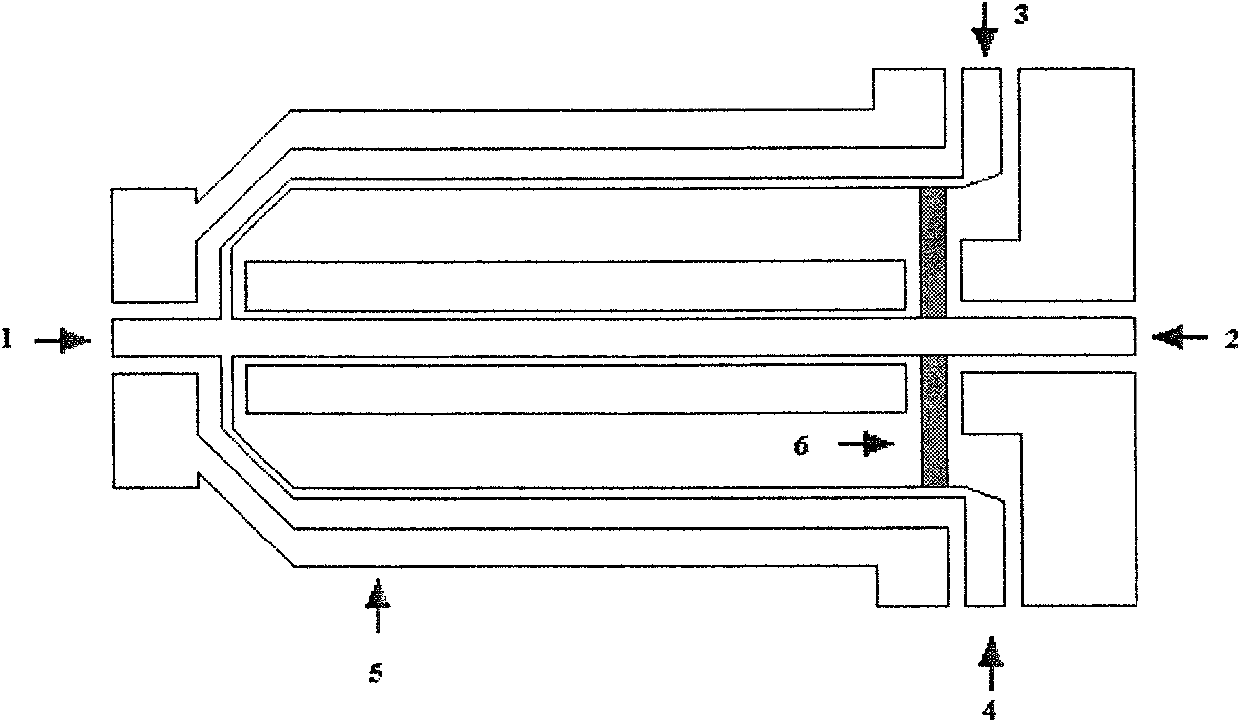

[0033] Such as figure 1 As shown, the microwave antenna receives the microwave signal to be tested and inputs it to port 1 of the one-to-three power splitter, and three identical signals (signal 1, signal 2, and signal 3) are generated at port 2, port 3, and port 4. . Signal 1, coplanar waveguide transmission line, MEMS cantilever beam capacitive microwave power sensor and MEMS thermoelectric microwave power sensor are cascaded to form the amplitude detection part of the microwave signal; signal 2, signal 3, coplanar waveguide transmission line, two-in-one power combiner , the MEMS cantilever beam capacitive microwave power sensor and the MEMS pyroelectric microwave power sensor are cascaded to form a phase difference detection part of the microwave signal. Signal 1 is used as the amplitude detection signal, and the amplitude of the signal is detected by the MEMS cantilever beam capacitive microwave power sensor and the MEMS pyroelectric microwave power sensor; signal 2 and s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com