Sorting method of low-grade black and white tungsten fine clay

A black and white tungsten, low-grade technology is applied in the field of sorting low-grade black and white tungsten fine mud, which can solve the problems affecting the overall benefit of the enterprise, the difficulty of selling low-tungsten products, and the decline in demand for tungsten concentrates, so as to expand product sales and facilitate Ease of management and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

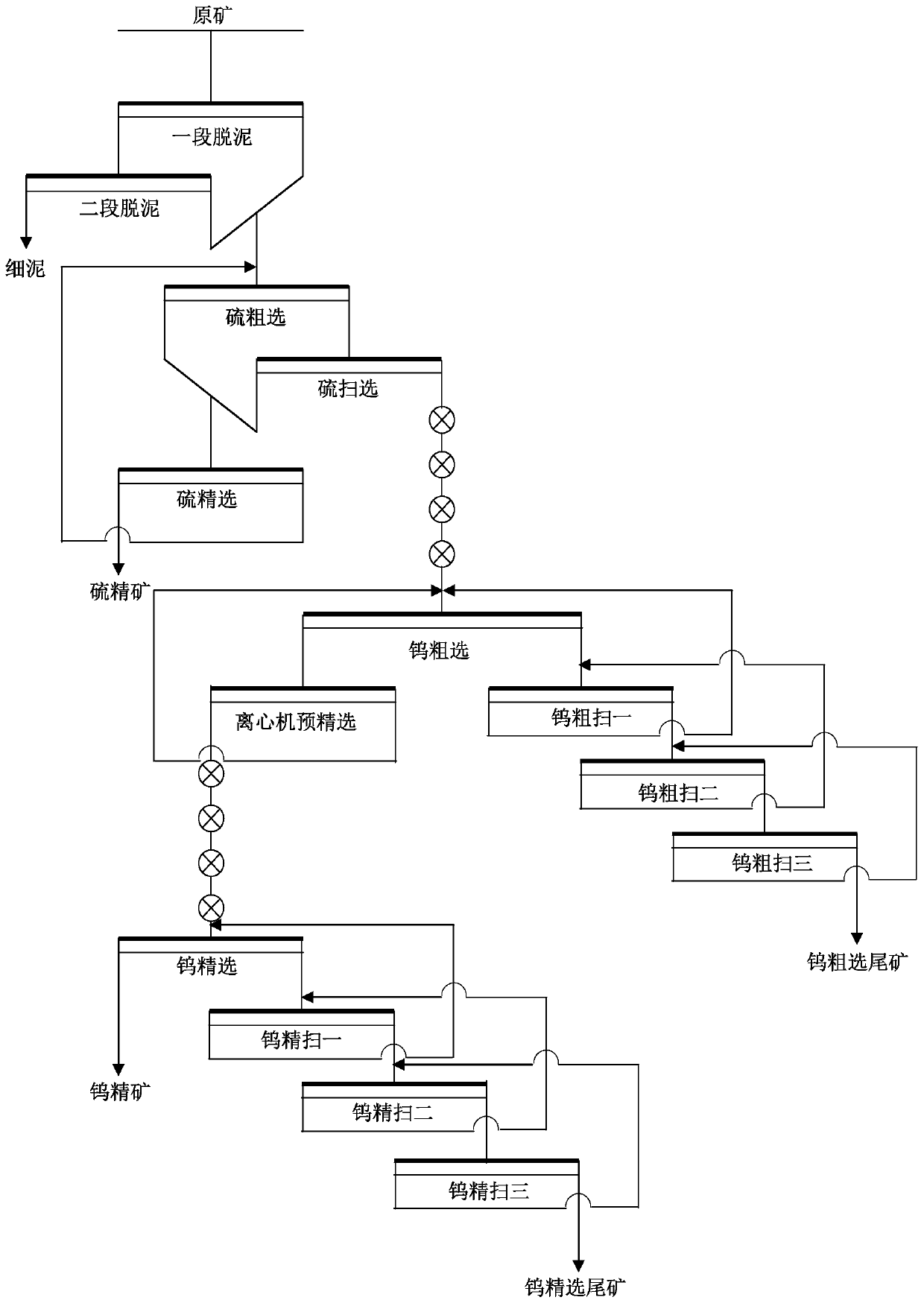

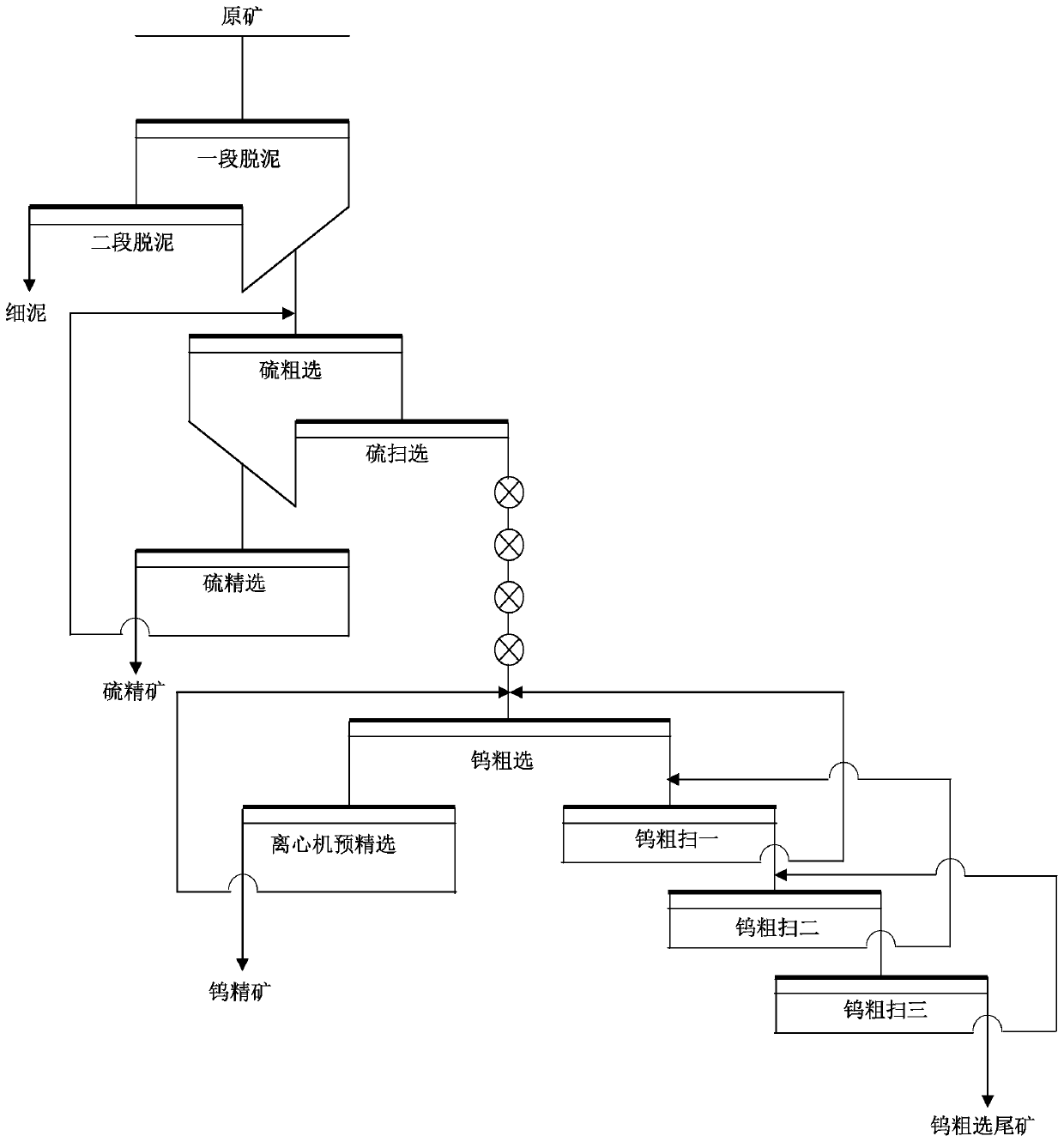

[0032] Such as figure 1 As shown, a sorting method of low-grade black and white tungsten fine mud, the feed grade of the low-grade black and white tungsten fine mud is 0.124%, fine mud fineness -200 mesh accounts for 58.76%, mud content -0.04mm accounts for 30.63%, Specifically include the following steps:

[0033] (1) The low-grade black and white tungsten fine mud is deslimed in the second stage to remove the fine mud below 10um with a yield of 15%. The first and second desliming equipment are 15 cyclone groups with a diameter of 150mm and a diameter of 100mm. 40 hydrocyclones;

[0034] (2) The material obtained in step (1) is desulfurized through a sulfur roughing and a sulfur sweeping in turn, and the desulfurization rate is 60-70%, and the sulfur that has been taken off is obtained through sulfur concentration to obtain a sulfur concentrate. Mine returns to the sulfur roughing of step (2); the desulfurization equipment is two jet flotation machines, the specification i...

Embodiment 2

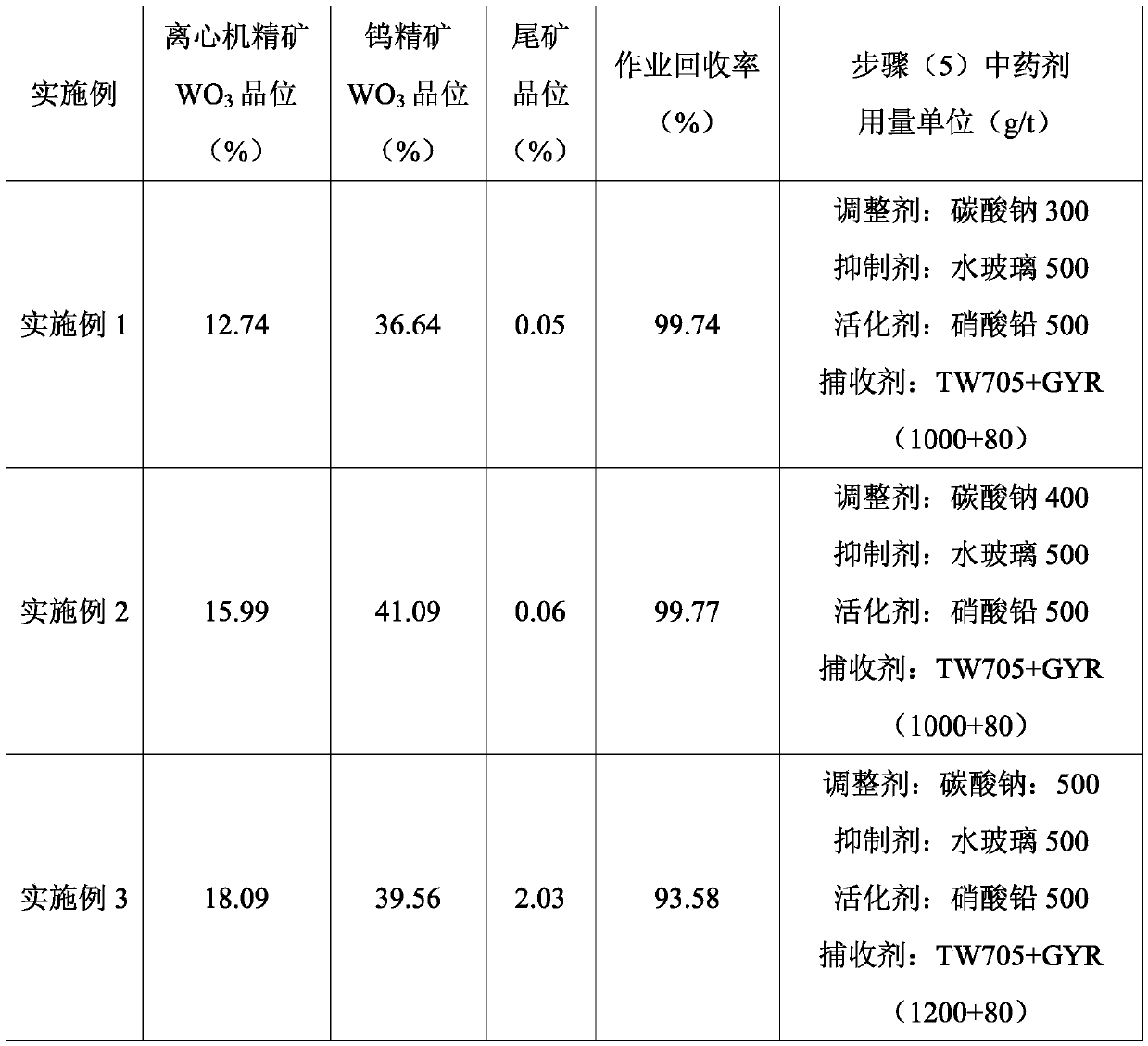

[0040] The specific process is the same as in Example 1. The reagents used in step (5) are shown in Table 1. In this example, the low-grade black and white tungsten fine mud is deslimed and desulfurized to obtain a tungsten flotation coarse concentrate grade of 3.65%, and then passed through a centrifuge The enriched concentrate grade reaches 15.99%. After improving the concentrate grade by flotation separation, the final tungsten concentrate grade is 41.09%, and the operation recovery rate is 99.77%. Compared with the original production process, the recovery rate has decreased by 0.16 percentage points, but the concentrate grade has increased by 25.10% percentage point.

Embodiment 3-4

[0042] The difference from Example 1 is that the centrifuge concentrate WO 3 The grades are different, and the re-flotation agents corresponding to the application amount are used (as shown in Table 1).

[0043] The concentrate grade of the centrifuge of different embodiments of table 1 adopts different medicament dosages to select and improve grade result

[0044]

[0045]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com