Negative electrode material, negative electrode plate, preparation method of negative electrode plate and all-solid-state lithium ion battery

A technology for lithium-ion batteries and negative electrode materials, applied in the direction of negative electrodes, battery electrodes, secondary batteries, etc., can solve the problems of low working voltage, need for improvement, low initial Coulombic efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

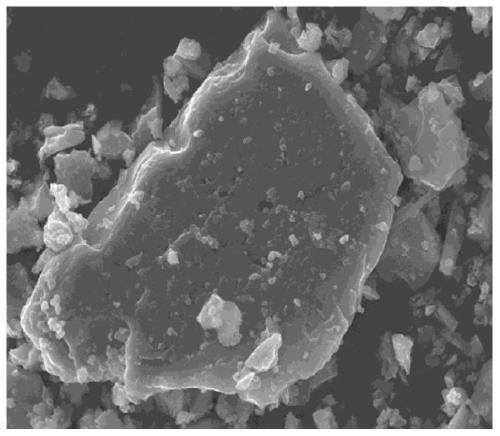

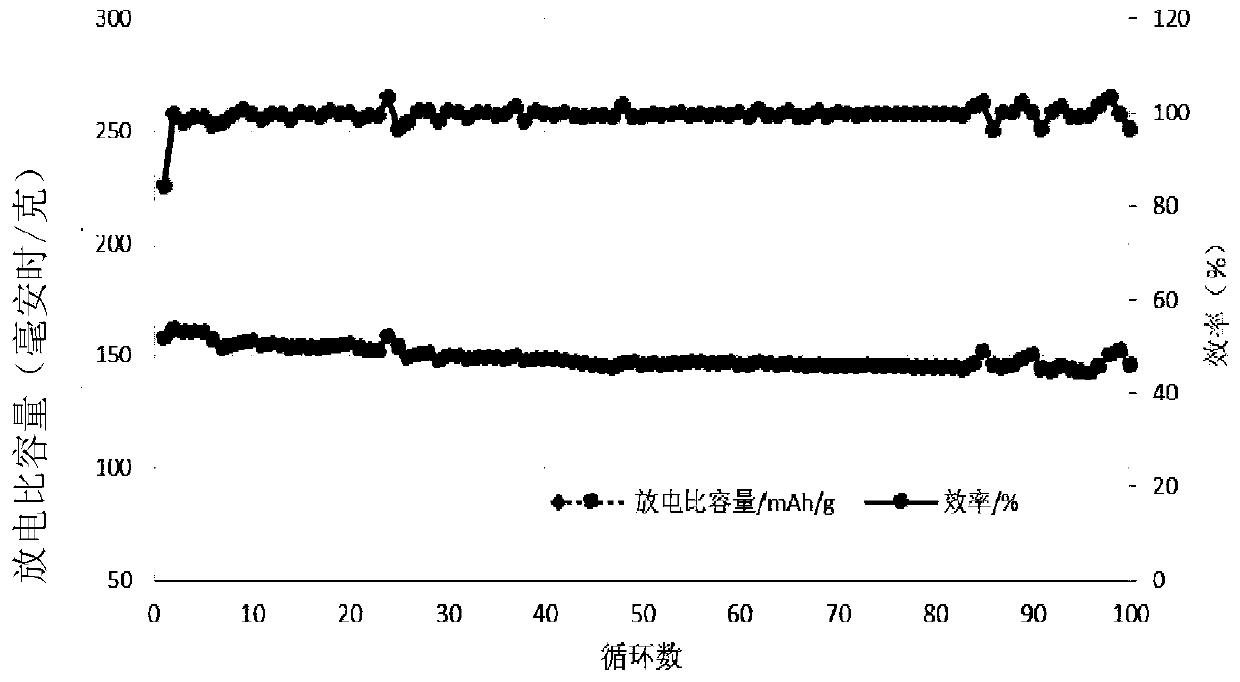

[0050] Under the protection of an argon atmosphere, silicon carbon powder (the outer surface of silicon oxide particles is coated with a carbon layer, and the D50 particle size is 4 microns) and coated lithium powder (the outer surface of lithium powder is coated with fluorine) with a purity of more than 99% Lithium oxide, D50 particle size is 8 microns), solid electrolyte Li 6 P.S. 5 Cl (D50 particle size is 6 microns) and conductive agent (1-2 micron conductive carbon) are weighed according to the mass ratio of 6:1:2.5:0.5, placed in the mortar and ground and mixed evenly (scanning electron microscope of the product obtained after grinding see photos figure 1 ), then put it into the self-made mold battery, press the tablet under 10MPa pressure, and then weigh 120mg Li 6 P.S. 5 Cl electrolyte powder, put it into a self-made mold sleeve, continue to compact with a pressure of 10MPa, and then add NCM622 positive electrode and Li 6 P.S. 5 The Cl electrolyte mixed powder was...

Embodiment 2

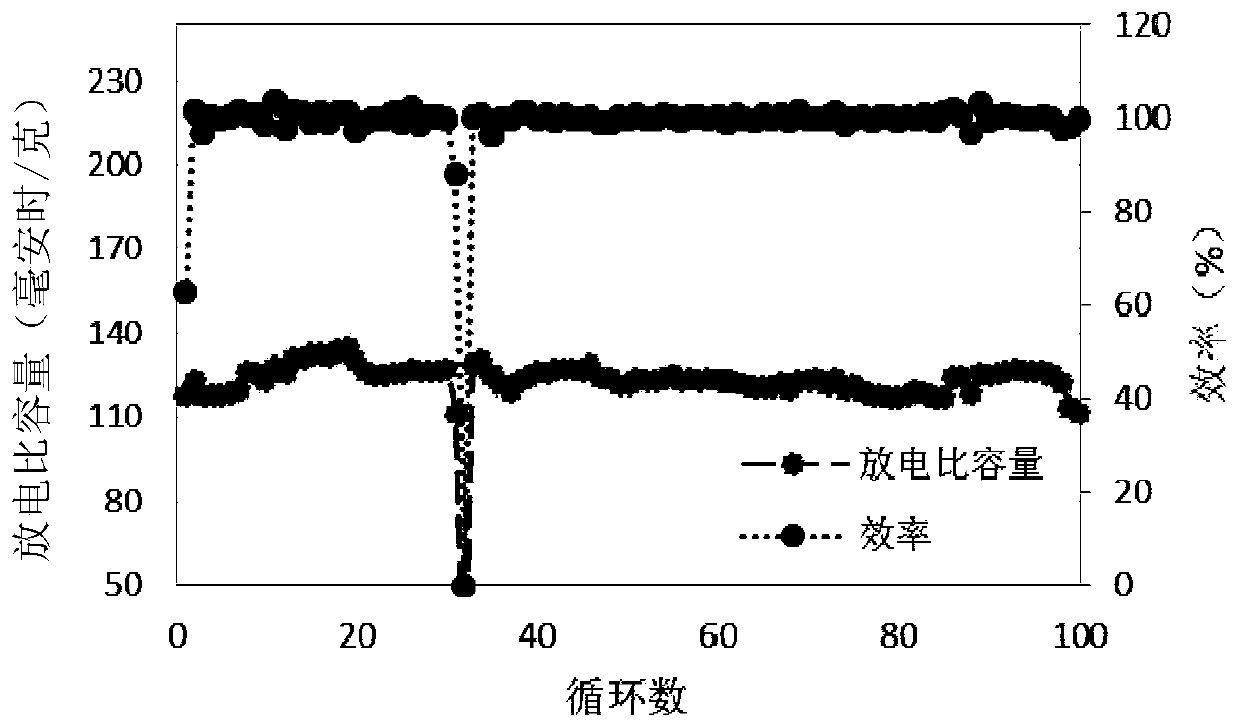

[0054] With embodiment 1, the difference is that silicon carbon powder, coated lithium powder, solid electrolyte Li 6 P.S. 5 Cl and conductive agent are mixed according to the mass ratio of 7:0.5:2:0.5.

Embodiment 3

[0056] With embodiment 1, the difference is that silicon carbon powder, coated lithium powder, solid electrolyte Li 6 P.S. 5 Cl and conductive agent are mixed according to the mass ratio of 4:2:3.5:0.5.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com