Silicon-base negative material with silane coupling agent and conductive polymer two-layer cladding structure as well as preparation method and application of material

A silicon-based negative electrode material and silane coupling agent technology, applied in battery electrodes, structural parts, circuits, etc., can solve problems such as hindering the commercialization process and high cost, and achieve high specific capacity, high initial Coulombic efficiency, heavy good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

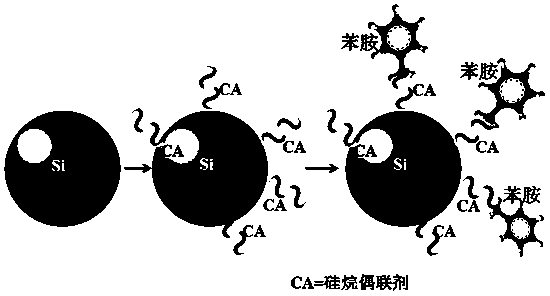

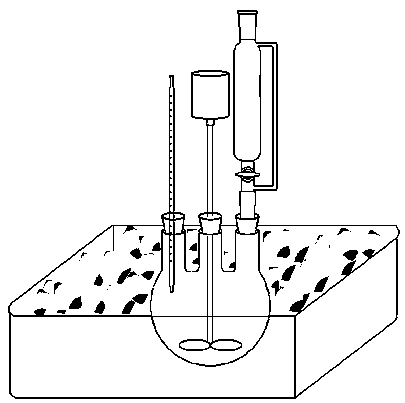

[0030] 1. Mix 0.1g of γ-(methacryloyloxy)propyltrimethoxysilane with 45mL of ethanol and 5mL of water in a three-necked flask for hydrolysis, add 4.9g of silicon powder, and mix ultrasonically for 0.5h; at an air flow rate of 200mL / min, temperature at 80°C, reflux for 10 h under magnetic stirring conditions, and vacuum drying at 55°C for 12 h to finally obtain γ-(methacryloyloxy)propyltrimethoxysilane surface-modified with a mass concentration of 2%. Silicon-based anode materials. The schematic diagram of the reaction between silane coupling agent and elemental silicon substrate is as follows: figure 1 As shown, starting from the simple silicon substrate, the first cladding layer is a silane coupling agent modification layer, and the second cladding layer is a proton-acid-doped conductive polyaniline. The infrared spectrum with silane coupling agent coating layer is as follows Figure 5 shown at 2972 and 2926 cm -1 An absorption peak appears at , which corresponds to the...

Embodiment 2

[0036] 1. Mix 0.25g of γ-(methacryloyloxy)propyltrimethoxysilane with 45mL of ethanol and 5mL of water in a three-neck flask for hydrolysis, add 4.75g of silicon powder, and mix ultrasonically for 0.5h; at an air flow rate of 200mL / min, temperature at 80°C, reflux for 10 h under magnetic stirring conditions, and vacuum drying at 55°C for 12 h to finally obtain γ-(methacryloyloxy)propyltrimethoxysilane surface-modified with a mass concentration of 5%. Silicon-based anode materials.

[0037] 2. Ultrasonic blend 0.045 g of aniline monomer and 0.2 g of modified silicon powder in 30 mL of 3.1% by volume hydrochloric acid system for 0.5 h, the ultrasonic power is 1.5 w / cm, the ultrasonic frequency is 30 kHz, and then heated at 0-5 °C 30 mL of a 3.1% by volume hydrochloric acid solution containing 0.0216 g of ammonium persulfate was added dropwise to carry out in-situ polymerization, and the polymerization reaction time was 10 h.

[0038] 3. Wash the mixed solution in step 2 altern...

Embodiment 3

[0041] 1. Mix 0.1g of γ-(methacryloyloxy)propyltrimethoxysilane with 45mL of ethanol and 5mL of water in a three-necked flask for hydrolysis, add 4.9g of silicon powder, and mix ultrasonically for 0.5h; at an air flow rate of 200mL / min, temperature at 80°C, reflux for 10 h under magnetic stirring conditions, and vacuum drying at 55°C for 12 h to finally obtain γ-(methacryloyloxy)propyltrimethoxysilane surface-modified with a mass concentration of 2%. Silicon-based anode materials.

[0042] 2. Ultrasonic blend 0.09g of aniline monomer and 0.2g of modified silicon powder in 30mL of 3.1% by volume hydrochloric acid system for 0.5 h, the ultrasonic power is 1.5w / cm, the ultrasonic frequency is 30kHz, and then heated at 0-5℃ 30 mL of a 3.1% by volume hydrochloric acid solution containing 0.0432 g of ammonium persulfate was added dropwise to carry out in-situ polymerization, and the polymerization reaction time was 10 h.

[0043] 3. Wash the mixed solution in step 2 alternately wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com