Graphene/solid-state electrolyte composite coated silicon composite negative electrode and preparation method thereof

A solid electrolyte and graphene technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of reducing the rate performance of materials, taking a long time, and not being able to form a complete coating, so as to improve the performance of high-current charging and discharging and avoid direct damage. Electricity, the effect of maintaining cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

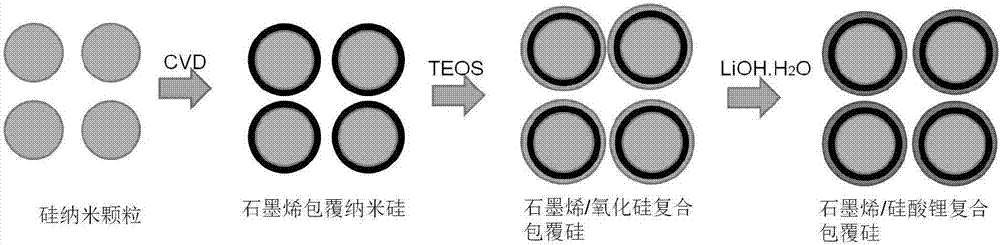

[0053] One embodiment of the present invention discloses a method for preparing a graphene / solid electrolyte composite-coated silicon negative electrode material, comprising the following steps:

[0054] (1) Under the protection of an inert gas, place 1 part of silicon particles in a high-temperature furnace, feed a gaseous carbon source and carbon dioxide mixed gas, and perform chemical vapor deposition of graphene;

[0055] (2) Evenly disperse the graphene-coated silicon composite material obtained in step (1) in 300-3000 parts of solvent, add 5-50 parts of ammonia water (concentration 25% to 28%) and stir, then add 1-80 parts of oxidation Continue stirring the ester precursors until the esters are hydrolyzed into oxides and evenly coated on the surface of the silicon substrate, centrifuged and dried to obtain a silicon composite material coated with oxides and graphene;

[0056] (3) Mix the silicon composite material coated with oxide and graphene obtained in step (2) with ...

Embodiment 1

[0062] (1) Chemical vapor deposition

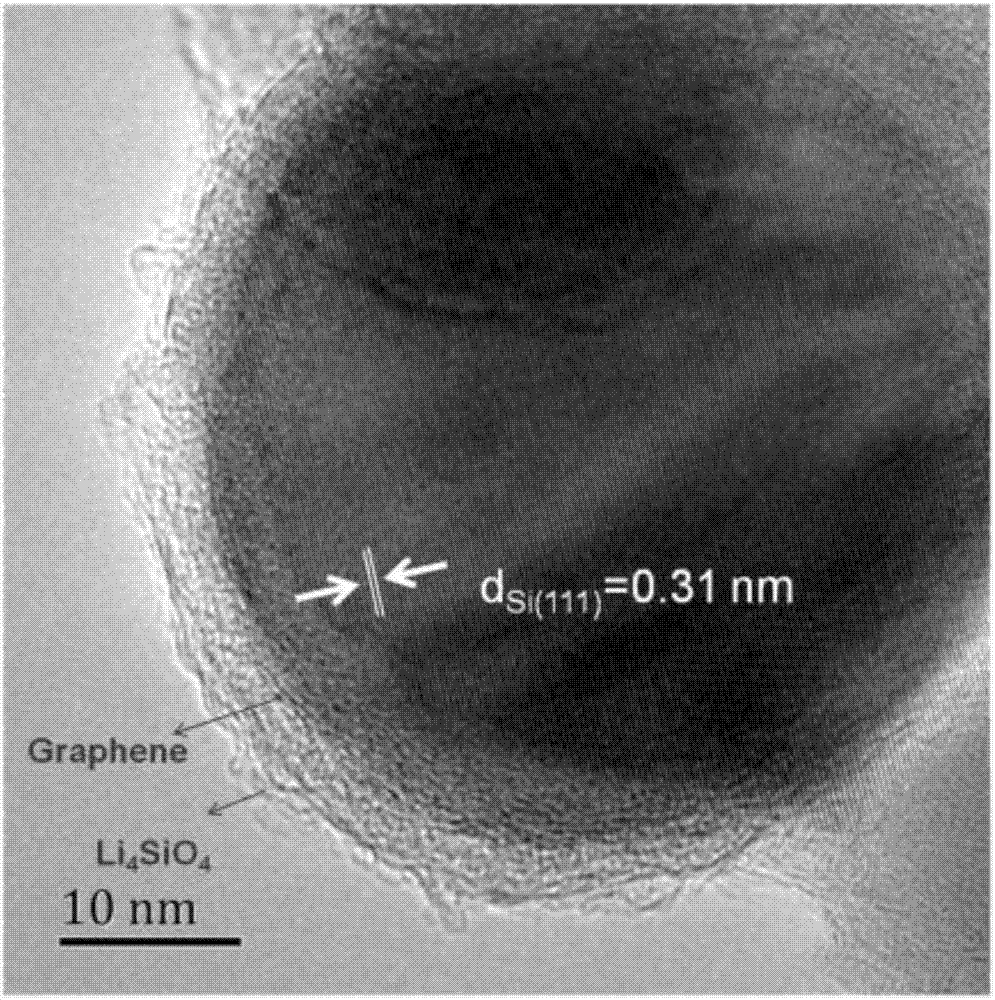

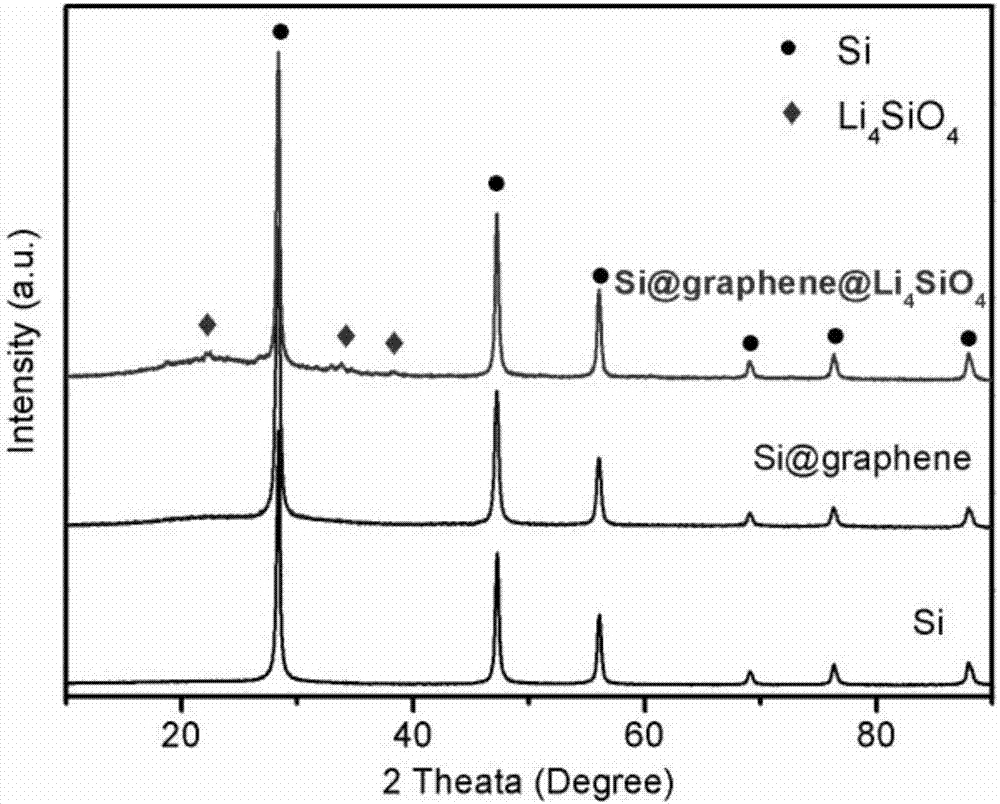

[0063] Preparation of graphene-coated silicon composite material: place 0.15g of nano-silicon in a tube furnace, feed argon (flow rate of 200 sccm) to discharge the air in the tube, heat up to 950°C in argon, and the heating rate is 30°C / min, feed carbon dioxide and methane (the volume ratio of carbon dioxide:methane is 1:1, and the total flow is 200sccm) at this time, close the argon, keep warm for 10 minutes to carry out chemical vapor deposition graphene, then open the argon, close the carbon dioxide and methane , naturally cooled to room temperature to obtain a graphene-coated silicon composite.

[0064] (2) Solid electrolyte coating

[0065] Disperse 0.15g of graphene-coated silicon composite material in a mixed solvent of 240ml of absolute ethanol and 60ml of water, disperse it evenly after 20 minutes of ultrasonic treatment, then take 3ml of concentrated ammonia water and put it into the solution and stir for 15 minutes Mix even...

Embodiment 2

[0070] (1) The chemical vapor deposition method is the same as in Example 1.

[0071] (2) Solid electrolyte coating

[0072] Disperse 0.15 g of the graphene-coated silicon composite material in a mixed solvent of 54 ml of absolute ethanol and water, and the volume ratio of absolute ethanol and water is 4:1. After 20 minutes of ultrasonic treatment to make it evenly dispersed, then take 0.8ml of concentrated ammonia water into the solution and stir for 15 minutes to mix evenly, take 0.15g of tetraethyl orthosilicate (TEOS) dropwise into the solution, fully stir and react for 12 After 1 hour, centrifuge at 10000r / min for 3 times, and vacuum dry at 80°C for 12 hours to obtain a graphene / silicon oxide-coated silicon composite material.

[0073]Take 0.1g of graphene / silicon oxide-coated silicon composite material and 0.02g of lithium hydroxide monohydrate salt and grind evenly, put the mixed powder into a tube furnace, first pass in argon to remove the air in the furnace, The tem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com