Lithium ion battery cathode material and preparation method thereof

A technology of lithium ion battery and negative electrode material, applied in the field of electrochemistry, can solve the problem that the volume change cannot be well alleviated, and achieve the effects of improving cycle stability, buffering volume change and reducing contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

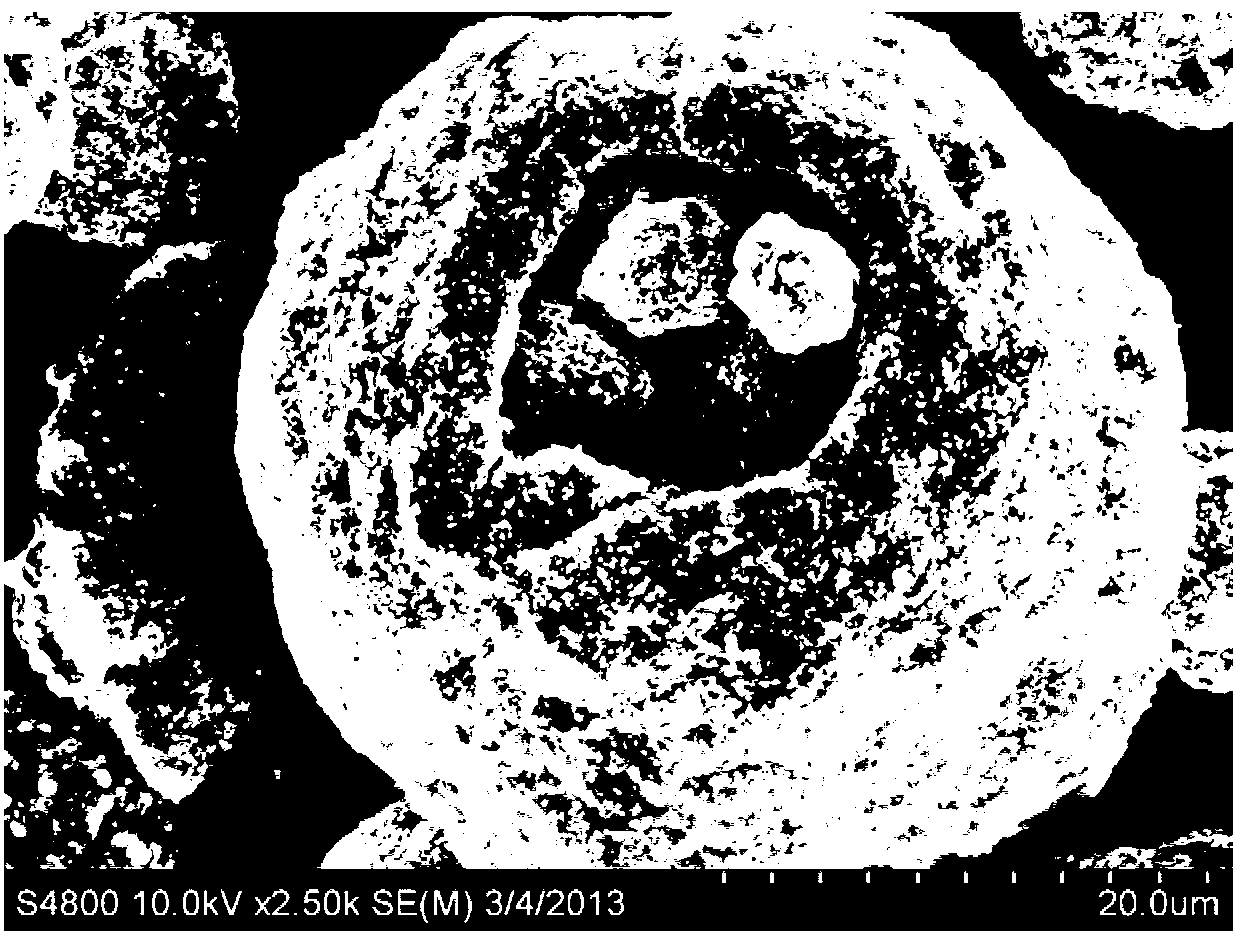

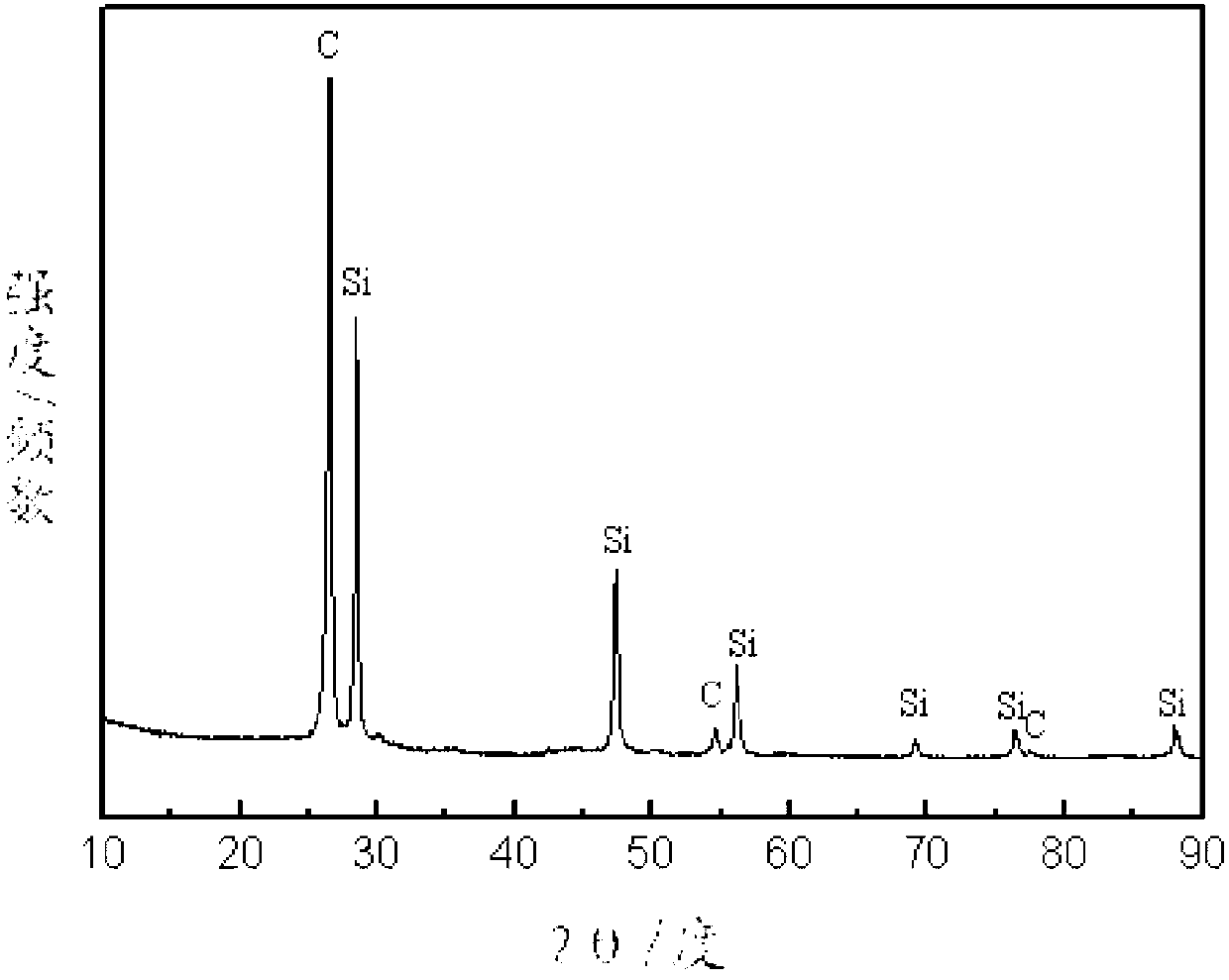

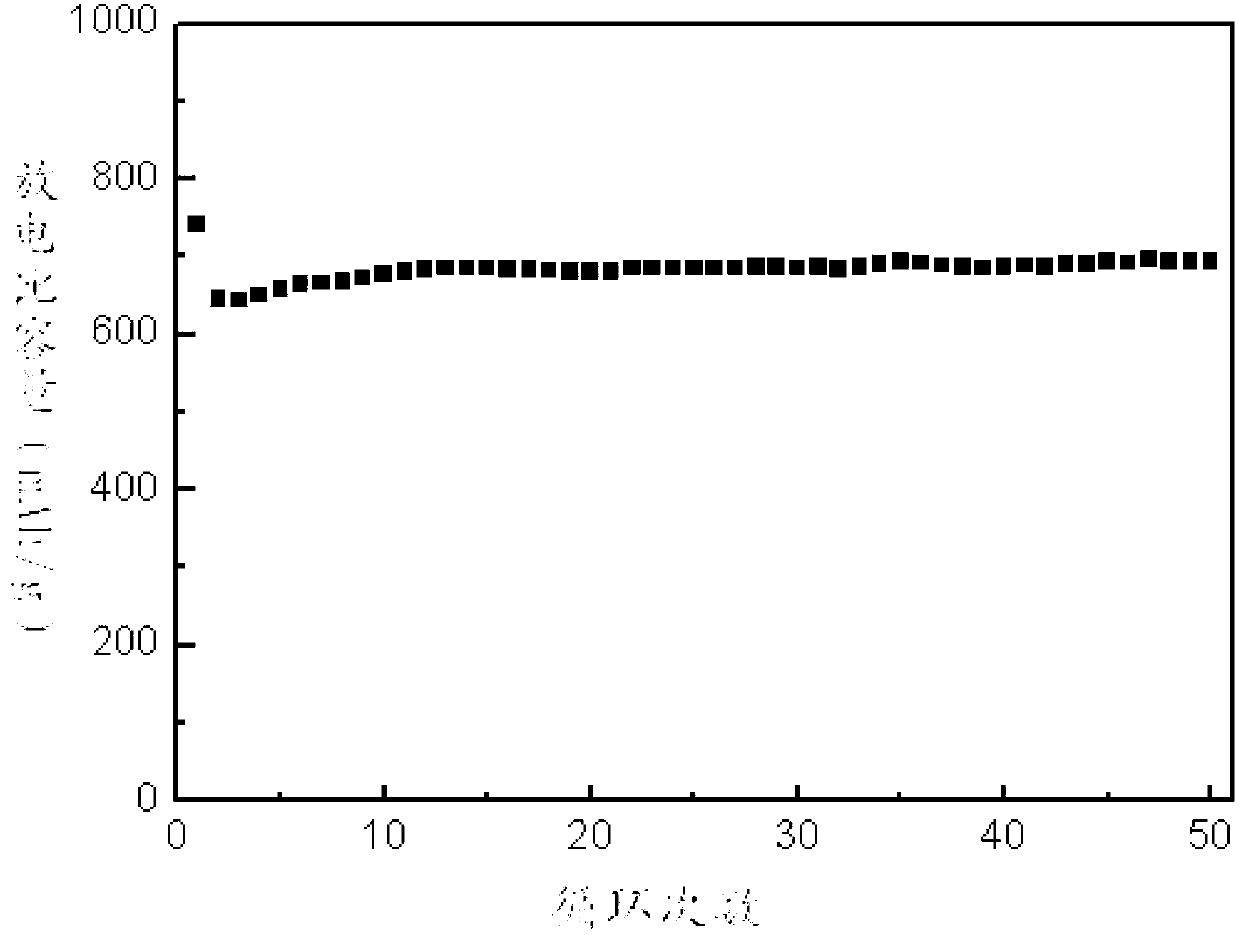

[0033] The present invention also provides a preparation method for the above lithium ion battery negative electrode material, which includes the following steps: A) mixing silicon particles, the second amorphous carbon precursor and the first ball milling medium, performing ball milling in a protective atmosphere, and then spray drying to produce Granules to obtain the first compound; B) Mix the first compound, carbon material, first amorphous carbon precursor and the second ball milling medium, perform ball milling in a protective atmosphere, spray dry and granulate to obtain the second Two composites; C) Calcining the second composite in a protective atmosphere to obtain a negative electrode material for a lithium ion battery.

[0034] All the raw materials in the present invention are commercially available, and there is no special limitation.

[0035] The silicon particles, the first amorphous carbon precursor, the carbon material, and the second amorphous carbon precurso...

Embodiment 1

[0045] 1.1 Add 0.5kg of silicon powder with a purity of 99.99% and 0.15kg of glucose into a ball milling tank, then add absolute ethanol as the ball milling medium, and under the protection of an argon atmosphere, perform 400rpm high-energy mechanical ball milling for 8 hours to obtain the first composite slurry .

[0046] 1.2 Pour the first composite slurry obtained in 1.1 into a centrifugal spray dryer, adjust the temperature of the centrifugal spray dryer to 120°C, and adjust the wind speed to control the particle size D50 of the dry granulation to 5 μm to obtain the first composite .

[0047] 1.3 Add 0.3kg of the first compound obtained in 1.2 and 0.3kg of mesophase carbon microspheres to the ball milling tank, then add 0.24kg of glucose, and finally add absolute ethanol as the ball milling medium, under the protection of argon atmosphere, 400rpm High-energy mechanical ball milling for 8 hours to obtain the second composite slurry.

[0048] 1.4 Pour the second compound s...

Embodiment 2

[0055] 2.1 Add 0.5 kg of silicon powder with a purity of 99.99% and 0.1 kg of phenolic resin to a ball milling tank, then add acetone as the ball milling medium, and perform 400 rpm high-energy mechanical ball milling for 8 hours under the protection of an argon atmosphere to obtain the first composite slurry.

[0056] 2.2 Pour the first composite slurry obtained in 2.1 into a centrifugal spray dryer, adjust the temperature of the centrifugal spray dryer to 150°C, and adjust the wind speed to control the particle size D50 of drying and granulation to 5 μm to obtain the first composite .

[0057] 2.3 Add 0.3kg of the first compound obtained in 2.2 and 0.2kg of natural graphite to the ball milling tank, then add 0.2kg of phenolic resin, and finally add acetone as the ball milling medium, under the protection of argon atmosphere, 400rpm high-energy mechanical ball milling for 8h , to obtain the second composite slurry.

[0058] 2.4 Pour the second compound slurry obtained in 2.3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com