Patents

Literature

144results about How to "Reduce hydraulic shock" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

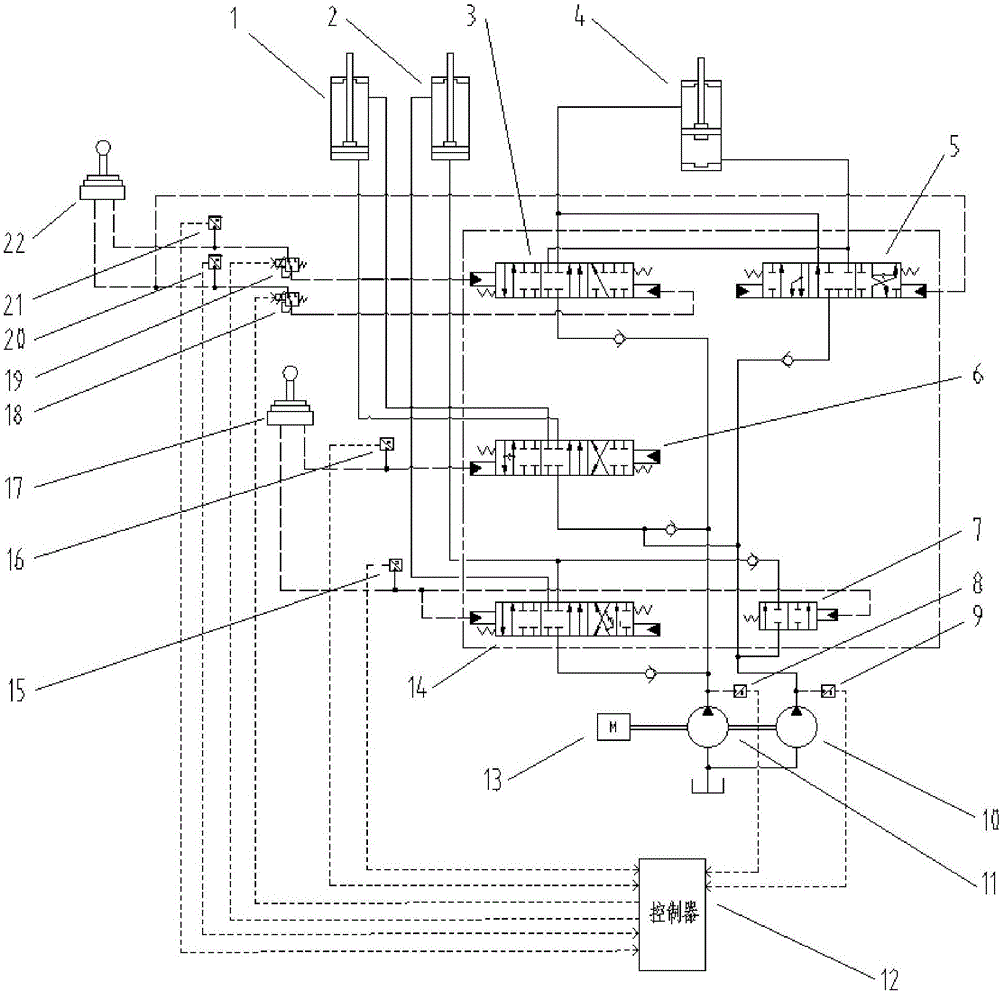

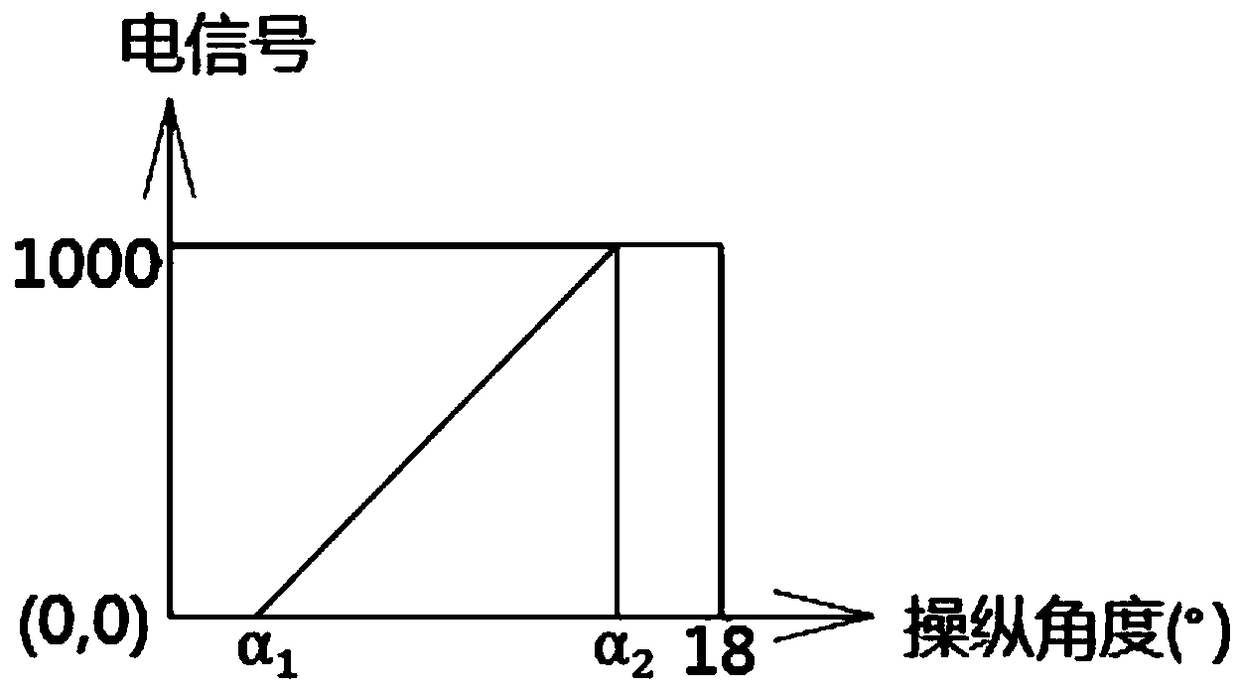

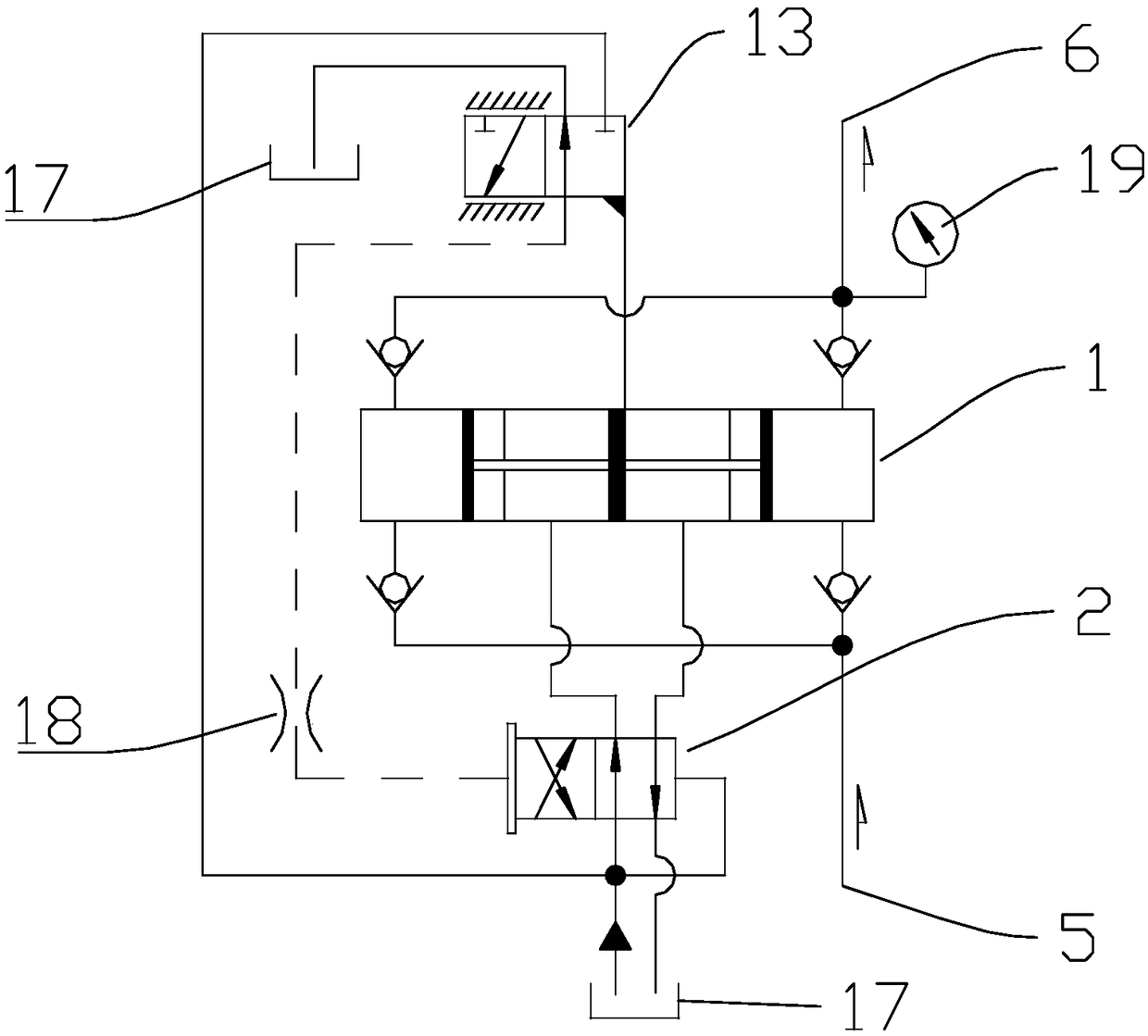

Intelligent shock absorption hydraulic control method and control system of excavator

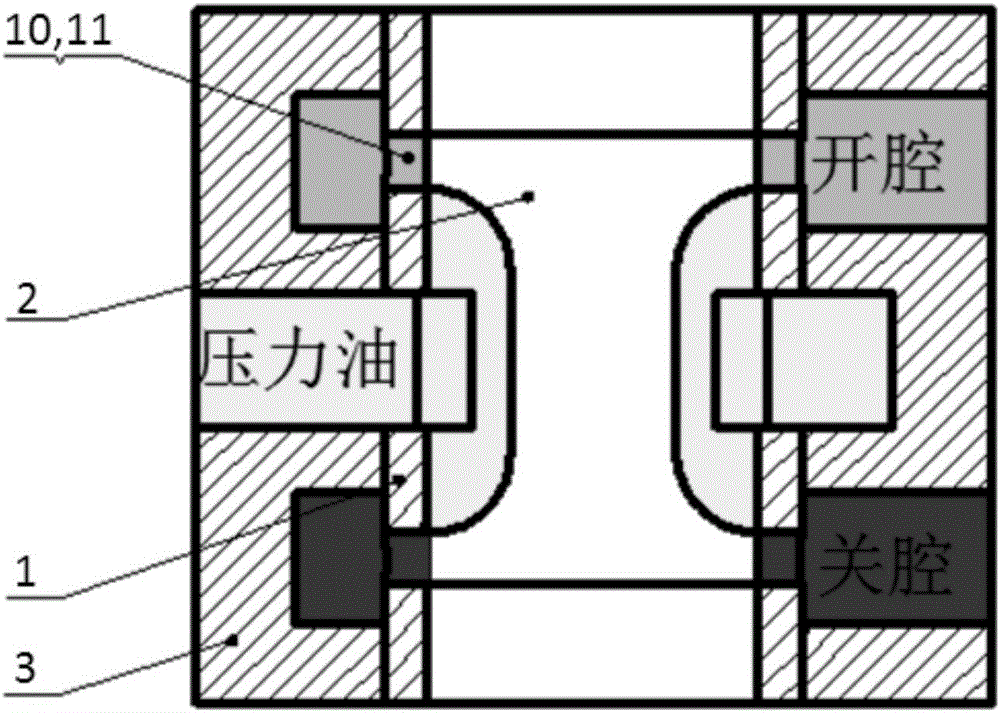

ActiveCN106703110ASlow stop accelerationReduce vibrationSoil-shifting machines/dredgersControl systemExcavator

The invention relates to hydraulic methods of excavators, aims to solve the problem that a conventional excavator is high in impact and relatively poor in operation experience, and provides an intelligent shock absorption hydraulic control method and control system of an excavator. The control method is characterized in that information like main pump pressure and pilot pressure signals is acquired through sensors, main pump pressure and pilot pressure are compared with preset pressure, a bucket rod confluence valve of the excavator is controlled through an electric proportional valve, logical judgment is carried out according to the action of an operator during operation of the excavator, when the excavator operates on uneven ground, through changing of an output current of the electric proportional valve, the motion speed of the bucket rod confluence valve is adjusted, the opening characteristic of a valve core is adjusted, hydraulic impact is reduced, and the effects of decreasing acceleration at stall of a working device and reducing vibration of the entire machine are achieved.

Owner:LIUZHOU LIUGONG EXCAVATORS +2

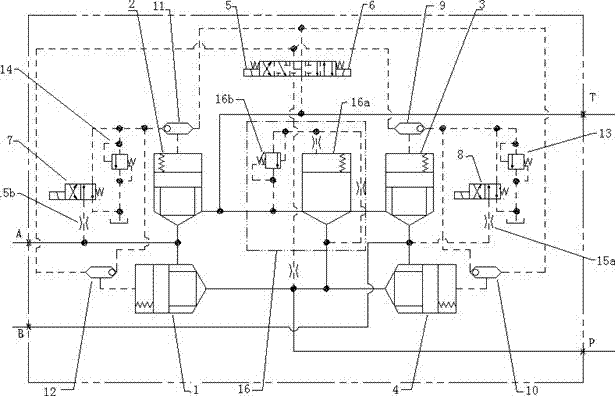

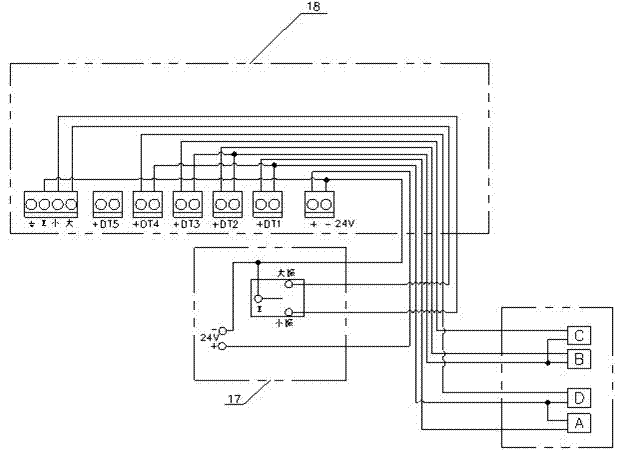

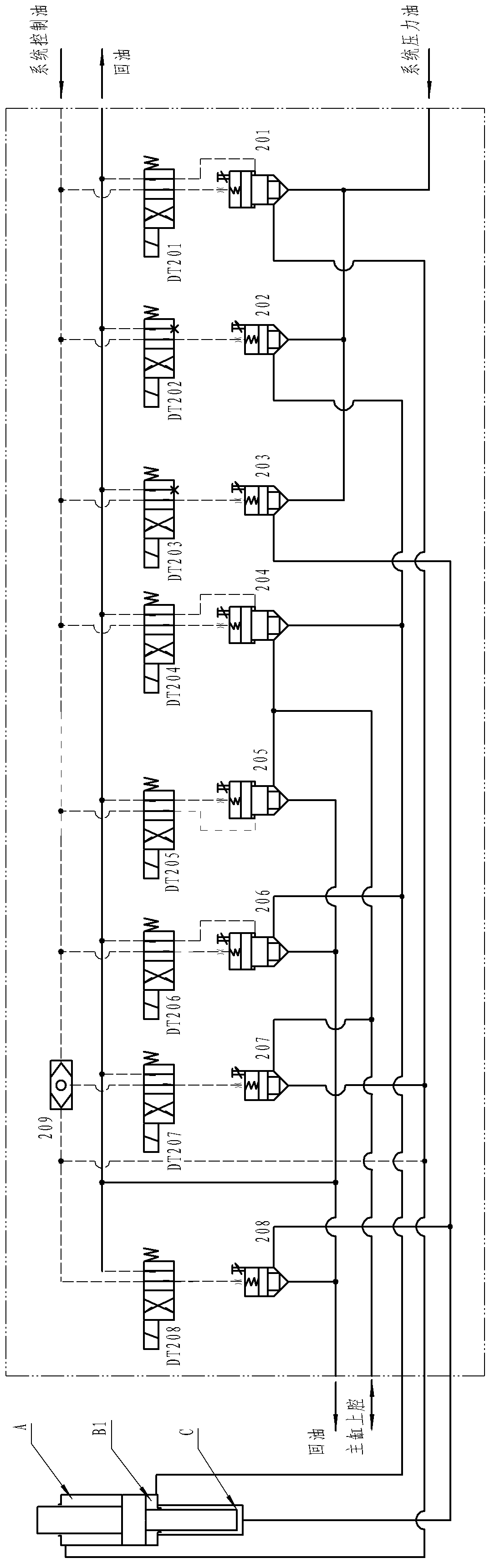

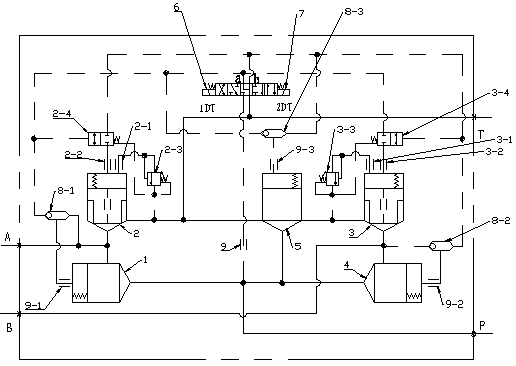

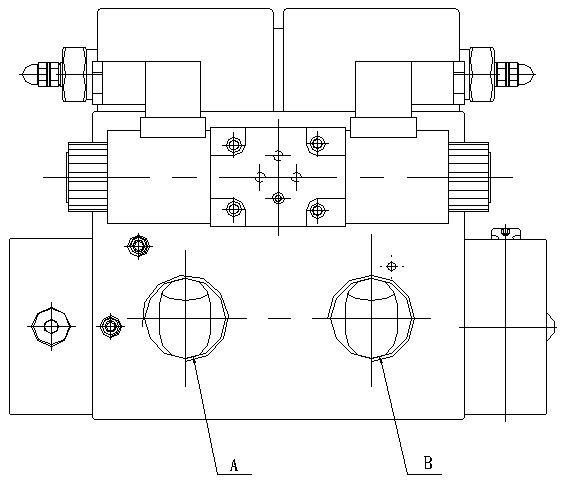

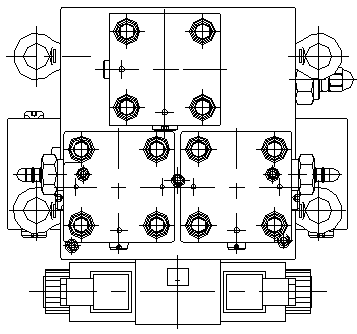

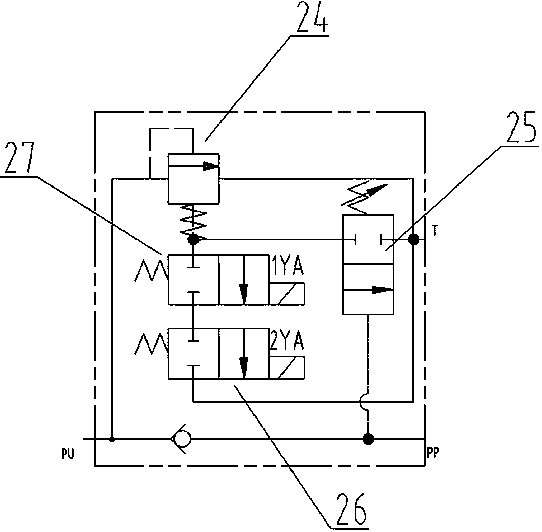

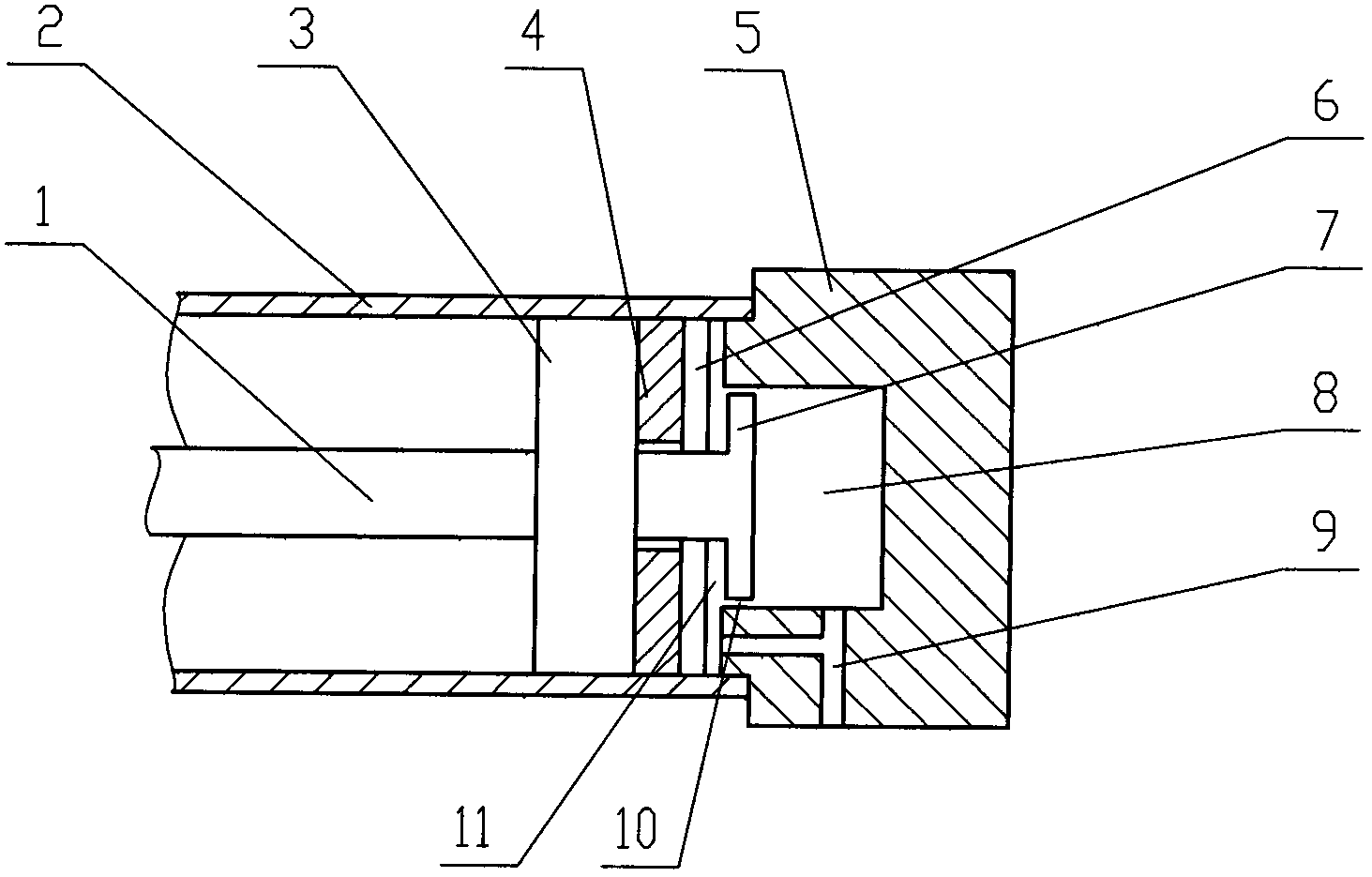

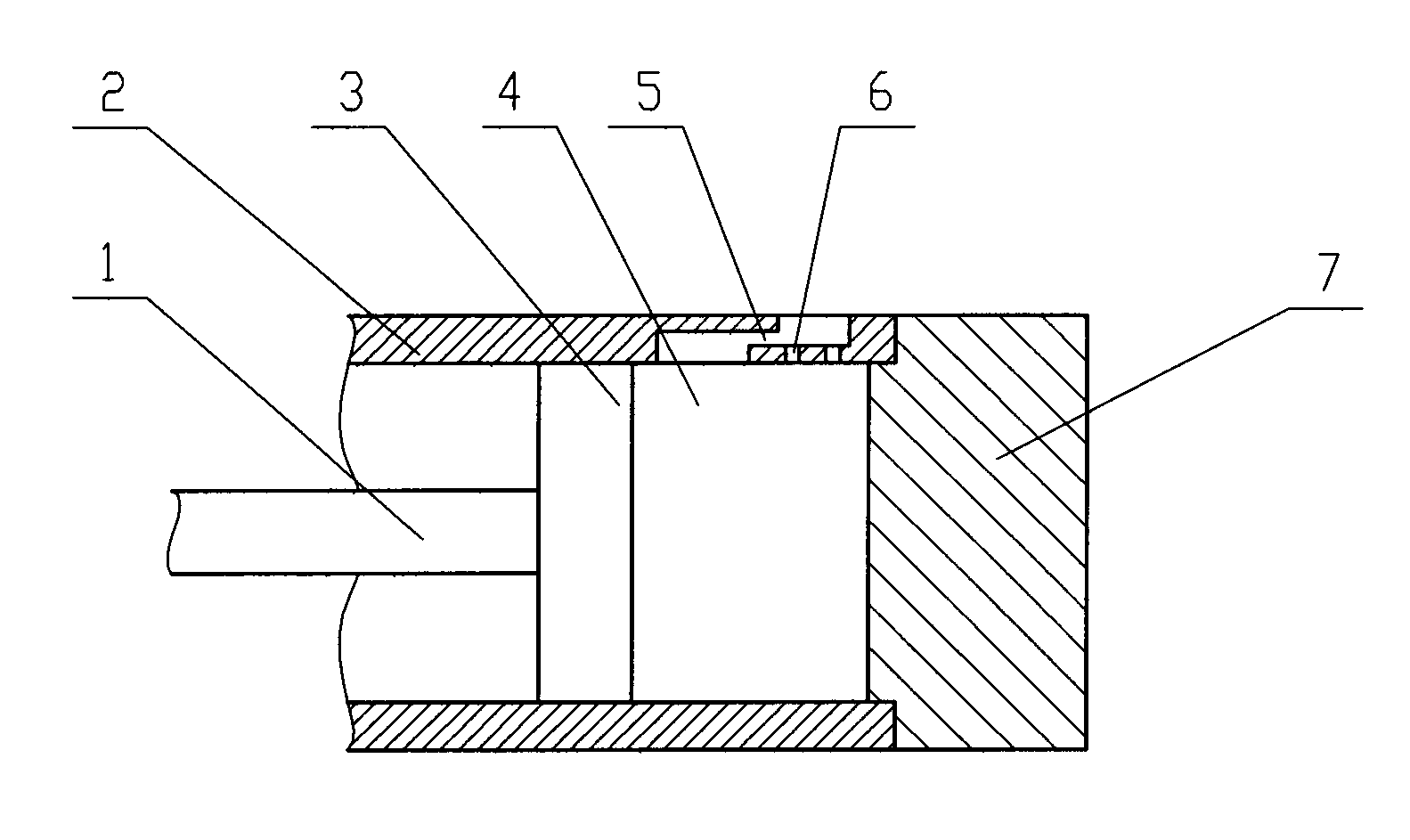

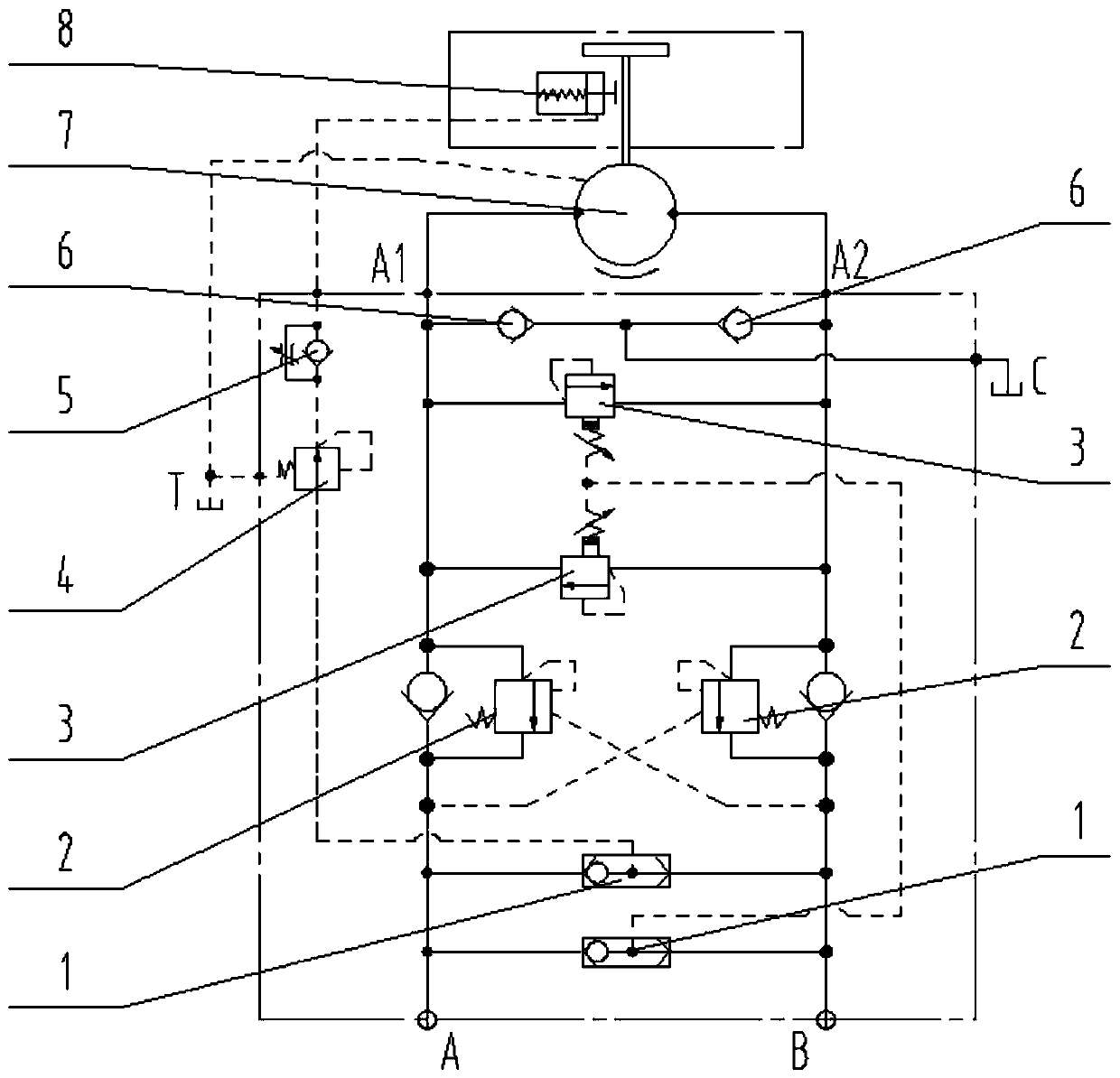

Two-way plug-in mounting vibrating valve and electric hydraulic control unit

ActiveCN103089725AReduce hydraulic shockThe stop time can be adjustedServomotor componentsHydraulic control unitHydraulic motor

The invention relates to a two-way plug-in mounting vibrating valve comprising a valve body and an electric hydraulic control loop. The valve body is plugged in a plug-in cavity of the valve body. The electric hydraulic control loop is used for controlling the operation of a hydraulic motor, and comprises a two-way plug-in valve, a control cover plate, a guide solenoid directional valve, an overflow valve and the like. The electric hydraulic control loop includes a directional auxiliary loop for controlling corotation and reversion of the hydraulic motor, an auxiliary loop for controlling stalling of the corotation and the reversion of the hydraulic motor, and another auxiliary loop for providing overload protection to the hydraulic vibration system of a pavement roller. The invention further relates to an electric hydraulic control unit comprising an exclusive-used vibrating controller for controlling the two-way plug-in mounting vibrating valve. By the aid of the vibrating controller, the operation time sequence of each solenoid valve can be controlled. By the invention, the hydraulic shock can be alleviated when a pavement roller starts oscillation, amplitudes and stops oscillation, peek value transmission of the hydraulic system can be reduced, and reliability and durability of the operation of the hydraulic components can be improved. The oscillation stop time is shortened and can be regulated and controlled, so that the working quality of the pavement roller is improved and the comfortableness of the drives is increased.

Owner:PERMCOTIANJINHYDRAULIC INC

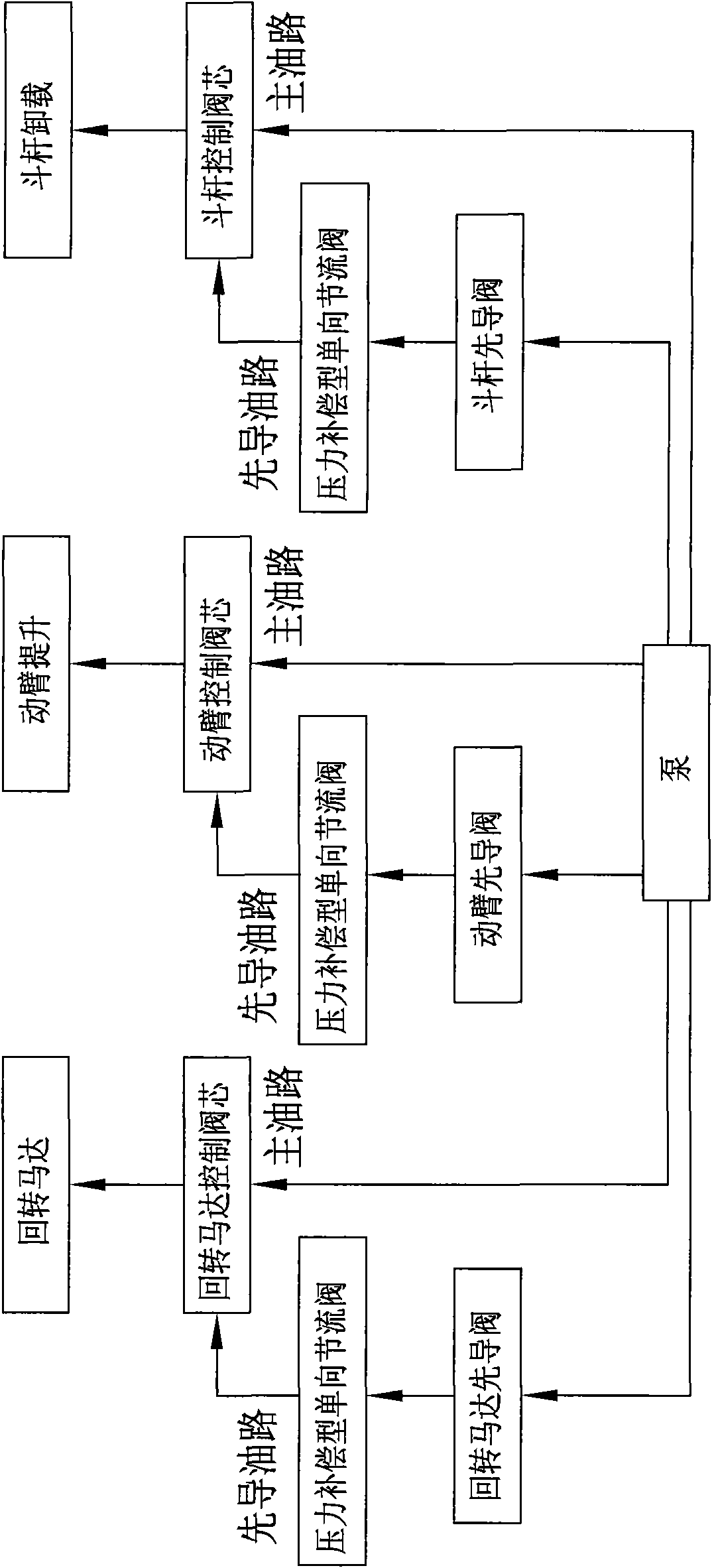

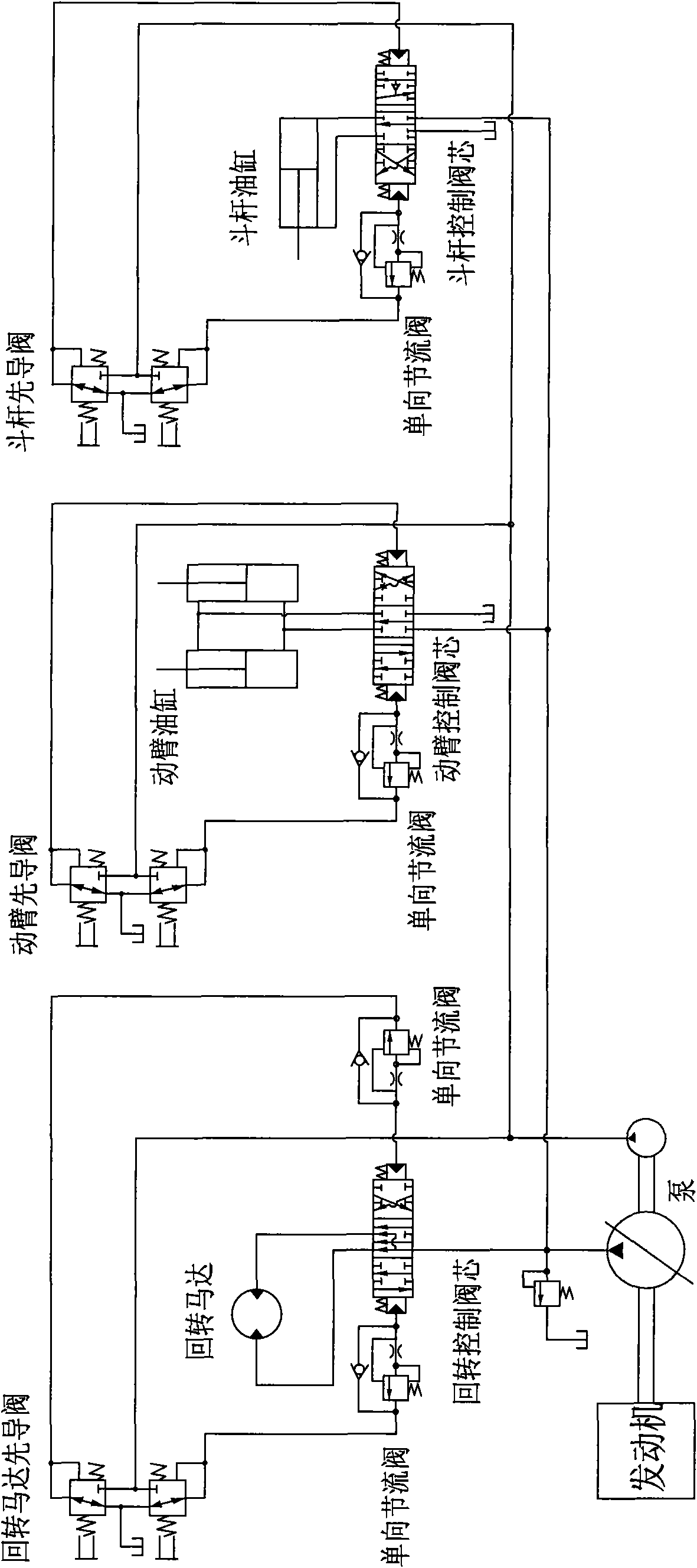

Method and device for improving operation comfort of excavator

InactiveCN101619580AExtended service lifeSlow down the oil return speedMechanical machines/dredgersEngineeringControl valves

The invention discloses a method and a device for improving the operation comfort of an excavator. The device is characterized in that a one-way throttle valve is additionally arranged at one end or both ends of a pilot oil line of a revolving control valve core and a movable arm control valve core; when pilot oil flows to a main control valve core from a corresponding pilot valve, the single throttle valve on the branch is in an opened state; when the pilot oil flows to the corresponding pilot valve from the main control valve core, the one-way throttle valve on the branch is in a closed state, and the pilot oil returns through throttle holes of the one-way throttle valve. By arranging the one-way throttle valve on the pilot oil of the revolving control valve core and the movable arm control valve core, the oil returning speed is limited, and the hydraulic impact is reduced, thus the operation comfort is enhanced.

Owner:SANY HEAVY MACHINERY

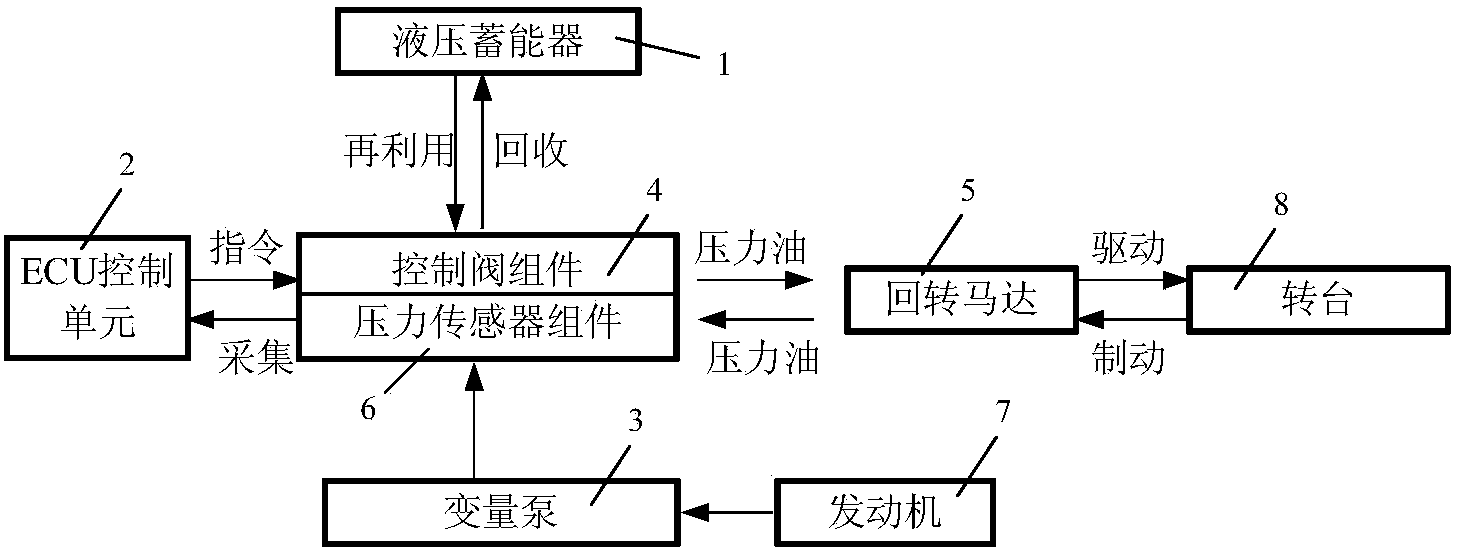

Recovering system for slewing and braking energy of excavator

ActiveCN104372823ASimple structureWork reliablySoil-shifting machines/dredgersFluid-pressure actuator componentsExcavatorEnergy storage

The invention provides a recovering system for slewing and braking energy of an excavator. A hydraulic energy accumulator serves as an energy storage element, a slewing motor / pump serves as an energy conversion element, inertia energy of a rotary table is converted into hydraulic energy and stored in the energy accumulator, namely, in the braking process, the slewing motor operates in the pump working condition, the slewing and braking energy of the excavator is recovered and stored in the energy accumulator, the energy is released during starting of the next time, by means of the control over energy distribution of an engine and the energy accumulator (a main power source and an auxiliary power source), the slewing and braking energy of the excavator is recovered and reused, and the purpose of energy saving is achieved.

Owner:福建华南重工机械制造有限公司

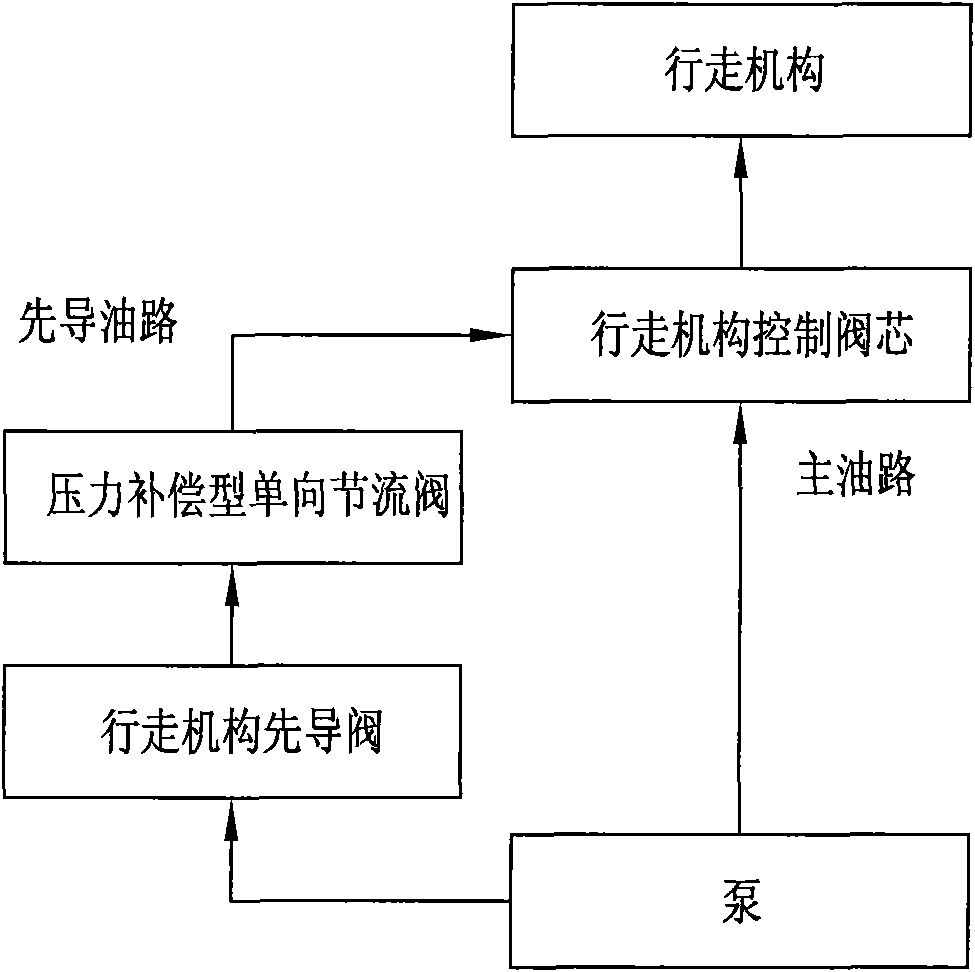

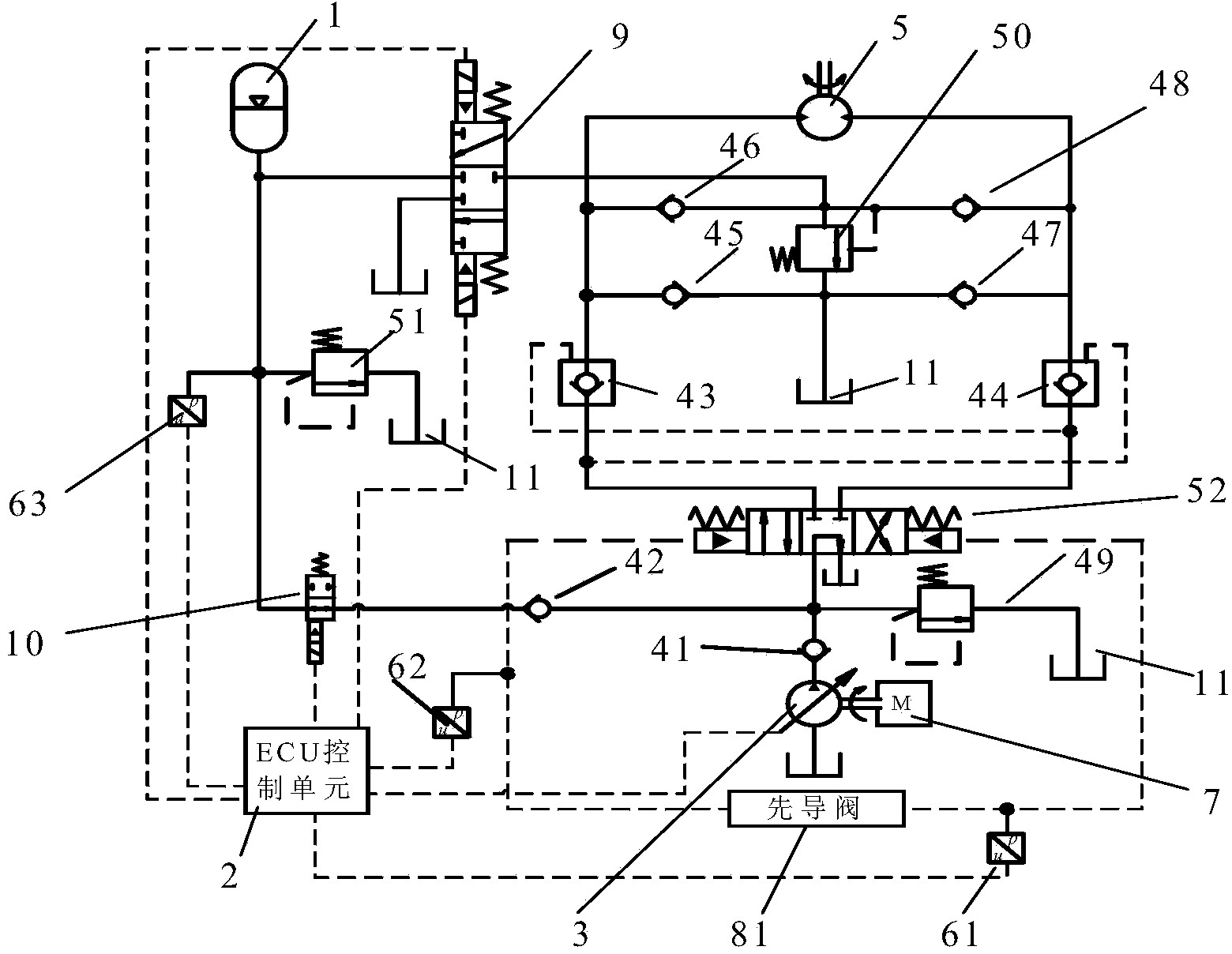

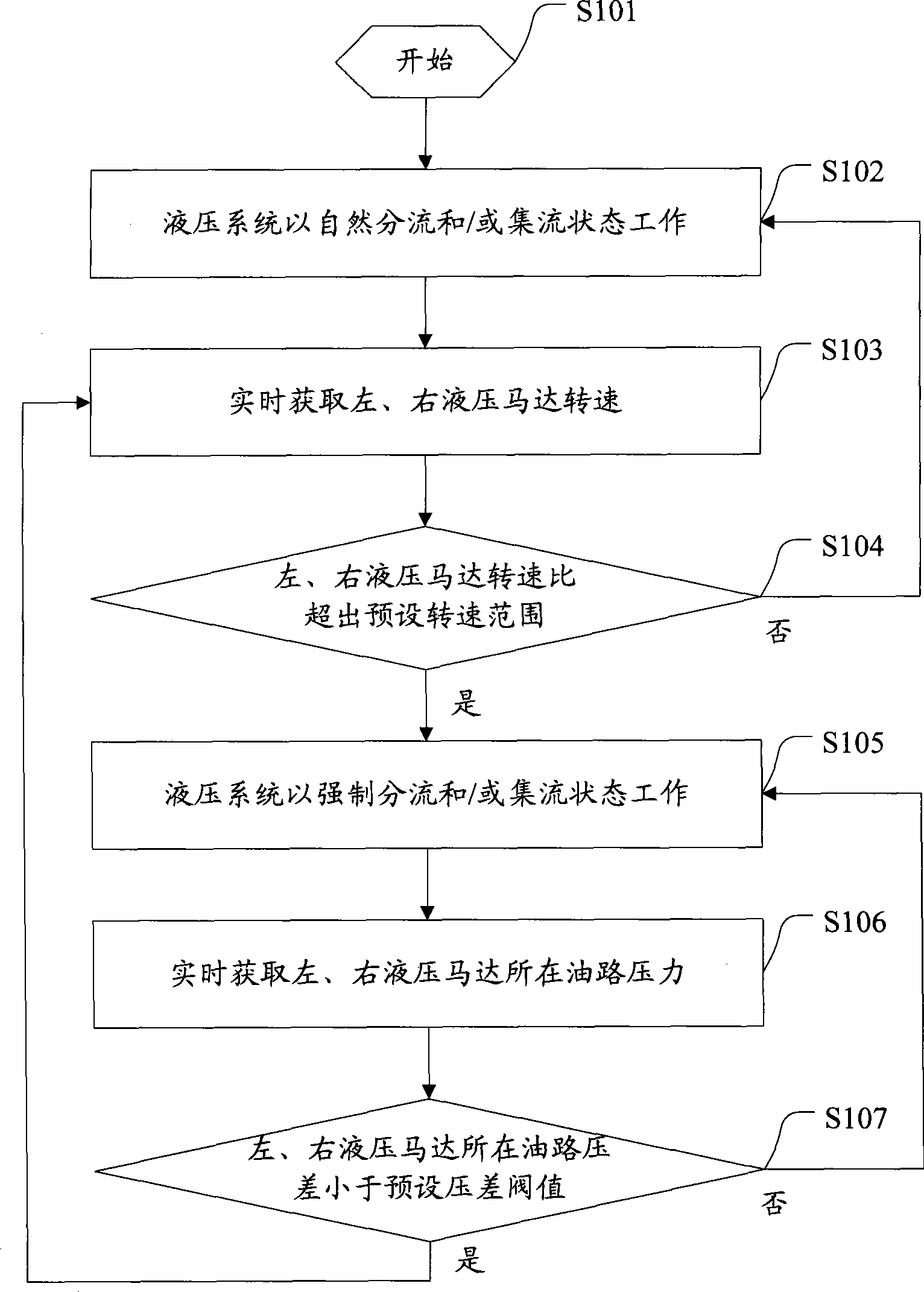

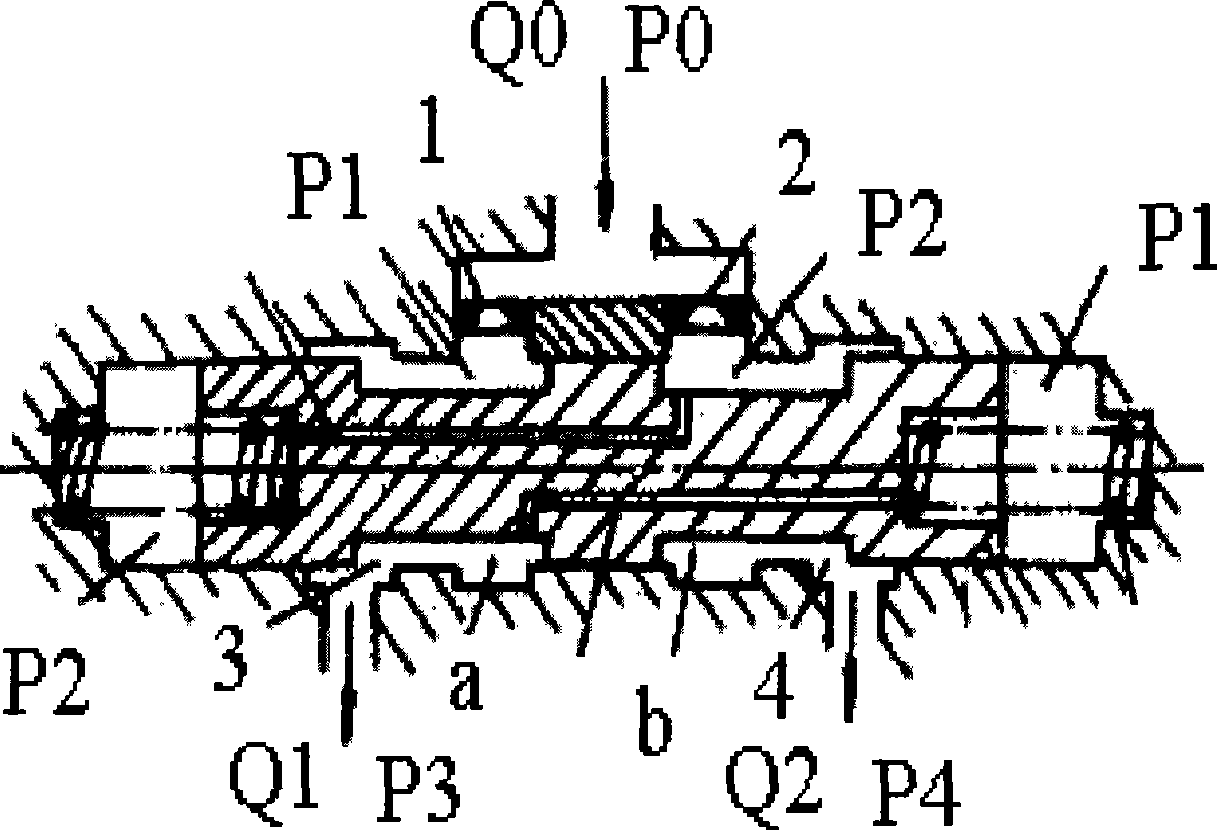

Control method and control device for driving hydraulic system of engineering vehicle by single pump and double motors

ActiveCN101392774APrevent the problem of unilateral slippageImprove adaptabilityServomotor componentsServomotorsHydraulic motorDifferential pressure

The invention discloses a method for controlling an engineering vehicle hydraulic system which is driven by a single pump and two motors. The method comprises the following steps: in a state of natural split flow and / or flow combine, obtaining the rotating speeds of a left hydraulic motor and a right hydraulic motor in real time; judging whether the rotating speed ratio of the left hydraulic motor to the right hydraulic motor exceeds the range of a preset rotating speed ratio; if the rotating speed ratio exceeds the range of the preset rotating speed ratio, controlling the hydraulic system to be in a state of enforced split flow and / or flow combine; in the state of enforced split flow and / or flow combine, obtaining the pressure on an oil path of the left and the right hydraulic motors in real time; judging whether the pressure on the oil path of the left and the right hydraulic motors is smaller than a preset differential pressure threshold value; and if the pressure is smaller than the preset differential pressure threshold value, controlling the hydraulic system to return to the state of natural split flow and / or flow combine. Through controlling the state of the hydraulic system to be switched between the state of natural split flow and / or flow combine and the state of enforced split flow and / or flow combine, the method can avoid the problem of single-side skid of an engineering vehicle and improves the self adaptability and the working efficiency of the engineering vehicle. On the basis, the invention also discloses a control device for the engineering vehicle hydraulic system which is driven by the single pump and the two motors.

Owner:SANY GRP

Braking kinetic energy regenerating hydraulic retarder for automobile

InactiveCN101786447AReduce feverReduce resistanceBraking element arrangementsBraking systemKinetic energy

The invention discloses a braking kinetic energy regenerating hydraulic retarder for an automobile. The hydraulic retarder is an oil pump and hydraulic system arranged on power takeoff windows for gearboxes of large and medium automobiles. The hydraulic retarder not only has functions of the hydraulic retarder for the automobile, but also can recycle kinetic energy to be abandoned when the automobile brakes. The hydraulic retarder is characterized in that: the hydraulic retarder is connected in parallel with main transmission of the automobile, so the hydraulic retarder is convenient to joint and separate; remarkable energy-saving effect is achieved; energy is released and more force is applied when a vehicle is started, so the working condition of an engine is improved and the emission of harmful gas is reduced; starting speed can be increased and running efficiency is improved; mechanical rigid braking is replaced by flexible hydraulic retarding, so riding comfort is improved, the service lives of vehicle braking and a braking system are prolonged, and the safety performance of the vehicle is enhanced; and conventional mature hydraulic technology and hydraulic components produced in a large scale are adopted, so the system is simple and reliable, has low manufacturing cost, and is easy to popularize and apply.

Owner:江绍成 +3

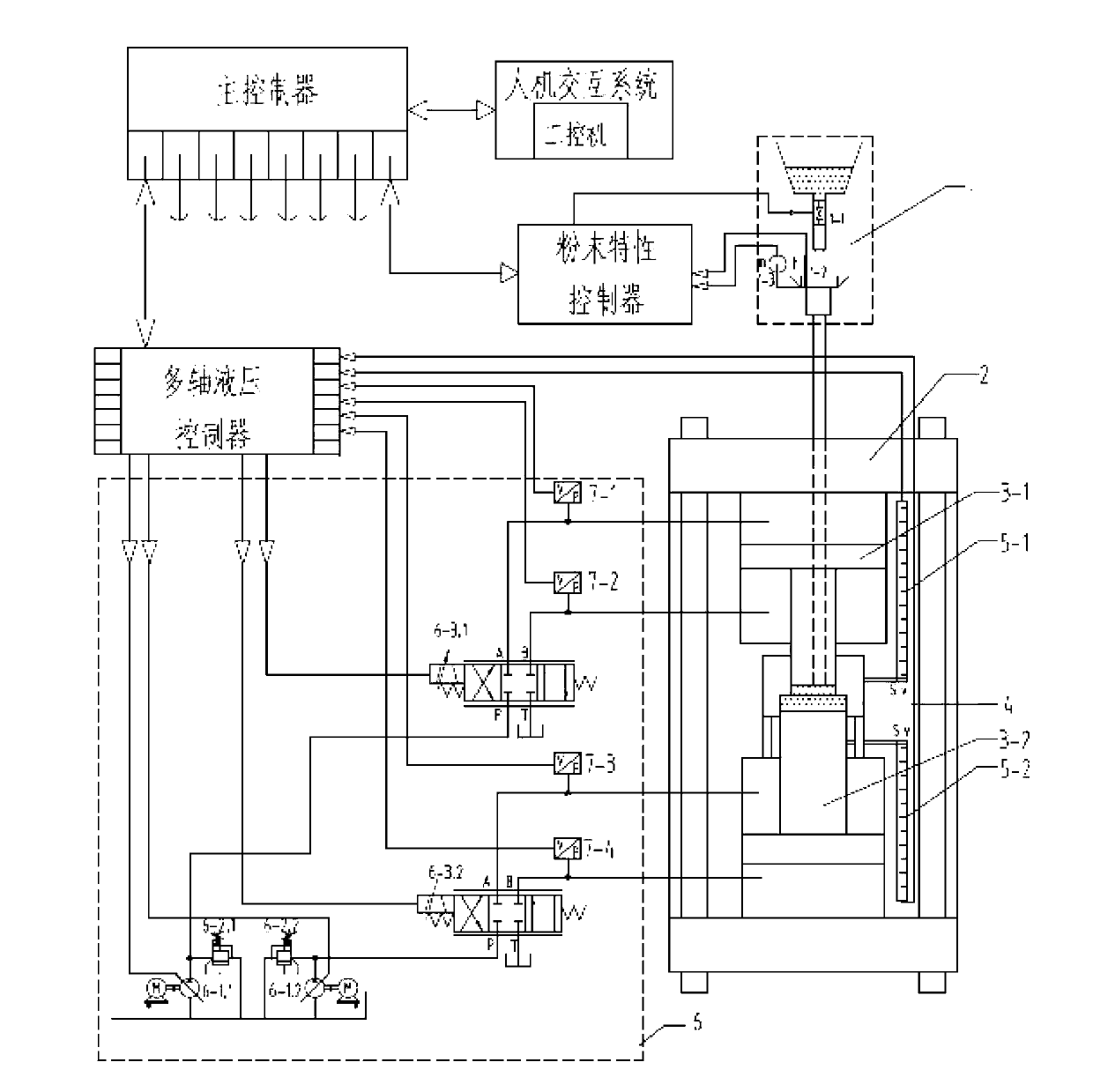

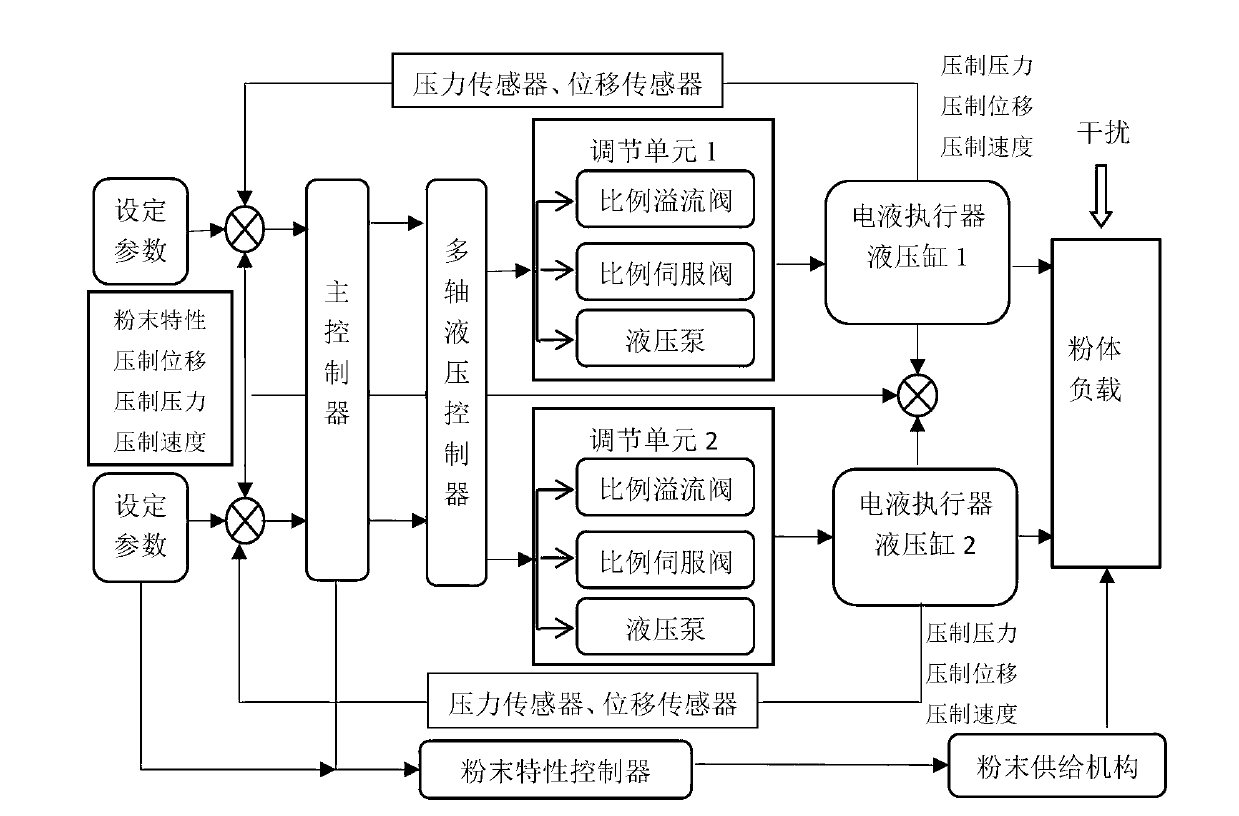

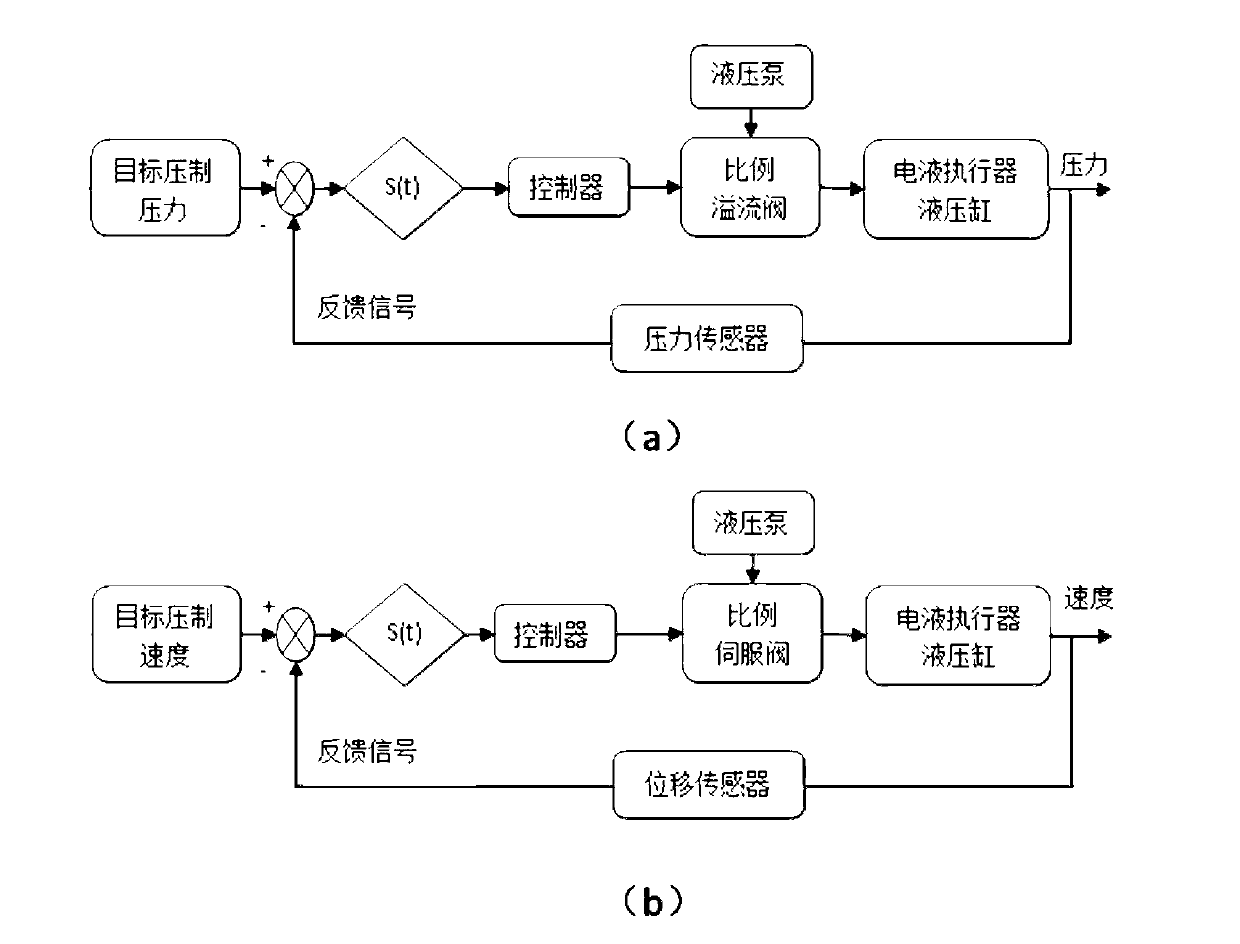

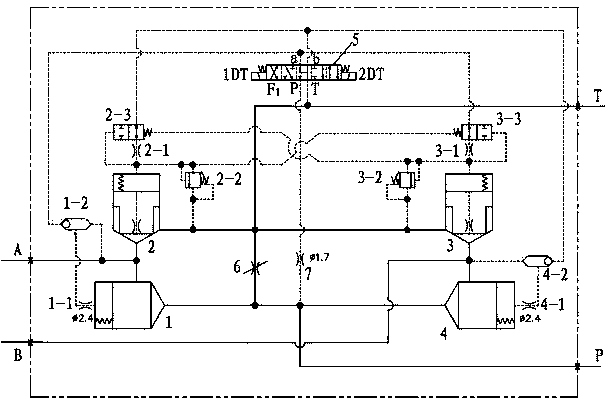

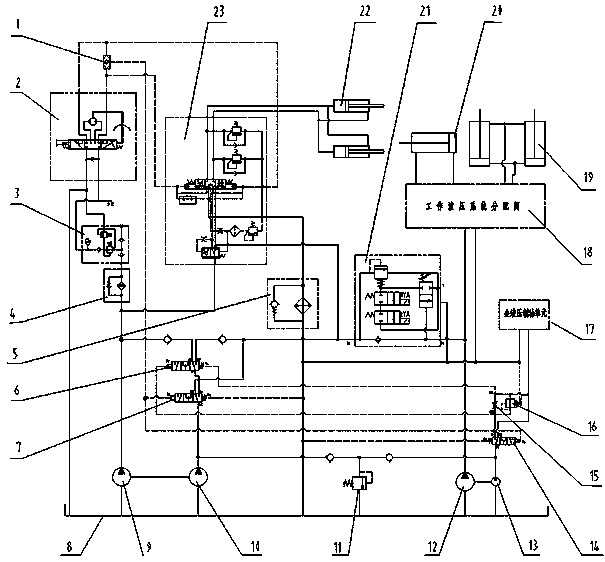

Powder forming hydraulic machine multi-parameter modularization electro-hydraulic control system

The invention discloses a powder forming hydraulic machine multi-parameter modularization electro-hydraulic control system. Various regulating units of an electro-hydraulic actuator regulating system are in one-to-one correspondence with electro-hydraulic actuator hydraulic cylinders of a powder forming hydraulic machine. In each regulating unit, an oil inlet of a hydraulic pump is communicated with an oil tank of the powder forming hydraulic machine, an oil inlet of a proportional overflow valve is communicated with an oil outlet of the hydraulic pump, an oil outlet of the proportional overflow valve is communicated with the oil tank of the powder forming hydraulic machine, an oil inlet of a proportional servo valve is communicated with the oil outlet of the hydraulic pump, a working oil port of the proportional servo valve is communicated with a corresponding electro-hydraulic actuator hydraulic cylinder, and an oil return opening of the proportional servo valve is communicated with the oil tank of the powder forming hydraulic machine. The hydraulic pump, the proportional overflow valve and the proportional servo valve of each regulating unit are respectively and electrically connected with an output end of a multispindle hydraulic controller. A main controller is connected with an industrial personal computer in a communicated mode, and an output end of the main controller is connected with an input end of the multispindle hydraulic controller.

Owner:ZHEJIANG UNIV

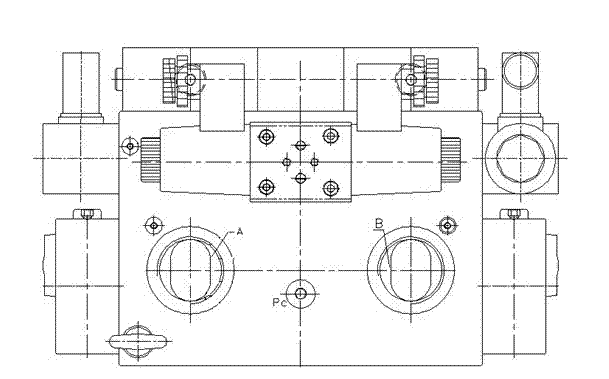

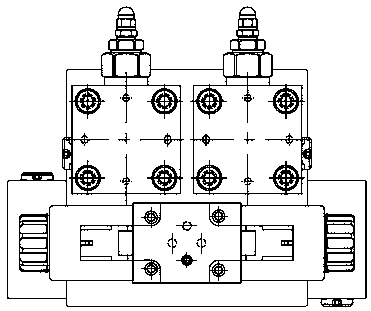

Two-way cartridge type vibration control valve

ActiveCN104214152AReduce hydraulic shockReduce peak pressureServomotor componentsStop timePeak pressure

The invention discloses a two-way cartridge type vibration control valve which comprises a valve body, a direction control branch loop, a vibration stop branch loop and a safe branch loop. The direction control branch loop is inserted in the valve body and formed by four two-way cartridge valves and the like. The hydraulic impact of a road roller in the vibration starting process is reduced, the peak pressure of a hydraulic system is lowered, the work reliability and durability of a hydraulic element are improved, the vibration stop time is shortened, and the operation quality of the road roller and the comfort feeling of a driver are improved. Compared with the prior art, a two-way cartridge valve and a control cover plate component of the two-way cartridge valve are omitted, the size is reduced, and the hydraulic system is simpler, more convenient to maintain and lower in production cost. Meanwhile, in the two-way cartridge type vibration control valve, an adjusting flow valve is arranged between the branch oil path position, communicated with the first two-way cartridge valve and the fourth two-way cartridge valve, of an oil inlet connector and an oil return connector, and the vibration frequency of the road roller can be adjusted when needed.

Owner:PERMCOTIANJINHYDRAULIC INC

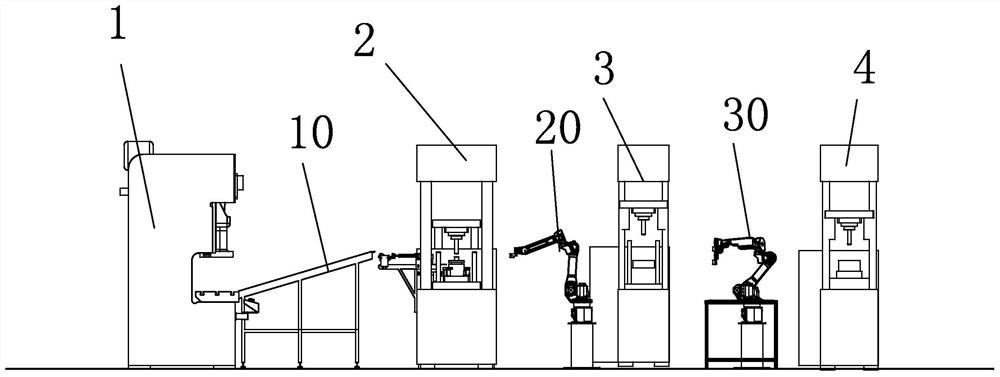

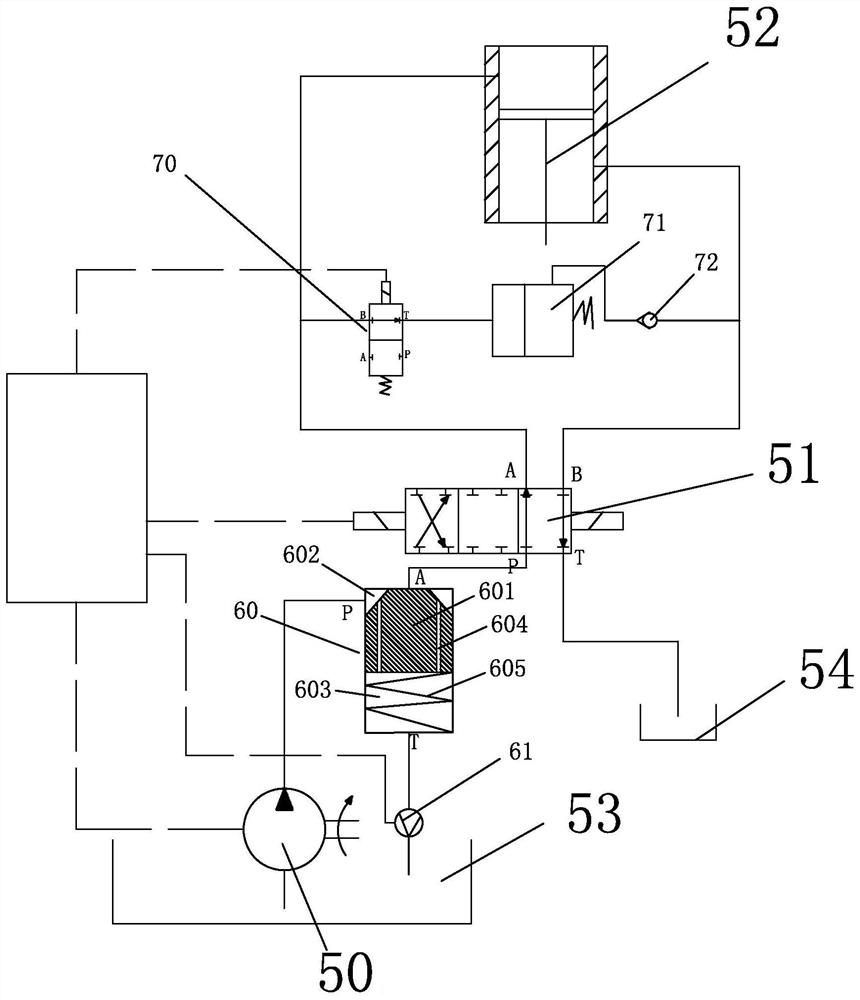

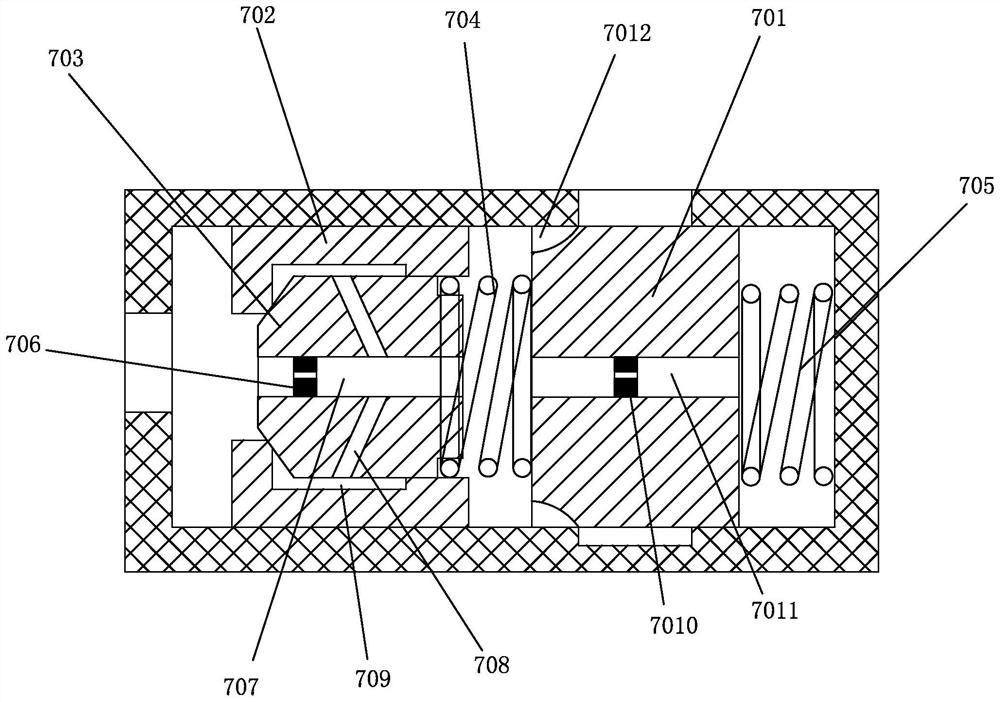

Stamping stretching full-automatic production device and control method thereof

The invention discloses a stamping stretching full-automatic production device and a control method thereof, and aims to provide the stamping stretching full-automatic production device which is highin stability, simple in structure and high in practicability. The stamping stretching full-automatic production device is characterized in that a first buffer oil path comprises a first buffer valve and a first on-off valve, a valve cavity of the first buffer valve is internally provided with an inner valve core, the inner valve core includes a mesa portion and a planar portion, the mesa portion is located in an oil return cavity, the planar portion is located in a re-pressing cavity, a mesa area of the mesa portion is less than the planar portion, the inner valve core is provided with a plurality of through holes communicating with the oil return cavity and the re-pressing cavity, a reset spring is arranged in the re-pressing cavity, and when a workpiece reaches a predetermined stretchingvalue, the first buffer valve is gradually closed by gradually closing the first on-off valve, and when the pressure of the valve core in the first buffer valve is gradually reduced from the pressureof a hydraulic pump until the first on-off valve is closed, the first buffer valve carries out the acting force of the reset spring, so that the plugging effect on the first buffer valve is formed; and the stamping stretching full-automatic production device is suitable for the technical field of machining equipment.

Owner:大昌汽车部件股份有限公司

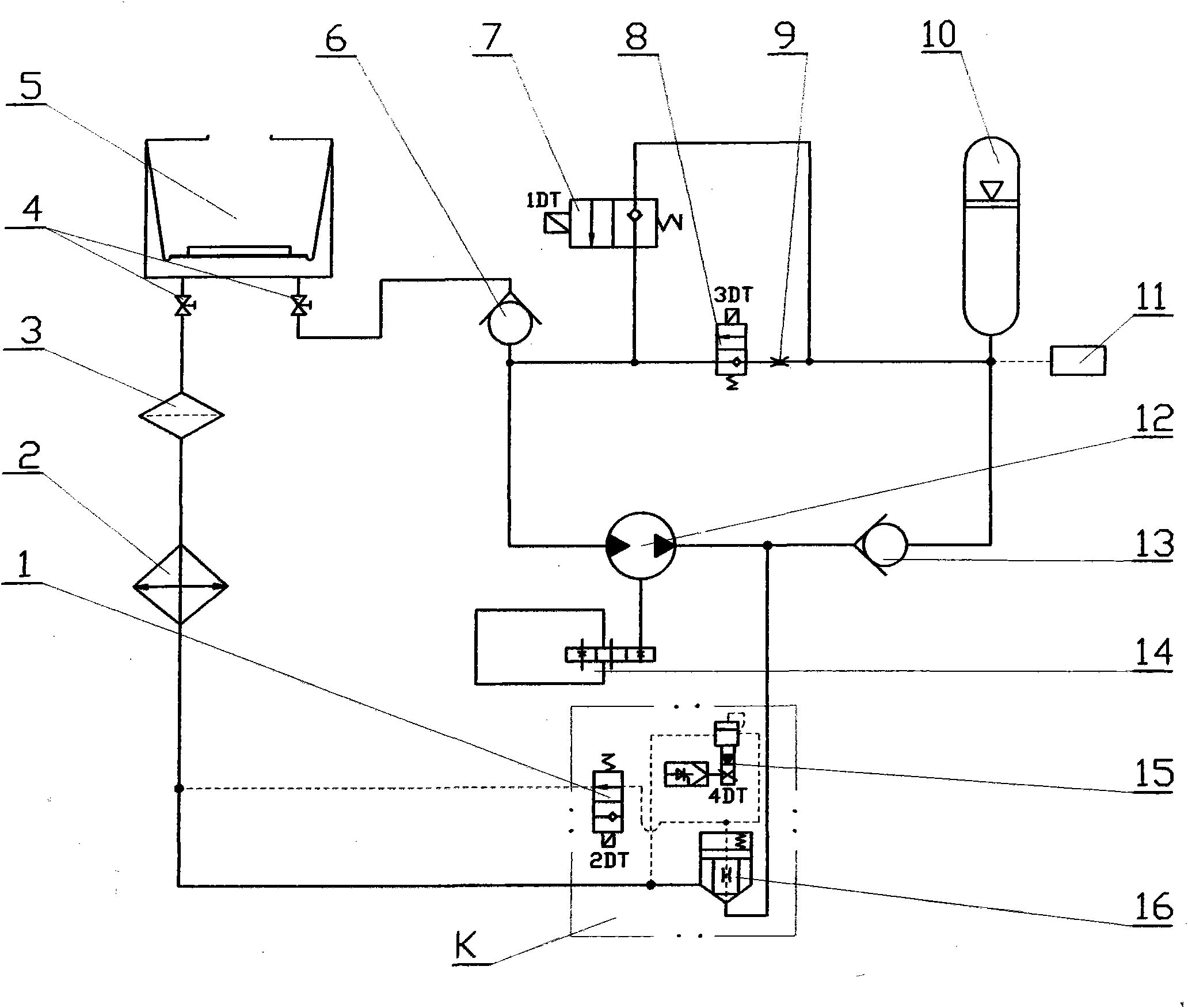

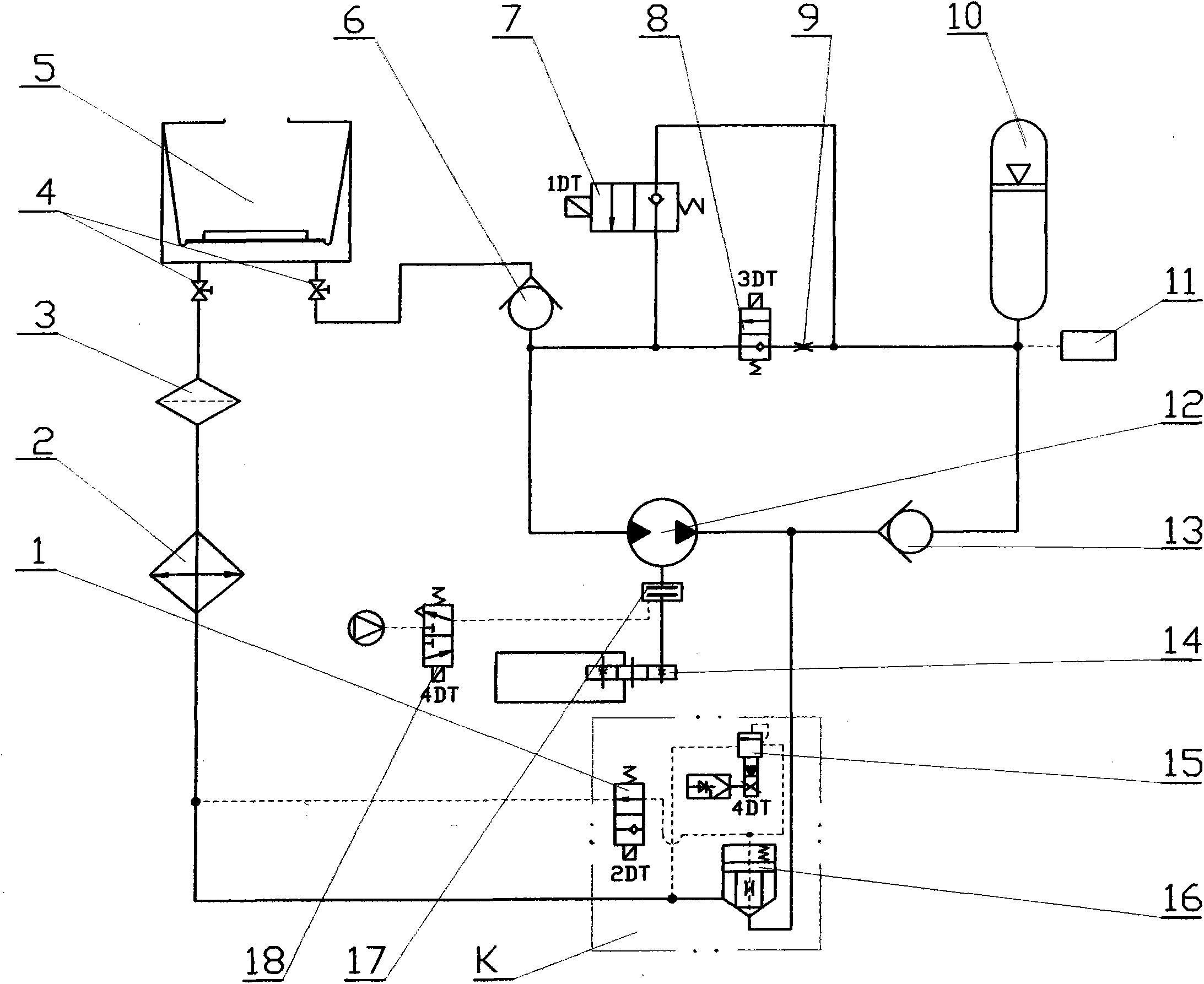

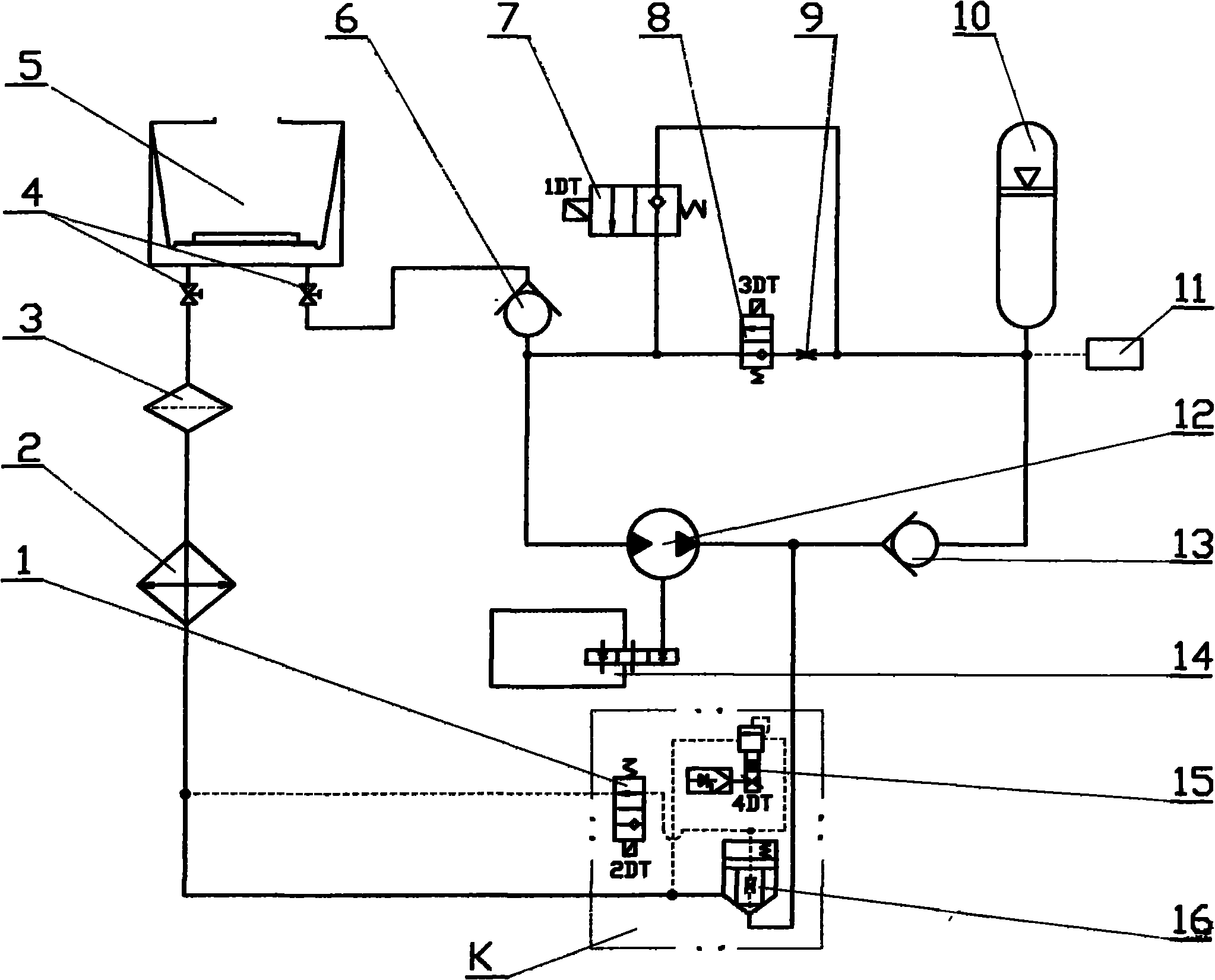

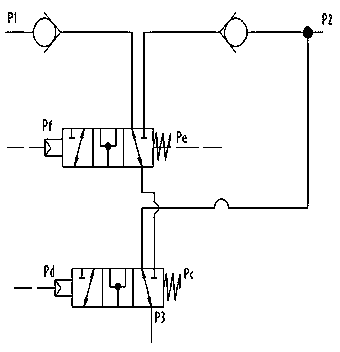

Free-slewing cushion and brake hydraulic system and method used in crawler crane

InactiveCN102249154AReduce discomfortStable and effective braking effectLoad-engaging elementsRotary pumpDriver/operator

The invention provides a free-slewing cushion and brake hydraulic system and method used in a crawler crane. The hydraulic system comprises a main rotary pump, an oil supplementing pump, an overflow valve, a brake valve, a brake, a rotary motor, a free-swing control valve and an inverse-proportional electromagnetic pressure reducing valve, wherein, the inverse-proportional electromagnetic pressure reducing valve is connected between the brake valve and the brake; the main rotary pump and the rotary motor are connected together to form a circuit; and the free-swing control valve is connected between the main rotary pump and the rotary motor. The free-slewing cushion and brake hydraulic system and method used in the crawler crane have the advantages of fast response speed and stable and reliable service performances; and by utilizing the system and method, stable and good brake effect can be provided, hydraulic impact and discomfort of a driver caused by brake are reduced maximally, and inertial impact on the active crawler crane from the passive crawler crane resulting from brake can be effectively prevented so as not to cause damage to the active crawler crane.

Owner:SHANGHAI SANY TECH

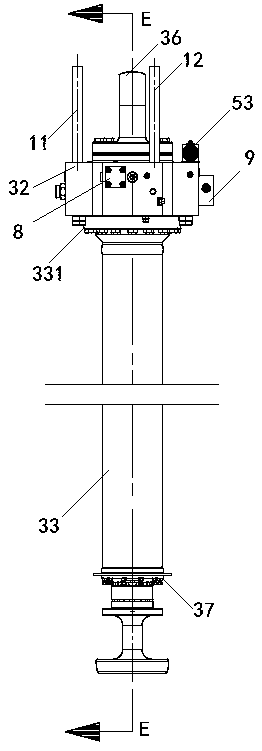

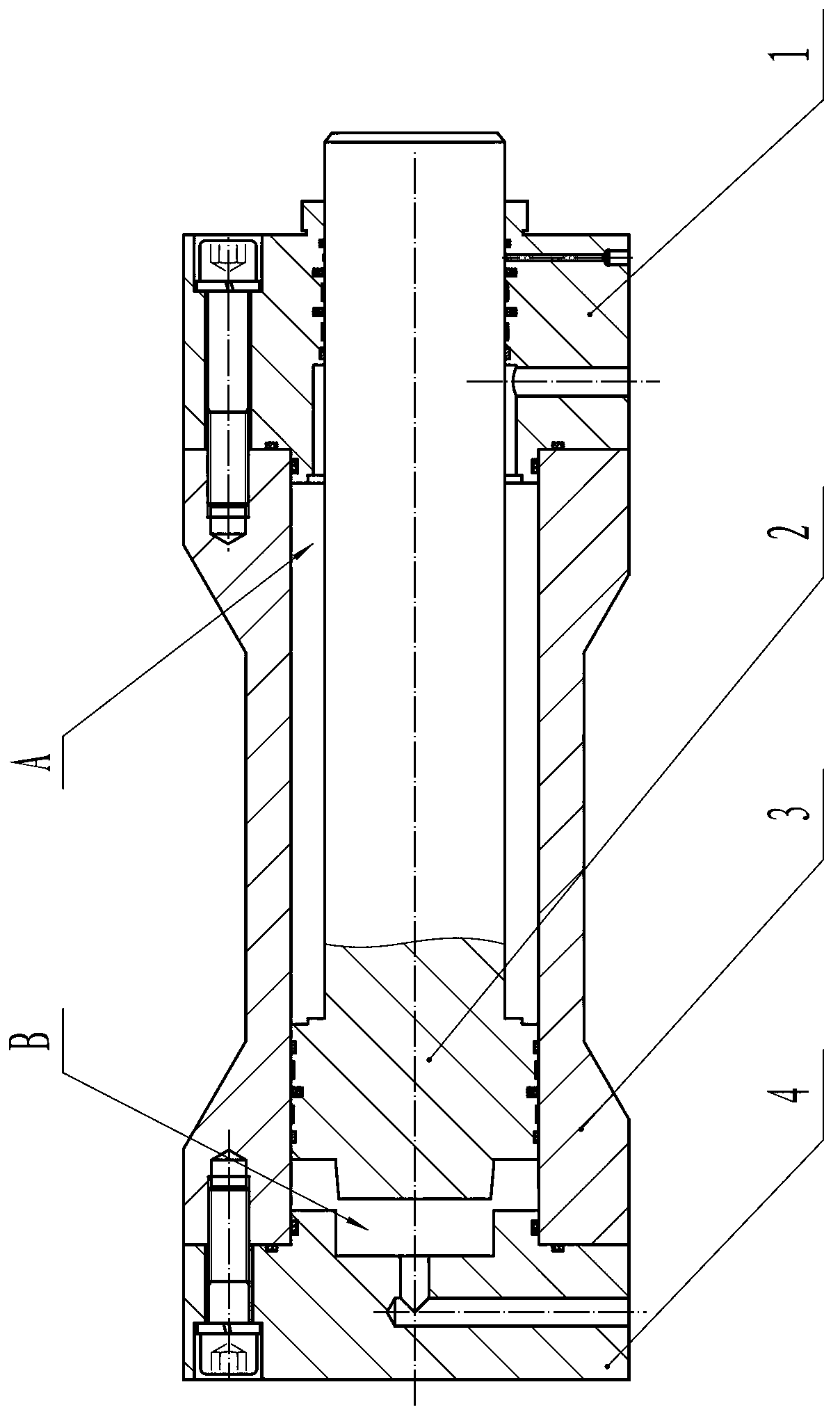

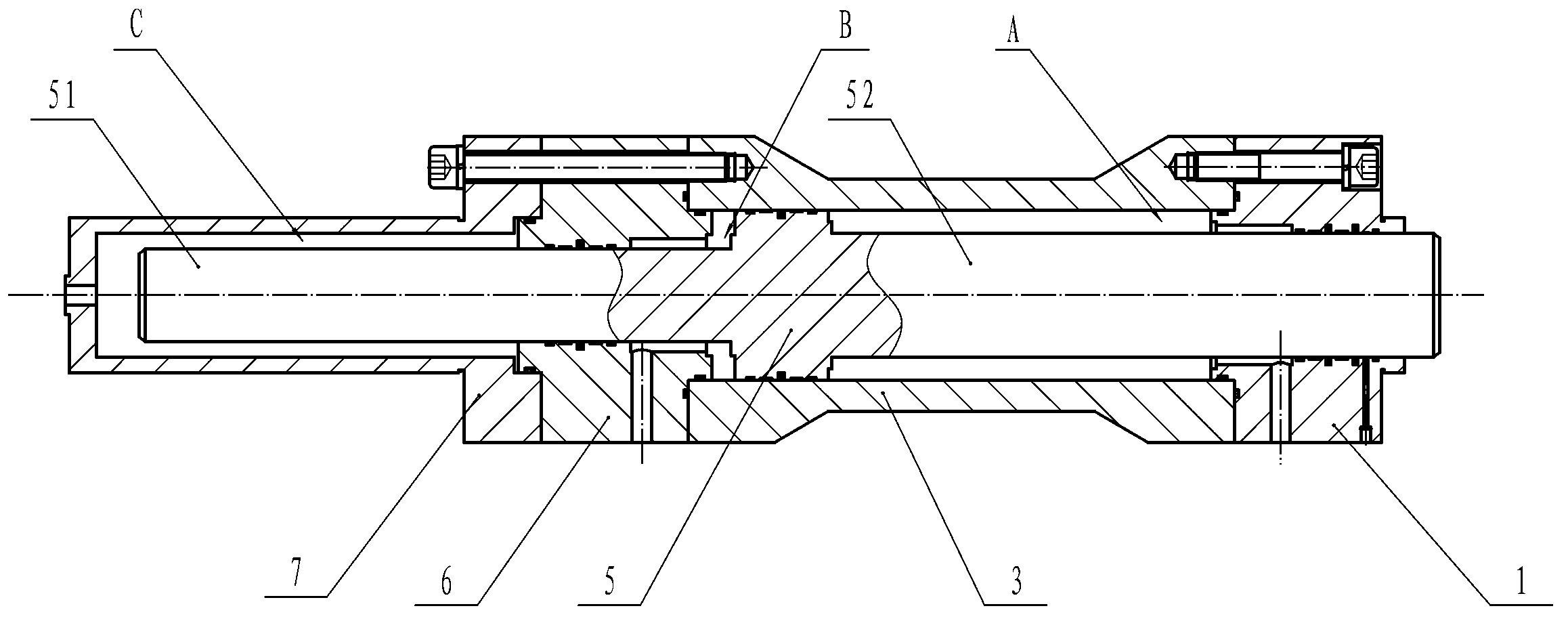

Hydraulic system for hydraulic hammer

PendingCN110985483ASpeed up the flowImprove high-speed reciprocating motion requirementsServomotor componentsFluid-pressure actuator componentsCheck valveImpact hammer

The invention discloses a hydraulic system for a hydraulic hammer. The hydraulic system comprises a power source, an oil tank, a lifting oil cylinder, an impact hammer core, a second electromagnetic reversing valve, a third electromagnetic reversing valve, a second plug-in valve, a third plug-in valve, a one-way plug-in valve, a second energy accumulator, a third energy accumulator, a fourth energy accumulator, a second check valve, a third check valve, a fourth check valve, a high-pressure pipeline, a low-pressure pipeline, a travel switch and a control unit, wherein the lifting oil cylinderis positioned in the central pit of a valve block through the inner cylinder barrel and the outer cylinder barrel of the lifting oil cylinder and is fastened with a cylindrical boss; the bottom of theinner cylinder barrel is provided with a plurality of oil holes for communicating a lower hydraulic cavity communicates with an annular oil channel; an upper hydraulic cavity and the lower hydrauliccavity communicate through switching on the one-way plug-in valve; and the second plug-in valve, the third plug-in valve and the one-way plug-in valve are independently installed on installation positions between a first oil channel and a third oil channel, between a fourth oil channel and a sixth oil channel as well as between a second oil channel and a fifth oil channel on the valve block. The hydraulic system has the characteristics of large blow energy, small hydraulic oil reversing pressure fluctuation, a low hydraulic element damage rate, small hydraulic pipeline vibration, high piling efficiency and the like, and is suitable for the high-speed flowing and the timely reversing of hydraulic oil.

Owner:上海工程机械厂有限公司 +1

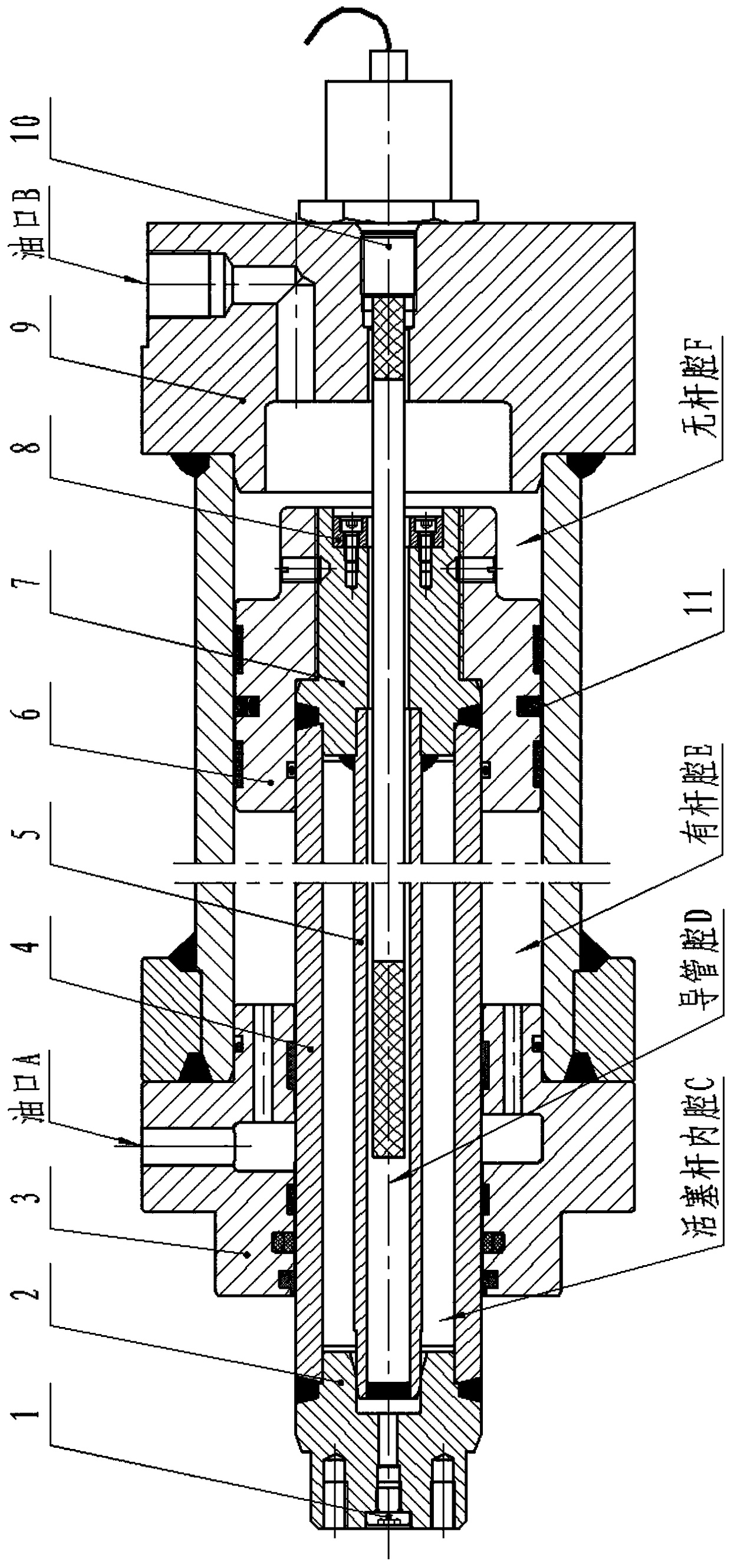

Multistage pressure cylinder and pressurization usage method and depressurization usage method thereof

ActiveCN103233941AImprove efficiencyReduce hydraulic shockFluid-pressure actuator componentsHydraulic cylinderMedicine

The invention relates to a multistage pressure cylinder. According to the multistage pressure cylinder, an ordinary pressure cylinder cavity B is divided into a cavity body B and a cavity body C through adding of a back rod of a piston and a secondary pressure cylinder, multiple pressure ratios which are convertible are provided, one of the cavity body B and the cavity body C, which is provided with the larger effective area, serves as a cavity body D, and the other one of the cavity body B and the cavity body C, which is provided with the smaller effective area, serves as a cavity body E. The pressurization process comprises two steps, firstly, pressure oil is input into the cavity body D, and a cavity body A outputs hydraulic oil with the pressure ratio to be D / A (an area ratio); and then the pressure oil is input into the cavity body D and the cavity body E simultaneously, and the cavity body A outputs the hydraulic oil with the pressure ratio to be (D+E) / A (an area ratio) to complete the pressurization process. During depressurization, firstly, a main hydraulic cylinder is communicated with the cavity body A of the multistage pressure cylinder, the cavity body D is communicated with an energy accumulator group, a liquid is charged into the energy accumulator group after the depressurization with the pressure reducing ratio of A / D (an area ratio) is achieved, and then the depressurization is conducted step by step. The multistage pressure cylinder is used in a hydraulic system of a hydraulic machine to achieve graded pressurization during pressurization, graded energy recovery is achieved stably through conversion of pressure ratios during depressurization, and hydraulic shocks are reduced.

Owner:FUJIAN HAIYUAN AUTOMATIC EQUIP CO LTD

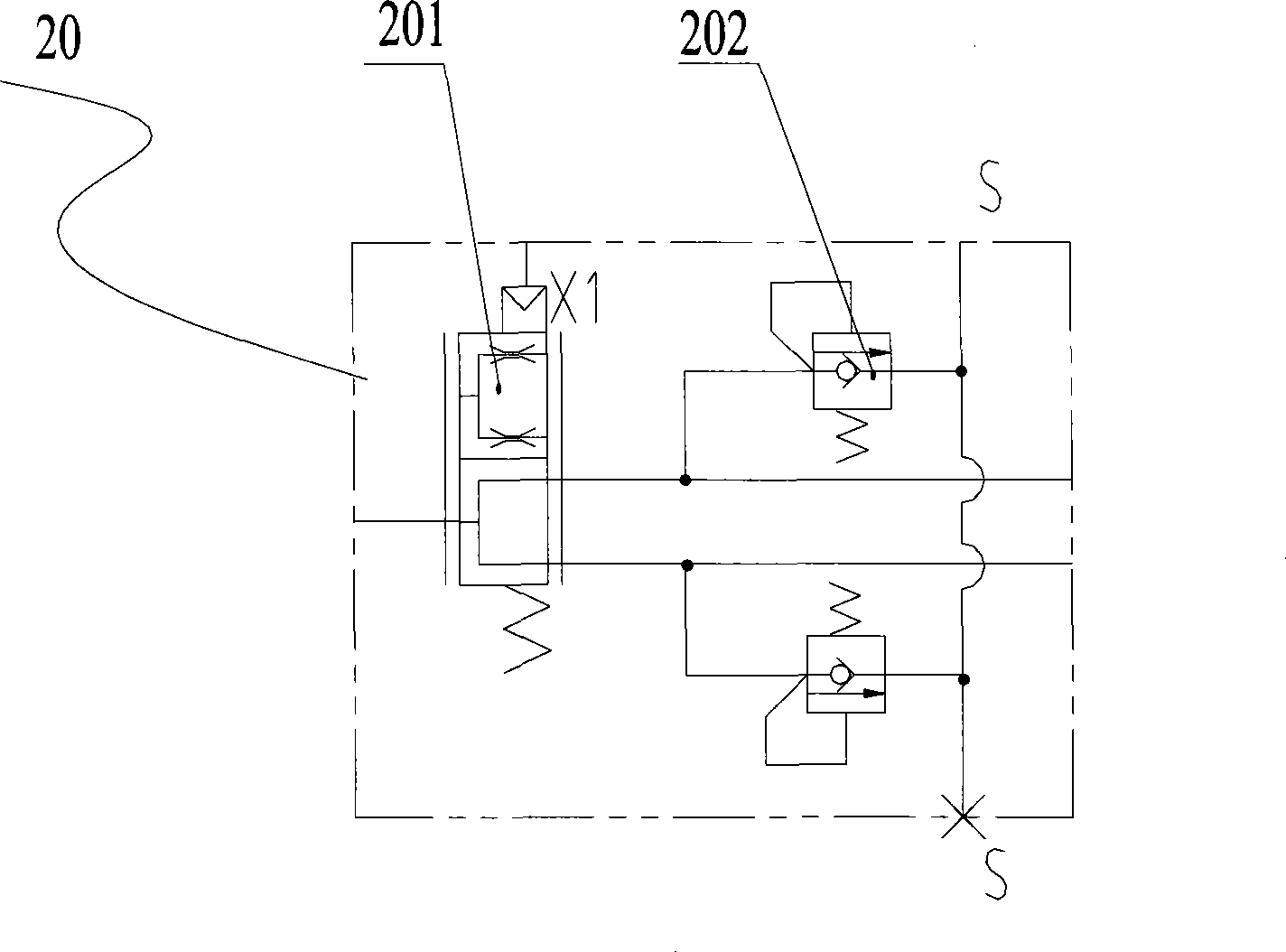

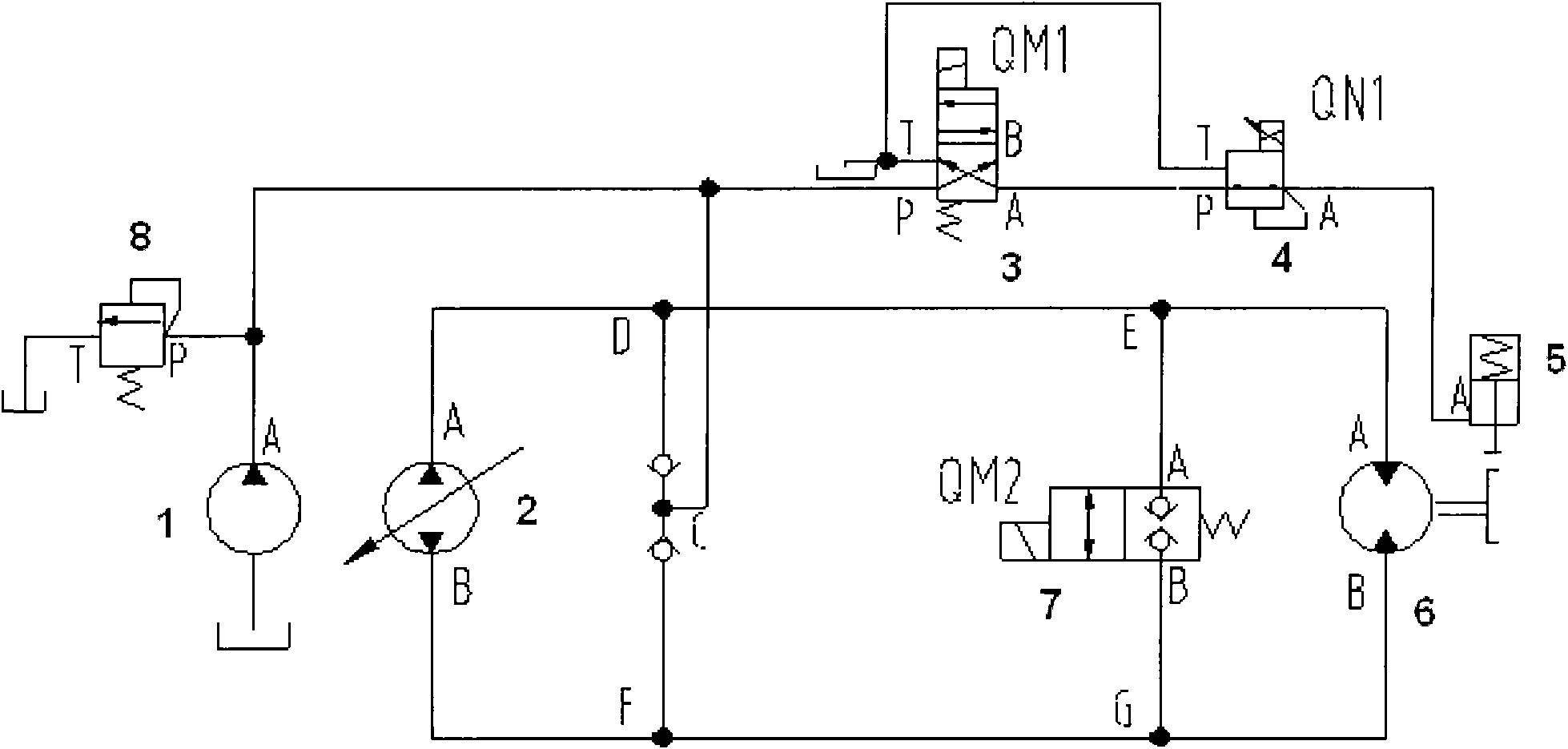

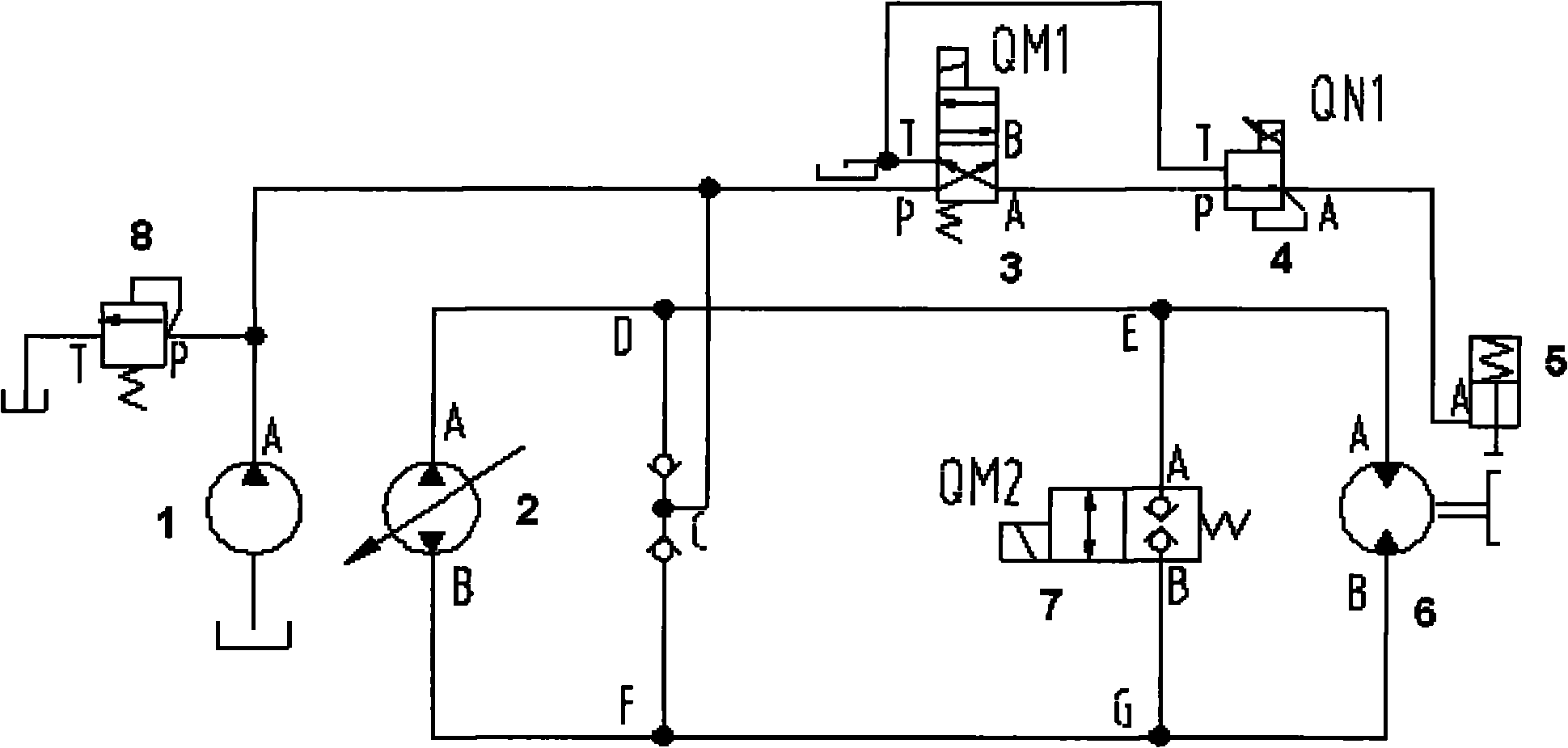

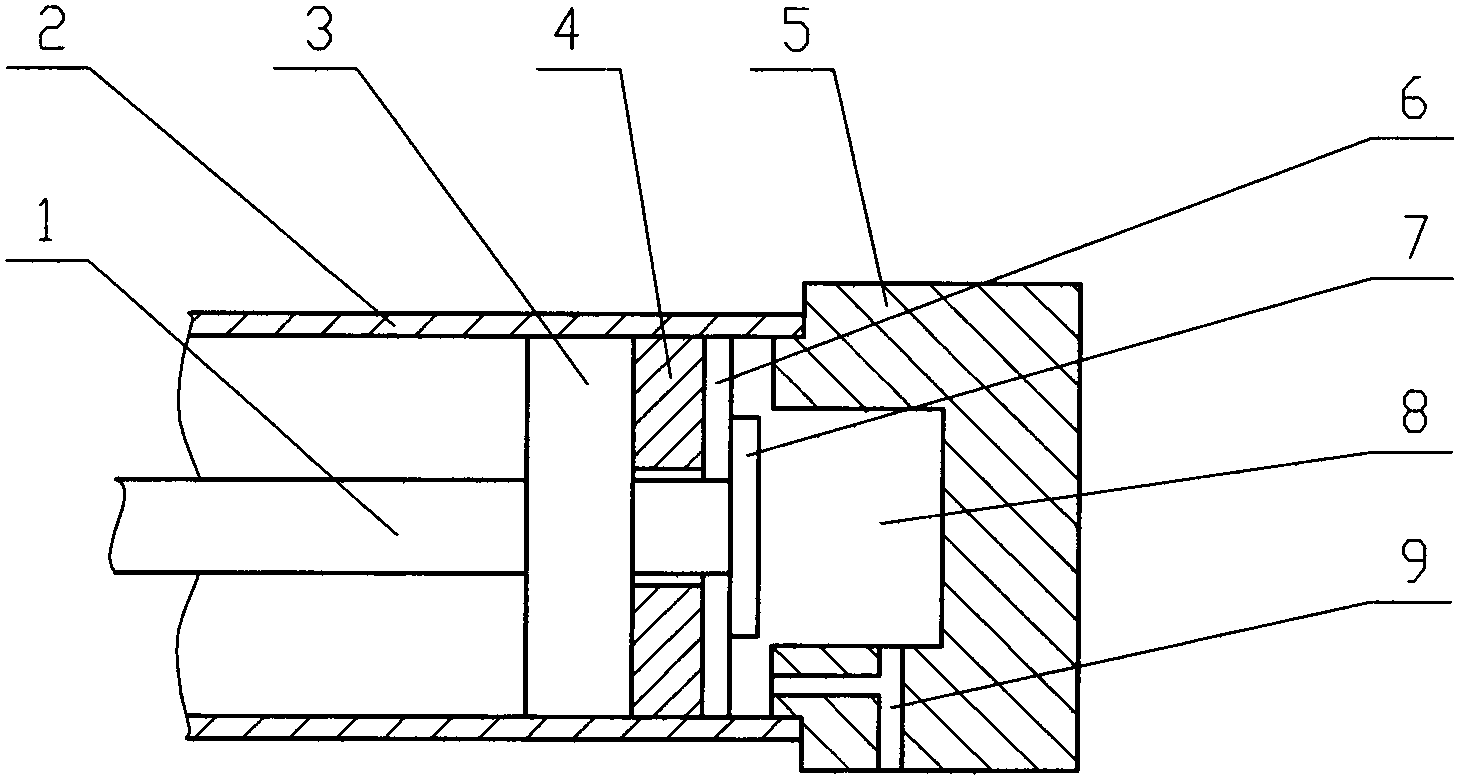

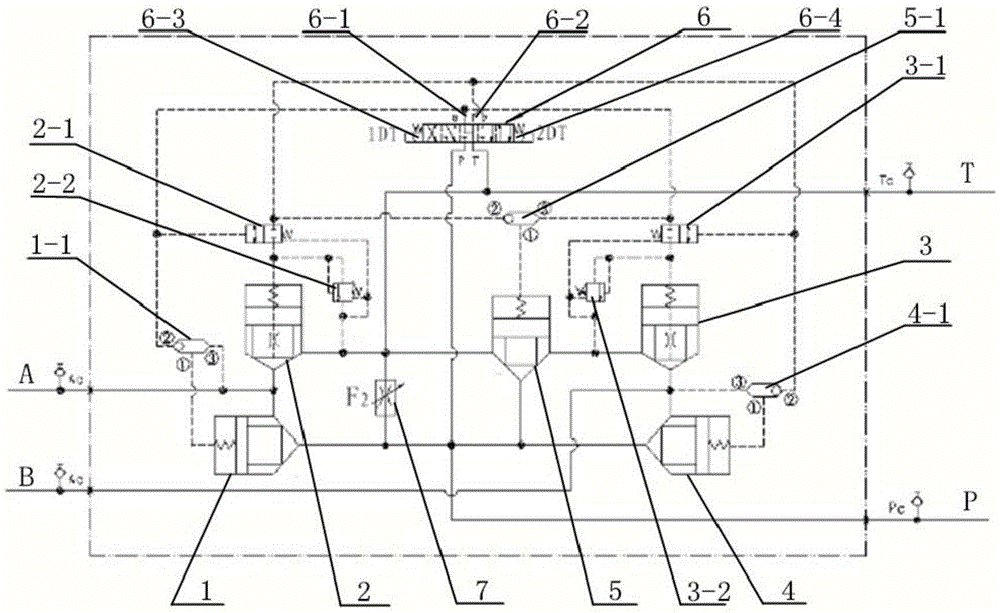

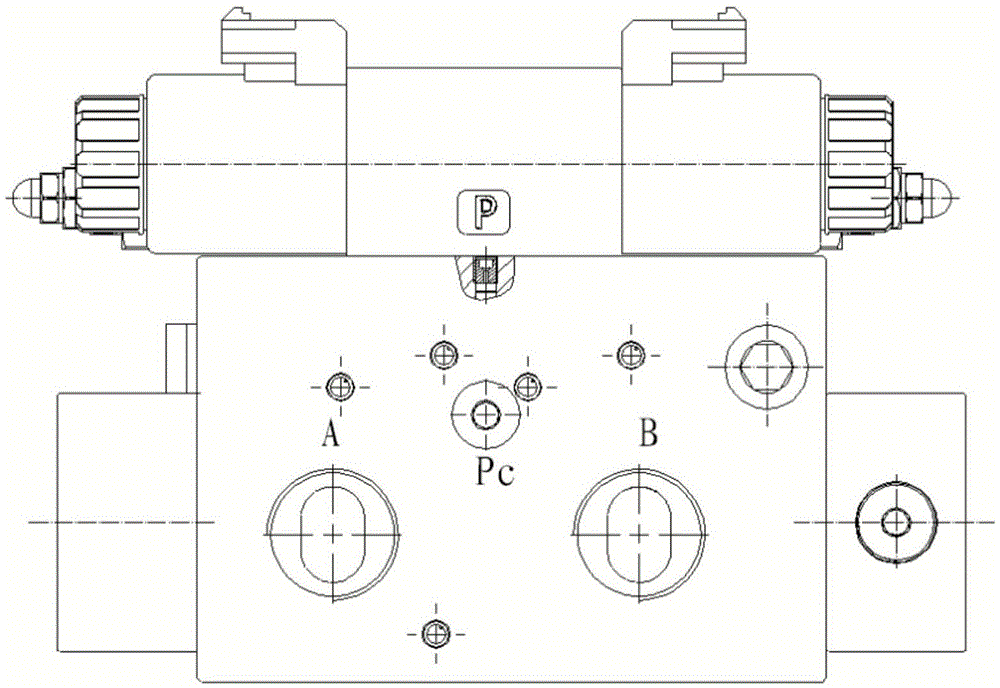

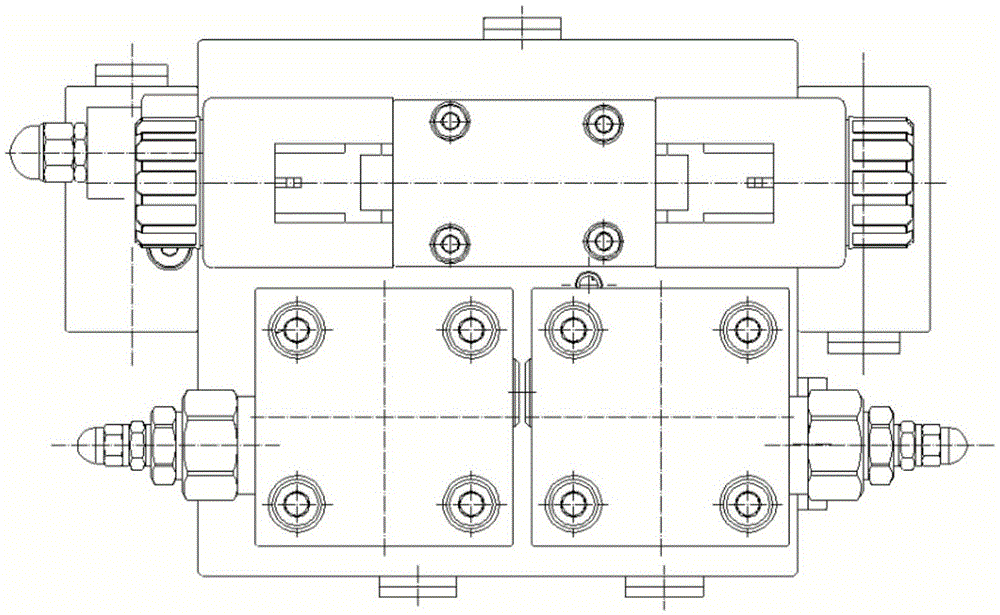

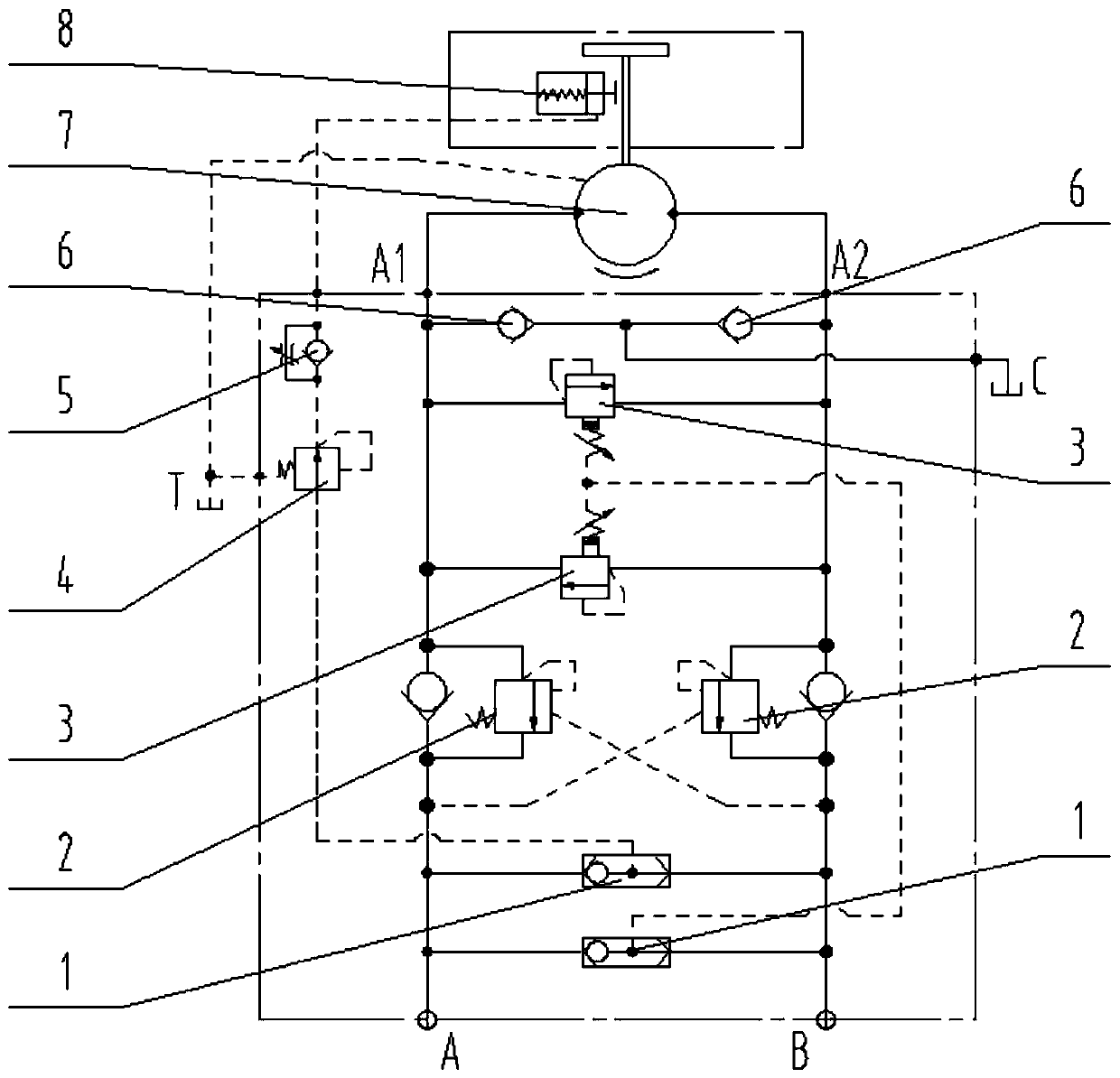

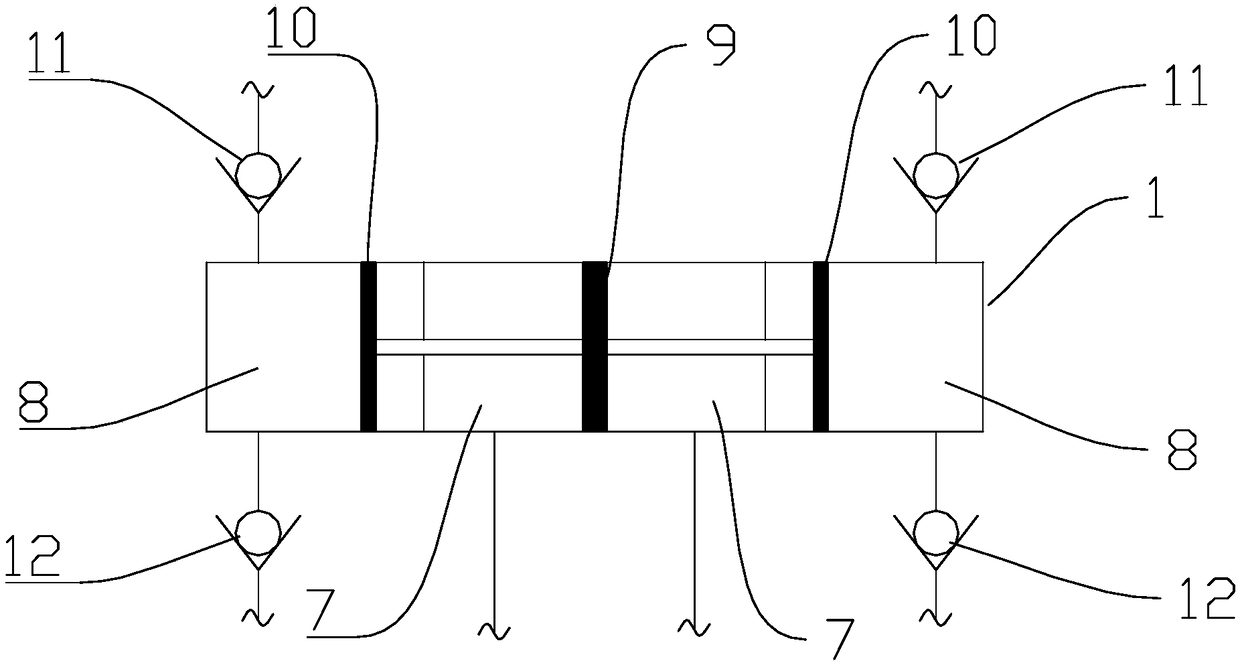

Two-way plug-in mounting type vibration control valve

ActiveCN103511375AReduce hydraulic shockReduce peak pressureServomotor componentsHydraulic motorLoop control

The invention relates to a two-way plug-in mounting type vibration control valve which comprises a valve body and an electric hydraulic control loop, wherein the valve body is inserted into a valve body inserting cavity, and the electric hydraulic control loop is composed of a two-way plug-in mounting type valve, a control cover plate, a two-position two-way hydraulic control direction valve, an overflow valve and the like and controls the operation of a hydraulic motor. The electric hydraulic control loop comprises a direction dividing loop controlling the hydraulic motor to rotate forward or reversely, a dividing loop controlling the hydraulic motor to stop rotating forward or reversely and a dividing loop providing overload protection for forward rotation or reverse rotation of the hydraulic motor. According to the two-way plug-in mounting type vibration control valve, the hydraulic shock can be relieved when a road roller starts vibrating, carries out amplitude of variation and stops vibrating, the peak pressure of a hydraulic system is reduced, and the working reliability and durability of a hydraulic element are improved. Due to the fact that the road roller automatically stops vibrating through hydraulic control, the vibrating stopping time is shortened, the probability that the whole road roller is resonant when the road roller stops vibrating is avoided, and the working quality of the road roller and the comfort of a driver are improved. The whole hydraulic system is simple in structure and small in number of elements, the control performance is improved, and cost is reduced.

Owner:PERMCOTIANJINHYDRAULIC INC

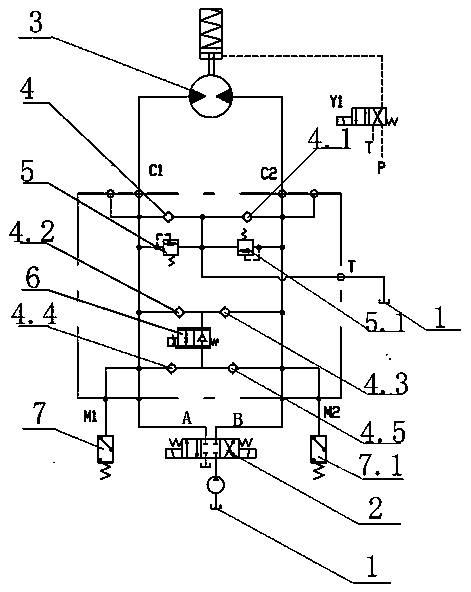

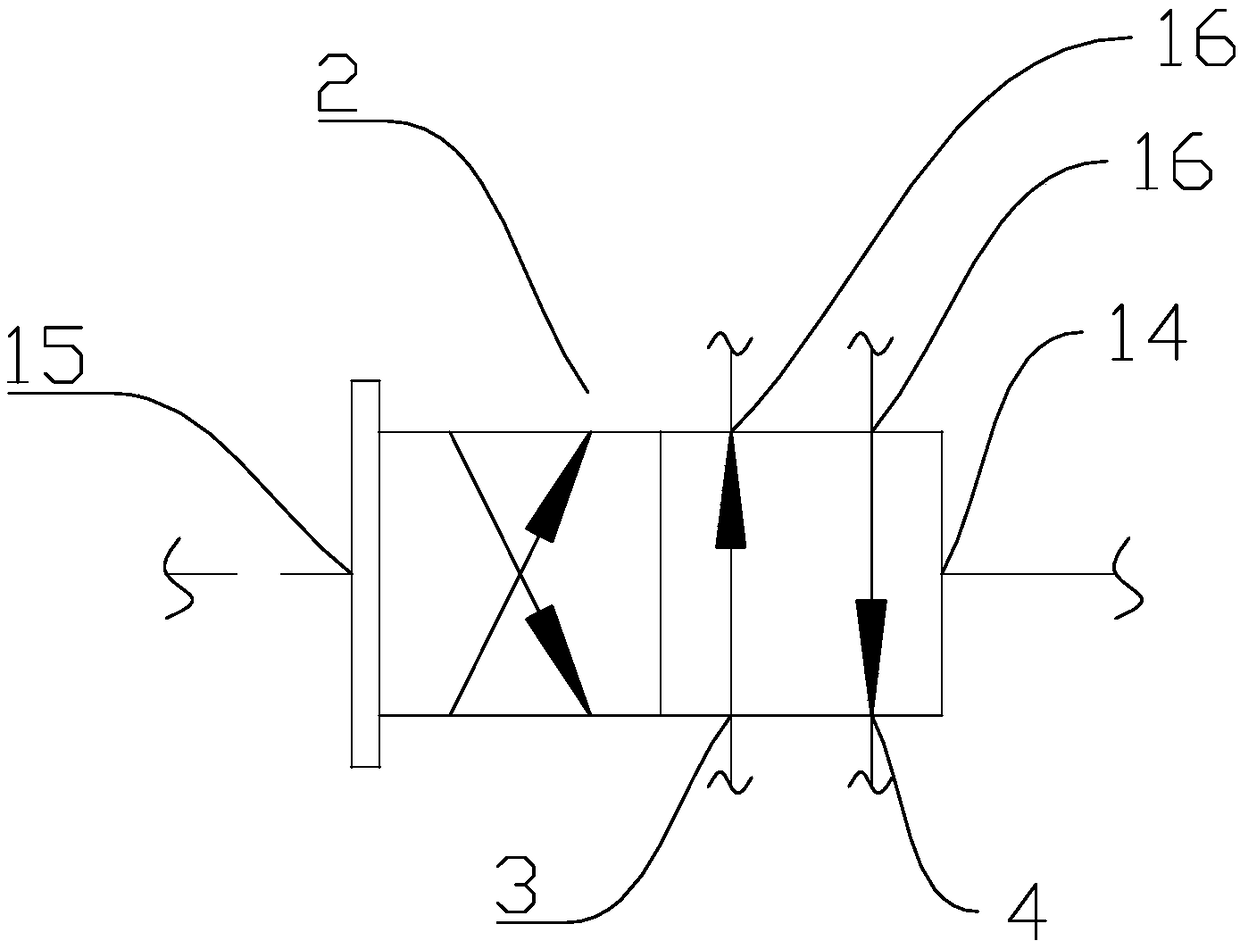

Intelligent buffering and overflowing device

The invention provides an intelligent buffering and overflowing device. A hydraulic oil tank (1) is communicated with a reversing valve (2) through a hydraulic pump; a first working oil opening A of a control valve is communicated with one end of a rotary motor (3) through a first executing oil opening C1; a fifth check valve (4.4), a third check valve (4.2), a first direct-acting type overflowing valve (5) and a first check valve (4) are connected between the first working oil opening A of the control valve and a pipeline of the rotary motor in parallel; the check valves and the direct-acting type overflowing valve are connected between a second working oil opening B of the control valve and the pipeline of the rotary motor by a second executing oil opening C2; an electric proportion flow control valve (6) is connected among the four check valves in parallel; a main oil pipeline which is connected between the check valves and the direct-acting type overflowing valve in parallel is in pipeline communication with the hydraulic oil tank through an oil supplementing opening T. The hydraulic impact when a rotary drilling rig does rotary movement is reduced and the getting-on shaking amount when the rotary drilling rig rotates is reduced; the stability of a main engine is improved and the service life of related components is prolonged.

Owner:XUZHOU XUGONG FOUND CONSTR MACHINERY

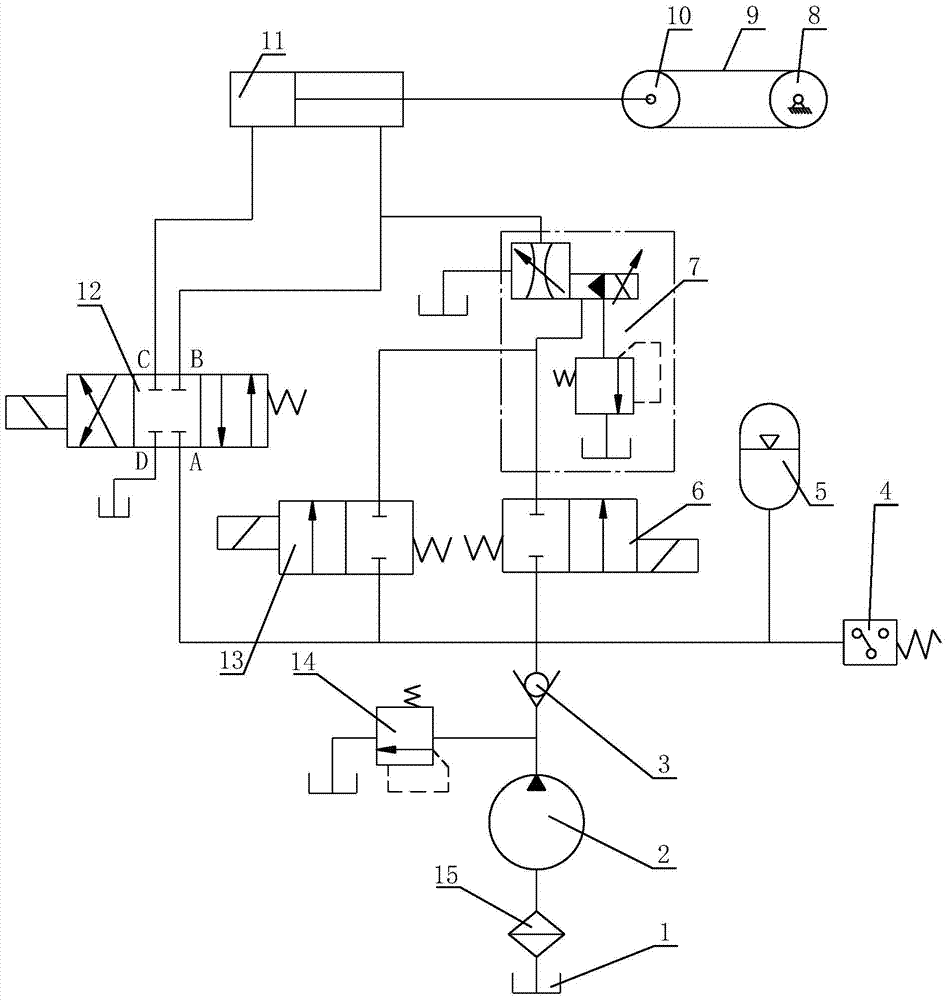

Hydraulic system for automatic tensioning device of belt pulley

InactiveCN104514854AReasonable designAchieving Adaptive TensioningServomotor componentsServomotorsHydraulic cylinderFuel tank

The invention discloses a hydraulic system for an automatic tensioning device of a belt pulley. The hydraulic system comprises a hydraulic cylinder, a hydraulic pump, an electromagnetic proportion valve block, an energy storing device and a pressure relay; an oil outlet of the hydraulic pump respectively communicates with the energy storing device and a first working end port of a second directional valve; a second working end port of the second directional valve communicates with a rod port of the hydraulic cylinder; a head port of the hydraulic cylinder communicates with a third working end port of the second directional valve; a fourth working end port of the second directional valve communicates with an oil tank; the rod port of the hydraulic cylinder communicates with the oil outlet of the hydraulic pump through the electromagnetic proportion valve block, a first directional valve and a third directional valve in a sequence, wherein the first directional valve and the third directional valve are connected in parallel; a pressure relay is mounted at an end port of the energy storing device. The hydraulic system for the automatic tensioning device of the belt pulley has the characteristics of being reasonable in design, capable of adaptive tensioning, high in adaptability and stability, high in automation degree, high in intelligent degree, long in service life, and wide in applicable scope.

Owner:XIAN ZHONGZHI HUIZE PHOTOELECTRIC TECH

Loader four-pump quantitative confluence hydraulic system

ActiveCN103711172AReduce hydraulic shockPrevent overflowSoil-shifting machines/dredgersOil pressureEngineering

A loader four-pump quantitative confluence hydraulic system comprises an auxiliary pump system. The auxiliary pump system comprises a fist flow switching valve and a second flow switching valve which are used for switching the pressure oil of an auxiliary pump from supplying oil to a steering system or an operating system. The oil outlet of a brake pump is connected to a third flow switching valve used for switching the pressure oil of the brake pump from supplying oil to a full hydraulic brake unit or supplying control oil pressure used for controlling reversing switching to the first flow switching valve. The steering system is provided with a shuttle valve; two inlets of the shuttle valve are connected to two oil outlets of a steering gear and are connected to the second flow switching valve and the third flow switching valve so as to pushing the second flow switching valve and the third flow switching valve to switch during steering. The loader four-pump quantitative confluence hydraulic system has the advantages the multiple pump confluence technology is adopted, displacement of the steering pump and operating pump is reduced, and energy saving is realized; by means of a direct pump unloading manner, hydraulic impact is reduced at the end of the cylinder stroke, and meanwhile, high-pressure large-amount overflow can be avoided.

Owner:GUANGXI LIUGONG MASCH CO LTD

Hydraulic buffer

InactiveCN103851022AImprove buffering effectReduce hydraulic shockFluid-pressure actuatorsHydraulic cylinderEngineering

The invention relates to a hydraulic buffer. The hydraulic buffer comprises a hydraulic cylinder, a piston and a cylinder cover fixedly connected to the hydraulic cylinder, the piston is fixedly connected to a piston rod, wherein the cylinder cover comprises a cylindrical cavity and a throttle orifice, the throttle orifice is communicated with the cavity, the piston is fixedly connected to a buffer ring; the buffer ring is fixedly connected to a blocking ring; the blocking ring is in sliding connection with the piston rod; the end part of the piston rod is fixedly connected to a baffle; the diameter of an outer ring of the baffle is smaller than the inside diameter of the hydraulic cavity. Compared with the traditional throttle buffer of a hydraulic cylinder, the hydraulic buffer provided by the invention adopts a compression structure of the buffer ring and the throttling and buffer actions of the throttle orifice, and has the advantages of good buffer effect, small hydraulic impact and stable running.

Owner:WUXI XIEXIN PNEUMATIC

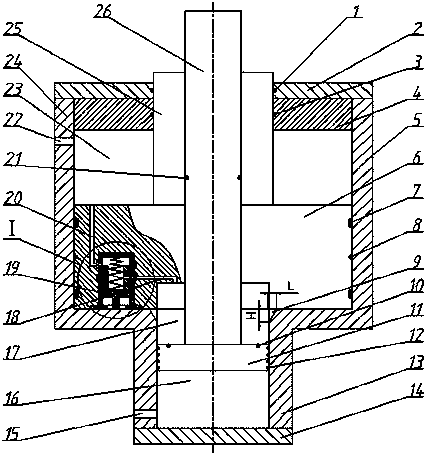

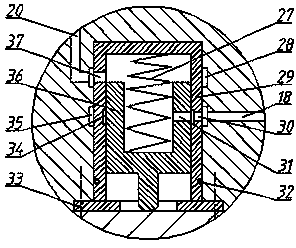

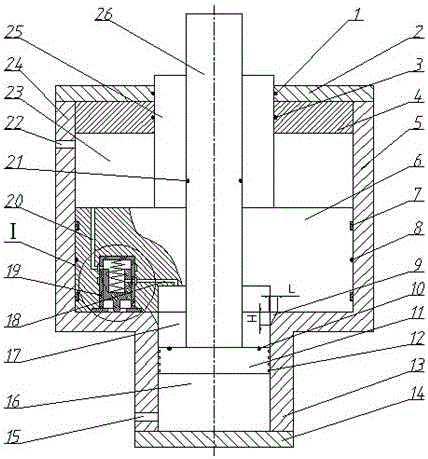

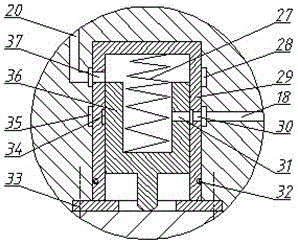

Variable speed double-piston series-connection hydraulic cylinder

InactiveCN103867525AFast low load movementCut offFluid-pressure actuatorsHydraulic cylinderEngineering

The invention particularly relates to a variable speed double-piston series-connection hydraulic cylinder. According to the technical scheme, the end of a large piston rod (25) extends out of a guide sleeve (4) and a large end cap (2), the other side of a large piston (6) is concentrically provided with a small piston hole, the aperture of the small piston hole is equal to the outer diameter of a small piston (11), the depth of the small piston hole is equal to the thickness of the small piston (11), the large piston (6) and the large piston rod (25) are concentrically provided with small piston rod through holes, and a small piston rod (26) penetrates through the small piston rod through holes. The side face of the large piston (6) on the same side with the small piston holes is provided with a valve base hole, the hole wall of the valve base hole is sequentially provided with a first annular oil groove (28) and a second annular oil groove (35) from inside to outside, the first annular oil groove (28) is communicated with a rod cavity (23) of the large piston rod through a first oil channel (20), the second annular oil groove (35) is communicated with the small piston hole of the large piston (6) through a second oil channel (18), and a quick stop valve (19) is fixed to the inside of the valve base hole. The variable speed double-piston series hydraulic cylinder has the advantages of being simple in switch, saving energy, lowering cost, and being convenient to maintain and stable in switch process.

Owner:WUHAN UNIV OF SCI & TECH

Novel two-way insert type oscillation control valve

InactiveCN105545857AReduce hydraulic shockImprove job qualityOperating means/releasing devices for valvesServomotor componentsVibration controlResonance

The invention belongs to the field of two-way insert type oscillation control valves, and particularly relates to a novel two-way insert type oscillation control valve which comprises a valve body, a main loop, an oscillation stop branch loop and a no-load oil return branch loop. The valve body is provided with an insert cavity, an oil inlet connector, an oil return connector, a first working interface and a second working interface. The main loop is inserted in the insert cavity of the valve body, and comprises a pilot direction control loop composed of five two-way insert valves and a three-position four-way electromagnetic reversing valve. The oscillation stop branch loop comprises a control large oscillation stop and a control small oscillation stop. When an engine idles or a road roller does not oscillate, the no-load oil return of a hydraulic pump is achieved through the no-load oil return branch loop. An adjustable throttling valve is arranged between the oil inlet interface and the oil return interface and on the valve and is used for adjusting the flow entering a motor. The valve has the advantages that hydraulic impact during oscillation of the road roller is reduced, oscillation stop time is shortened, resonance of the whole machine is avoided, two oscillation amplitudes can be switched, and oscillation frequency can be adjusted within a certain range.

Owner:PERMCOTIANJINHYDRAULIC INC

Oil cylinder for built-in displacement sensor

PendingCN108488140AReduce processing difficultyGuaranteed processing reliabilityFluid-pressure actuatorsPiston rodPetroleum engineering

The invention relates to an oil cylinder for a built-in displacement sensor. The displacement sensor is arranged in a cavity with a piston rod, and an induction rod on the displacement sensor penetrates the cavity with the piston rod and a cavity with a piston rod; the partial piston rod body is located in a tube cavity; the outer diameter of the induction rod is smaller than the inner diameter ofthe tube cavity, so that hydraulic oil can enter the tube cavity through a cavity clearance between the induction rod and a tube; a cylinder barrel and a guide sleeve are each provided with an oil hole, and the hydraulic oil enters the cavity through the oil hole in the cylinder barrel or the oil hole in the guide sleeve; a piston component is pushed by the hydraulic oil in the cavity to move axially, and cursor magnetic rings are driven by the piston component to move; and the moving signals of the cursor magnetic rings are transmitted to the displacement sensor so that the moving distance of the piston component is obtained. The oil cylinder is high in safety, and the processing of the piston rod is simple; the tube can be deformed freely, and the disadvantages during installation of anexisting sensor are overcome.

Owner:陕西昆仑机械装备制造有限责任公司

Porous buffer of hydraulic cylinder

InactiveCN103851026AImprove securityImprove buffering effectFluid-pressure actuatorsHydraulic cylinderEngineering

The invention relates to a porous buffer of a hydraulic cylinder. The porous buffer of the hydraulic cylinder comprises a hydraulic cylinder, a piston and a cylinder cover fixedly connected to the hydraulic cylinder, and the piston is fixedly connected to a piston rod, wherein the side wall of the hydraulic cylinder comprises a bent throttle orifice and a plurality of pores, and the pores are respectively communicated with an inner cavity of the hydraulic cylinder and the throttle orifice. Compared with the traditional hydraulic cylinder annular throttle buffer, the porous buffer of the hydraulic cylinder provided by the invention has the advantages of good safety, good buffer effect, small hydraulic impact and stable running.

Owner:WUXI XIEXIN PNEUMATIC

Quick pressurizing injection device of hydraulic press

InactiveCN102773451AHigh degree of integrationDoes not affect control accuracyInlet channelDie casting

The invention discloses a quick pressurizing injection device of a hydraulic press. The quick pressurizing injection device solves technical problems of complicated structure and low response speed of an existing injection device. The quick pressurizing injection device of the hydraulic press comprises an injection cylinder, a pressurizing cylinder and a hydraulic driving mechanism, an injection piston is arranged in the injection cylinder, a pressurizing piston is arranged in the pressurizing cylinder, the injection cylinder and the pressurizing cylinder are integrally molded, an oil inlet channel is arranged in the pressurizing piston, a rodless cavity of the injection cylinder is communicated with a rodless cavity of the pressurizing cylinder via the oil inlet channel, and a one-way control valve for controlling opening or closing of the oil inlet channel is arranged in the oil inlet channel. The quick pressurizing injection device in an embodiment of the invention is mainly used for hydraulic presses and die-casting machines, and die-casting molding of parts such as automobile engines is realized.

Owner:HUZHOU MACHINE TOOL WORKS

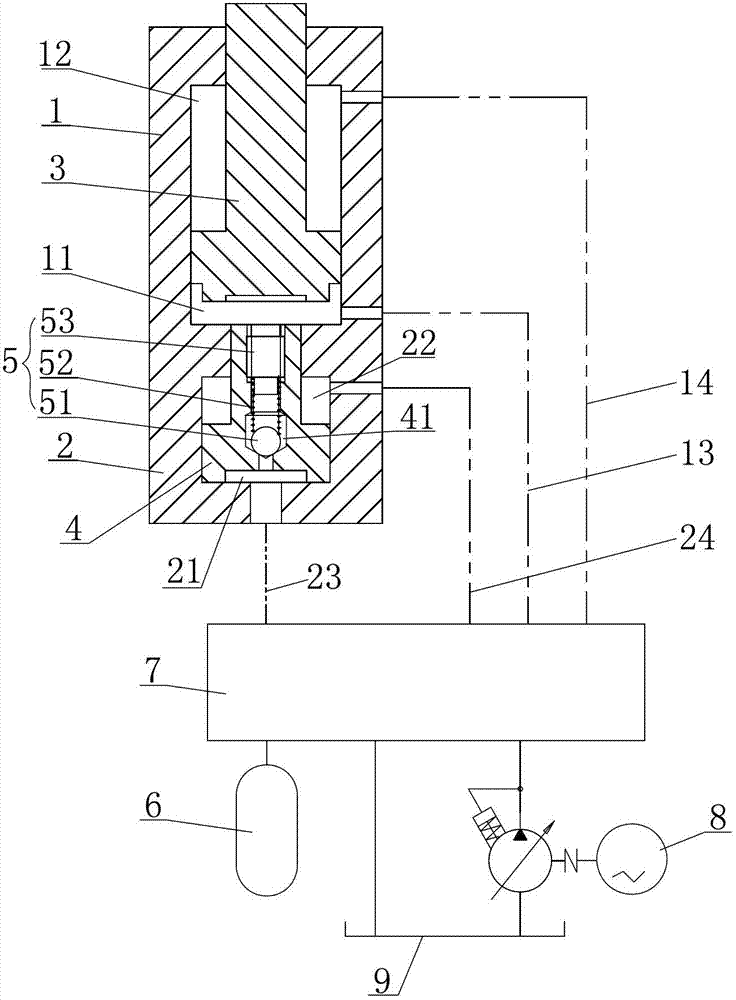

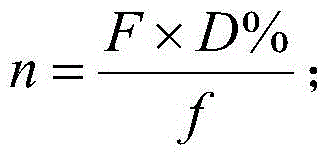

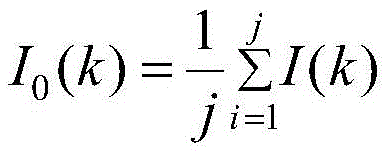

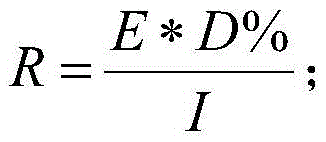

Hydraulic gear shifting oil pressure control method based on proportional electromagnetic valve

InactiveCN105673833AReduce biasEasy to callGearing controlProportion integration differentiationAverage current

The invention provides a hydraulic gear shifting oil pressure control method based on a proportional electromagnetic valve. The hydraulic gear shifting oil pressure control method based on the proportional electromagnetic valve comprises the steps that firstly, no temperature sensor is needed, and the equivalent inductance Ld of the proportional electromagnetic valve in the working process is measured directly; then a relation curve of the output oil pressure P, the average current I and the equivalent inductance Ld of the proportional electromagnetic valve at various oil temperatures is obtained, and obtained data are stored into a database, so that calling in the control process is facilitated; and then the control process is divided into s stages, feedforward control is conducted on the proportional electromagnetic valve in all stages of the control process through the relation curve of the output oil pressure P, the average current I and the equivalent inductance Ld in the database, and proportion integration differentiation (PID) feedback control is conducted after the feedforward control is finished, so that the difference between the actual output oil pressure and the ideal oil pressure in all stages of the control process is decreased, and thus the oil pressure impact in the hydraulic gear shifting process is reduced.

Owner:TSINGHUA UNIV

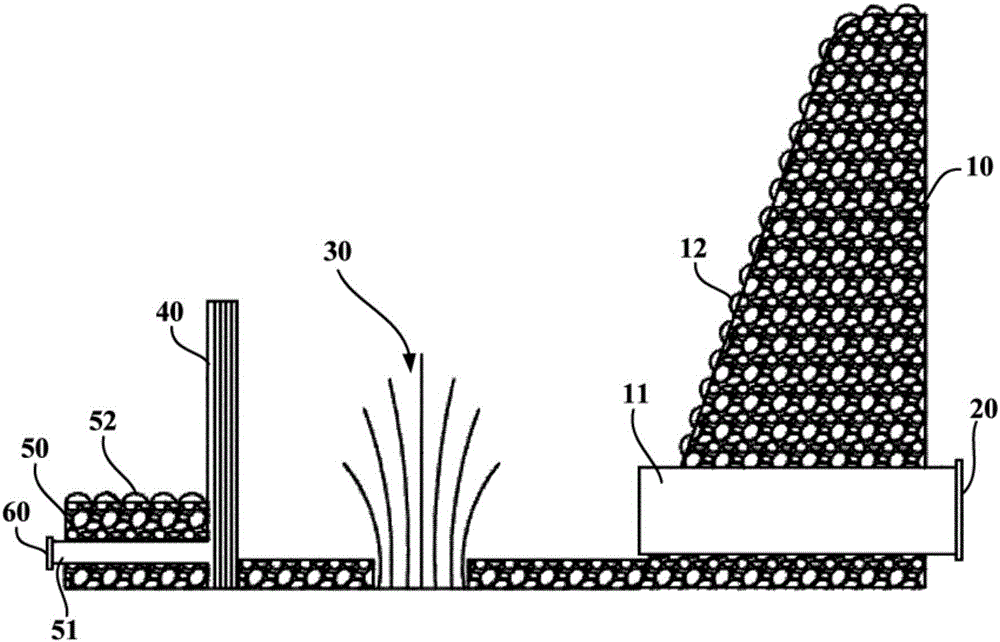

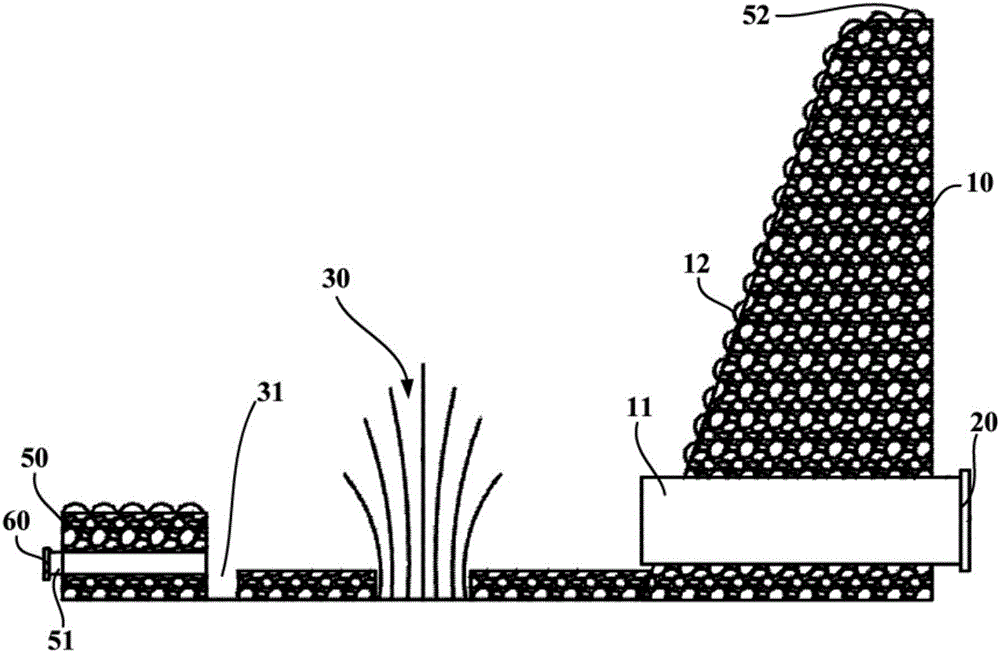

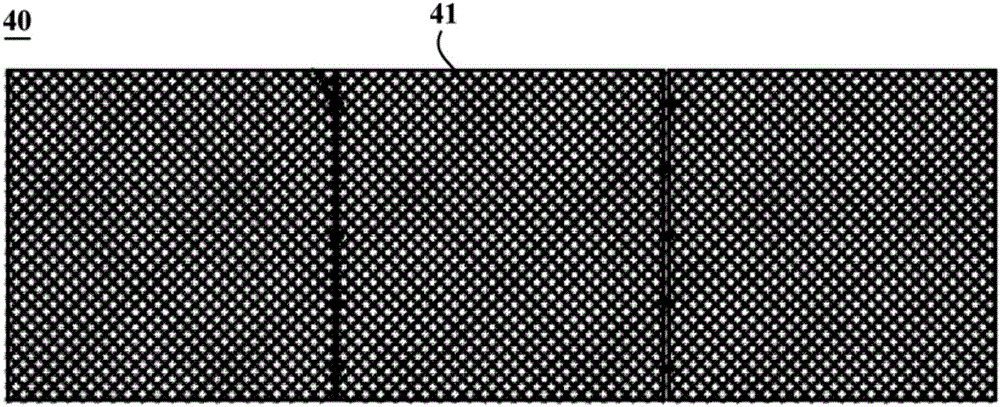

Dam body device for treatment of urban artificial watercourse

ActiveCN106677127AImprove exchange capacityIncrease dissolved oxygenBarrages/weirsDamsFiberActivated carbon

The invention provides a dam body device for treatment of an urban artificial watercourse. The dam body device comprises a first dam body, a first plugging device, an aquatic plant planting zone and a blocking device, wherein the first dam body extends in the width direction of the urban artificial watercourse; the lower part of the first dam body is provided with a first drainage channel; the side surface, facing the downstream part of the urban artificial watercourse, of the first dam body is a slope surface; a plurality of first salient points are arranged on the slope surface; the first plugging device is arranged to conduct or cut off the first drainage channel; the aquatic plant planting zone is arranged at the downstream part of the first dam body; the aquatic plant planting zone is arranged for planting aquatic plants; the blocking device is arranged at the downstream part of the aquatic plant planting zone, and is provided with at least one blocking unit; and the blocking units are provided with first fish screens, activated carbon fiber filter cloth, chitosan fiber filter cloth and second fish screens which are sequentially arranged in the water flowing direction. The dam body device is simple in structure, can isolate algae floating objects like blue-green algae in a water body, can block and remove parts of organic substances and heavy metals, and has an excellent treatment effect.

Owner:YIKANG TECH CO LTD

Hydraulic rotation control system of dynamic compaction machine

PendingCN111173788AEnsure safetyReduce failureServomotor componentsServomotorsPressure riseShuttle valve

The invention discloses a hydraulic rotation control system of a dynamic compaction machine. The system comprises a two-way quantitative hydraulic motor, a shuttle valve, a balance valve and a cushionvalve. Two oil inlets of the two-way quantitative hydraulic motor are each connected with one oil supply line. The shuttle valve, the balance valve and the cushion valve are arranged between the twooil supply lines in a connected manner. The shuttle valve is used to supply oil to the cushion valve. An oil inlet and an oil outlet of the cushion valve are located on the two oil supply lines respectively, and are located between the balance valve and the two-way quantitative hydraulic motor. After rotation operation stops, the balance valve plays a role in hydraulic braking; after rotation stops suddenly, because of the inertia of the motor, the pressure of an oil return chamber rises, and when the pressure rises to a set pressure, because the cushion valve loses balance at the moment, a higher chamber and a lower chamber communicate with each other, a peak pressure will disappear, and shaking impact of a complete machine will not happen; and additionally, compared with a traditional overload valve or an overload time delay valve system, the cushion valve directly adopts rotation pressure control, and thereby being capable of meeting the requirement for control in time, and then theresponse speed is high.

Owner:HANGCHA GRP +1

A speed-changing double-piston series hydraulic cylinder

InactiveCN103867525BFast low load movementCut offFluid-pressure actuatorsHydraulic cylinderMechanical engineering

The invention particularly relates to a variable speed double-piston series-connection hydraulic cylinder. According to the technical scheme, the end of a large piston rod (25) extends out of a guide sleeve (4) and a large end cap (2), the other side of a large piston (6) is concentrically provided with a small piston hole, the aperture of the small piston hole is equal to the outer diameter of a small piston (11), the depth of the small piston hole is equal to the thickness of the small piston (11), the large piston (6) and the large piston rod (25) are concentrically provided with small piston rod through holes, and a small piston rod (26) penetrates through the small piston rod through holes. The side face of the large piston (6) on the same side with the small piston holes is provided with a valve base hole, the hole wall of the valve base hole is sequentially provided with a first annular oil groove (28) and a second annular oil groove (35) from inside to outside, the first annular oil groove (28) is communicated with a rod cavity (23) of the large piston rod through a first oil channel (20), the second annular oil groove (35) is communicated with the small piston hole of the large piston (6) through a second oil channel (18), and a quick stop valve (19) is fixed to the inside of the valve base hole. The variable speed double-piston series hydraulic cylinder has the advantages of being simple in switch, saving energy, lowering cost, and being convenient to maintain and stable in switch process.

Owner:WUHAN UNIV OF SCI & TECH

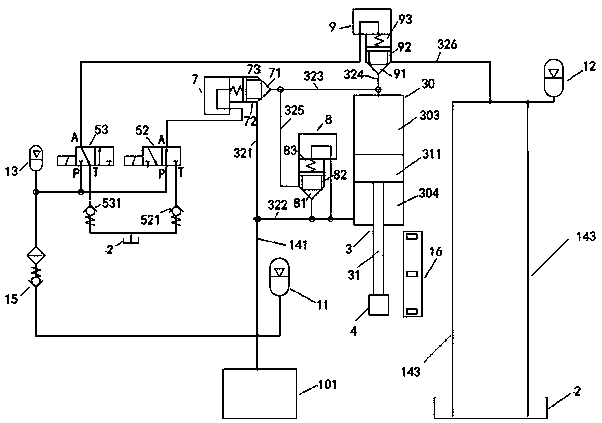

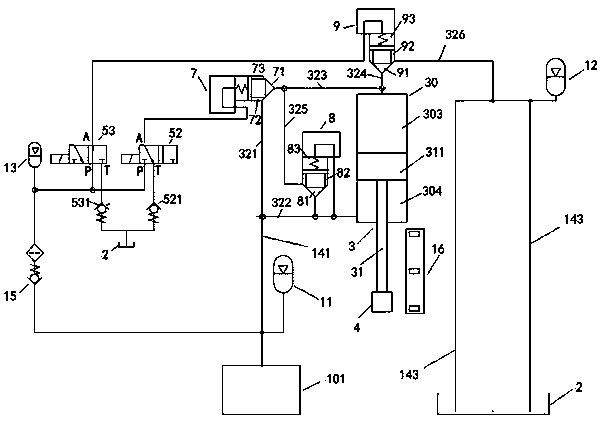

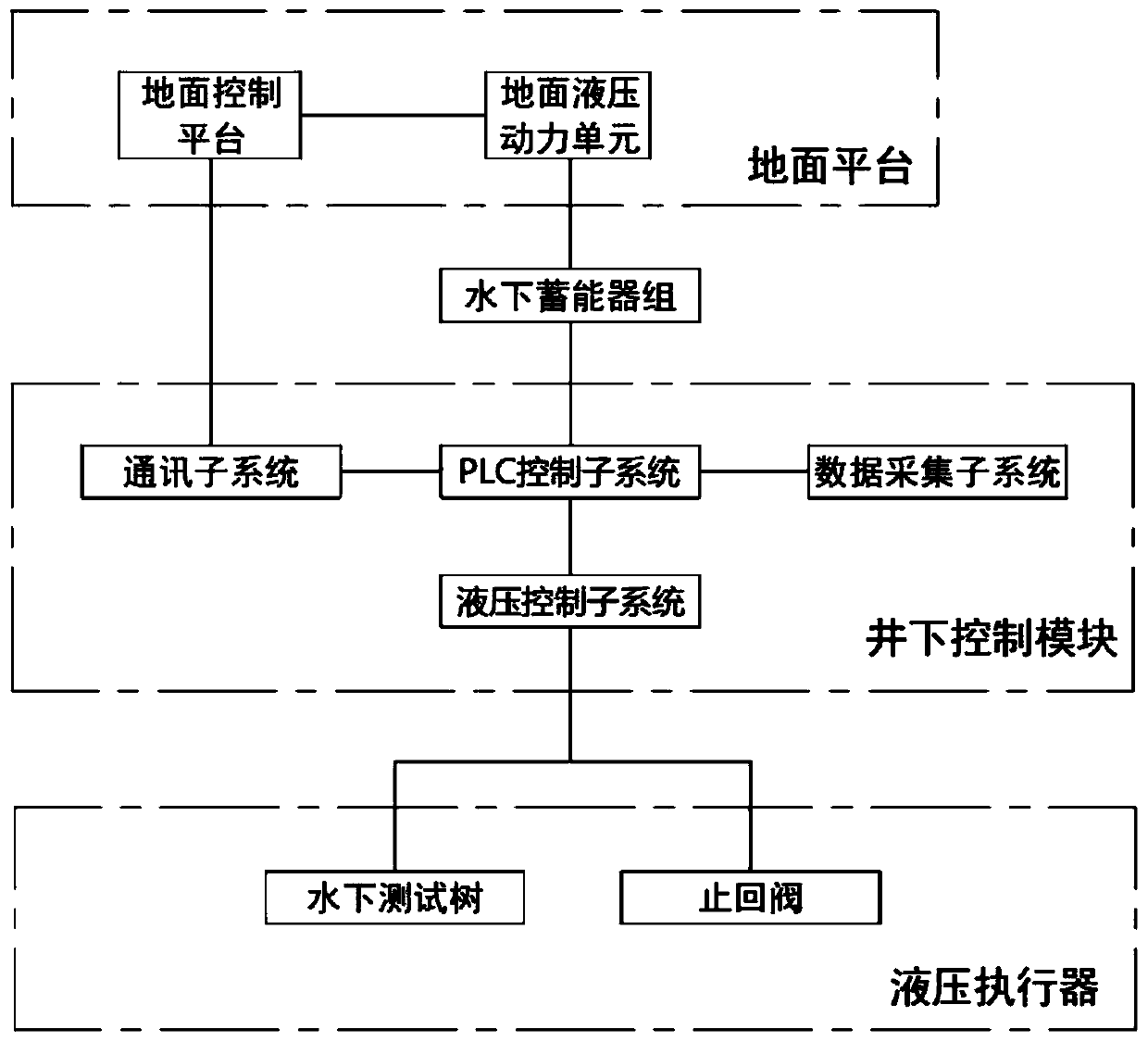

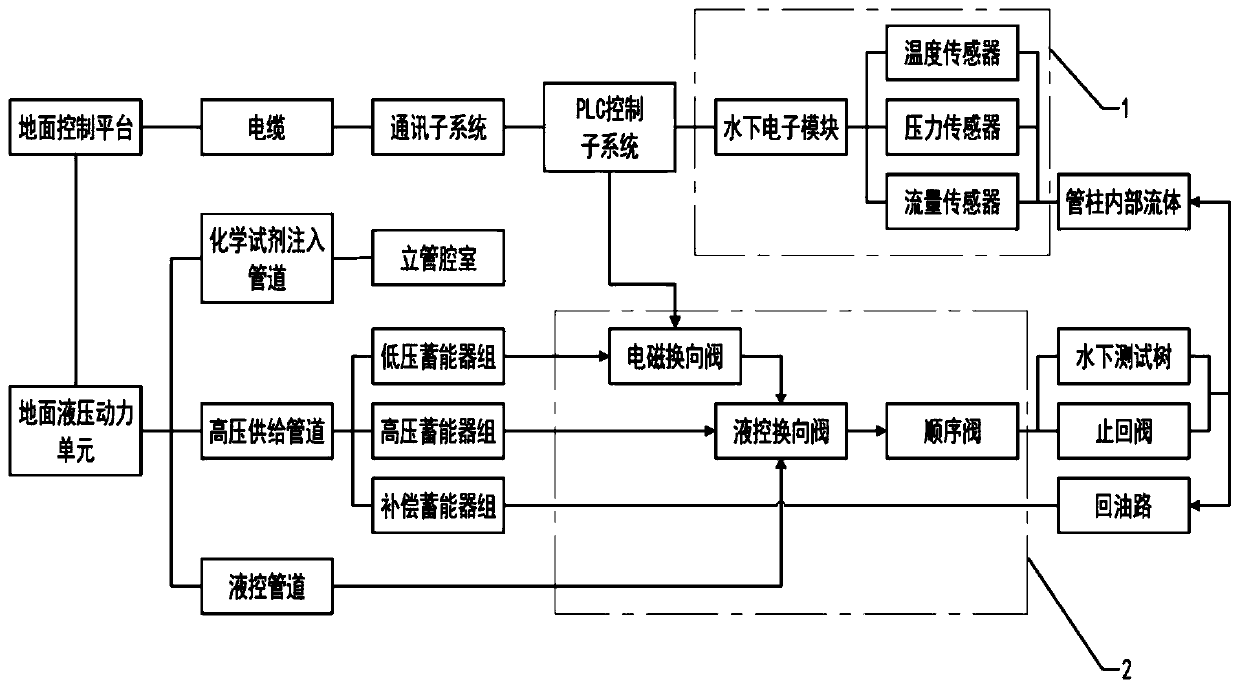

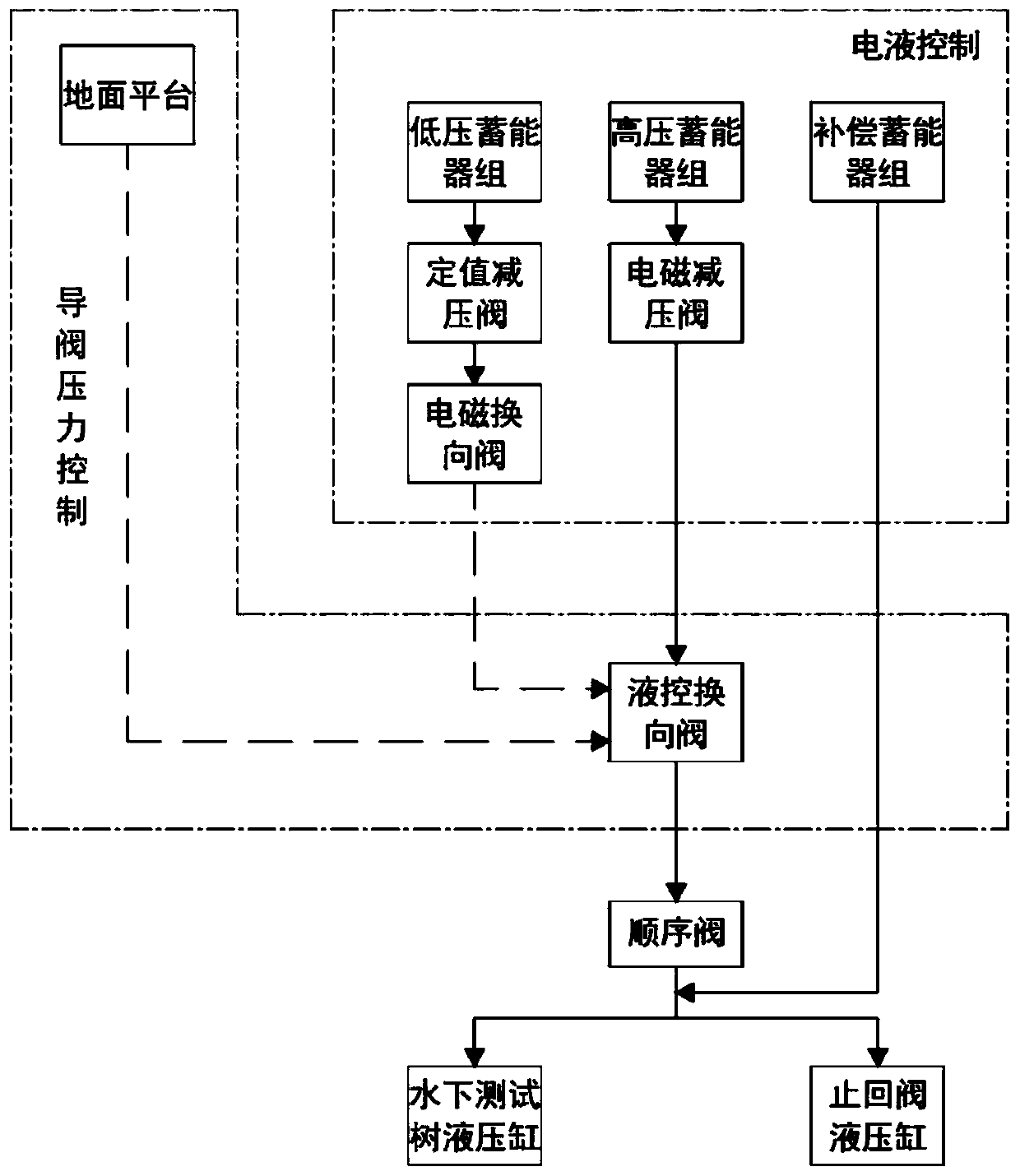

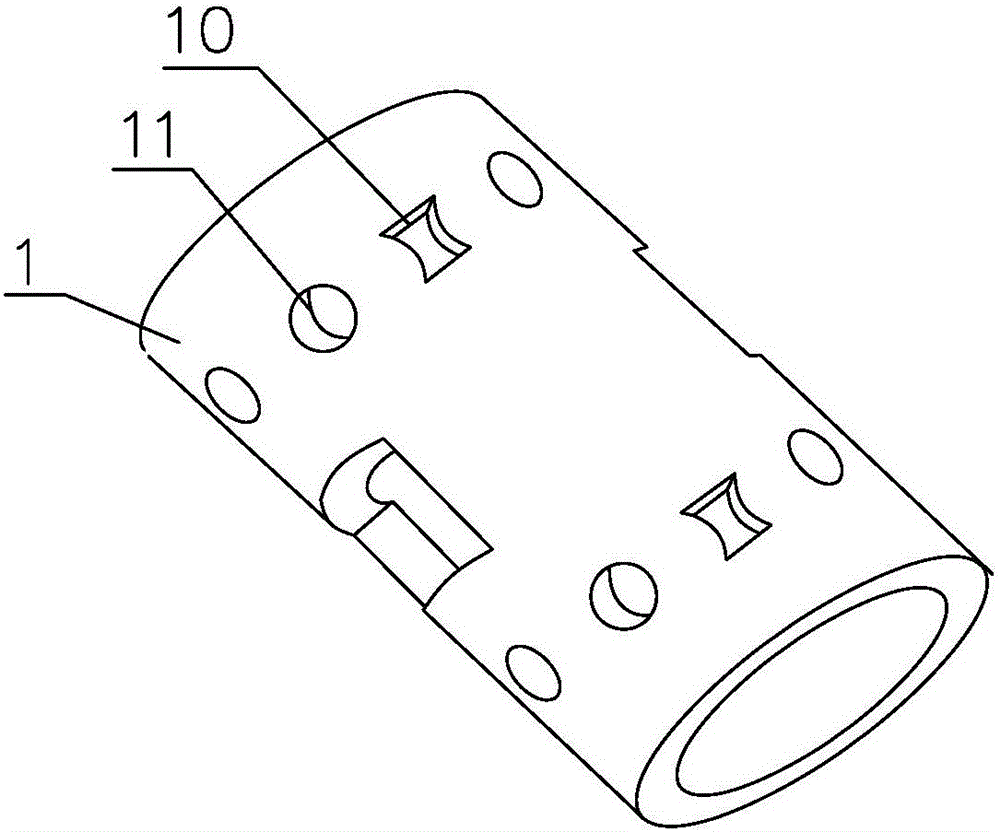

Compound electro-hydraulic downhole control system of deepwater test tubular column safety device

PendingCN110630221AAchieve conductionReduce distanceConstructionsBorehole/well accessoriesControl systemElectro hydraulic

The invention discloses a compound electro-hydraulic downhole control system of a deepwater test tubular column safety device. The compound electro-hydraulic downhole control system comprises a groundplatform, an umbilical cable, an underwater energy accumulator group, a downhole control module and a hydraulic actuator. Through sensor devices installed on the interface circuit and control circuitof the hydraulic actuator, environmental parameter data such as the pressure are collected, the ground platform analyzes and compares the collected data with a database, and then sends out control command, the control command is transmitted to the downhole control module through the umbilical cable, and the hydraulic actuator is controlled. According to the compound electro-hydraulic downhole control system, two modes of electro-hydraulic control and pilot valve pressure control are achieved, the reliability of the deepwater test tubular column safety device is effectively improved, the characteristics of fast response, real-time monitoring, high flexibility and the like are achieved, and the deepwater test safety operation can be better ensured.

Owner:SOUTHWEST PETROLEUM UNIV

Throttling window valve sleeve of main distributing valve

ActiveCN106122147AReduce hydraulic shockImprove control stabilityServomotor componentsCentrosymmetryEngineering

The invention discloses a throttling window valve sleeve of a main distributing valve. Two groups of throttling windows are respectively arranged on the upper and lower sides of the valve sleeve, each group of throttling window comprises a plurality of I-shaped holes and a plurality of round holes, and the I-shaped holes and the round holes in each group of throttling window are uniformly distributed in the circumference of the valve sleeve. Thus, the I-shaped holes and the round holes are not necessarily separated from each other, and only the spacing between the holes needs to be proper. The length of the I-shaped holes along the axial direction of the valve sleeve is not less than the diameters of the round holes; the upper and lower groups of throttling windows are symmetrically arranged. The cross section of each I-shaped hole is designed into an I shape enclosed by straight opposite sides and curved opposite sides, and the cross section is in axial symmetry and central symmetry. By designing the throttling windows of the valve sleeve of the main distributing valve, hydraulic shock can be reduced, and the control stability of the main distributing valve is increased.

Owner:NANJING NARI GROUP CORP +1

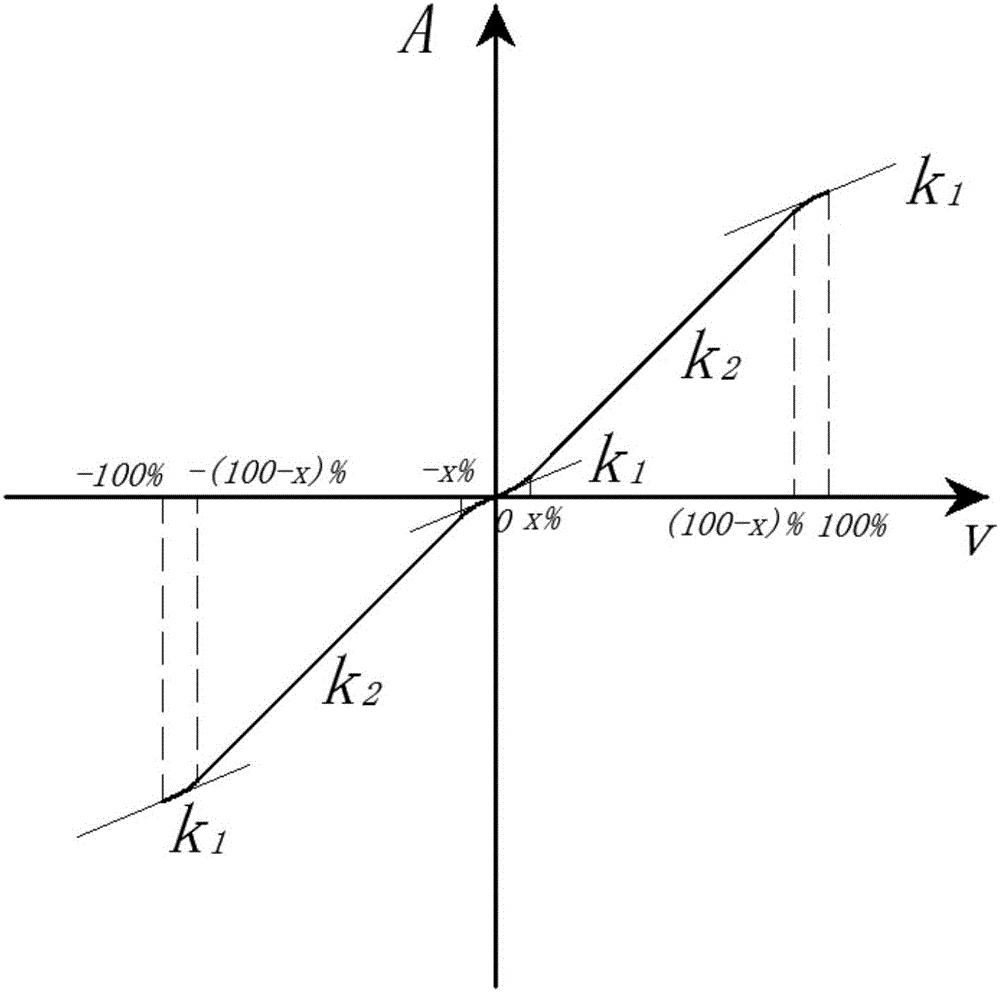

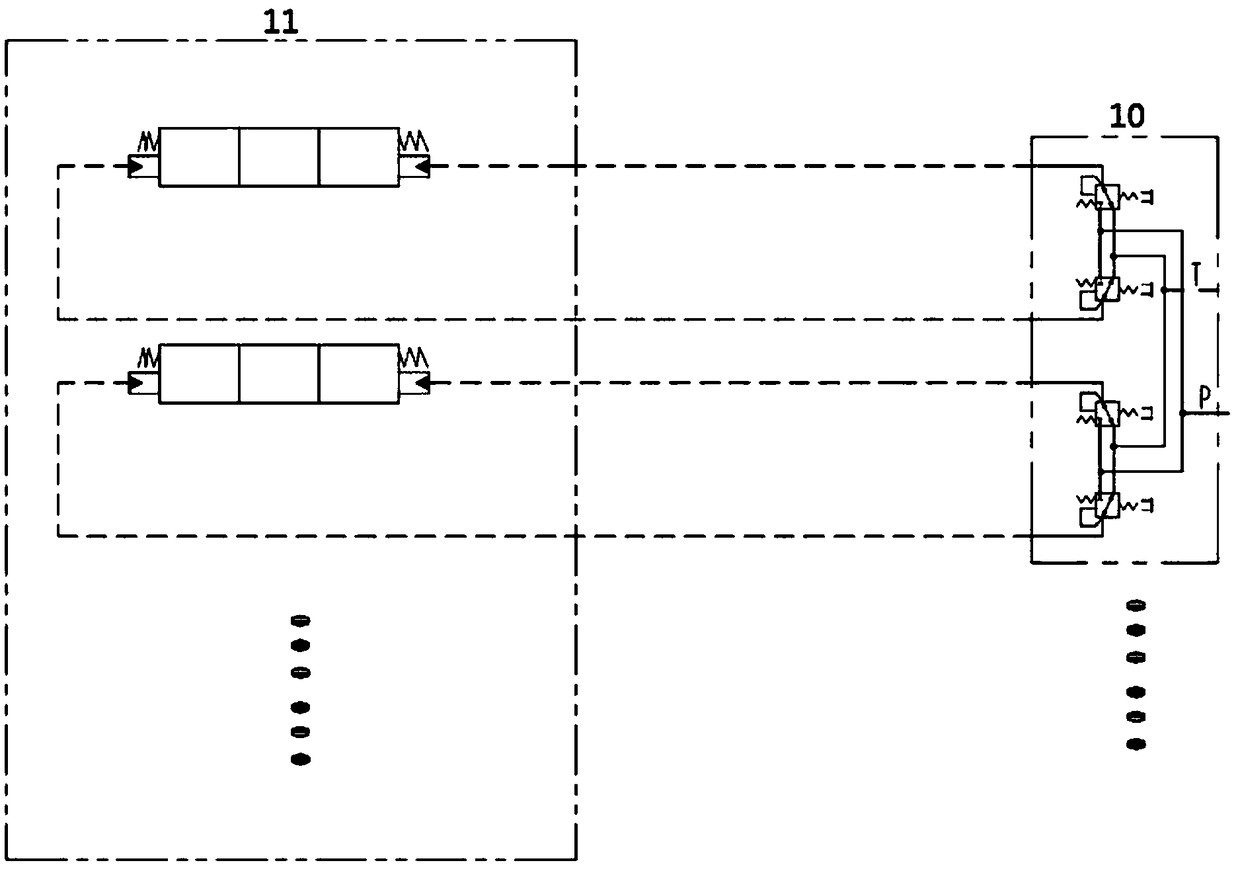

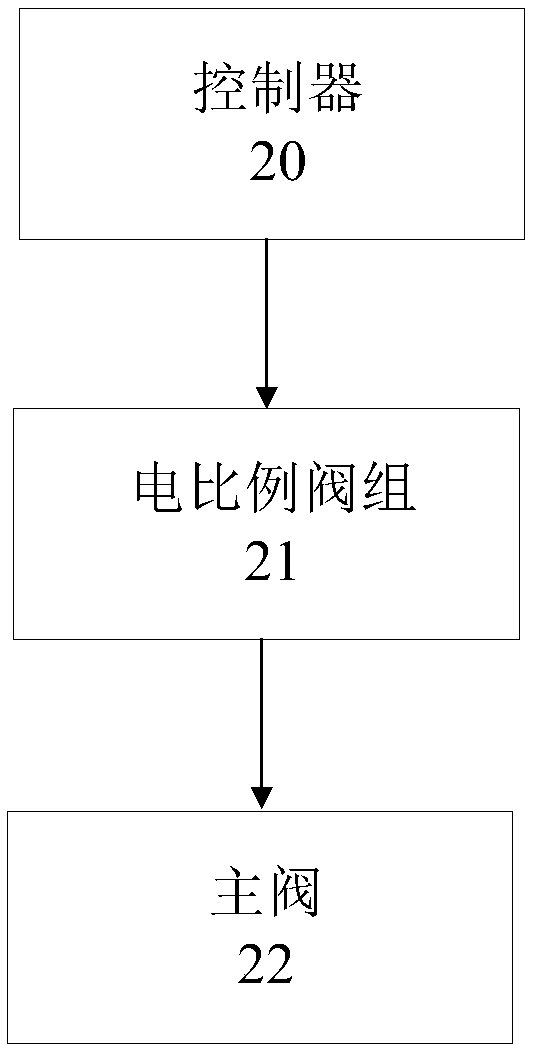

Control system and method for engineering machinery and engineering machinery

ActiveCN109281897AGuaranteed uptimeReduce hydraulic shockServomotor componentsSoil-shifting machines/dredgersElectricityControl system

The invention relates to the field of engineering machinery, and discloses a control system and method for engineering machinery and the engineering machinery. The control system comprises a main valve, an electric proportional valve set and a controller. The main valve is used for controlling an executing mechanism of the engineering machinery to act. The electric proportional valve set comprisesa first electric proportional valve and a second electric proportional valve. The first electric proportional valve is connected with a first lateral cavity of the main valve. The second electric proportional valve is connected with a second lateral cavity of the main valve. The electric proportional valve set is used for outputting different voltage to control a valve core of the main valve to move. The controller used for outputting different pulse width modulation signals to the first electric proportional valve and the second electric proportional valve of the electric proportional valveset according to electric signals output by a left operation handle and a right operation handle of the engineering machinery. The control method is simple and flexible, hydraulic impact of the hydraulic system can be reduced, and therefore stable running of the whole engineering machinery is achieved.

Owner:中联重科土方机械有限公司

Hydraulic-driven reciprocating water pump used in fresh water cooling and dust removal system

PendingCN108561285AReduce hydraulic shockEasy to controlPositive displacement pump componentsPump controlWater flowFresh water

The invention provides a hydraulic-driven reciprocating water pump used in a fresh water cooling and dust removal system. The water pump comprises a water pump shell and a reversing valve, wherein thereversing valve is provided with an oil inlet, an oil return port and two working ports, a water inlet and a water outlet are formed in the water pump shell, a reversing mechanism for switching the valve core station is arranged on the reversing valve, and the inner cavity of the water pump shell is divided into an oil cavity and two water cavities which are arranged on the left side and the right side of the oil cavity respectively; an oil piston is arranged in the oil cavity, and water pistons rigidly connected with the oil piston is arranged in the two water cavities respectively; the twoworking ports communicate with the parts, at the two sides of the oil piston, of the oil cavity respectively; and the two water cavities are provided with first one-way valves communicating with the water outlet correspondingly, and the two water cavities are provided with second one-way valves communicating with the water inlet correspondingly. According to the work of the oil pressure-driven reciprocating type water pump, the hydraulic impact of pumped water flow is small, the water flow is stable, meanwhile, the water pump can be automatically reversed, control is simple, the manufacturingand maintenance cost is low, and the operation is simple and reliable.

Owner:HUST WUXI RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com