Variable speed double-piston series-connection hydraulic cylinder

A series hydraulic cylinder and speed conversion technology, applied in the field of hydraulic cylinders, can solve the problems of complex structure, difficult maintenance and high cost of variable variable pumps, and achieve the effects of simplifying structure and control, reducing machining accuracy and saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

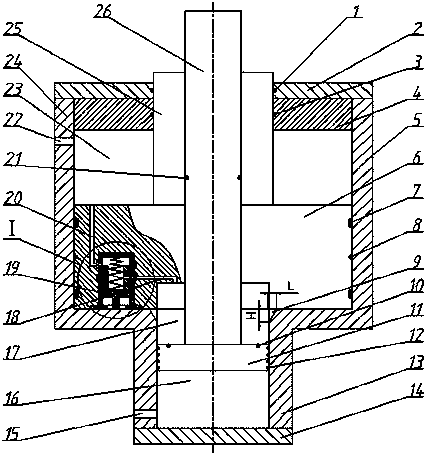

[0028] The utility model relates to a speed-changing double-piston serial hydraulic cylinder. Such as figure 1 As shown, the hydraulic cylinder includes a large end cover 2, a guide sleeve 4, a cylinder body 24, a large piston 6, a large piston rod 25, a small piston 11, a small piston rod 26, a small end cover 14 and a quick shut-off valve 19.

[0029] Such as figure 1 As shown, the cylinder body 24 is an integral body composed of the large cylinder body 5 and the small cylinder body 13. The end portion of big cylinder body 5 is fixedly equipped with large end cap 2, and the end portion of small cylinder body 13 is fixedly equipped with small end cap 14, and guide sleeve 4 is closely attached to large end cap 2 and is concentrically fixed in large cylinder body 5. The large cylinder body 5 has a first oil port 22 which is close to the guide sleeve 4 ; the small cylinder body 13 has a second oil port 15 which is close to the small end cap 14 . Four triangular grooves 9 are ...

Embodiment 2

[0038] The utility model relates to a speed-changing double-piston serial hydraulic cylinder. Present embodiment except following technical parameters, all the other are with embodiment 1:

[0039] The axial length H of described triangular groove 9 is 7 ~ 8mm, and the radial length L of triangular groove 9 is 5 ~ 6mm; The isosceles included angle of the projection is 60-75°, and the vertical plane is a plane perpendicular to the radial direction of the triangular groove 9 .

[0040] The groove width of the pressure equalizing groove 12 is 0.6~0.8mm, and the groove depth is 0.8~1.0mm.

[0041] The working process of this embodiment:

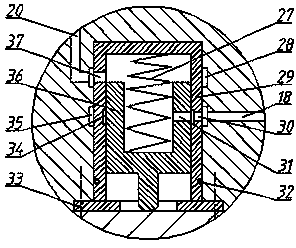

[0042] When the hydraulic oil enters the large piston rod cavity 23 from the first oil port 22, the large piston 6 moves inward to the bottom of the large cylinder 5, and the ejector rod of the valve core 36 is reacted by the bottom of the large cylinder 5, and the valve The core 36 compresses the spring 27, so that the hydraulic oil in the ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com