Intelligent buffering and overflowing device

A technology of overflow device and direct-acting overflow valve, which is applied in the direction of fluid pressure actuating device, servo motor, mechanical equipment, etc. The problem of poor effect and other problems can reduce the shaking of the whole machine, the structure is simple, and the hydraulic shock can be reduced.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

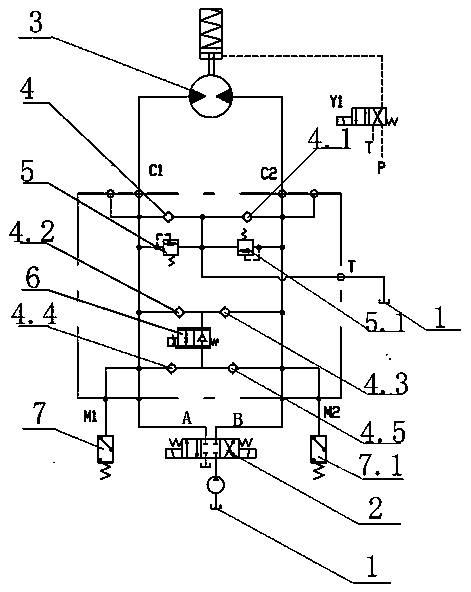

[0012] The present invention will be further described below in conjunction with accompanying drawing.

[0013] Such as figure 1 As shown: an intelligent buffer overflow device provided by the present invention includes a hydraulic oil tank 1 and a rotary motor 3. The hydraulic oil tank 1 communicates with the reversing valve 2 through a hydraulic pump, and the left position of the reversing valve 2 passes through the first working oil Port A and the first executive oil port C1 are connected to one end pipeline of the swing motor 3, and the fifth check valve 4.4 is sequentially connected between the left position of the reversing valve 2 and the connection pipeline at one end of the swing motor 3. The oil inlet, the oil outlet of the third one-way valve 4.2, the oil inlet of the first direct-acting overflow valve 5 and the oil outlet of the first one-way valve 4, the right position of the reversing valve 2 passes through the second The working oil port B and the second execut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com