Free-slewing cushion and brake hydraulic system and method used in crawler crane

A crawler crane and slewing buffer technology, which is applied in the directions of load hanging components, transportation and packaging, can solve the problems of driver's cab jitter, poor running stability, hydraulic shock, etc., and achieves fast response speed, stable and reliable work, and avoids damage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings.

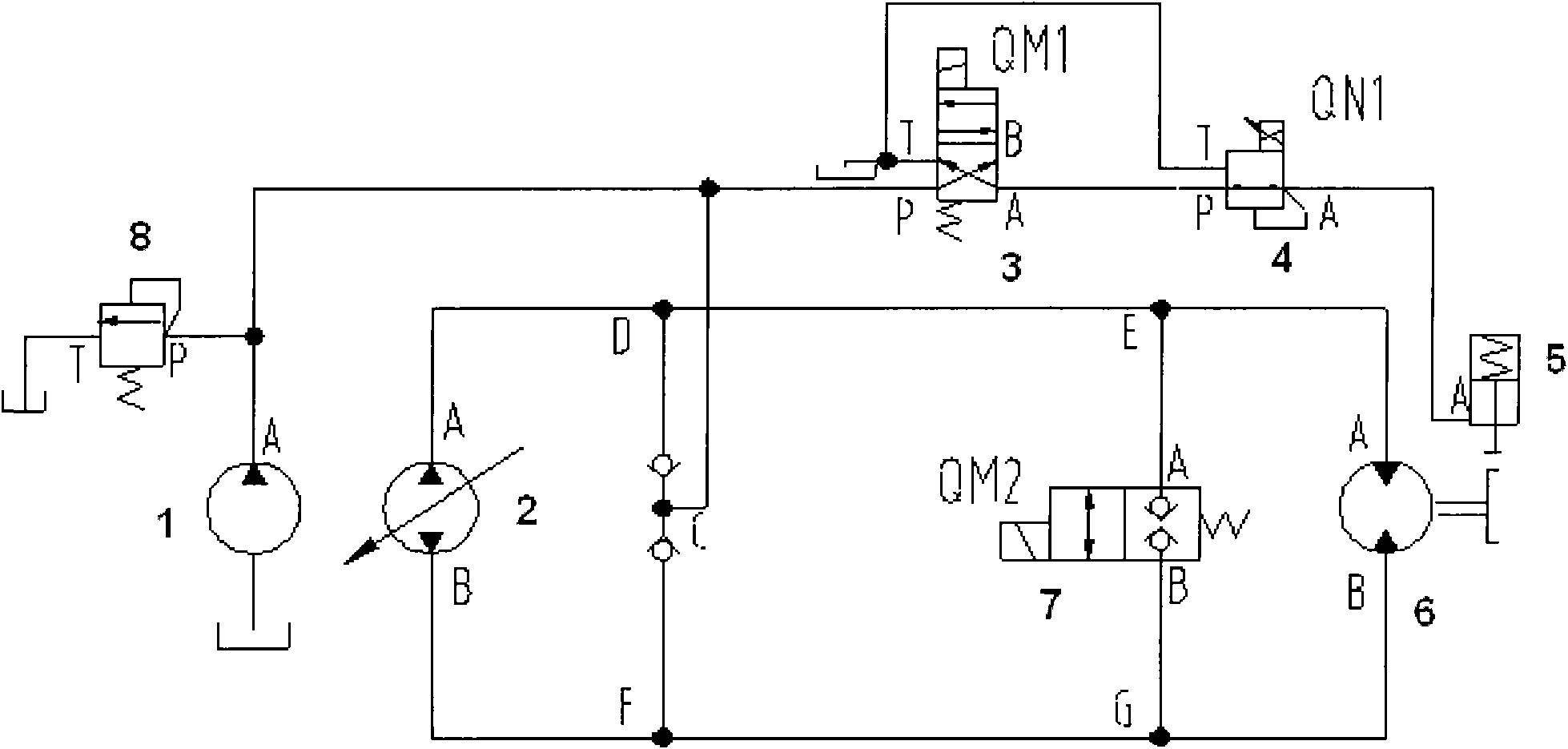

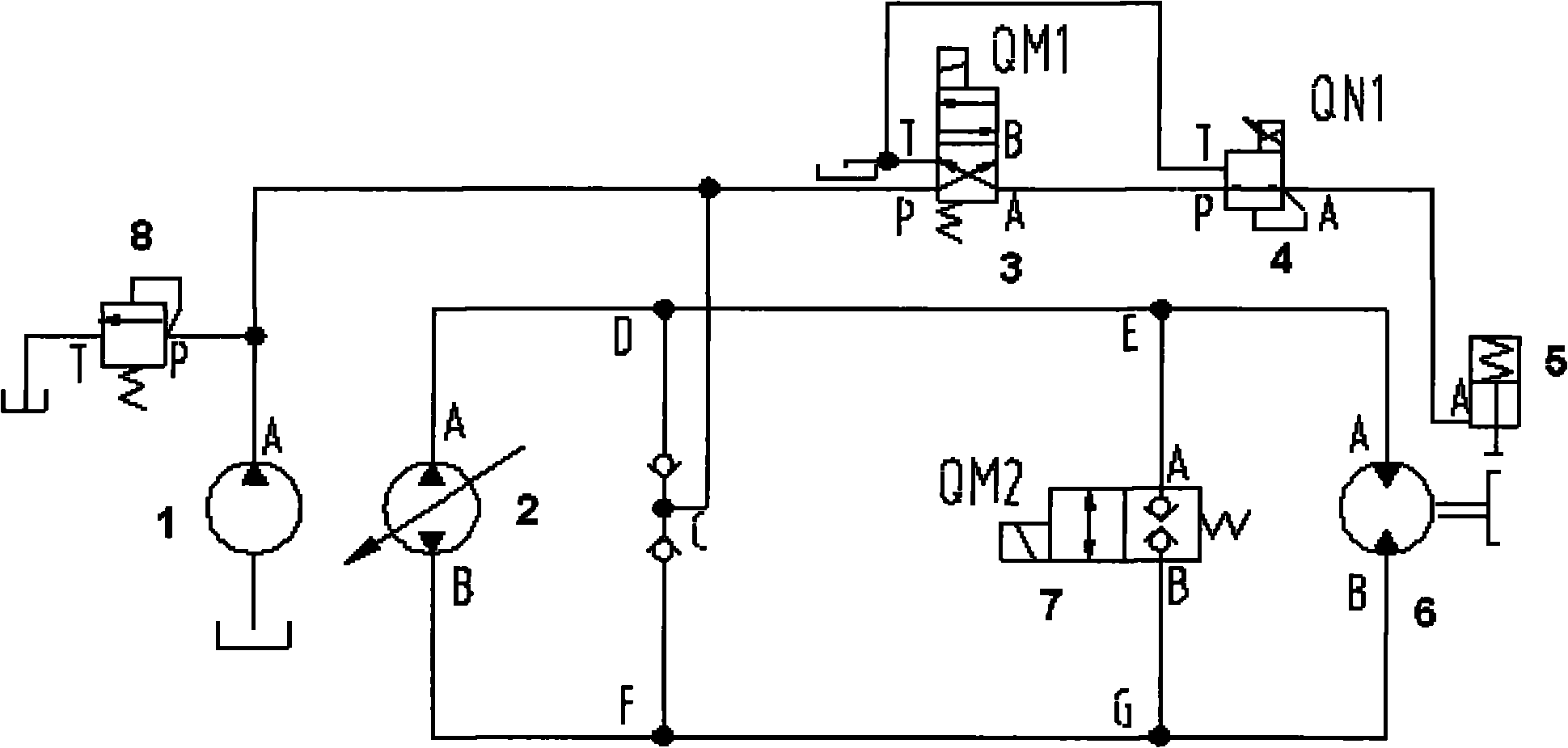

[0022] see figure 1 As shown, a free-slewing buffer braking hydraulic system for a crawler crane of the present invention includes a charge pump 1, a main slewing pump 2, a brake valve 3, an inverse proportional electromagnetic pressure reducing valve 4, a brake 5, a slewing motor 6, a free Swing control valve 7 and relief valve 8.

[0023] Wherein, the main rotary pump 2 and the rotary motor 6 are connected to form a circuit, and the free rotation control valve 7 is connected between the main rotary pump 2 and the rotary motor 6 . An inverse proportional electromagnetic decompression valve 4 is connected between the brake valve 3 and the brake 5 . The pressure output of the inverse proportional electromagnetic decompression valve 4 will decrease with the increase of the current, and the electric pedal or the rotary switch can be used for the current control. In add...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com