Hydraulic gear shifting oil pressure control method based on proportional electromagnetic valve

A proportional solenoid valve, oil pressure control technology, used in transmission control, components with teeth, belts/chains/gears, etc., can solve the problem of not considering changes in system oil temperature, requiring temperature sensors, and large workload. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The hydraulic shift oil pressure control method based on the proportional solenoid valve of the present invention will be described in detail below.

[0055] The hydraulic shift oil pressure control method based on a proportional solenoid valve according to the present invention includes steps 1 to 8.

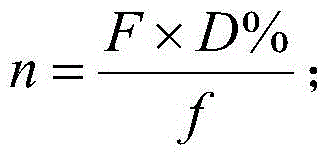

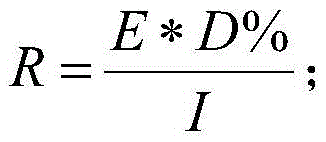

[0056] Step 1: Input the PWM signal to the proportional solenoid valve, and use the data acquisition module to collect the data points of the input voltage signal and the corresponding data points of the current signal, and then obtain the steady-state current and voltage waveform; the frequency of the PWM signal is fHz, accounting for Duty ratio D%, the voltage amplitude of the PWM signal is E; the sampling frequency of the data acquisition module is FHz, and within one cycle of the PWM signal, the number of data points of the collected voltage signal and the corresponding number of data points of the current signal:

[0057] n = ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com