Quick pressurizing injection device of hydraulic press

A hydraulic press and fast technology, applied in the field of injection devices, can solve the problems of not being able to adapt to the rapid injection booster system, prolonging the pressure build-up booster time, and complicating the structure of the device, achieving small occupied space, small hydraulic impact, Responsive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

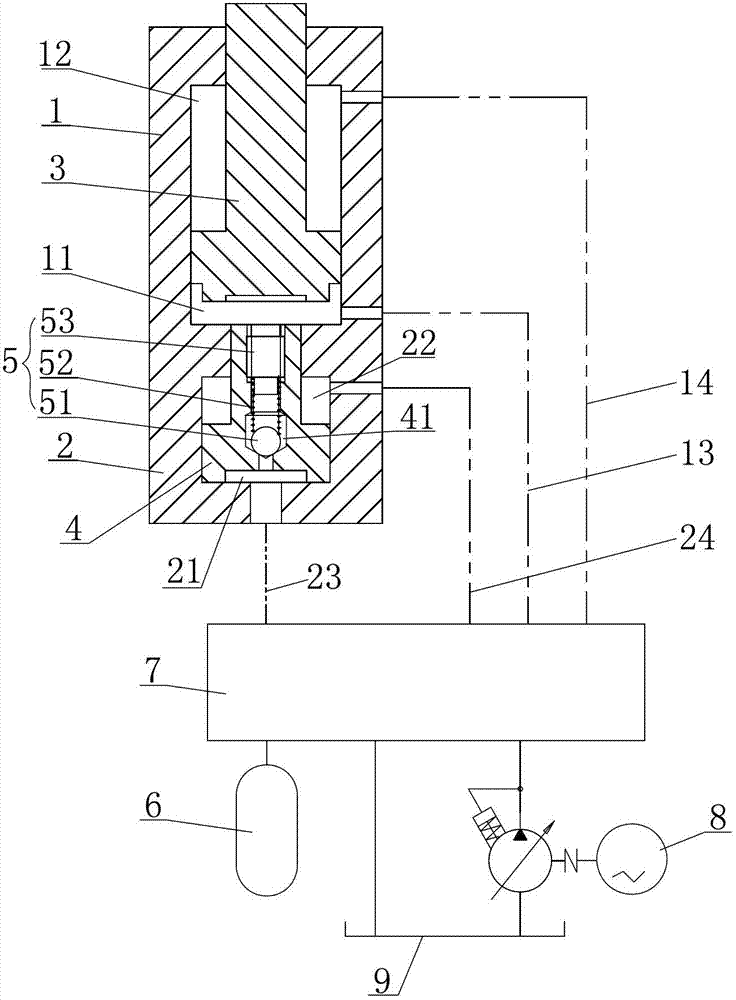

[0016] The present invention provides a rapid pressurized injection device for a hydraulic press, which includes an injection cylinder with a built-in injection piston, a booster cylinder with a built-in booster piston, and a hydraulic drive mechanism. The injection cylinder and the booster cylinder are integrally formed. The booster piston is provided with an oil inlet channel for communicating with the rodless chamber of the injection cylinder and the rodless chamber of the booster cylinder, and a one-way control valve is provided in the oil inlet channel to control the opening or closing of the oil inlet channel. Combining the injection cylinder and the booster cylinder into one body, the degree of integration is high. On the basis of not affecting the control accuracy, the structure of the device is simpler and more compact, and the space occupied is small.

[0017] The technical solution of the embodiment of the present invention will be explained and described below in co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com