Hydraulic system for automatic tensioning device of belt pulley

An automatic tensioning device and hydraulic system technology, which is applied in transmission devices, fluid pressure actuating devices, belts/chains/gears, etc., can solve problems such as inability to realize self-adaptive tensioning, and achieve small hydraulic impact and intelligent level High, adaptable and stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

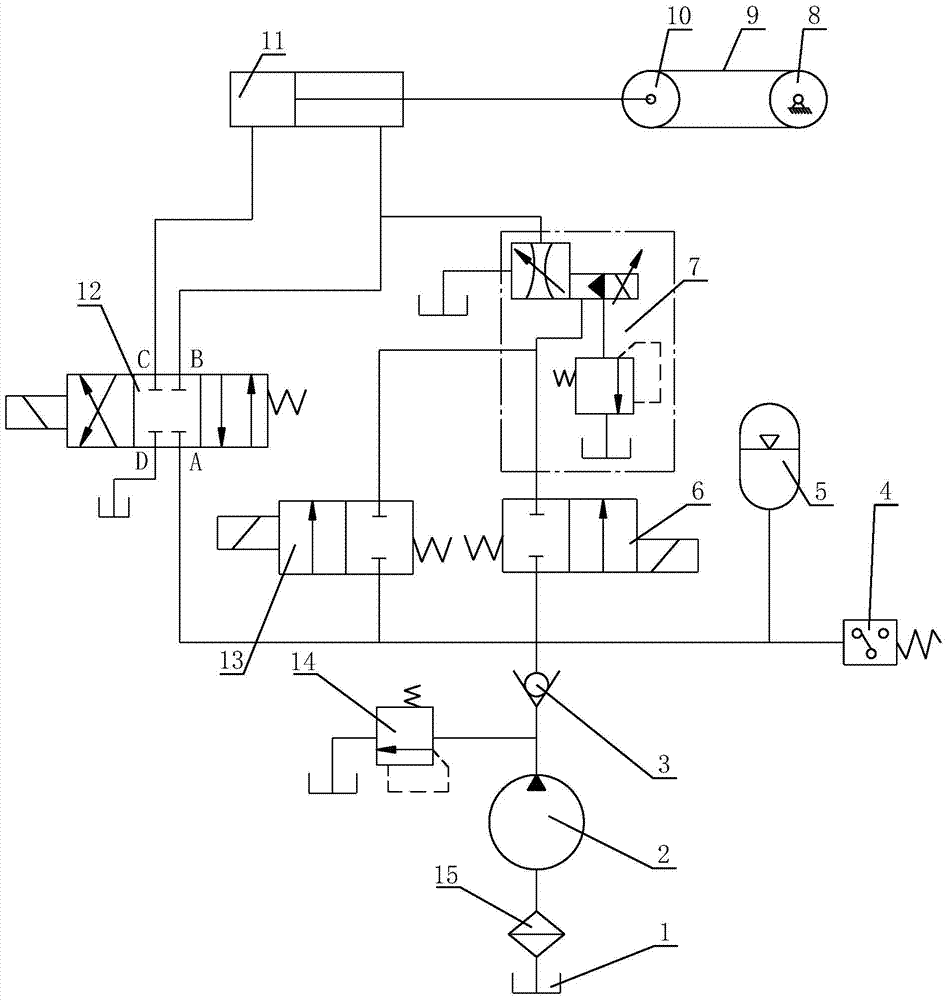

[0019] Such as figure 1 The shown hydraulic system for a pulley automatic tensioning device includes a hydraulic cylinder 11 for adjusting the position of the movable pulley 10 so that the belt 9 between the fixed pulley 8 and the movable pulley 10 reaches a suitable tension force and for The hydraulic cylinder 11 provides the hydraulic pump 2 of high-pressure hydraulic oil, and also includes an electromagnetic proportional valve group 7 for adjusting the oil inlet speed of the hydraulic cylinder 11, and stores high-pressure hydraulic oil for the system to prevent the hydraulic pump 2 from frequently starting. The accumulator 5 and the pressure relay 4 that automatically controls the start or stop of the hydraulic pump 2 according to the pressure value of the hydraulic oil in the accumulator 5; the oil outlet of the hydraulic pump 2 is respectively the accumulator 5 and the The A port of the reversing valve 12 is connected, the B port of the reversing valve 12 is connected wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com