Hydraulic buffer

A technology of hydraulic buffers and hydraulic cylinders, applied in the field of buffers of hydraulic cylinders, can solve the problems of poor buffering effect and large hydraulic shock, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

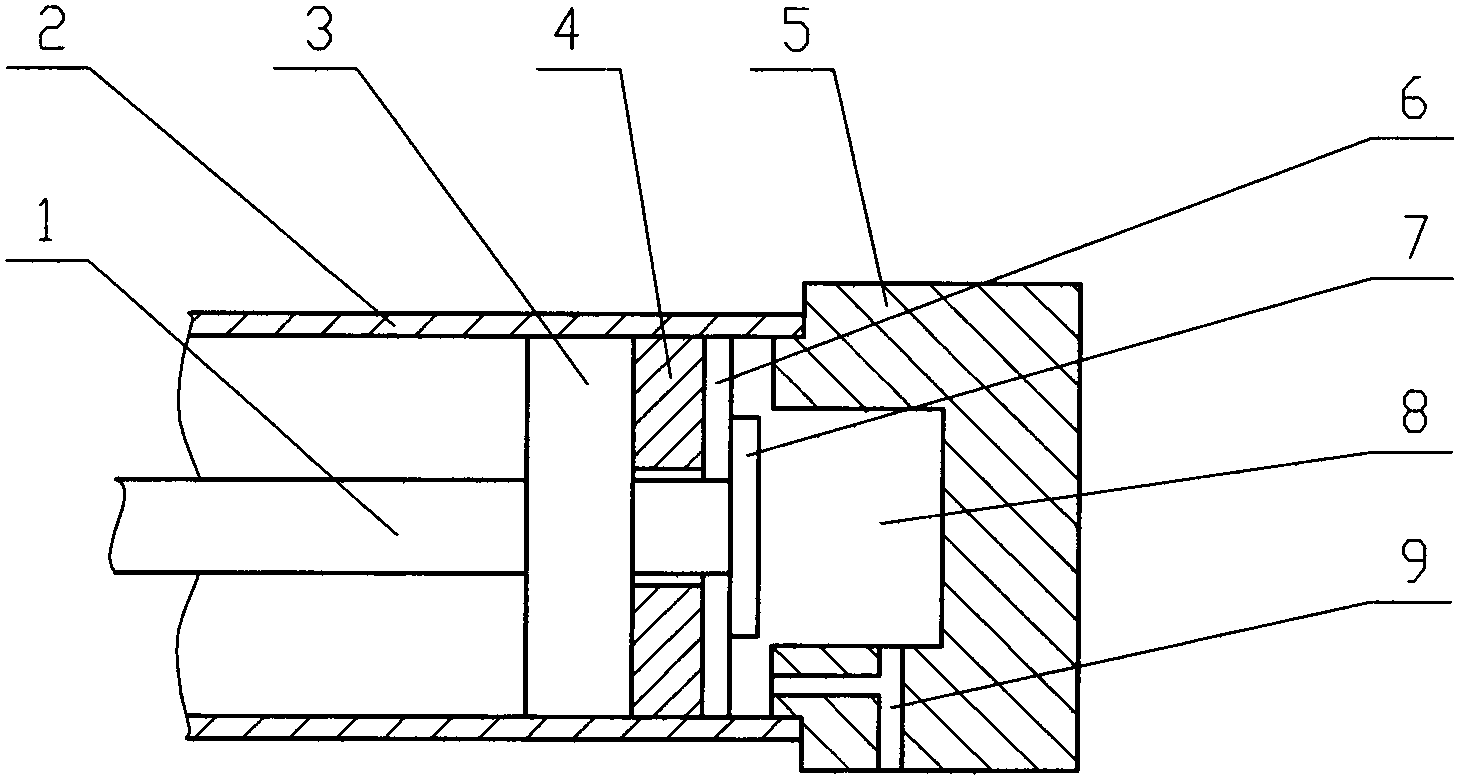

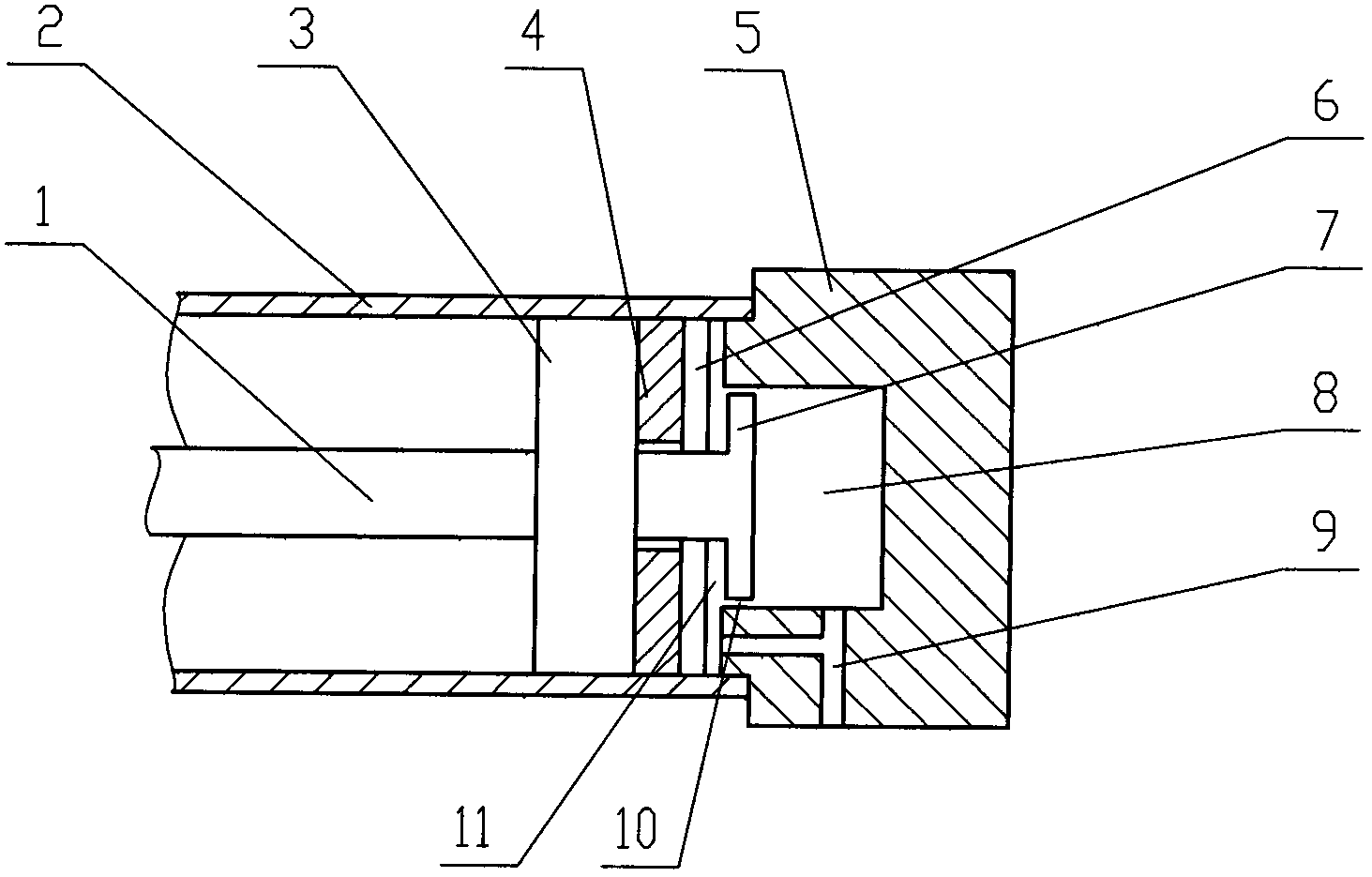

[0010] See figure 1 , figure 2 , the present invention comprises a hydraulic cylinder 2, a piston 3 and a cylinder head 5 fixedly connected to the hydraulic cylinder 2, the piston 3 is fixedly connected to a piston rod 1, and is characterized in that: the cylinder head 2 has a cylindrical cavity 8 and an orifice 9 , the throttle hole 9 communicates with the cavity 8, the piston 3 is fixedly connected to the buffer ring 4, the buffer ring 4 is fixedly connected to the stop ring 6, and the stop ring 6 is slidably connected to the piston rod 1, The end of the piston rod 1 is fixedly connected to a baffle 7 , the diameter of the outer ring of the baffle 7 is smaller than the inner diameter of the cylindrical cavity 8 , and the baffle and the cavity form an annular gap 10 .

[0011] When the present invention is working, when the piston rod 1 pushes the piston 3 to move toward the cylinder head 5, the cylindrical cavity 8 forms a buffer oil chamber, and the oil pressure pushes th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com