Throttling window valve sleeve of main distributing valve

A throttling window and main pressure distribution valve technology, which is applied in the direction of fluid pressure actuators, servo motor components, mechanical equipment, etc., can solve problems such as hydraulic shock, reduced system control stability, and rapid oil velocity changes. Achieve the effects of reducing hydraulic shock, ensuring control accuracy and improving control stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solutions in the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the embodiments of the present invention. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

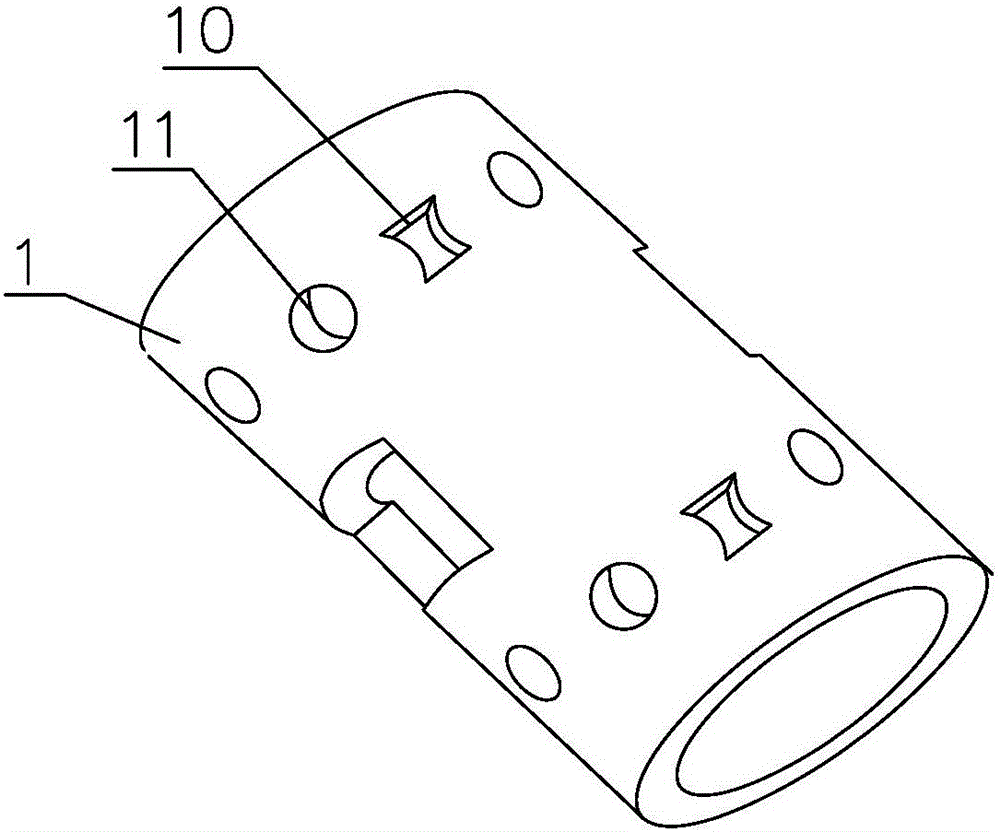

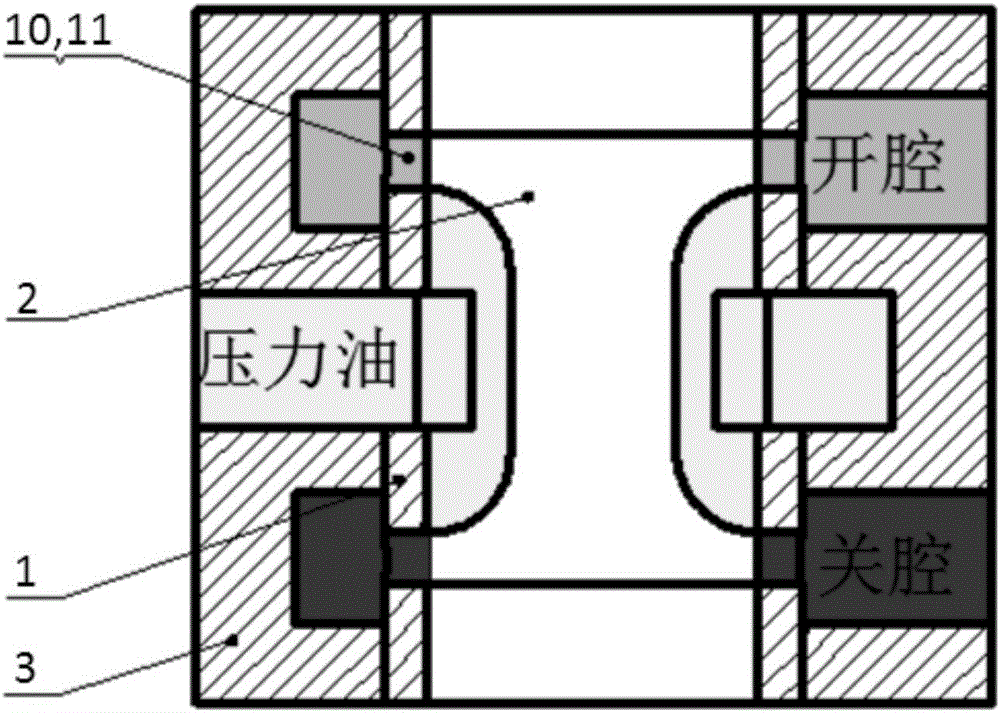

[0022] Such as figure 1 As shown, it is a throttling window sleeve of a main pressure distribution valve. A set of throttling windows is respectively provided on the upper side and the lower side of the valve sleeve 1, and each set of throttling windows includes a plurality of I-shaped holes 10 and a plurality of round The I-shaped holes 10 and circular holes 11 in each group of throttling windows are evenly arranged on the circumference of the valve sleeve 1 . Here, the I-shaped hole 10 and the circular hole 11 do not have to be spaced apart from each other, as long as the distance between the holes is equal....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com