Control method and control device for driving hydraulic system of engineering vehicle by single pump and double motors

A technology for hydraulic systems and engineering vehicles, which is applied in the direction of fluid pressure actuators, servo motors, servo motor components, etc., and can solve problems that affect the service life of hydraulic pumps, reduce the traction force of the whole machine, and reduce work efficiency, so as to improve operating efficiency , prolong the service life and prevent the effect of unilateral slipping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

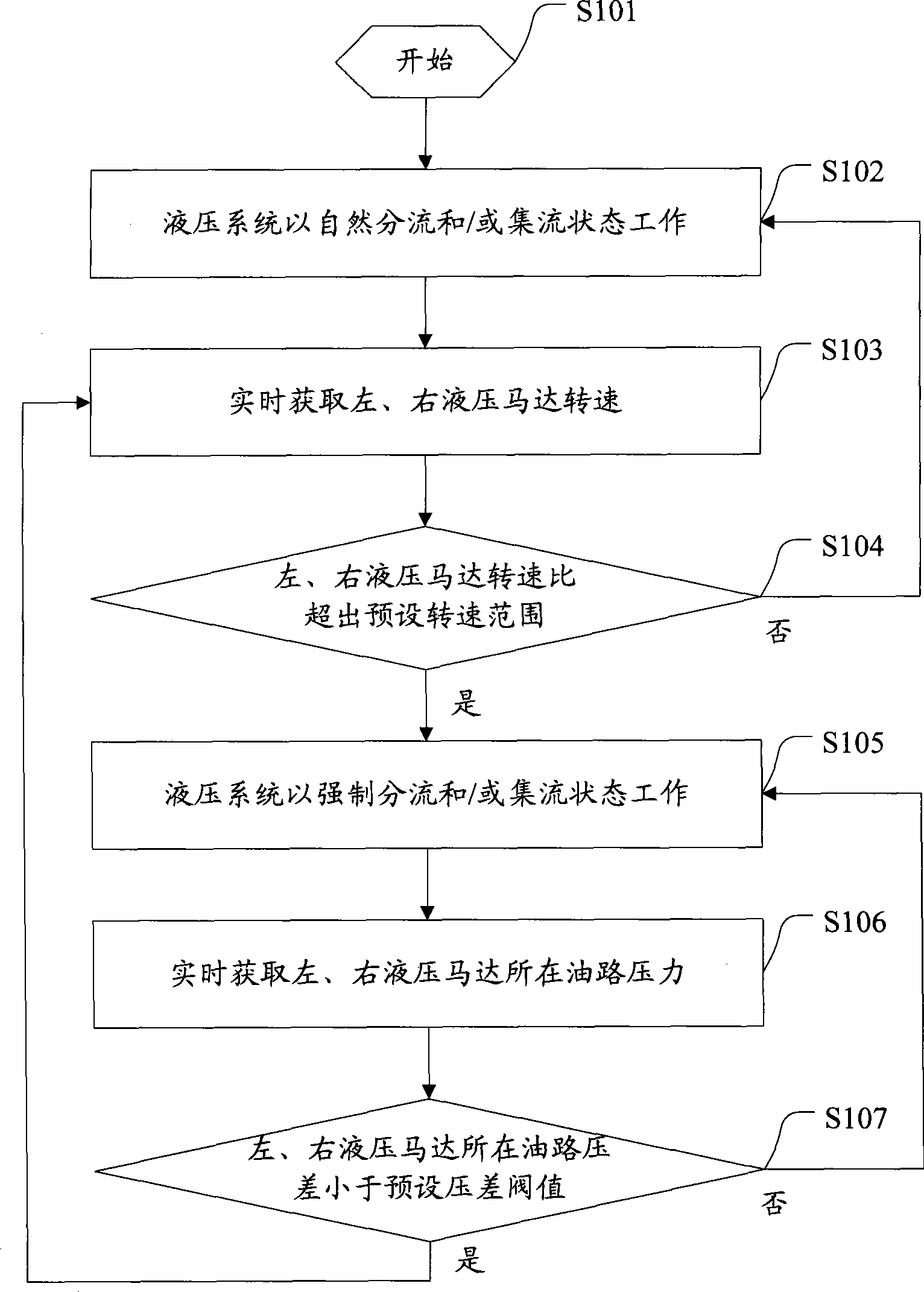

[0028] The basic idea of the present invention is: control the hydraulic system according to the working conditions to switch between the natural diversion and / or flow concentrating state and the forced diversion and / or concentrating state; 1. When the speed ratio of the right hydraulic motor exceeds the preset speed ratio range, the hydraulic system is controlled to forcibly divide and / or flow; in the state of forced flow and / or flow, when the pressure difference between the two branches of the diverter valve is judged, Control the hydraulic system to return to the natural flow diversion and / or flow collection state.

[0029] Wherein: the state of natural diversion and / or concentration includes two states of natural diversion and natural concentration; the state of forced diversion and / or concentration includes two states of forced diversion and forced concentration. For the sake of convenience, in the present invention, the concepts of flow diversion and / or flow concentrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com