Novel two-way insert type oscillation control valve

A vibration control and cartridge valve technology, applied in valve details, valve devices, engine components, etc., can solve the problems of polluting the environment, leakage of hydraulic components and pipelines, affecting the work quality of rollers, and operator comfort, etc. The effect of low cost, increased oil passage area, and shortened vibration stop time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

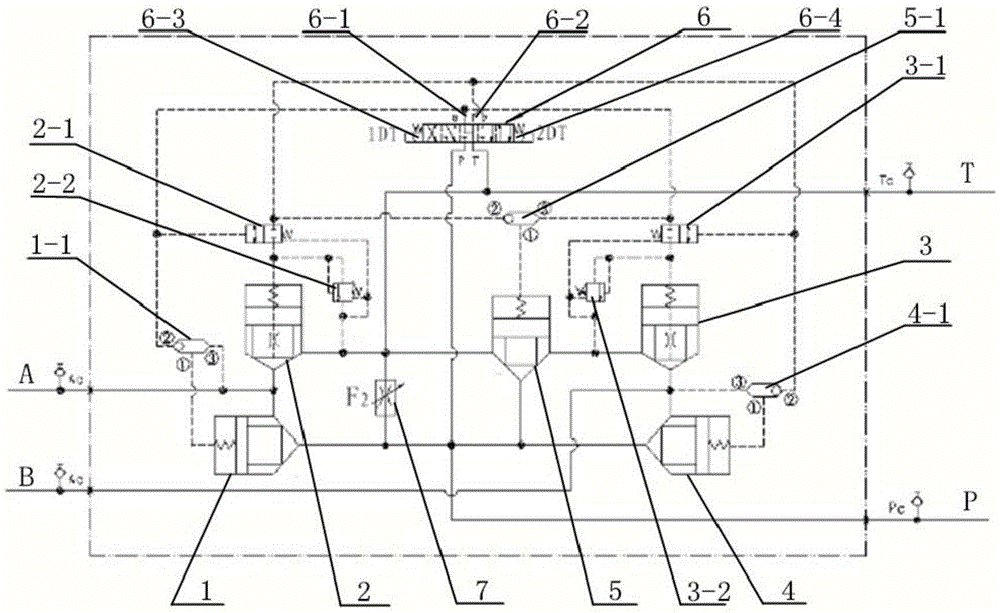

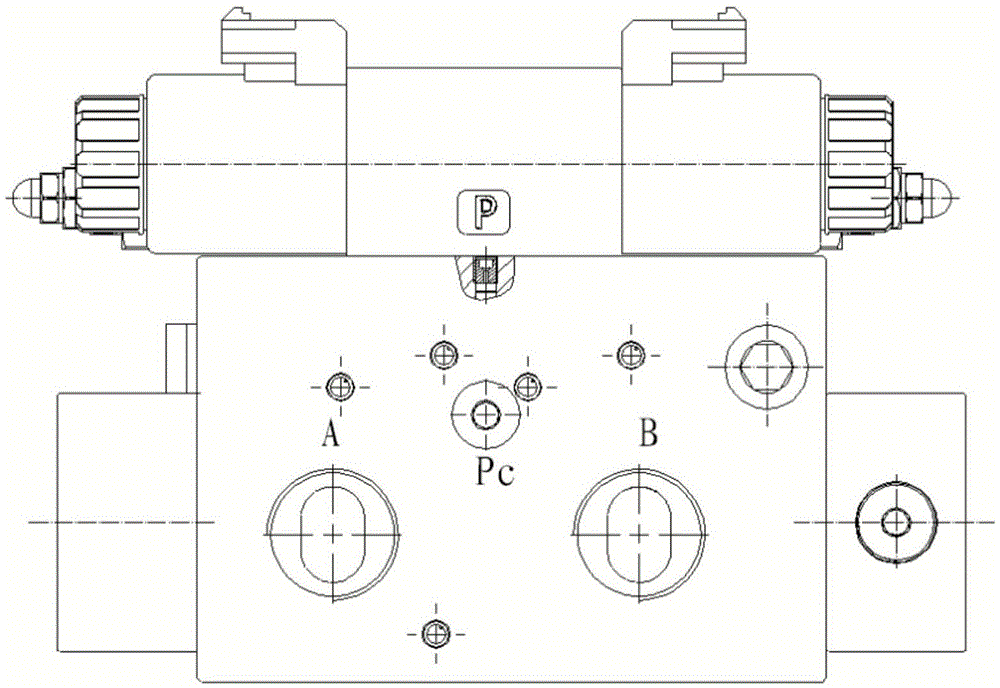

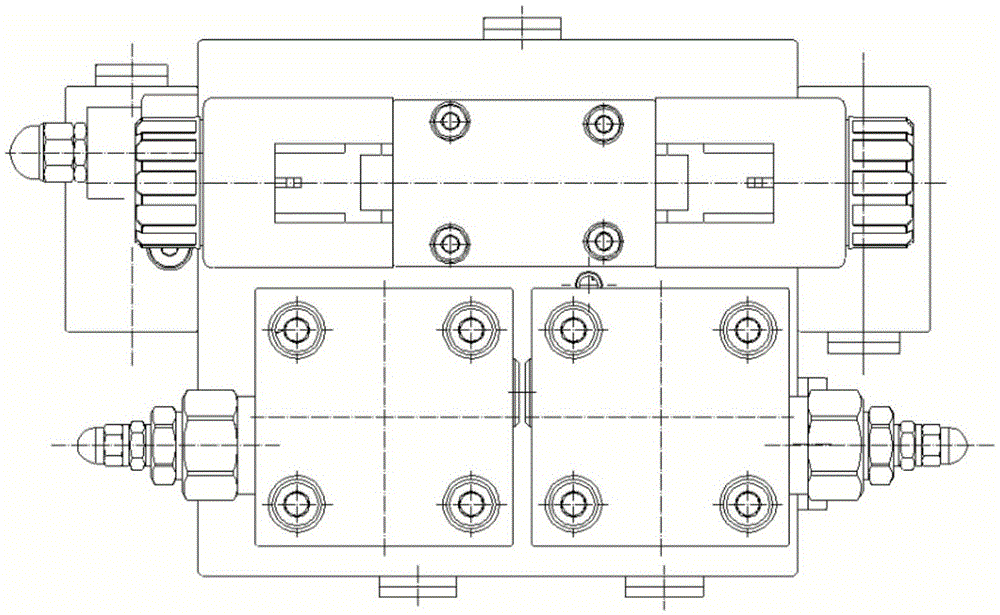

[0038] Such as Figure 1 to Figure 3As shown, a novel two-way plug-in vibration control valve of the present invention includes a valve body, a plug-in cavity is formed on the valve body, and an oil inlet port P communicated with the oil outlet of the hydraulic pump, and connected with the hydraulic system The oil return interface T connected to the oil tank of the hydraulic motor, the first working interface A and the second working interface B respectively communicated with the first oil port and the second oil port at both ends of the hydraulic motor; the main circuit, the main circuit is inserted in the In the cartridge cavity of the valve body, there are five two-way cartridge valves and a pilot direction control circuit composed of a three-position four-way electromagnetic reversing valve 6, wherein the first two-way cartridge valve 1 is set at the oil inlet Between the port P and the first working port A, the liquid supply from the oil inlet port to the first working po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com