Porous buffer of hydraulic cylinder

A hydraulic cylinder and buffer technology, applied in the field of hydraulic cylinder buffers, can solve problems such as poor buffering effect and large hydraulic shock, and achieve the effects of small hydraulic shock, stable operation and good buffering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

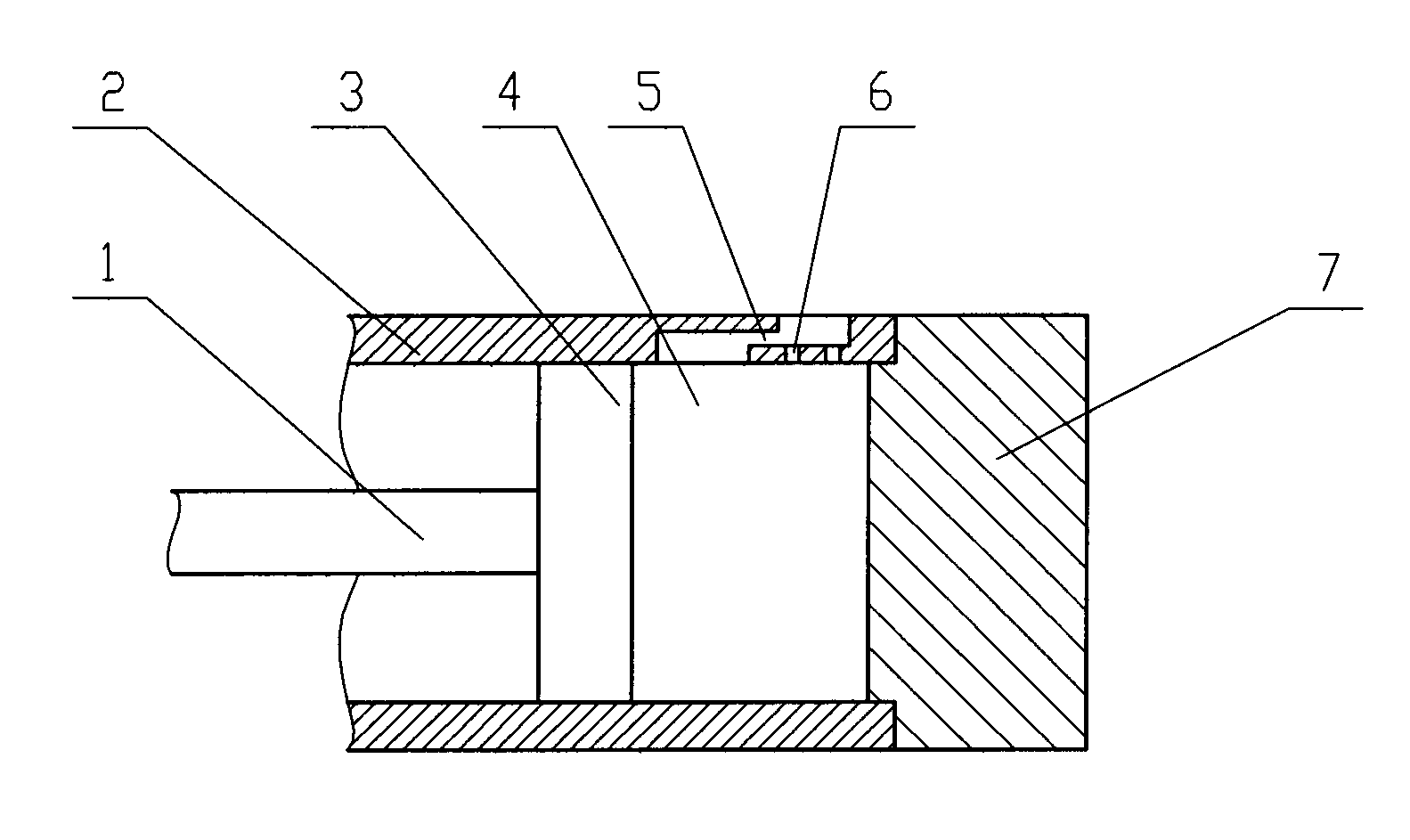

[0009] See figure 1 , the present invention comprises a hydraulic cylinder 2, a piston 3 and a cylinder cover 7 fixedly connected to the hydraulic cylinder 2, the piston 3 is fixedly connected to the piston rod 1, and the side wall of the hydraulic cylinder 2 has a bent orifice 5 and a thin hole 6, and the thin The hole 6 includes a plurality of holes, which respectively communicate with the inner chamber 4 and the orifice 5 of the hydraulic cylinder 2, wherein the purpose of the bent orifice 5 is to further increase the flow resistance of the oil, and the purpose of the thin hole 6 is to act as the inner cavity After the oil pressure in 4 increases to a certain level, the discharge of the oil is accelerated to prevent damage to the hydraulic cylinder 2 caused by excessive internal pressure.

[0010] When the present invention works, when the piston rod 1 moves toward the cylinder head 7 with the piston 3, a buffer oil chamber is formed between the cylinder head 7 and the pist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com