Recovering system for slewing and braking energy of excavator

A technology for slewing braking energy and recovery system, which is applied to fluid pressure actuation system components, earthmoving machines/shovels, mechanical equipment, etc. The working performance of the slewing mechanism will affect the working life of the system and other problems, so as to improve the energy reuse rate, the structure is simple, and the effect of preventing the reversal of the turntable can be achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

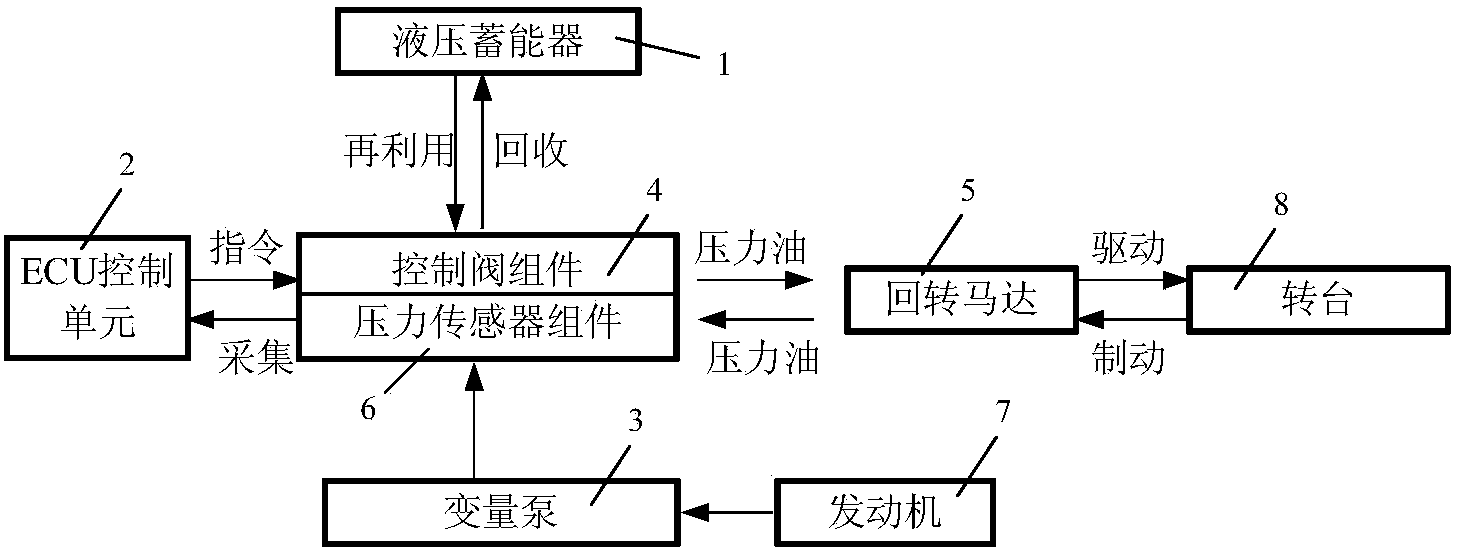

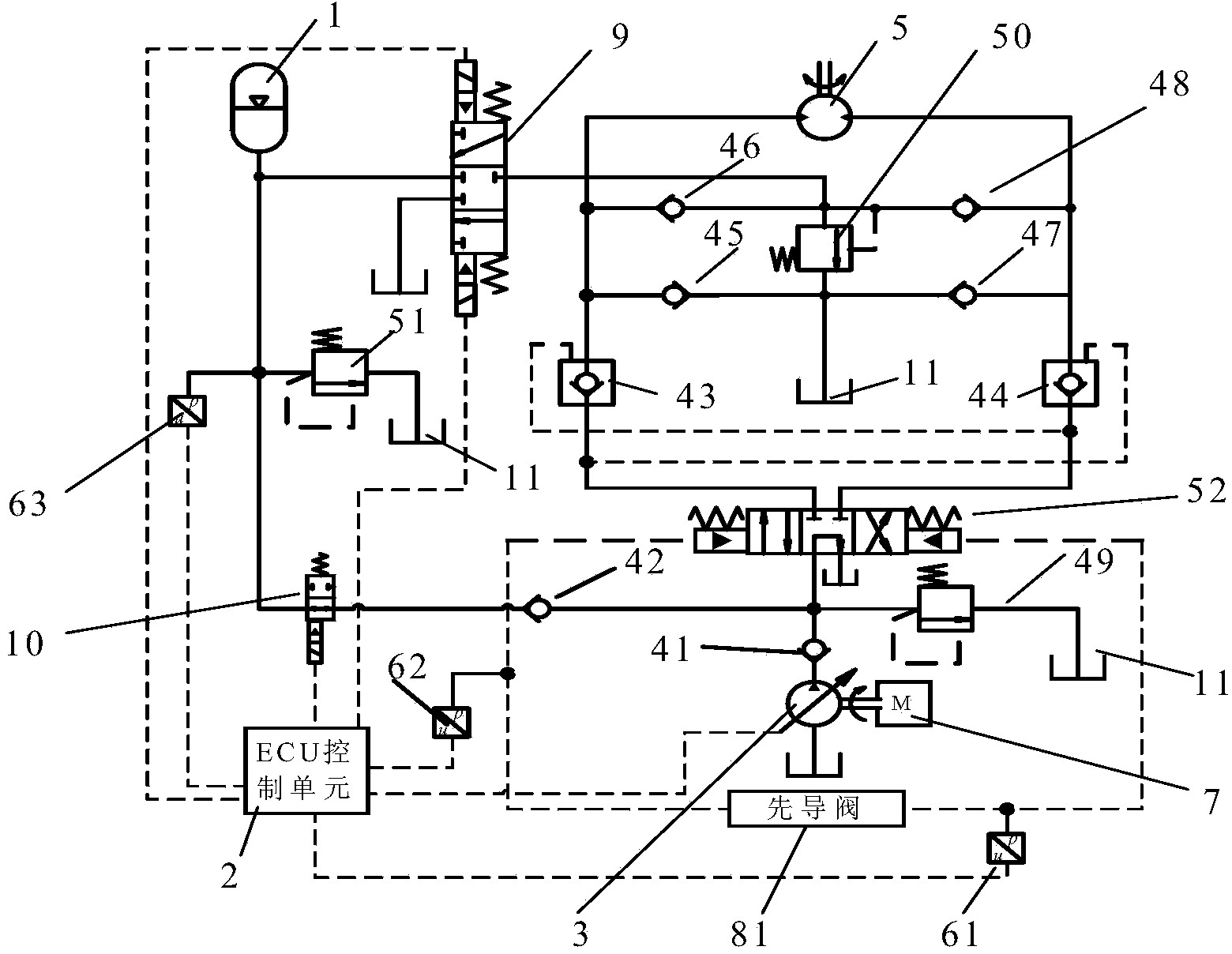

[0016] see figure 1 and figure 2 As shown, an excavator slewing braking energy recovery system of the present invention includes a hydraulic accumulator 1, an ECU control unit 2, a variable displacement pump 3, a control valve assembly 4, a slewing motor 5, and a pressure sensor assembly 6; The engine 7 of the excavator (not shown) is connected to the variable pump 3, and the ECU control unit 2 controls the hydraulic accumulator 1, the variable pump 3, and the swing motor 5 through the control valve assembly 4; The control unit 2 respectively collects the pressure of the hydraulic accumulator 1, the pilot valve 81, and the swing motor 5 through the pressure sensor assembly 5; the swing motor 5 drives the turntable 8 of the excavator; the ECU control unit 2 collects the pressure of the pressure sensor assembly 6 The feedback signal controls the on-off of the control valve assembly 4, converts the inertial energy of the turntable 8 of the excavator into hydraulic energy and st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com