Oil cylinder for built-in displacement sensor

A technology of displacement sensor and oil cylinder, which is applied in the direction of fluid pressure actuating device, etc., to achieve the effect of reducing hydraulic shock, reducing processing cost and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

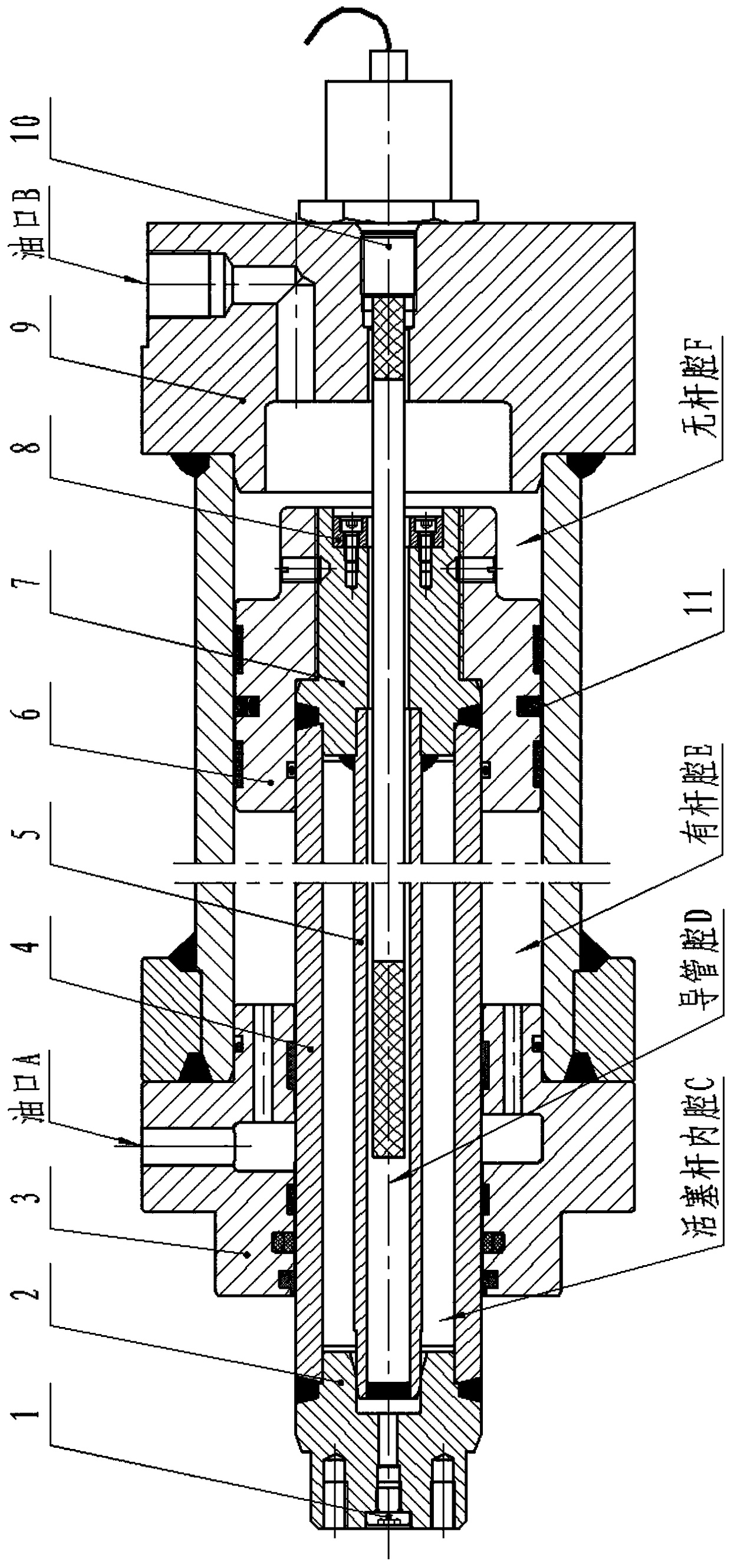

[0019] A built-in displacement sensor type oil cylinder of the present invention comprises a cylinder barrel 9, a guide sleeve 3, a piston assembly, a vernier magnetic ring 8, a conduit 5 and a displacement sensor 10; the piston assembly includes a piston and a piston rod, and the piston rod consists of a piston rod head 2, The piston rod body 4 and the piston rod tail 7 are welded, and the piston rod adopts a welded structure, which avoids the processing of slender holes on the piston rod, thus simplifying the processing process and ensuring the feasibility of processing; the cylinder barrel 9 and the guide sleeve 3 It is coaxial and fixed; the piston assembly passes through the cavity of the guide sleeve 3 and the cylinder 9; the piston assembly is provided with a vernier magnetic ring 8, which is fixed at the end of the piston rod tail 8; the inside of the piston rod head 2 is designed with a guide tube Guide hole, the diameter of the guide hole of the guide tube is slightly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com