Method and device for improving operation comfort of excavator

A comfort and excavator technology, applied in the direction of mechanically driven excavators/dredgers, etc., can solve the problems of affecting the working efficiency, affecting the working quality, and increasing fatigue of excavators, so as to improve the operating comfort and stability , The effect of slowing down the oil return speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

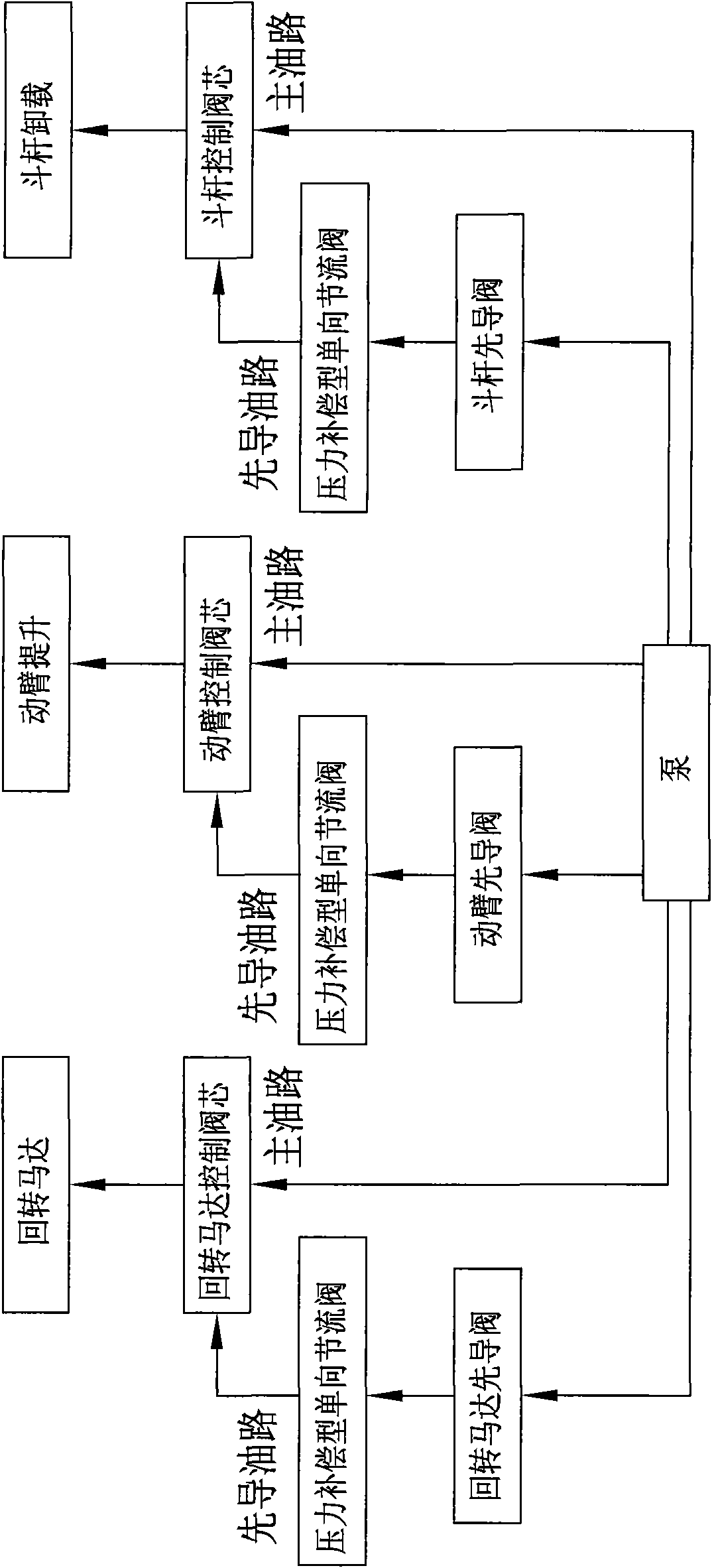

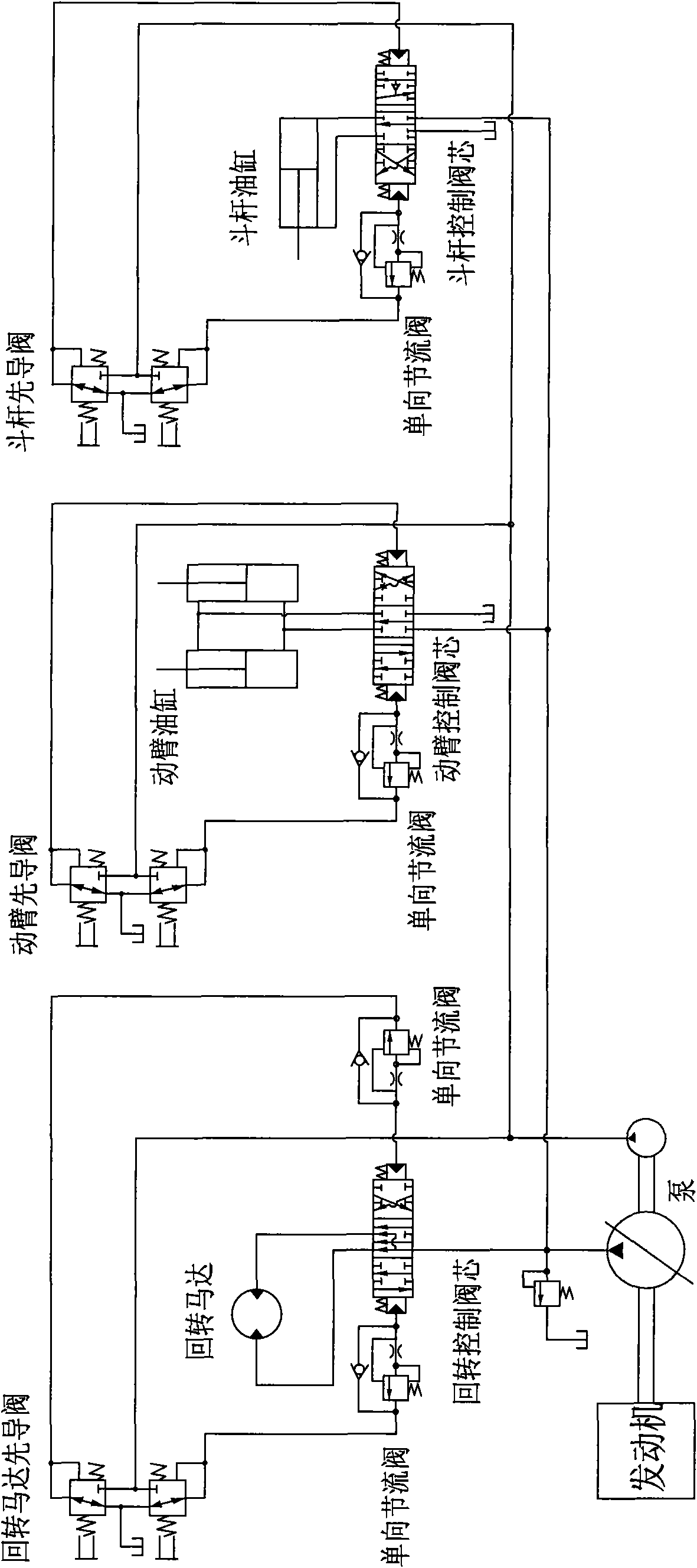

[0025] Example 1: see Figure 1 to Figure 2 As shown, a method and device for improving the operating comfort of an excavator are provided with a one-way throttle valve at each end of the pilot oil path of the swing control spool, and a small cavity end in the pilot oil path of the boom control spool. A one-way throttle valve is set, and a one-way throttle valve is set at the unloading end of the pilot oil circuit of the stick control spool; the one-way throttle valve has the function of pressure compensation, and is composed of a one-way valve, a throttle A valve and a pressure reducing valve are combined, the throttle valve and the pressure reducing valve are connected in series, the two ends of the one-way valve are respectively connected in parallel to the input end of the throttle valve and the output end of the pressure reducing valve. The input end is located on the side of the corresponding pilot valve, and the output end is located on the side of the corresponding mai...

Embodiment 2

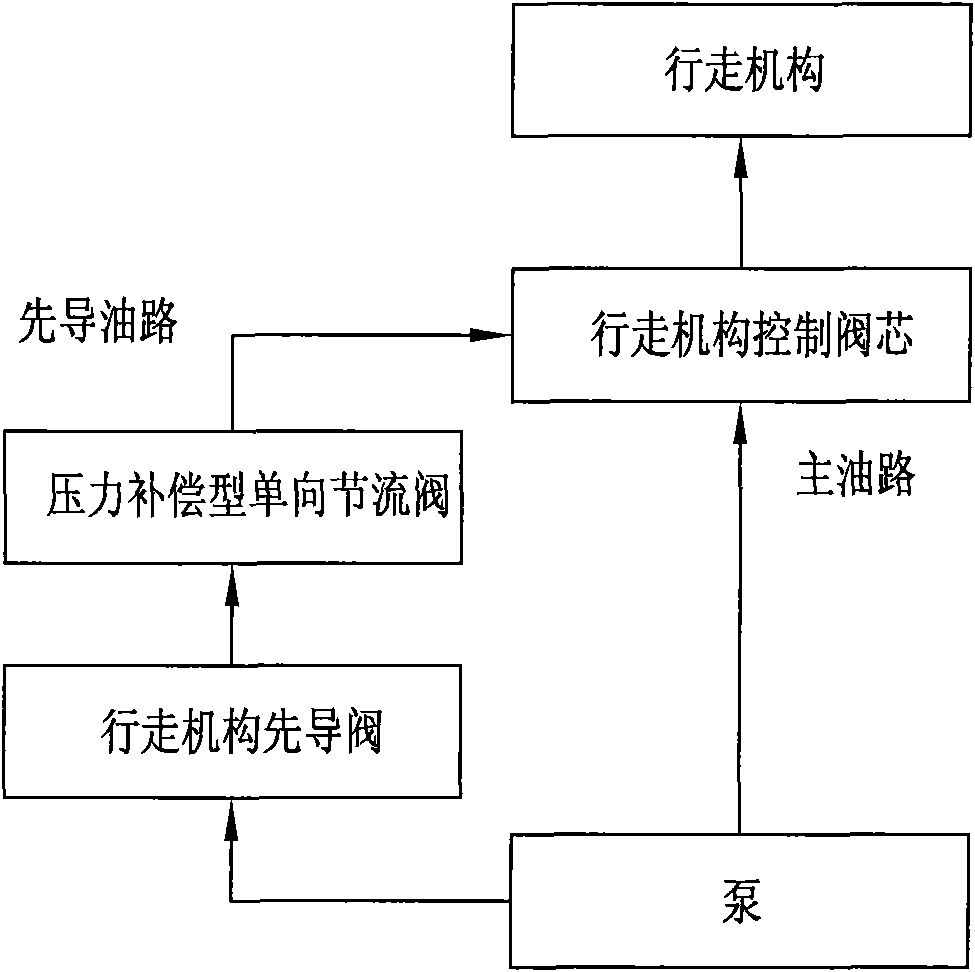

[0027] Example 2: see image 3 , 4 As shown in the figure, a method and device for improving the operating comfort of an excavator are provided with a one-way throttle valve at each end of the pilot oil path of the swing control spool, and pilot oil is provided in the control spool of the boom, stick and bucket. A one-way throttle valve is respectively set at both ends of the road, and a one-way throttle valve is respectively set at both ends of the pilot oil circuit of the traveling mechanism control spool; A one-way valve, a throttle valve and a pressure reducing valve are combined, the throttle valve and the pressure reducing valve are connected in series, and the two ends of the one-way valve are respectively connected in parallel to the input end of the throttle valve and the pressure reducing valve. On the output end, the input end of the check valve is located on the side of the corresponding pilot valve, and the output end is located on the side of the corresponding m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com