Multistage pressure cylinder and pressurization usage method and depressurization usage method thereof

A technology of booster cylinder and secondary booster, applied in the field of hydraulic booster cylinder, can solve the problems of low utilization rate of energy recovery, difficult to control the pressurization process, waste of energy, etc. consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Best practice:

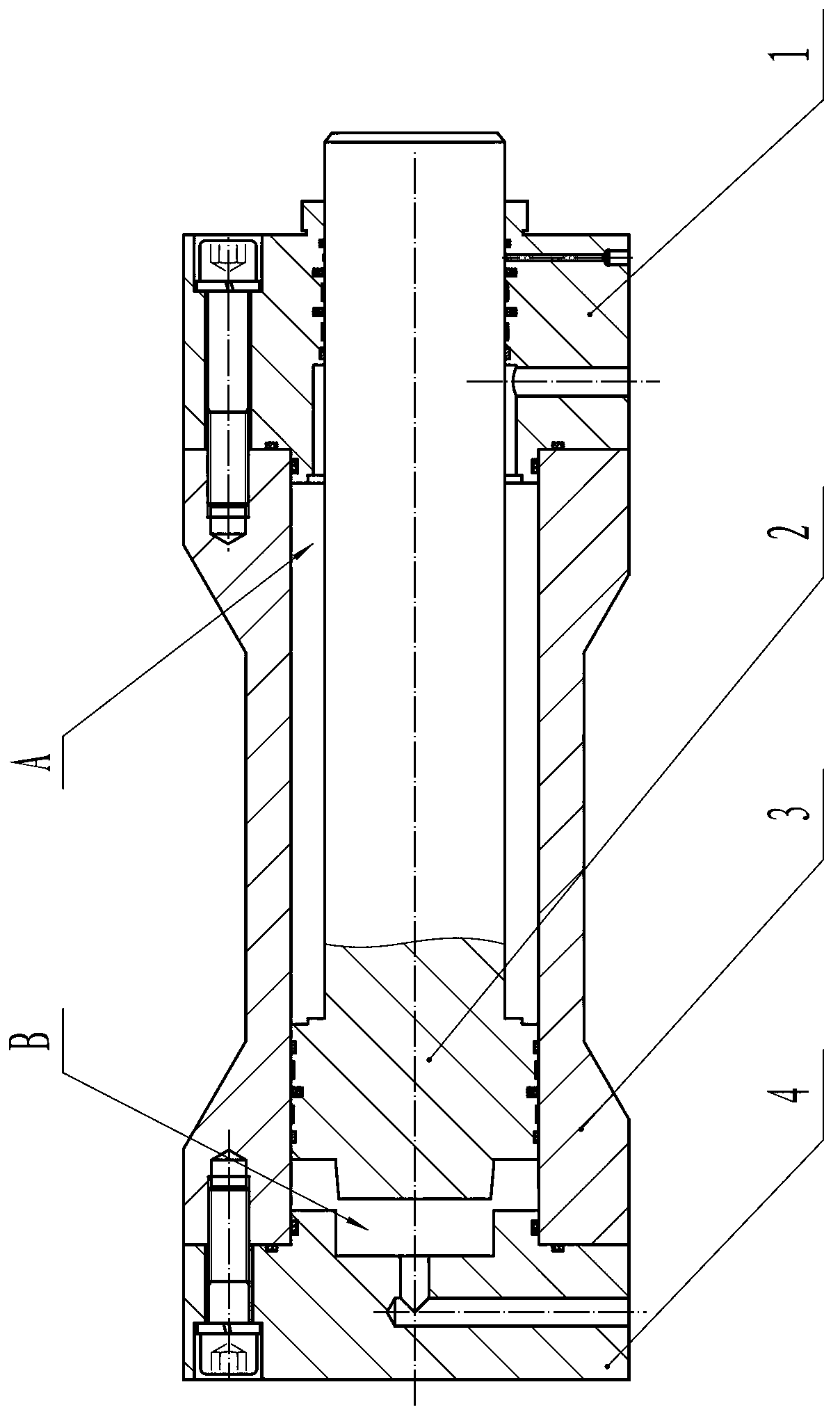

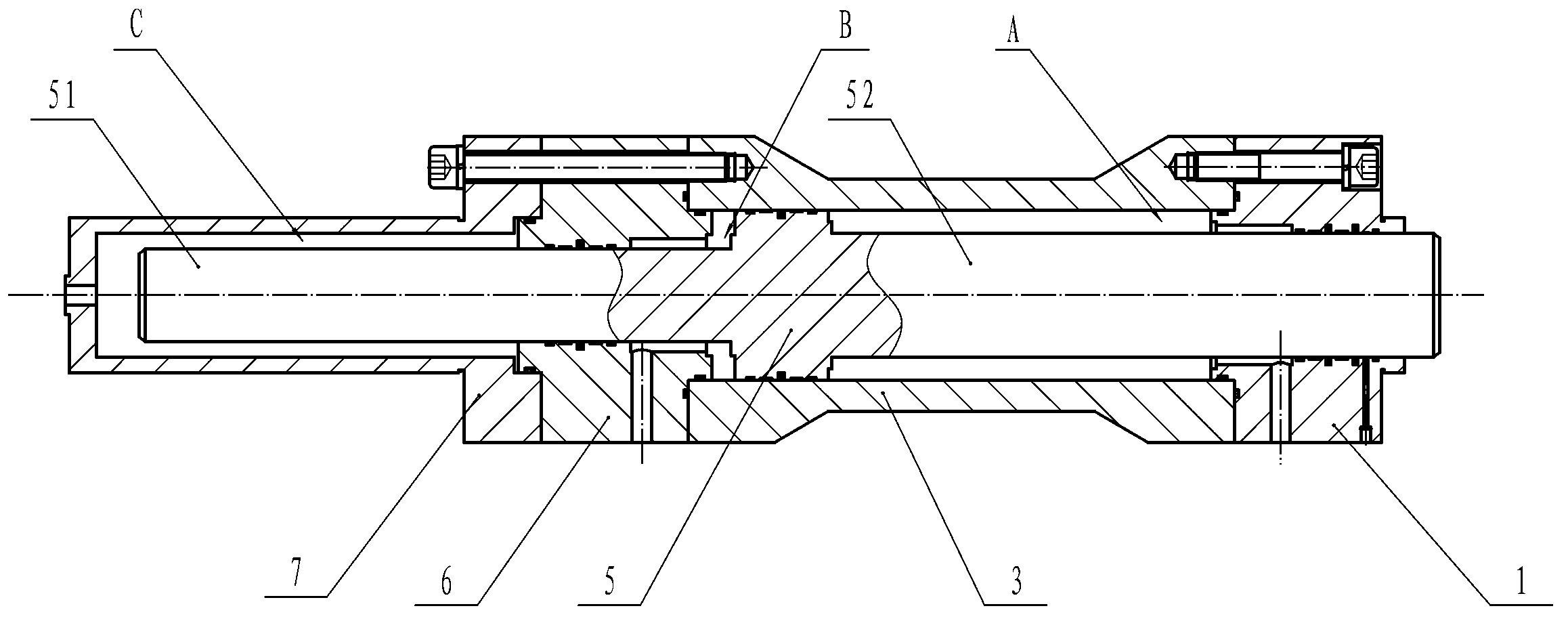

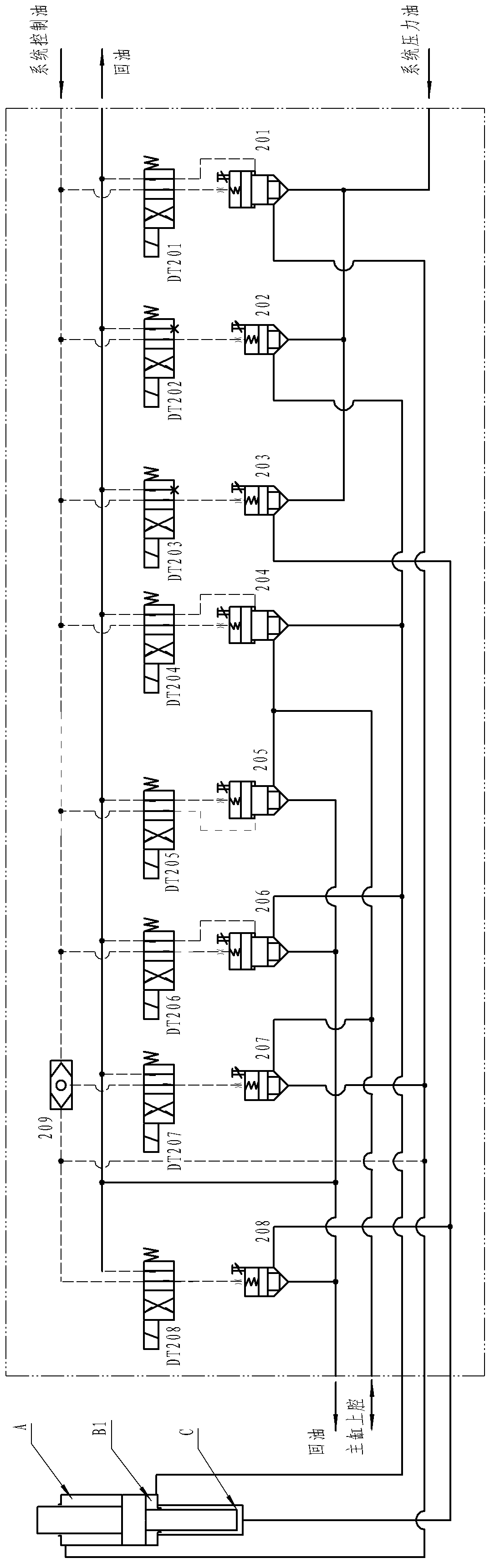

[0039] Such as figure 2 As shown, the multi-stage booster cylinder includes a front cylinder cover 1, a cylinder barrel 3, a piston 2 and a rear cylinder cover 4, the piston 2, the piston front rod 51 and the front cylinder cover 1 form an A cavity with a front rod, and also includes The secondary booster cylinder 7, the piston has a rear rod, the secondary booster cylinder 7 is fixedly installed behind the rear cylinder head 4, and the piston rear rod 51 passes through the rear cylinder head 4 and enters the rear of the secondary booster cylinder 7. In the barrel cavity, the piston rear rod 51, the cylinder barrel 3, and the rear cylinder cover 4 form the B chamber with the rear rod, and the rear cylinder cover 4, the piston rear rod 51, and the secondary booster cylinder 7 form the C cavity with the rear rod. The effective area of chamber B is larger than that of chamber A, and the effective area of chamber C is smaller than that of chamber A. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com