Method for eliminating keyhole-free friction stir spot welding ring groove

A friction stir and spot welding technology, used in welding equipment, non-electric welding equipment, welding/welding/cutting items, etc., it can solve problems such as the gap between the stirring sleeve and the pressing sleeve becoming larger, affecting the mechanical properties of the solder joints, and metal loss. , to achieve easy operation, solve welding ring groove defects, and achieve remarkable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

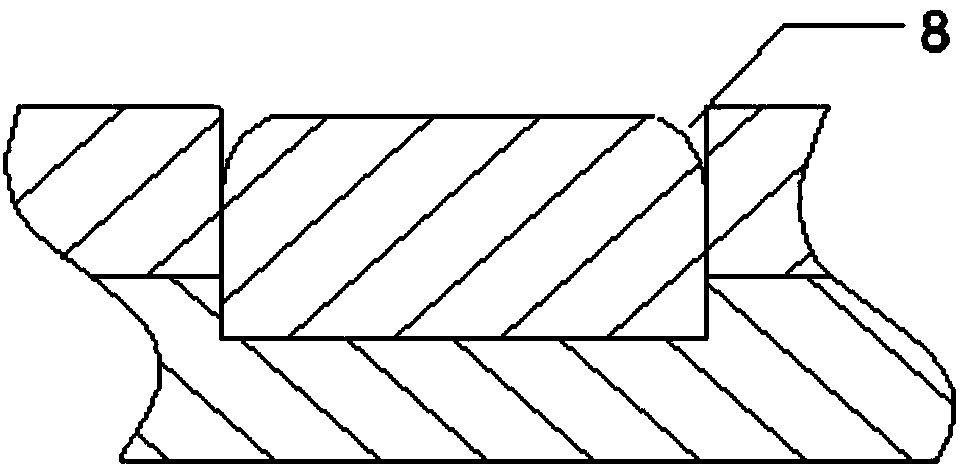

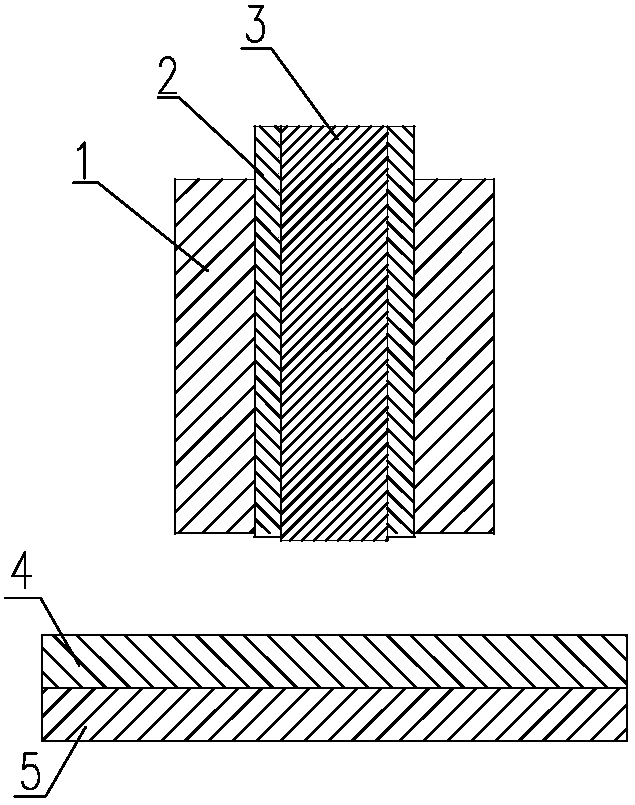

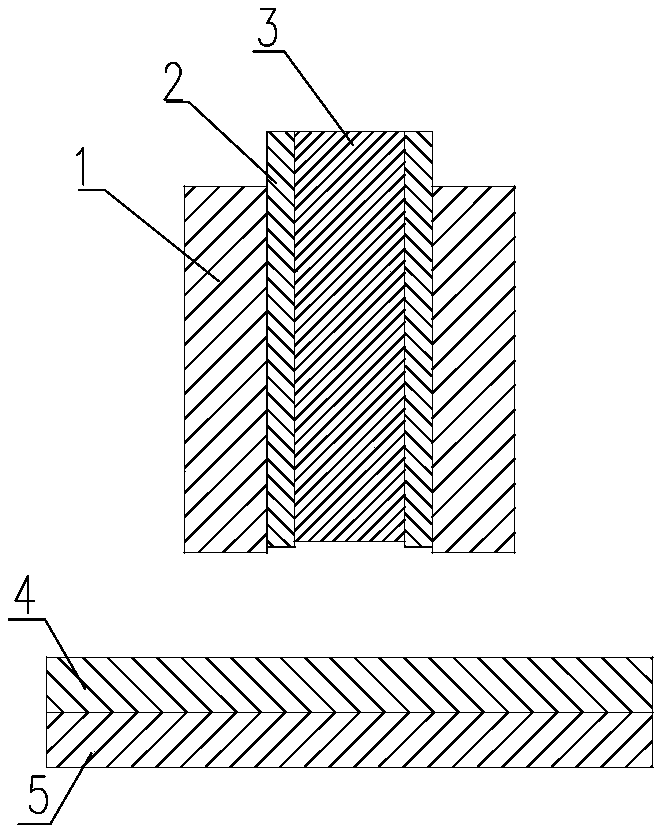

[0036] like Figure 2-7 The shown method for eliminating the ring groove of keyhole friction stir spot welding includes the following steps:

[0037] 1) Base material preparation: the base material thickness is 1 mm, which is two layers, namely the upper base material 4, the lower base material 5,

[0038] 2) Pre-welding preparation: install stirring tools on the welding equipment, wherein the stirring tools are respectively stirring needle 3, stirring sleeve 2 and compression sleeve 1 from the inside to the outside;

[0039] 3) Zero point setting: Before welding, take the bottom surface of the compression sleeve 1 as the reference plane, adjust the equipment so that the stirring needle 3 protrudes downward from the reference plane, and the length of the stirring needle 3 protruding from the reference plane is 0.1mm; at the same time, adjust the equipment so that The stirring sleeve 2 protrudes downwards from the reference plane, and the length of the stirring sleeve 2 protru...

Embodiment 2

[0048] like Figure 2-7 The shown method for eliminating the ring groove of keyhole friction stir spot welding includes the following steps:

[0049] 1) Base material preparation: the base material thickness is 3 mm, which is two layers, that is, the upper base material 4, the lower base material 5,

[0050] 2) Pre-welding preparation: install stirring tools on the welding equipment, wherein the stirring tools are respectively stirring needle 3, stirring sleeve 2 and compression sleeve 1 from the inside to the outside;

[0051] 3) Zero point setting: Before welding, take the bottom surface of the compression sleeve 1 as the reference plane, adjust the equipment so that the stirring needle 3 protrudes downward from the reference plane, and the length of the stirring needle 3 protruding from the reference plane is 0.2mm; at the same time, adjust The equipment makes the stirring sleeve 2 protrude downward from the reference plane, and the length of the stirring sleeve 2 protrudi...

Embodiment 3

[0060] like Figure 2-7 The shown method for eliminating the ring groove of keyhole friction stir spot welding includes the following steps:

[0061] 1) Base material preparation: the base material thickness is 5mm, which is two layers, namely the upper base material 4 and the lower base material 5,

[0062] 2) Pre-welding preparation: install stirring tools on the welding equipment, wherein the stirring tools are respectively stirring needle 3, stirring sleeve 2 and compression sleeve 1 from the inside to the outside;

[0063] 3) Zero point setting: Before welding, take the bottom surface of the compression sleeve 1 as the reference plane, adjust the equipment so that the stirring needle 3 protrudes downward from the reference plane, and the length of the stirring needle 3 protruding from the reference plane is 0.2mm; at the same time, adjust The equipment makes the stirring sleeve 2 protrude downward from the reference plane, and the length of the stirring sleeve 2 protrudi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com