Preparation method and device of passivated lithium microspheres and application

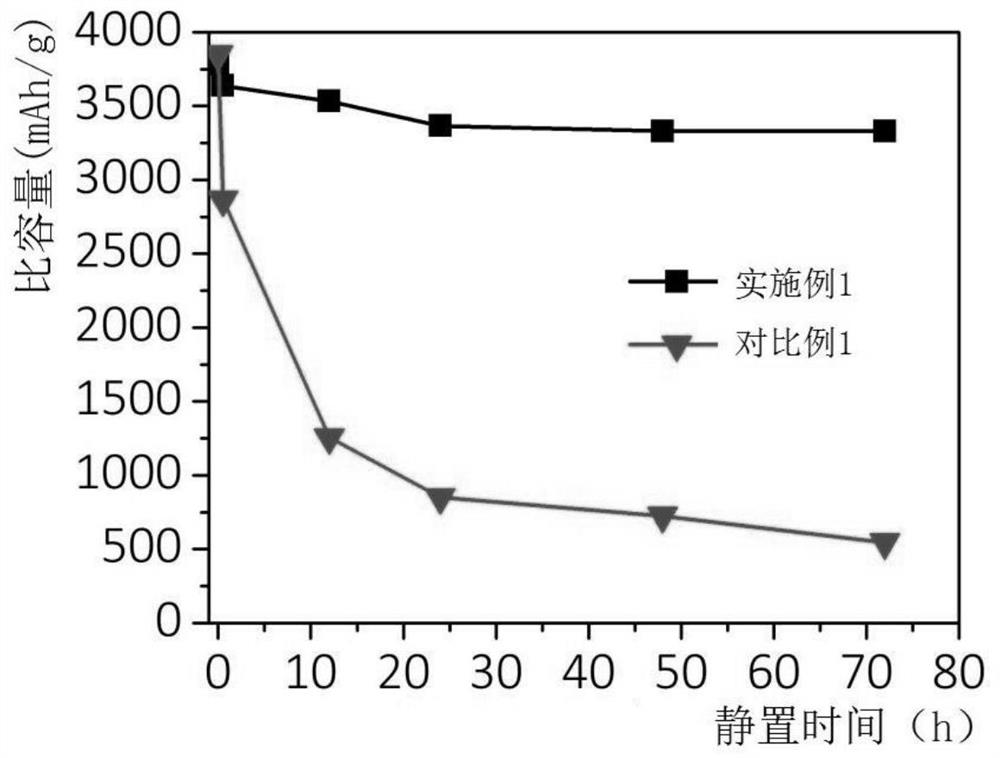

A technology for preparing devices and passivating lithium, which is used in transportation and packaging, electrochemical generators, metal processing equipment, etc. The problem of large size of lithium powder can achieve the effect of offsetting irreversible lithium loss, high first efficiency and narrow particle size distribution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

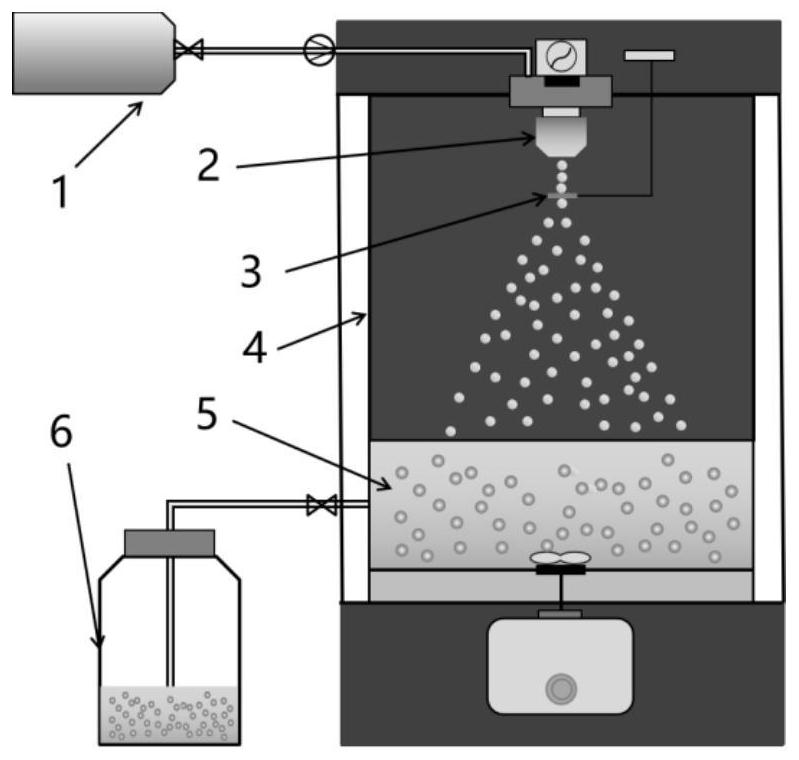

[0051] This embodiment adopts as figure 1 The device prepares passivation lithium microsphere, comprises the steps:

[0052] 1) In a stainless steel melting lithium tank 1 protected by an inert gas, a metal lithium ingot with a purity greater than 99.9% is heated to a molten state at 260° C.

[0053] 2) Transport the molten metal lithium to the fluid vibration nozzle 2 by air pressure pumping, the delivery flow rate is 25mL / min, and the diameter of the fluid vibration nozzle is 0.04mm.

[0054] 3) The metal lithium jet flowing in laminar flow is dispersed into metal lithium droplets by superimposed vibration at the fluid vibration nozzle 2, and the vibration frequency is set to 2000 Hz.

[0055] 4) Metal lithium droplets enter the electrode control unit 3 with static electricity, and gradually solidify into metal lithium microspheres in the dispersion chamber 4 filled with argon gas. The temperature of the dispersion chamber 4 is set at 60°C.

[0056] 5) The metal lithium mi...

Embodiment 2

[0060] This embodiment adopts as figure 1 The device prepares passivation lithium microsphere, comprises the steps:

[0061] 1) In a stainless steel melting lithium tank 1 protected by an inert gas, a metal lithium ingot with a purity greater than 99.9% is heated to a molten state at 260° C.

[0062] 2) The molten metal lithium is transported to the fluid vibration nozzle 2 by pneumatic pumping, the delivery flow rate is 10 mL / min, and the diameter of the fluid vibration nozzle is 0.15 mm.

[0063] 3) The metal lithium jet flowing in laminar flow is dispersed into metal lithium droplets by superimposed vibration at the fluid vibration nozzle 2, and the vibration frequency is set to 4000 Hz.

[0064] 4) The lithium metal droplets enter the electrode control unit 3 with static electricity, and gradually solidify into lithium metal microspheres in the dispersion chamber 4 filled with argon gas. The temperature of the dispersion chamber 4 is set at 80°C.

[0065] 5) The metal li...

Embodiment 3

[0068] This embodiment adopts as figure 1 The device prepares passivation lithium microsphere, comprises the steps:

[0069] 1) In a stainless steel melting lithium tank 1 protected by an inert gas, a metal lithium ingot with a purity greater than 99.9% is heated to a molten state at 260° C.

[0070] 2) Transport the molten metal lithium to the fluid vibration nozzle 2 by air pressure pumping, the delivery flow rate is 30mL / min, and the diameter of the fluid vibration nozzle is 0.06mm.

[0071] 3) The metal lithium jet flowing in laminar flow is dispersed into metal lithium droplets by superimposed vibration at the fluid vibration nozzle 2, and the vibration frequency is set to 1500 Hz.

[0072] 4) Metal lithium droplets enter the electrode control unit 3 with static electricity, and gradually solidify into metal lithium microspheres in the dispersion chamber 4 filled with argon gas. The temperature of the dispersion chamber 4 is set at 50°C.

[0073] 5) The metal lithium mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com