Patents

Literature

100results about How to "Low chemical activity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Freeze-drying protective agent of nucleic acid amplification reaction reagents and freeze-drying method

InactiveCN103911367AHigh glass transition temperatureLess internal hydrogen bondsMicrobiological testing/measurementDNA preparationMANNITOL/SORBITOLFreeze-drying

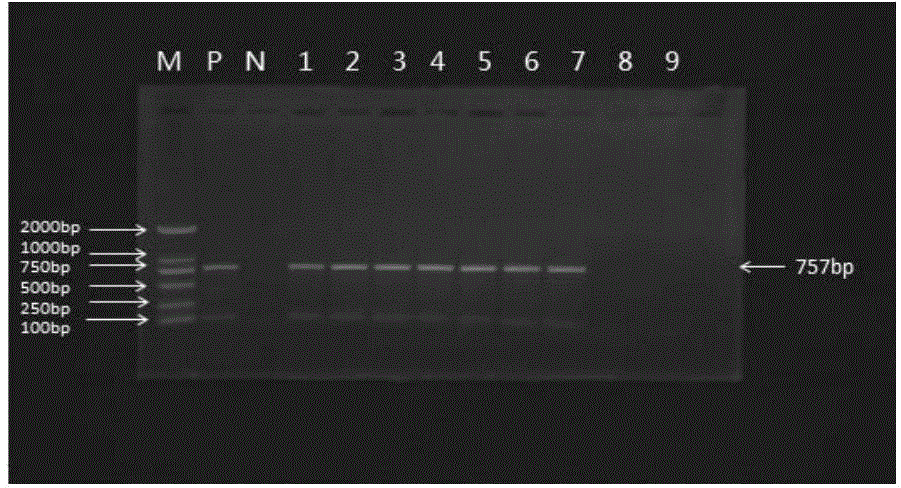

The invention relates to a freeze-drying protective agent of nucleic acid amplification reaction reagents and a freeze-drying method. The invention provides a composition for freeze-drying protection, which is the following 1) or 2): 1) the composition comprises mycose, mannitol, bovine serum albumin, and water with a ratio of 4.0-25g:1-7g:1.0-7g:49-50ml; 2) the composition comprises mycose, mannitol, bovine serum albumin, Tween, Tris-HCl and water with a ratio of 4.0-25g:1-7g:1.0-7g:0.1-0.25ml:2.5*10<-3>-5.0*10<-3>mol:49-50ml. The freeze-drying protective agent of the invention is low in raw material cost, simple in operation, and suitable for large-scale production, can reduce production cost, and can effectively prolong the storage life of nucleic acid amplification reaction reagents.

Owner:CHINA AGRI UNIV

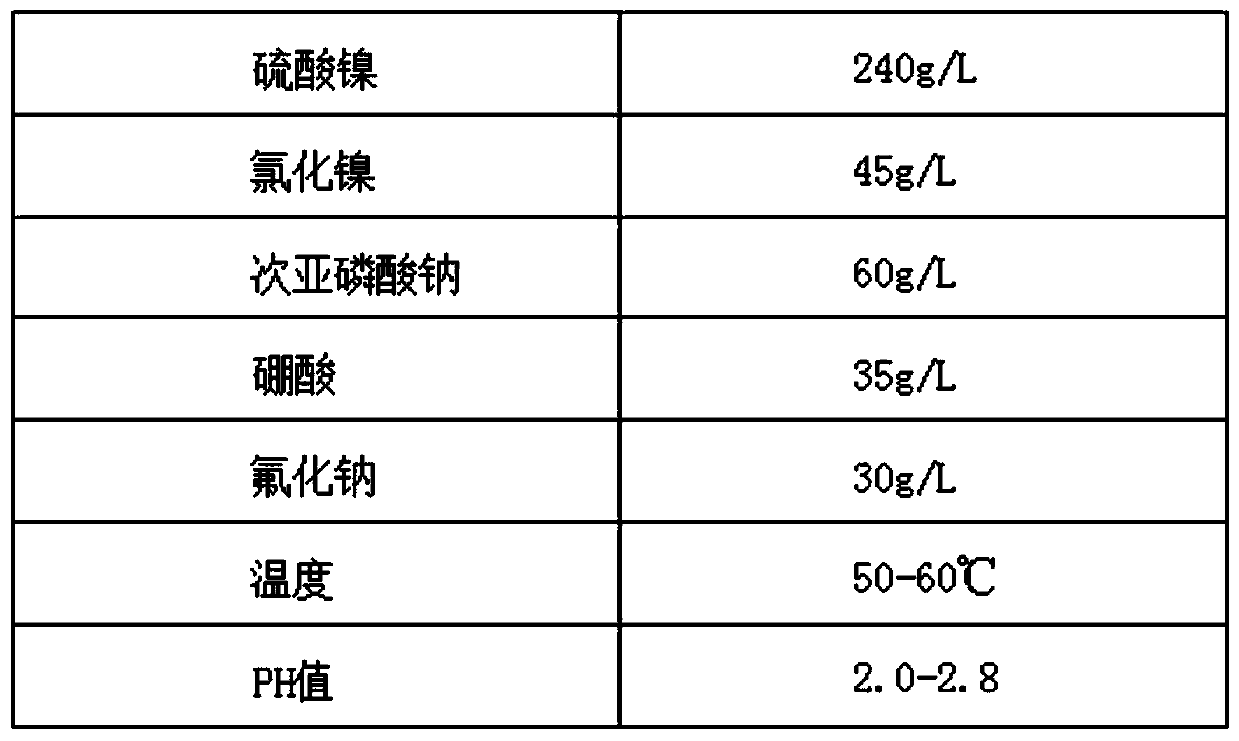

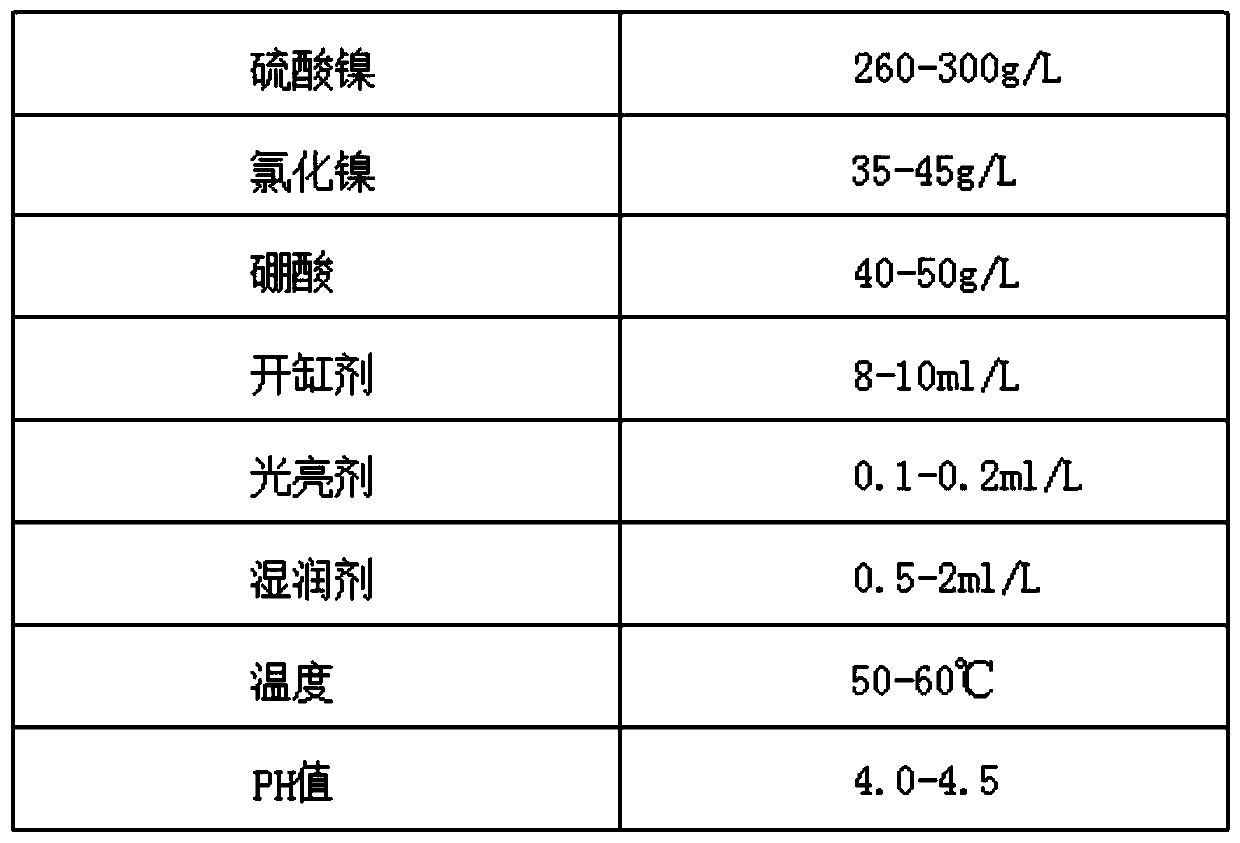

Method for electroplating inorganic molten salt on surface of magnesium and magnesium alloy with aluminum

The invention relates to a method for electroplating inorganic molten salt on surface of magnesium and magnesium alloy with aluminum, which belongs to the technical field of metal surface treatment. The method comprises a step of preplating a zinc layer as a substrate and a step of electroplating inorganic molten salt with aluminum. The step of preplating the zinc layer as the substrate comprises a step of immersion-plating the zinc layer and a step of electroplating the zinc layer. The step of electroplating the zinc layer is performed in an inorganic molten salt system, wherein anhydrous aluminum chloride is main salt, and sodium chloride, potassium chloride or a mixture of the two is a main complexing agent. An aluminum coating obtained by the method is complete, dense, uniform and bright, is firmly combined with a matrix, can be individually used as a protective layer, and can be prepared into a surface functional layer with better corrosion resistance, better wear resistance and high hardness through subsequent treatment. The whole process of the method has the advantages of simple process, cheap equipment, friendliness to environment, and the like.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

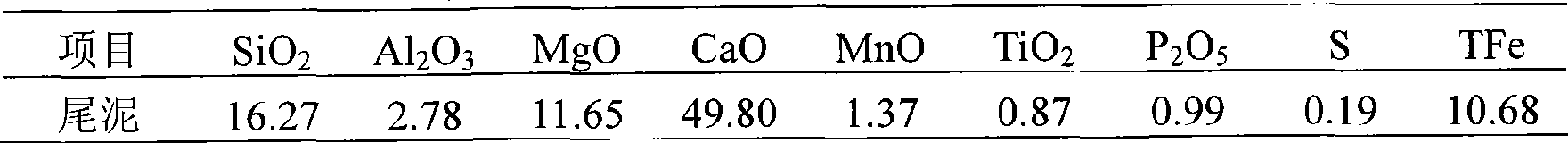

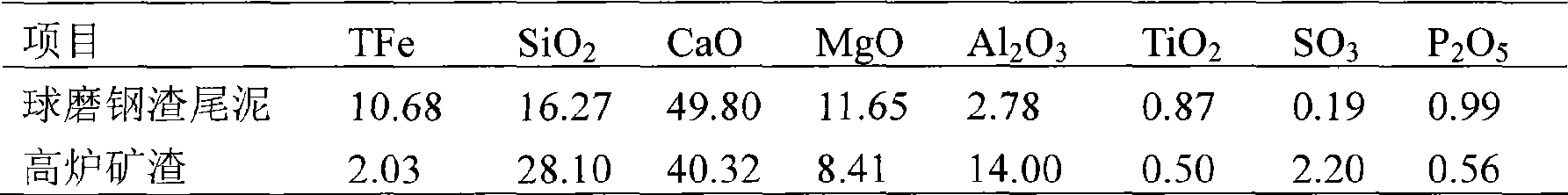

Method for producing steel-scoria and mine-scoria cement by using steel-scoria ball milled waste mud

InactiveCN101172788AReduced influence of volume stabilityLow chemical activityCement productionSlagHigh water content

The invention relates to a production method of steel slag mud slag cement and applying the steel slag ball trail cement in the steel slag mud slag cement. The method comprises the steps as follows: firstly, the steel slag ball trail cement with high water content is dried and dehydrated through heat treatment so as to lower the water content of the steel slag trail cement to be below 4 percent; broken steel slag trail cement is delivered to a ball mill to have powder milling and silicate clinker, blast furnace slag and natural gypsum are matched according to a certain proportion then are mixed in a mixer, thereby producing the steel slag scoria cement of different labels. Adopting the solid castoff of steel enterprises effectively, the invention changes the waste into treasure by a simple production art. The production cost of cement is remarkably reduced.

Owner:LAIWU IRON & STEEL GRP

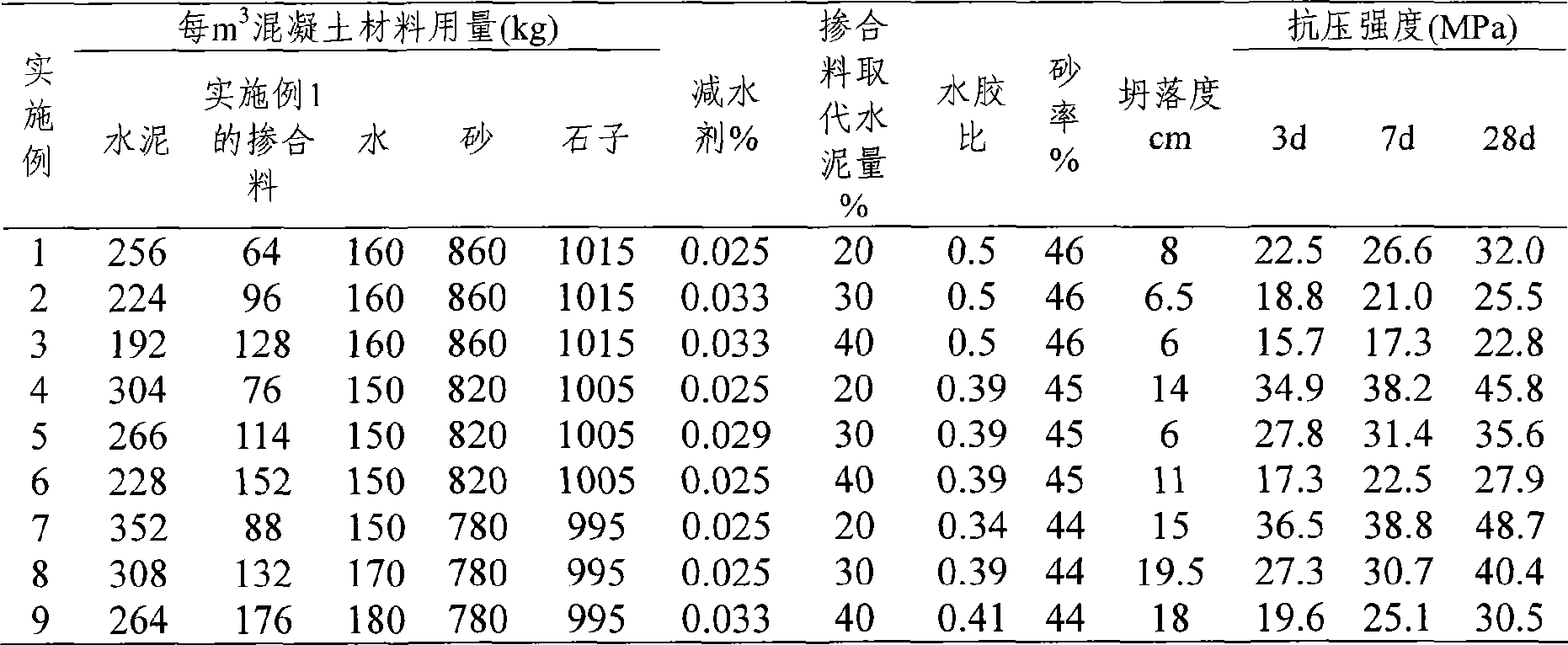

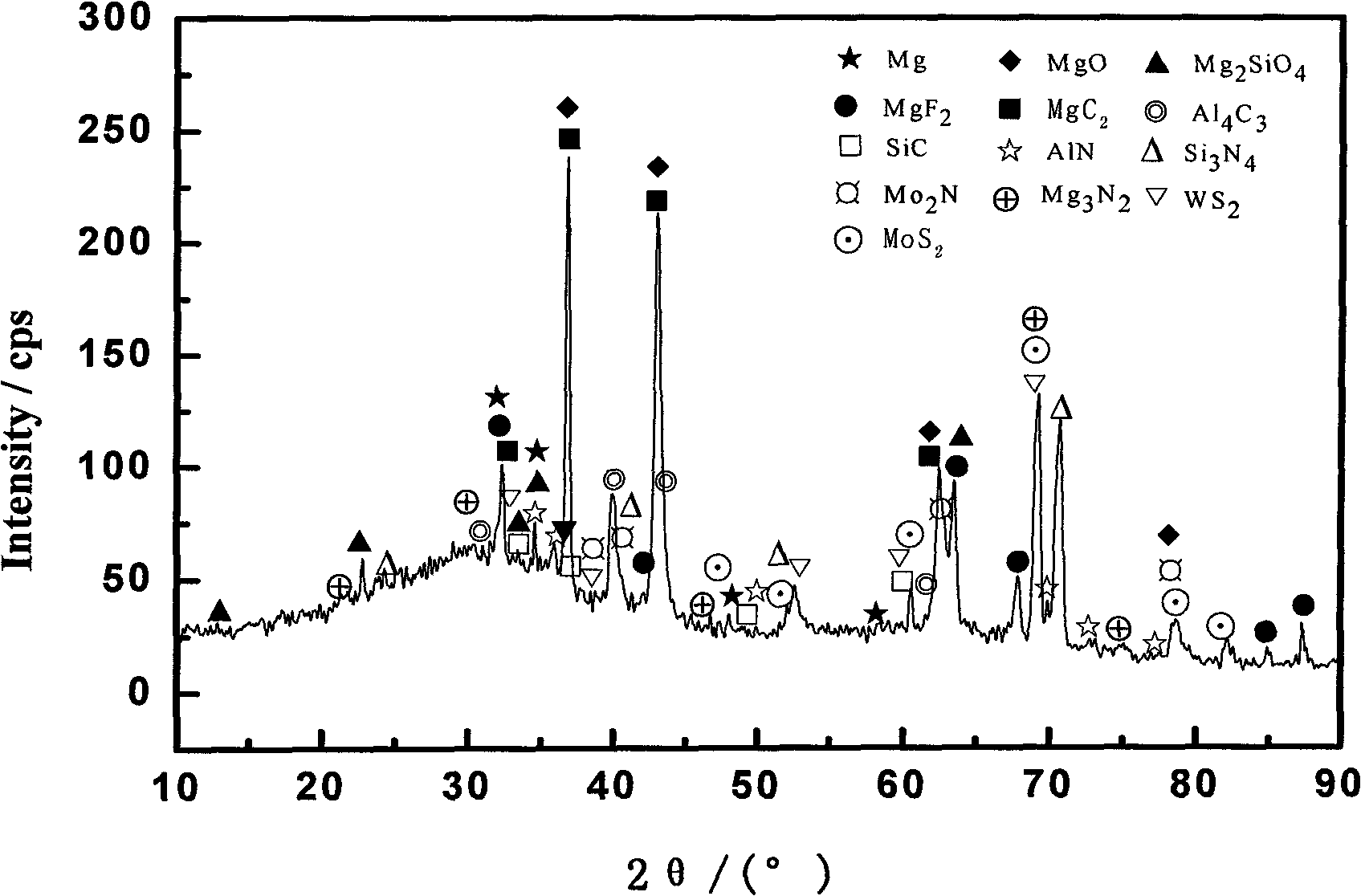

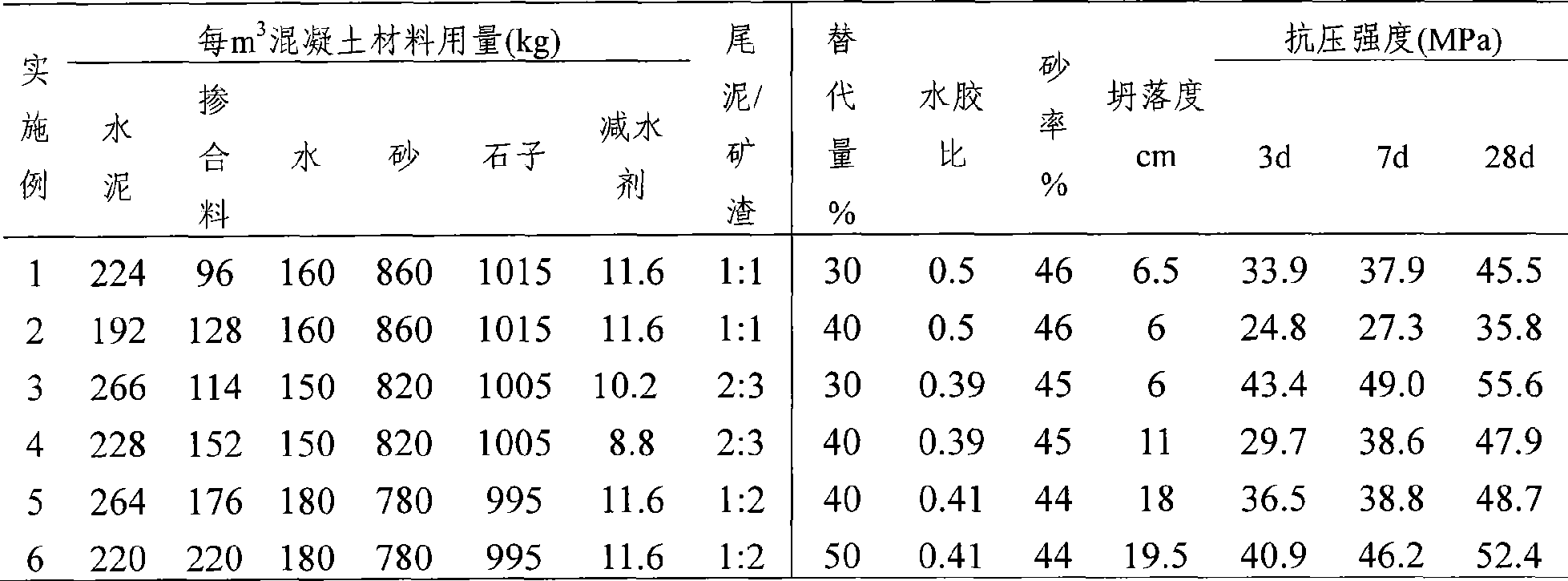

Admixture of active powder of ball milling steel slag tailing slurry and application thereof in preparing concrete

InactiveCN101544480AReduced influence of volume stabilityLow chemical activityCement productionSlagSlurry

The invention relates to an admixture of active powder of ball milling steel slag tailing slurry and the application thereof in preparing concrete. Firstly, the ball milling steel slag tailing slurry with high water content is naturally air-dried and air-cured until the water content of the same is less than 10 percent; secondly, the ball milling steel slag tailing slurry is dried, dehydrated and heated at certain temperature so as to cause the water content of the same to be less than 4 percent, natural gypsum and the dried broken ball milling steel slag tailing slurry are proportionally mixed in a ball mill to be milled into certain fineness so as to be used as concrete admixture; and due to the adoption of proper concrete mixing proportion, the admixture of active powder of ball milling steel slag tailing slurry can be used for partially replacing cement gel according to the weight percentage of 20 to 40 percent, and the concrete with C20-C40 strength degree can be prepared. The invention efficiently utilizes solid wastes of steel enterprises, changes the solid wastes into valuable and has simple production process, obviously reduced concrete production cost and favorable economic and environmental benefit.

Owner:LAIWU IRON & STEEL GRP

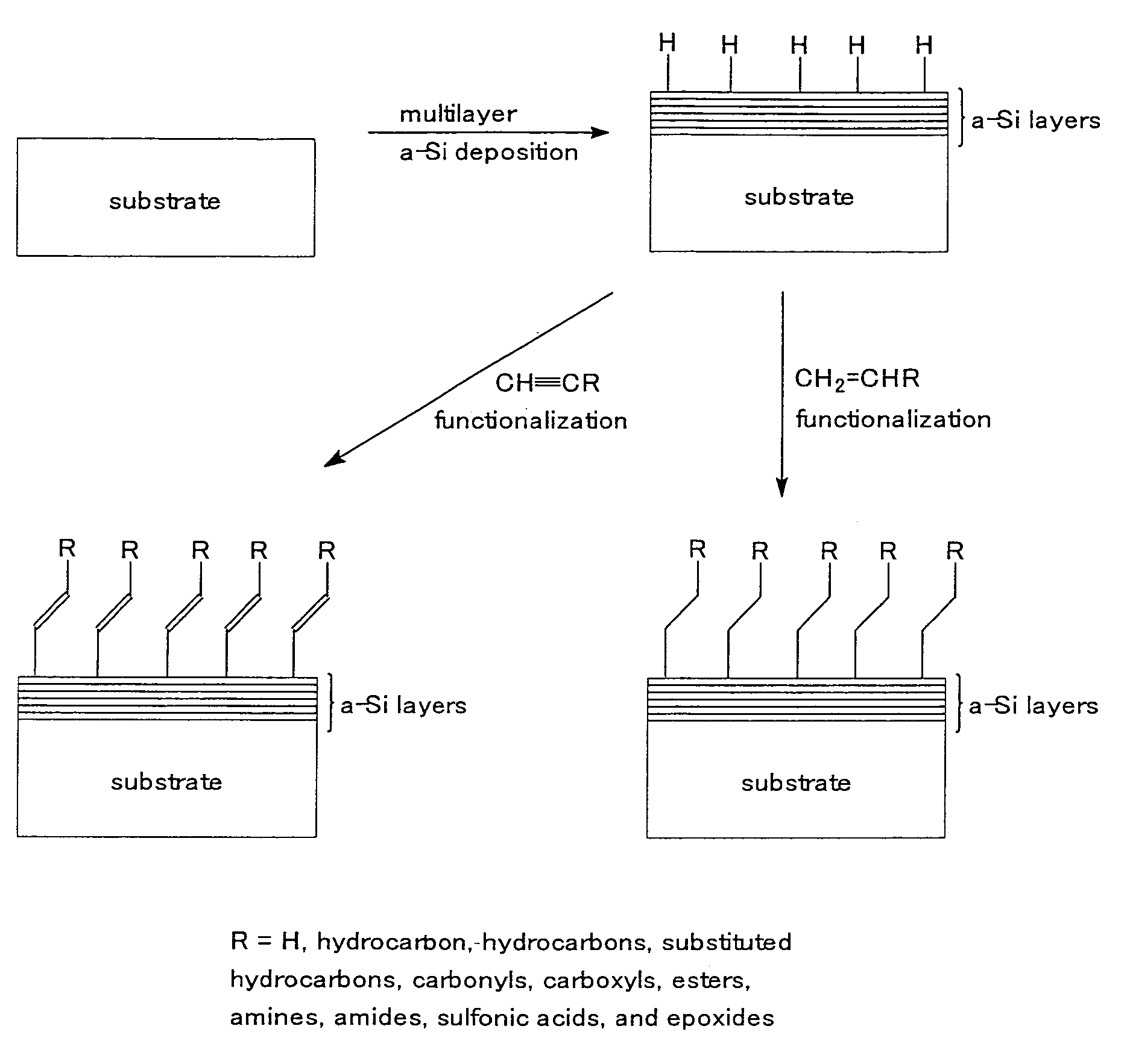

Process for the modification of substrate surfaces through the deposition of amorphous silicon layers followed by surface functionalization with organic molecules and functionalized structures

ActiveUS7867627B2Avoid corrosionRapid desorption of waterGlass/slag layered productsChemical vapor deposition coatingCoated surfaceGas phase

Owner:SILCOTEK CORP

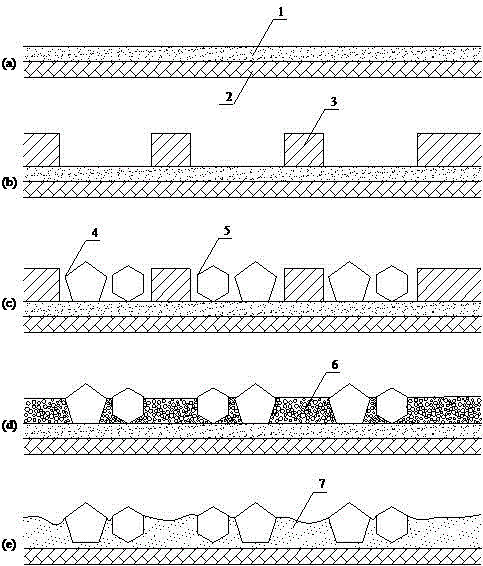

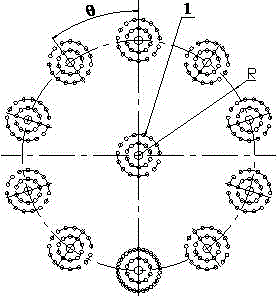

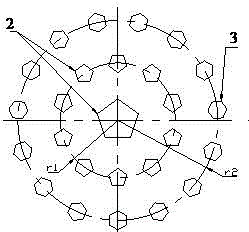

Method for manufacturing abrasive tool with abrasive particle collaborative configuration by virtue of brazing

The invention discloses a method for manufacturing an abrasive tool with abrasive particle collaborative configuration by virtue of brazing, which comprises the following steps: 1) carrying out pretreatment on abrasive materials and a steel substrate; 2) smearing binder onto the surface of the steel substrate uniformly; 3) configuring two kinds of abrasive materials on the surface of the binder according to a corresponding geometric structure; 4) covering the surroundings of the abrasive materials with brazing filler metal, putting into a vacuum furnace, heating at a high temperature, and cooling so as to obtain the abrasive tool. According to the method, diamond and cubic boron nitride are preferably adopted as abrasive materials for manufacturing the brazing tool with abrasive material collaborative configuration by virtue of high-temperature brazing; the excellent thermal expansion performance of the brazing filler metal (Ag-Cu-Ti brazing filler metal and Cu-Sn-Ti brazing filler metal) is utilized to make up the thermal expansion difference of the steel substrate, the alloy brazing filler metal and the abrasive materials, the brazed connection of the abrasive materials and the steel substrate is successively realized, and the application field of the brazing abrasive tool is broadened.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

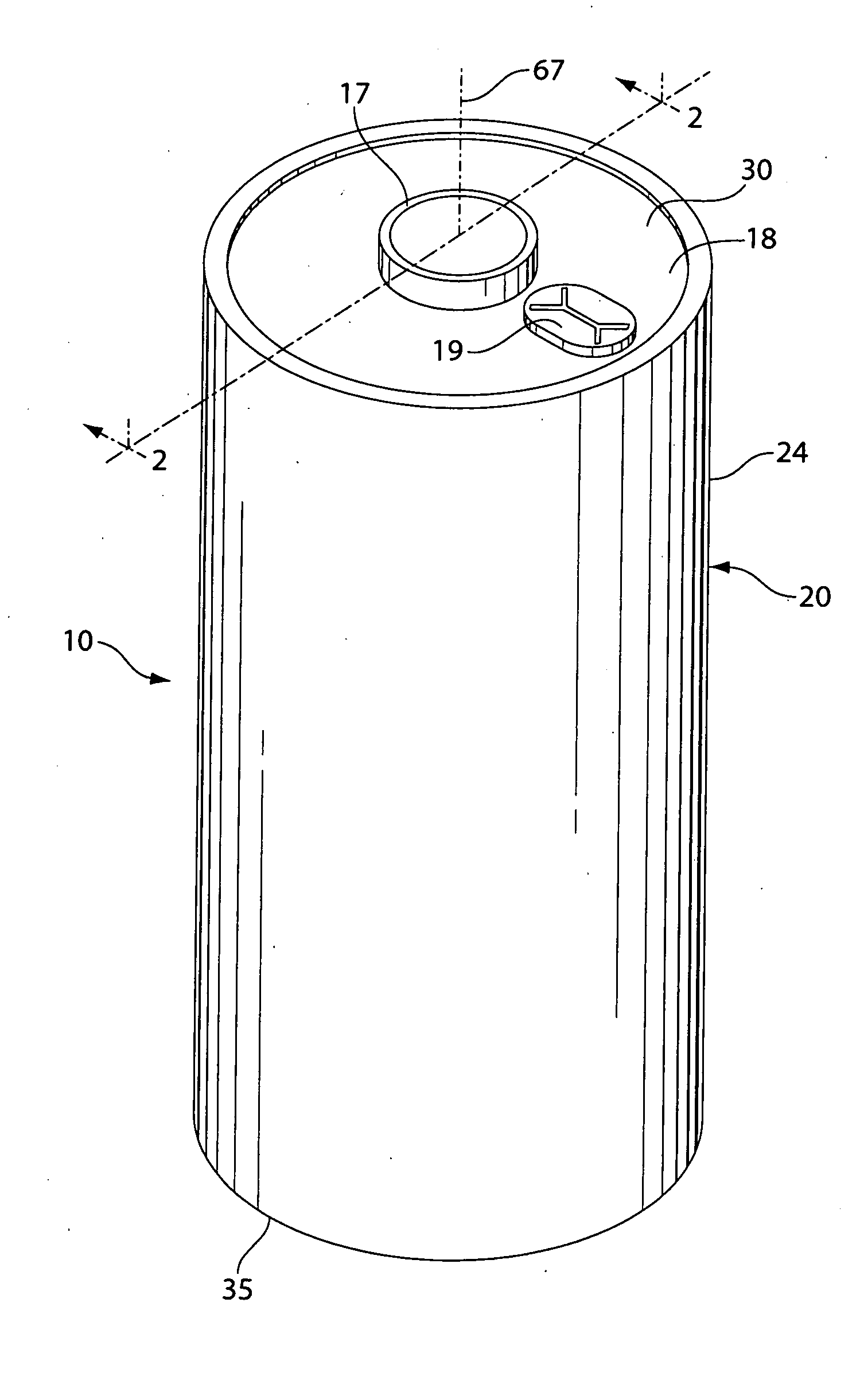

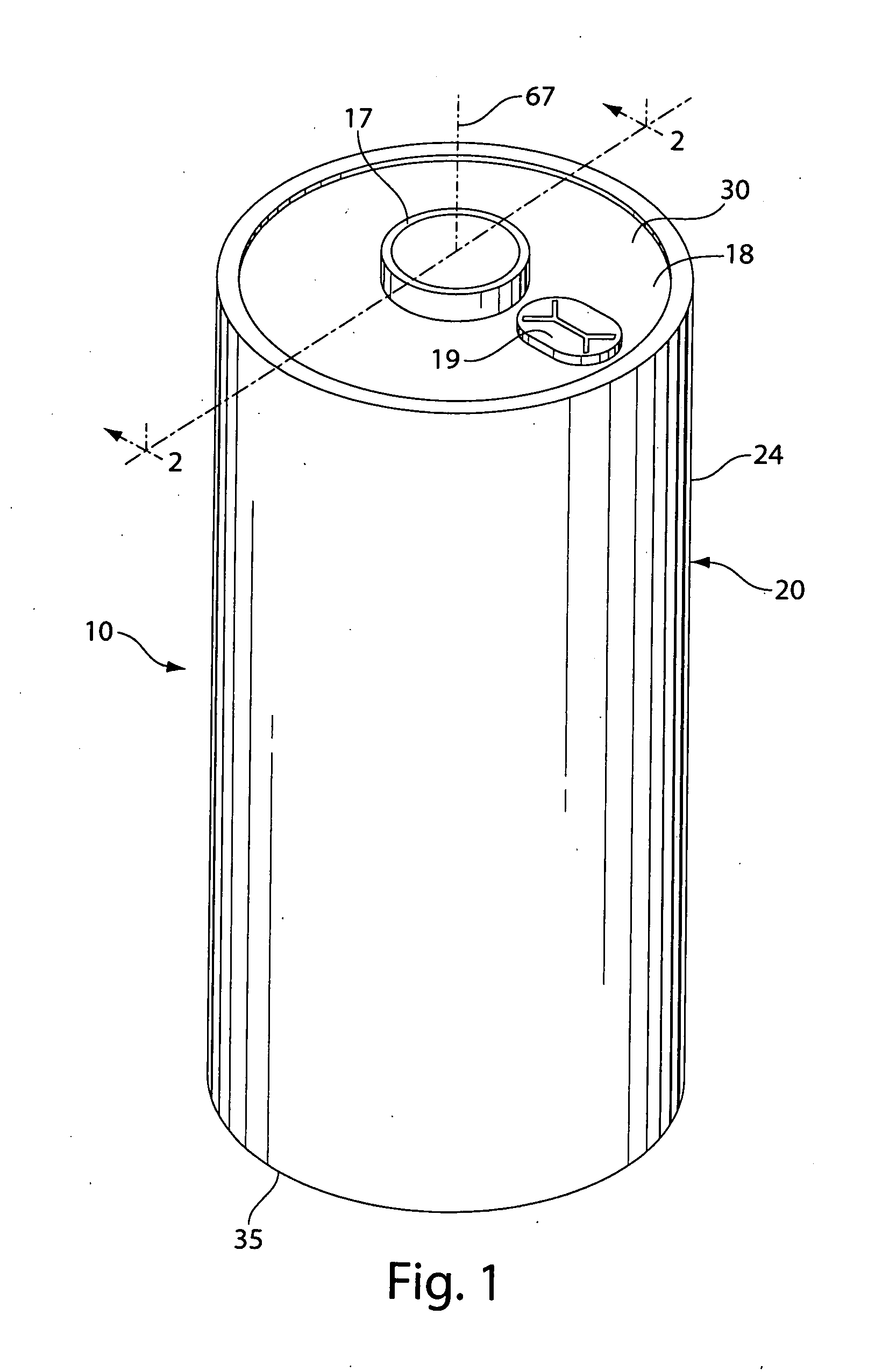

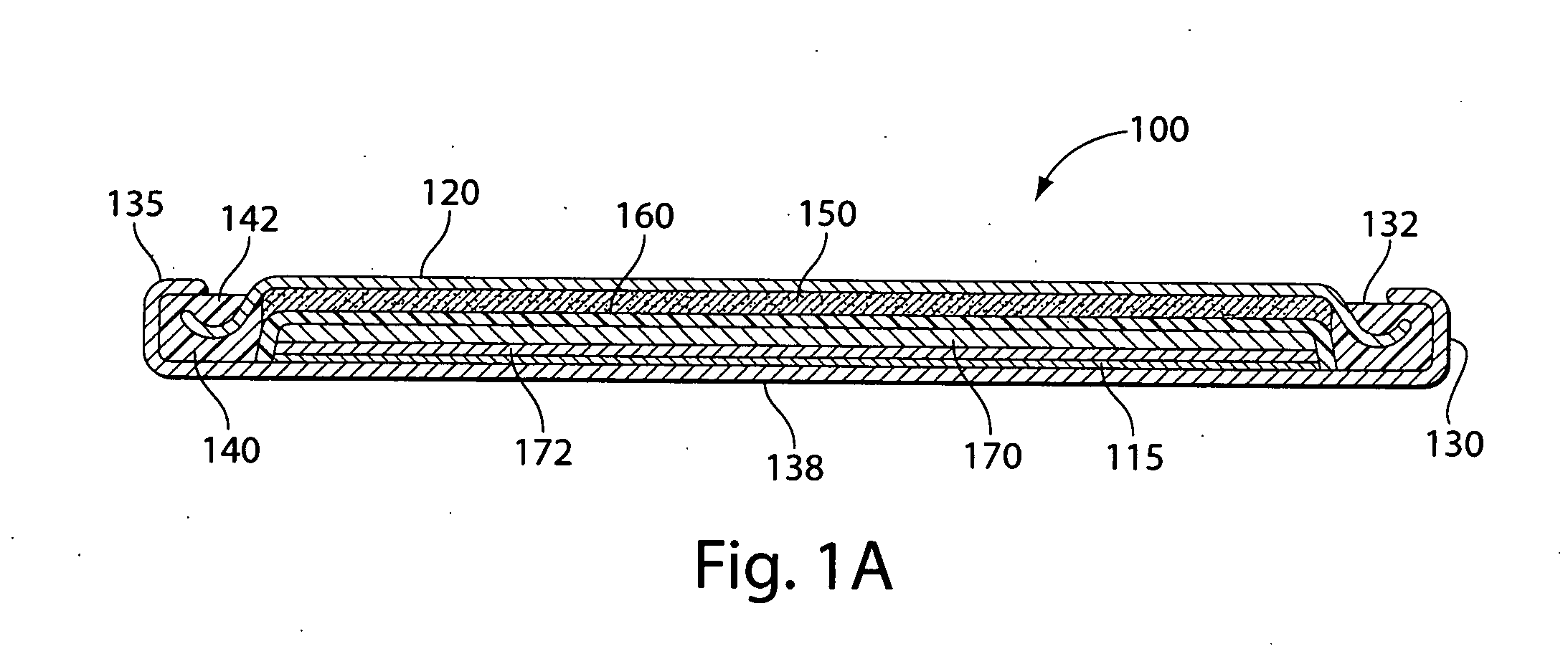

Lithium cell with iron disulfide cathode

InactiveUS20100203370A1Advantage in cell performanceAdvantages in cell performanceCell electrodesOrganic electrolyte cellsLithium metalAlloy

A primary cell having an anode comprising lithium or lithium alloy and a cathode comprising iron disulfide (FeS2) and carbon particles. The electrolyte comprises a lithium salt preferably lithium iodide (LiI) dissolved in an organic solvent mixture. The solvent mixture preferably comprises dioxolane and dimethoxyethane. The electrolyte typically contains between about 100 and 2000 parts by weight water per million parts by weight (ppm) electrolyte therein. The anode may be lithium metal or preferably is a lithium alloy. A cathode slurry is prepared comprising iron disulfide powder, carbon, binder, and a liquid solvent. The mixture is coated onto a conductive substrate and solvent evaporated leaving a dry cathode coating on the substrate. The anode and cathode can be spirally wound with separator therebetween and inserted into the cell casing with electrolyte then added.

Owner:THE GILLETTE CO

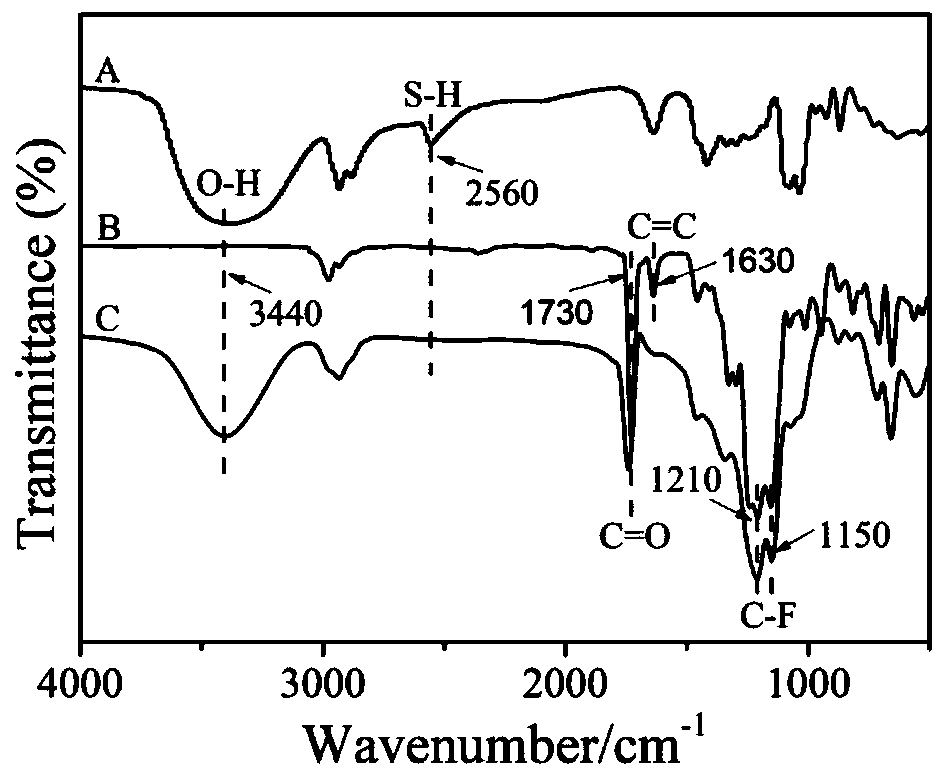

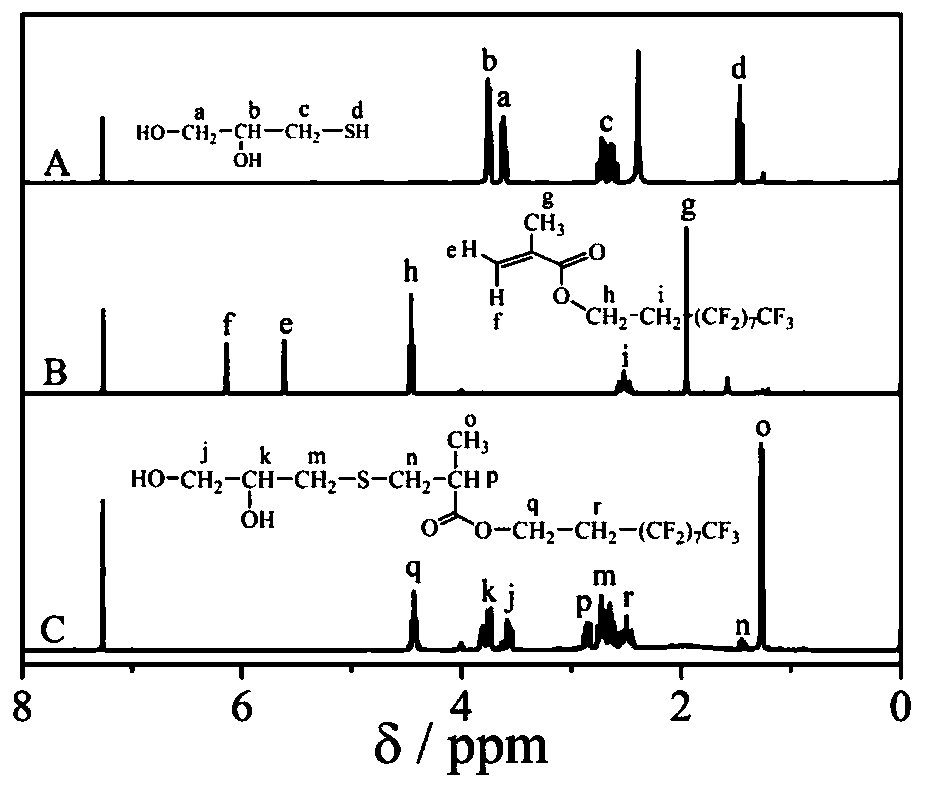

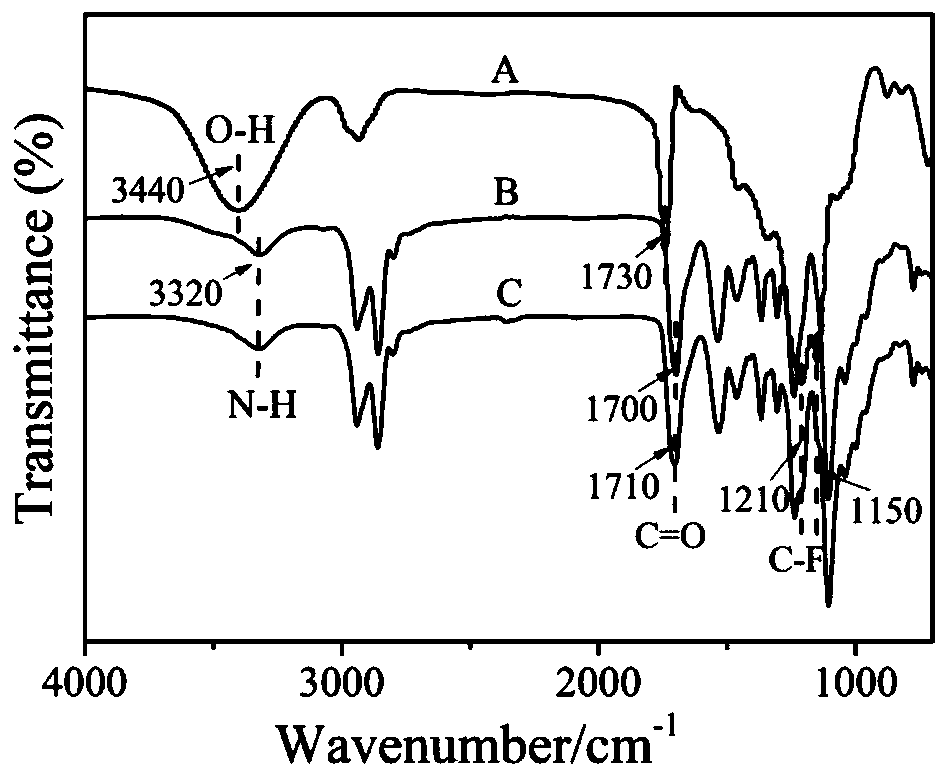

Fluorine-containing waterborne polyurethane material with waterproof, oil-proof and anti-fouling properties

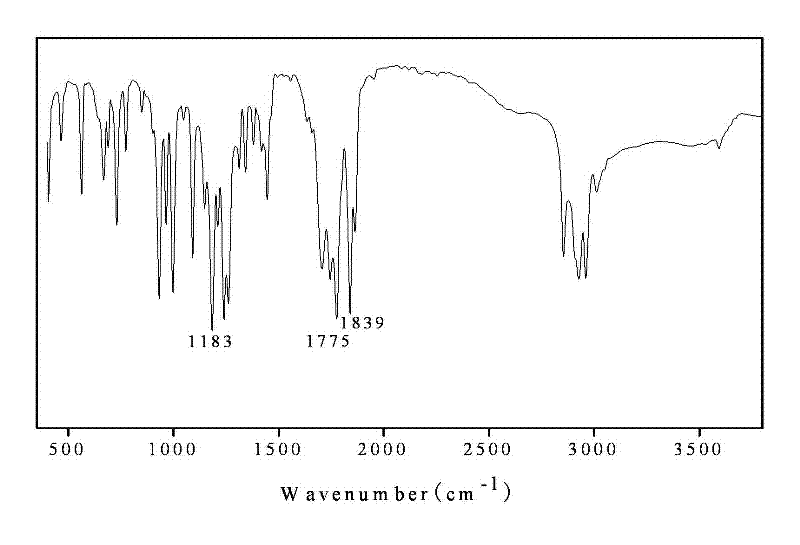

ActiveCN111423554AWaterproofGood biocompatibilityAntifouling/underwater paintsPaints with biocidesPolymer scienceFluorocarbon

The invention discloses a fluorine-containing waterborne polyurethane material with waterproof, oil-proof and anti-fouling properties. The preparation method comprises the following steps: firstly, synthesizing a dihydroxy fluorocarbon chain monomer through sulfydryl-vinyl Michael addition reaction; carrying out addition polymerization reaction with a diisocyanate-terminated polyurethane prepolymer to introduce the prepolymer into polyurethane, and respectively carrying out chain extension reaction and neutralization reaction to obtain the fluorine-containing waterborne polyurethane material with the waterproof, oil-proof and anti-fouling properties. The fluorine-containing waterborne polyurethane material has a wide application prospect in the fields of biomedicine, leather finishing agents and the like.

Owner:SICHUAN UNIV

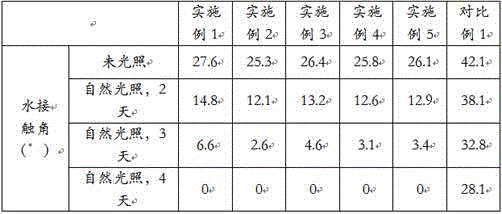

Modified nano titanium dioxide self-cleaning coating and preparation method thereof

ActiveCN106380981AHigh purityUniform particle sizeAntifouling/underwater paintsPaints with biocidesFiltrationUltrasonic dispersion

The invention belongs to the technical field of chemical coatings, and in particular, relates to a modified nano titanium dioxide self-cleaning coating and a preparation method thereof. The preparation method comprises the following steps: adding 1.5-3 parts of boron and nitrogen doped and coated nano titanium dioxide into an ethanol aqueous solution, stirring and dispersing, adding 0.5-2.5 parts of an organic silane coupling agent, carrying out stirring and heat preservation reaction, then carrying out suction filtration, drying and grinding to obtain silanized boron and nitrogen doped and coated nano titanium dioxide; dispersing 1.5-3 parts of the silanized boron and nitrogen doped and coated nano titanium dioxide into a mixed solution of 15-25 parts of an acrylate monomer and 0.5-2 parts of a co-emulsifier, stirring, carrying out ultrasonic dispersion, then adding 2-6 parts of an emulsifier and 50-90 parts of deionized water, stirring, carrying out ultrasonic dispersion, adding 0.3-0.6 part of an initiator, and carrying out heat preservation for 3-5 h, to obtain the modified nano titanium dioxide self-cleaning coating. The self-cleaning coating has the advantages of good dispersion of titanium dioxide and strong self-cleaning ability.

Owner:ZHEJIANG RUNYANG NEW MATERIAL TECH

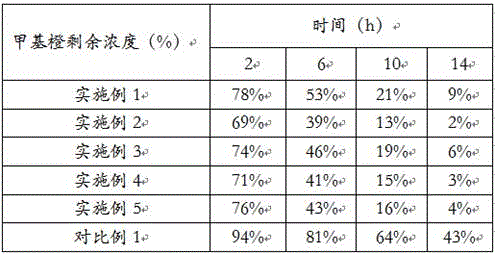

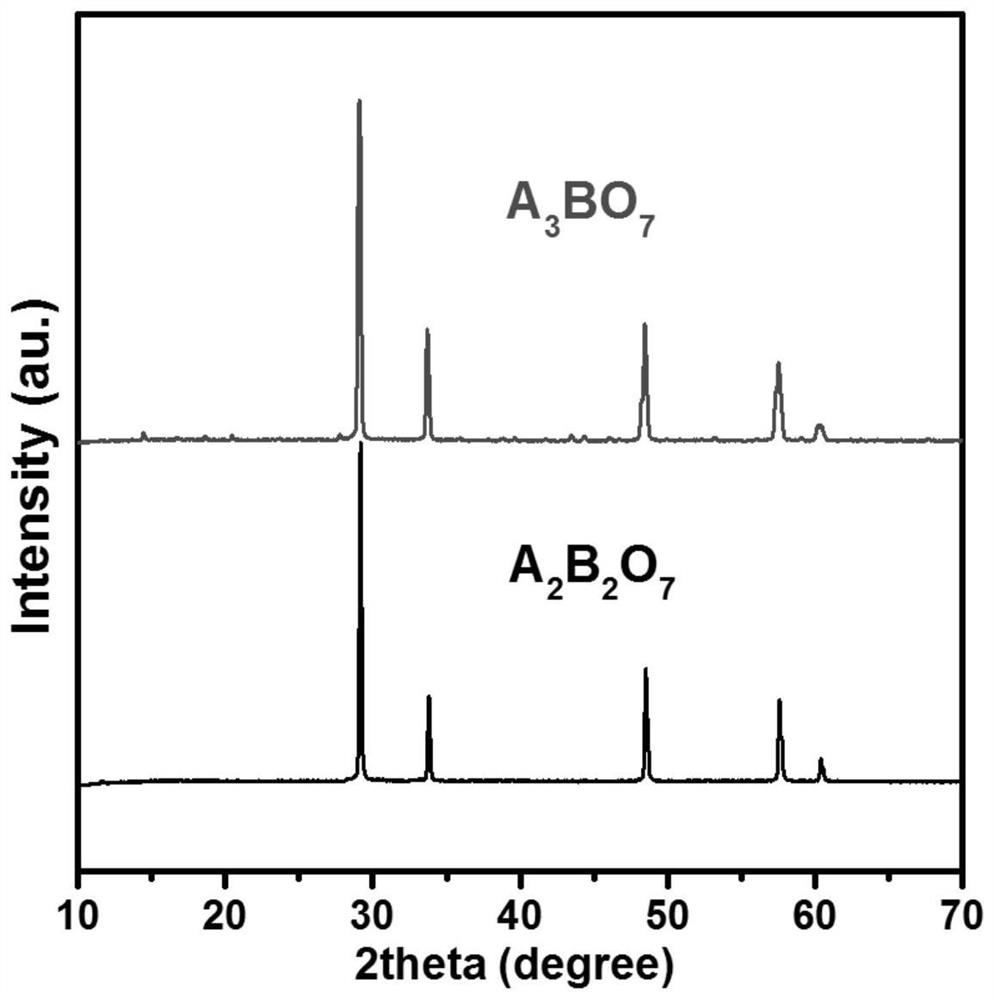

High-entropy stable rare earth tantalate/niobate ceramic and preparation method thereof

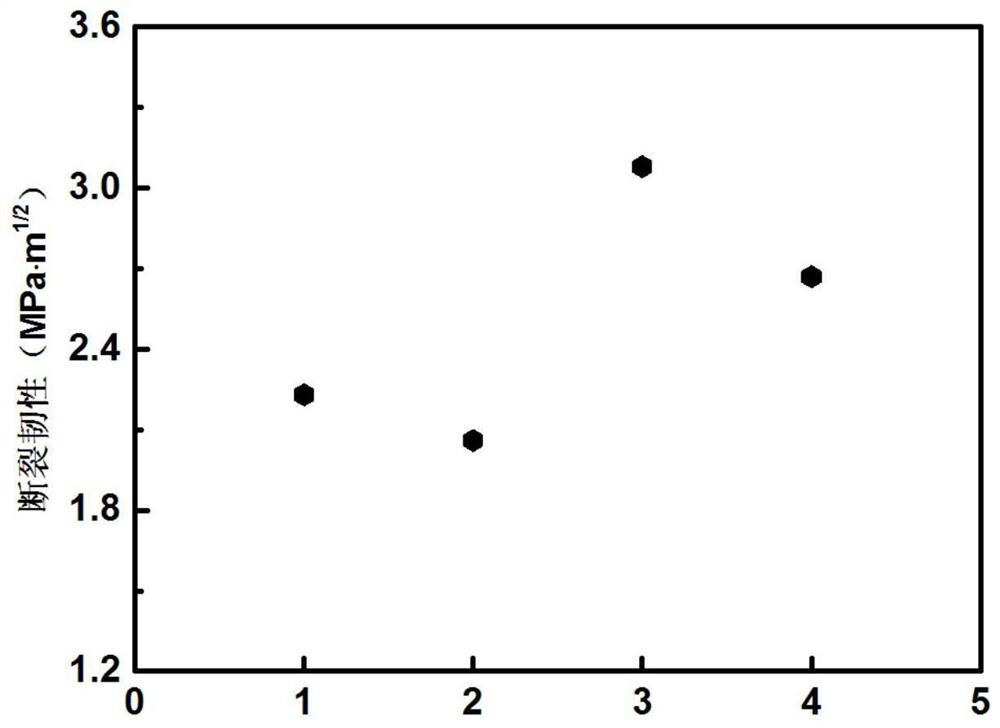

The invention discloses a high-entropy stable rare earth tantalate / niobate ceramic and a preparation method thereof, and the preparation method comprises the following steps: taking rare earth oxide RE2O3, tantalum oxide Ta2O5, niobium oxide Nb2O5 and MO2 oxide as raw materials, and taking A3BO7 type rare earth tantalate / niobate RE<3>Ta<1-x> Nb<x>O<7> ceramic as a matrix, and adding three or more MO2 oxides to equivalently replace rare earth and tantalum / niobium elements at positions A and B to obtain the novel high-entropy stable rare earth tantalate / niobate ceramic material RE < 3-y > Ta < 1-y / 2-x > Nb < x-y / 2 > M < 2y > O<7>. The ceramic material prepared by the invention has the characteristics of low thermal conductivity, high thermal expansion coefficient, high hardness, high fracture toughness, controllable crystal structure and the like, and can be used as a high-temperature protection material for thermal barrier coatings, environmental barrier coatings, nuclear material storages and the like.

Owner:KUNMING UNIV OF SCI & TECH

Preparation method of composite film on surface of magnesium alloy and solution formula for preparation method

InactiveCN102321906AImprove performanceImprove carrying capacityAnodisationFriction reductionPlasma electrolytic oxidation

The invention relates to a preparation method of a composite film on the surface of a magnesium alloy and a solution formula for the preparation method. The preparation method comprises the following steps of: (1) placing a polished and washed magnesium alloy work piece into electrolyte containing elements to be permeated and then carrying out plasma electrolytic permeation treatment to form a surface modified layer containing distributed permeated elements on the surface of the magnesium alloy work piece; (2) washing the processed work piece, placing the processed work piece into alkaline electrolyte and carrying out plasma electrolytic oxidation treatment; and finally, obtaining a composite film on the surface of the work piece, wherein the composite film has excellent combination properties, such as high hardness, corrosion resistance, wear resistance and friction reduction. The solution formula for the preparation method is as follows: the electrolyte for carrying out the plasma electrolytic permeation treatment contains 10-140 g / L of compound A containing elements C, N, B and S to be permeated and 2-30 g / L of sodium hydroxide; and the compound A is one or combination of more of formamide, urea, ethanolamine, borax and thiourea.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

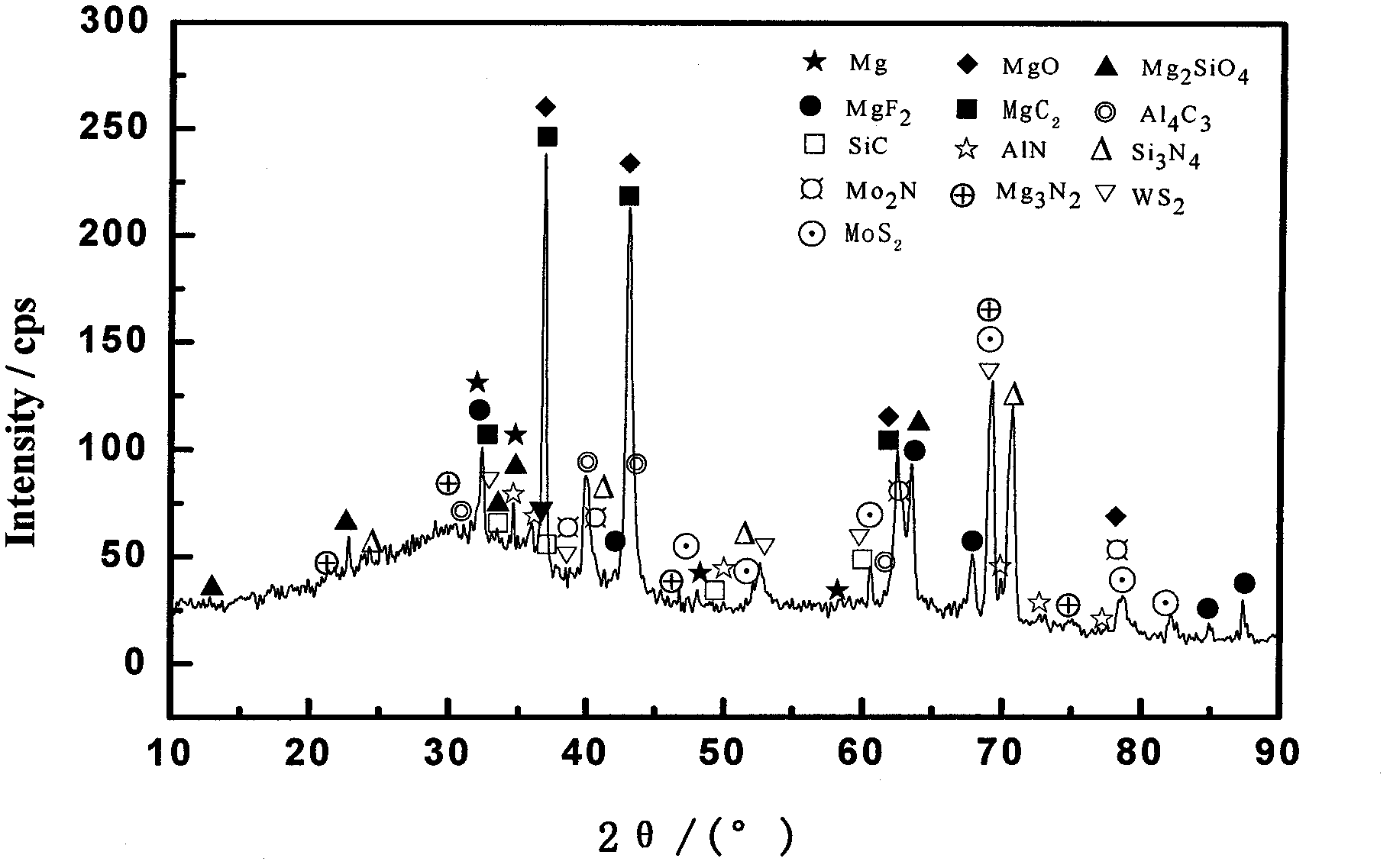

Compound active powder of ball milling steel slag tailing slurry and blast-furnace slag and application of compound active powder in preparing concrete

InactiveCN101544479AReduced volume stabilityReduced Volume Stability EffectsCement productionSlagSlurry

The invention relates to compound active powder of ball milling steel slag tailing slurry and blast-furnace slag and the application of the compound active powder in preparing concrete. The admixture is prepared by mixing ball milling steel slag tailing slurry powder and blast-furnace slag powder with equal Brinell specific surface area of 500-600 m <2> / kg according to the weight ratio of 1:1-2. When the compound active powder is used as concrete admixture, proper concrete mixing portion is adopted; and the admixture can be used for partially replacing equivalent cement gel according to the proportion of 30-50 percent so as to prepare the concrete with C30-C50 strength degree. The invention utilizes solid wastes of steel enterprises, changes the solid wastes into valuable and has simple production process, ensures that the concrete has good performance and markedly lowered manufacturing cost.

Owner:LAIWU IRON & STEEL GRP

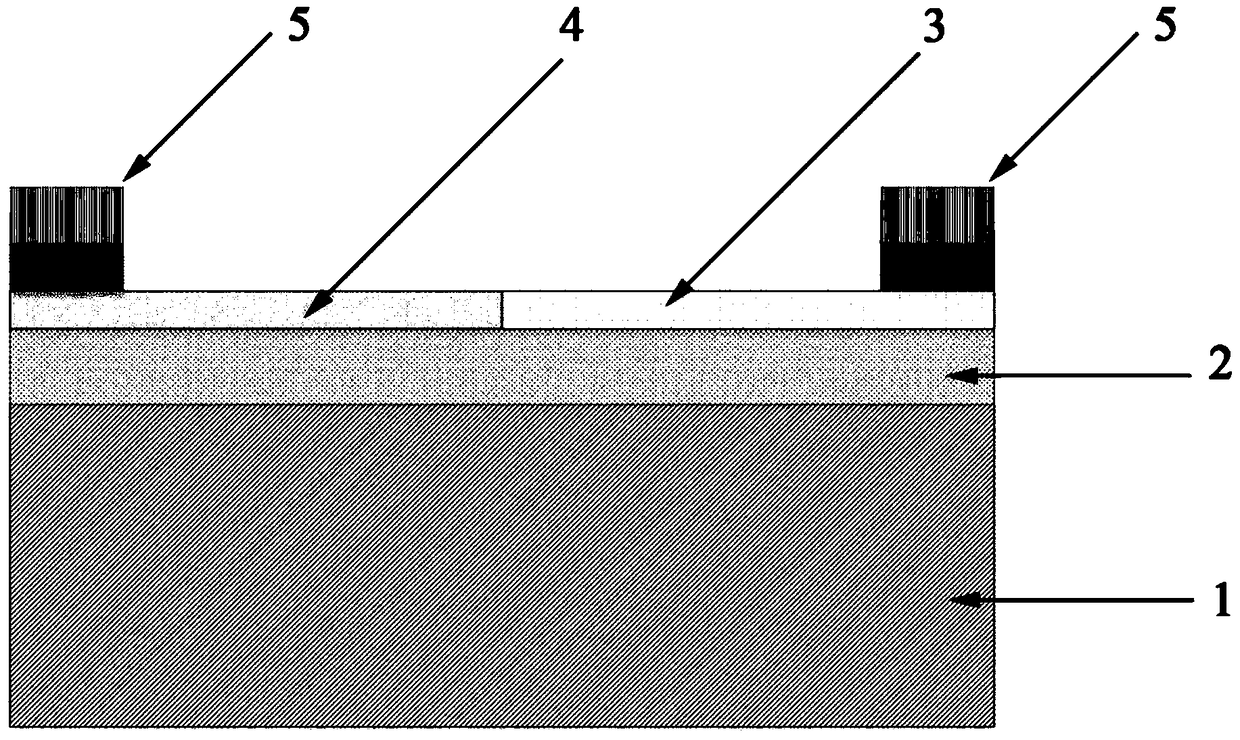

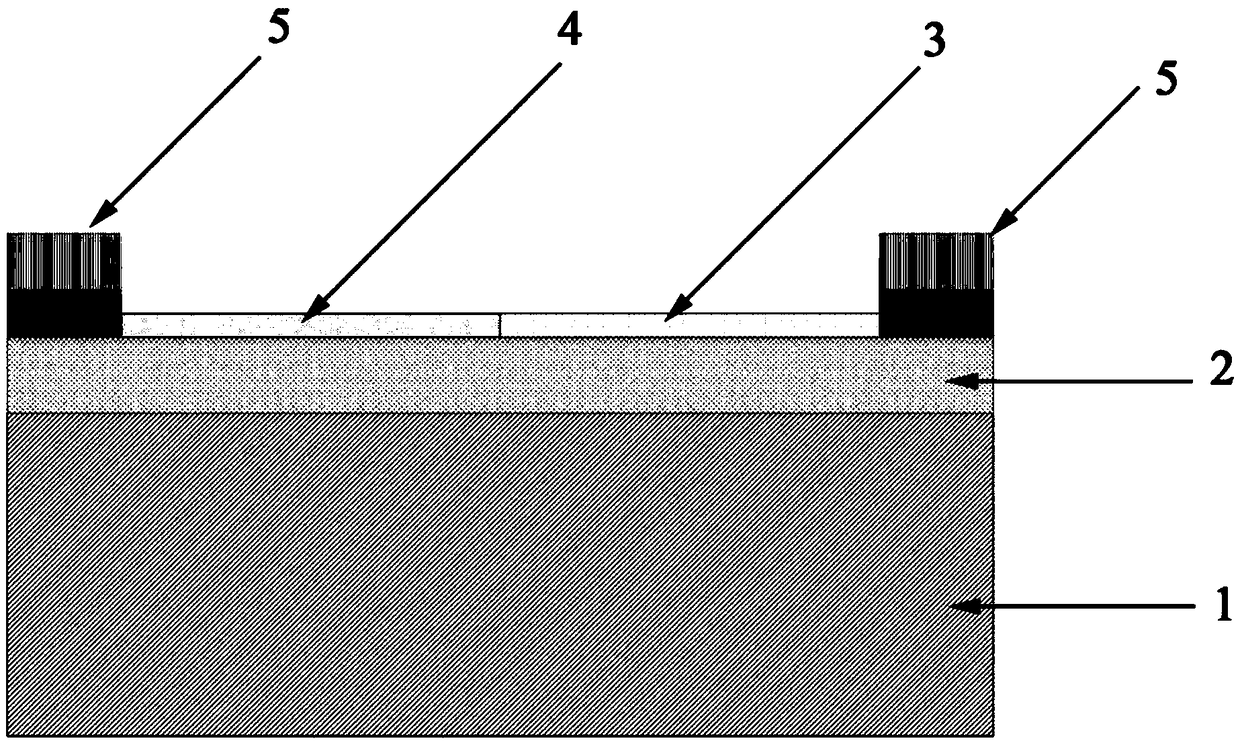

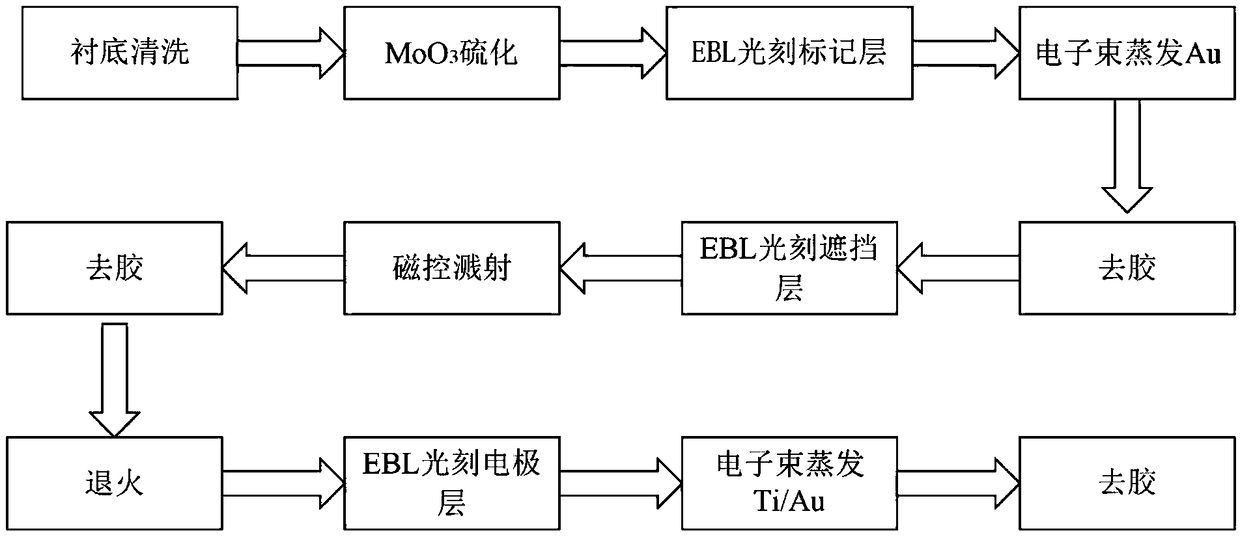

Nanometer layered horizontal homogeneous PN diode and fabrication method and application thereof

InactiveCN108666375AClose contactReduce contact resistanceFinal product manufactureNanotechnologyPhotovoltaic detectorsOxygen plasma

The invention discloses a nanometer layered horizontal homogeneous PN diode and fabrication method and application thereof. A p-type transition metal chalcogenide film and an n-type transition metal chalcogenide film both are arranged on an upper surface of a dielectric layer and are transversely connected, an electrode layer is longitudinally connected or transversely connected with the p-type transition metal chalcogenide film and the n-type transition metal chalcogenide film, and the p-type transition metal chalcogenide film and the n-type transition metal chalcogenide film comprises the same transition metal chalcogenide. The fabrication method is simple, high-efficiency and low-damage p-type doping of the transition metal chalcogenide is achieved through oxygen plasma by magnetron sputtering, effective and controllable doping is achieved, and the obtained diode is used for a photoelectric detector and has more rapid optical response and higher detection rate.

Owner:HUAZHONG UNIV OF SCI & TECH

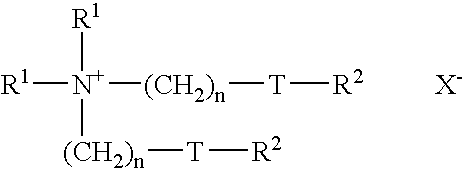

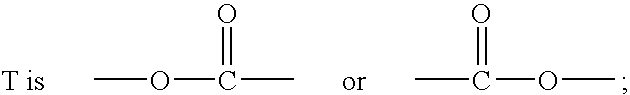

Laundry articles

ActiveUS20080004198A1Maximize effectivenessImprove performanceNon-surface-active detergent compositionsHollow article cleaningLaundryLiquid composition

Owner:HENKEL KGAA

Bio-magnesium alloy with anti-bacterial function and manufacturing method thereof

InactiveCN107794424AWell mixedGuaranteed chemical activityAdditive manufacturing apparatusIncreasing energy efficiencyAnti bacterialBall mill

The invention relates to a bio-magnesium alloy with an anti-bacterial function and a method for manufacturing the bio-magnesium alloy by utilizing the laser selective smelting technology. The bio-magnesium alloy with the anti-bacterial function consists of a bio-magnesium alloy substrate and nanometer TiO2 distributed in the bio-magnesium alloy substrate; and in the bio-magnesium alloy with the anti-bacterial function, the mass percentage of the nanometer TiO2 is 3-7%. The manufacturing method comprises the steps that nanometer TiO2 powder and bio-magnesium alloy powder are prepared accordingto a designed ratio; the prepared powder is placed in a ball mill; in a protective atmosphere, mixed powder is obtained through high-speed ball milling; and then in the protective atmosphere, the bio-magnesium alloy with the anti-bacterial function is manufactured through laser selective smelting. The bio-magnesium alloy manufactured with the method has excellent anti-bacterial performance and cyto-compatibility, improved mechanical performance and a proper degradation rate; and the bio-magnesium alloy is advantaged compared with a current material when serving as an implant material.

Owner:CENT SOUTH UNIV

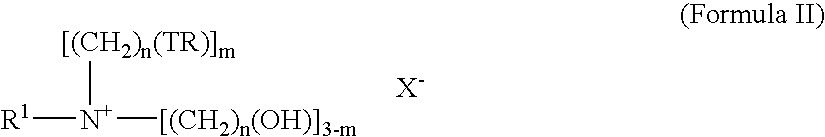

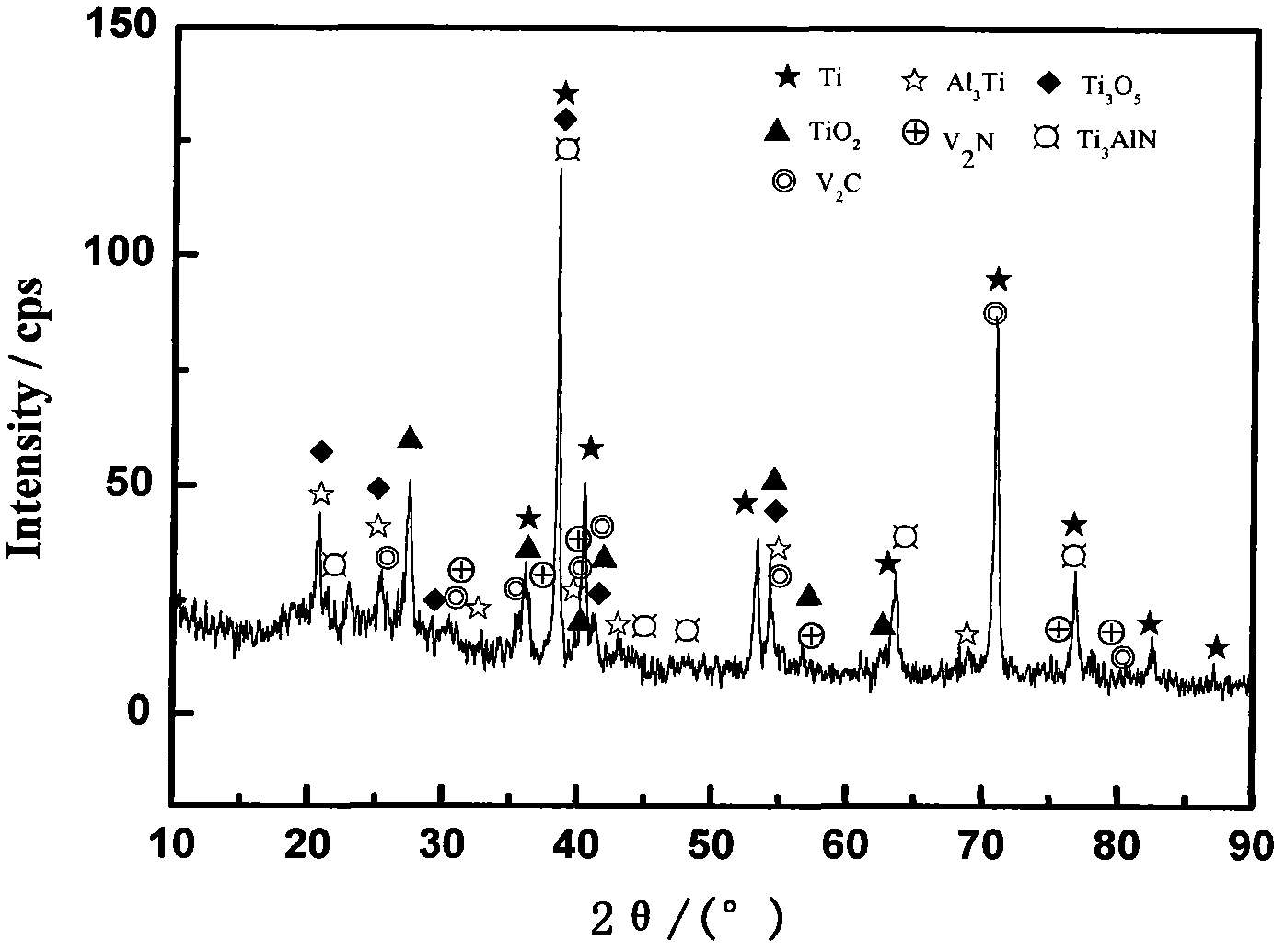

Three-dimensional porous carbon material with carbon nanotubes vertically grown on multilayer graphene surface, preparation method and lithium ion battery applying material

ActiveCN105958071AEasy to prepareLow chemical activityCell electrodesSecondary cellsCvd grapheneLithium electrode

Embodiments of the invention disclose a three-dimensional porous carbon material with carbon nanotubes vertically grown on a multilayer graphene surface, a preparation method and a lithium ion battery applying the material, wherein the preparation method of the three-dimensional porous carbon material with the carbon nanotubes vertically grown on the multilayer graphene surface comprises the following steps: S10, utilizing a pi-pi action to deposit iron and manganese oxide nanoparticles distributed at high density on a graphene surface; and S20, enabling nanotubes to vertically grow on the graphene surface by utilizing a chemical vapor deposition method, thereby obtaining the three-dimensional porous carbon material. The three-dimensional porous carbon material prepared by the preparation method can solve an agglomeration problem of the graphene and the nanotubes during drying; when as a negative electrode of a lithium ion battery, the three-dimensional porous carbon material has three-dimensional carbon grids capable of effectively improving electron conductivity of the carbon material; due to the porosity, ion transfer capability can be improved, and lithium ion storage capability of the nanotubes and the graphene is fully exerted.

Owner:杭州中盟智控科技集团有限公司

Preparation method of composite film on surface of metallic material and solution composition for preparation method

InactiveCN102321903AImprove carrying capacityImprove performanceAnodisationFriction reductionPlasma electrolytic oxidation

The invention relates to a preparation method of a composite film on the surface of a metallic material and a solution composition for the preparation method. The preparation method comprises the following steps of: (1) placing a polished and washed metal work piece into electrolyte containing elements to be permeated and then carrying out plasma electrolytic permeation treatment to form a surface modified layer containing distributed permeated elements on the surface of the metal work piece; (2) washing the processed work piece, then placing the processed work piece into alkaline electrolyte and carrying out plasma electrolytic oxidation treatment, and finally, obtaining a composite film on the surface of the work piece, wherein the composite film has excellent combination properties, such as high hardness, corrosion resistance, wear resistance and friction reduction. The solution composition for the preparation method is as follows: the electrolyte for carrying out the plasma electrolytic permeation treatment contains 10-140 g / L of compound A containing elements C, N, B and S to be permeated and 2-30 g / L of sodium hydroxide; and the compound A is one or the combination of more of formamide, urea, ethanolamine, borax and thiourea.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

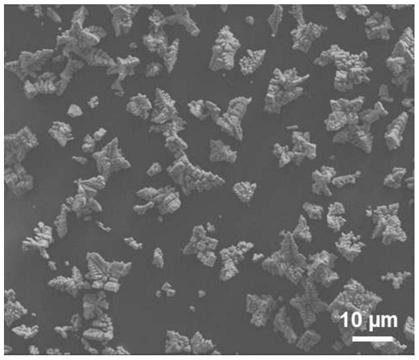

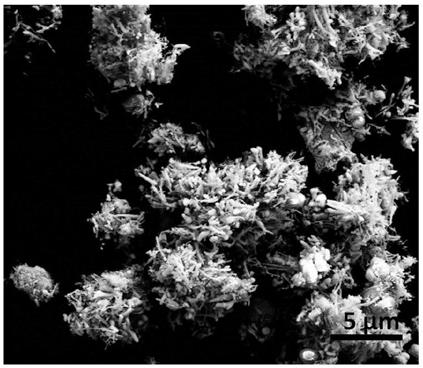

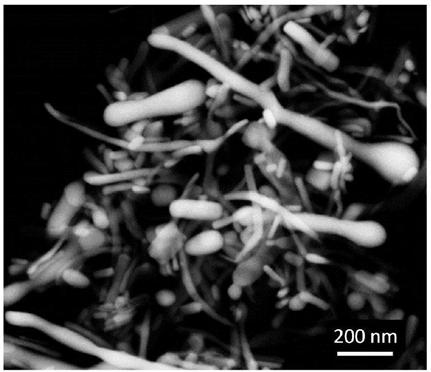

Preparation method of metal powder materials

ActiveCN111590084ALow chemical activityLow costTransportation and packagingMetal-working apparatusMicron scaleAlloy

The invention relates to a preparation method of metal powder materials. An alloy sheet containing a matrix phase and a dispersion phase with different chemical reactivities is prepared through a rapid solidification technology of an alloy melt. Metal powder is prepared through reaction of the alloy sheet and an acid solution, and the detailed preparation method is shown in the specification. Themethod is simple in process, can be used for preparing various nano-scale, sub-micron-scale and micron-scale metal powder materials with different morphologies, and has a good application prospect inthe fields of catalysis, powder metallurgy, 3D printing and the like.

Owner:赵远云

Nano TiO2/nano ZnO compounded lubricating oil additive and preparation method thereof

The invention discloses a nano TiO2 / nano ZnO compounded lubricating oil additive and a preparation method thereof. The addition amount of the nano TiO2 / nano ZnO is 0.02-1%, the particle size of the nano TiO2 is 10-20nm, the particle size of the nano ZnO is 20-40nm, and the weight ratio of the nano TiO2 to the nano ZnO is 1:1, 1:2 or 2:1. The nano TiO2 / nano ZnO compound is coated with oleic acid in the preparation process to enhance the stability and form a barrier between the surface and ambient medium, thereby lowering the chemical activity of the nano TiO2 / nano ZnO, being beneficial to enhancing the dispersity, weather resistance and chalking resistance and enhancing the continuous stability; and the prepared lubricating oil can not have the phenomenon of precipitation or separation, and can be firmly attached to the friction surface to protect the surface, thereby lowering and transferring the friction factor and prolonging the service life of the lubricating oil. The lubricating oil has the advantages of superhigh abrasion resistance, and greatly enhanced extreme pressure performance and long-time abradability.

Owner:南宁飞日润滑科技股份有限公司

Methods and compositions for passivating heat exchanger systems

InactiveUS20090045379A1Low chemical activityOther chemical processesHeat-exchange elementsPhosphateEngineering

A method for treating parts in a heat exchanger system is provided. In the method, heat exchanger parts with metal surfaces which chemically and detrimentally interact with additives in coolant fluids in the heat exchanger system are treated by contacting the metal surfaces with a phosphate-containing solution for the phosphate-containing solution to passivate the metal surface for subsequent contact with the coolant fluids.

Owner:CHEVROU USA INC +1

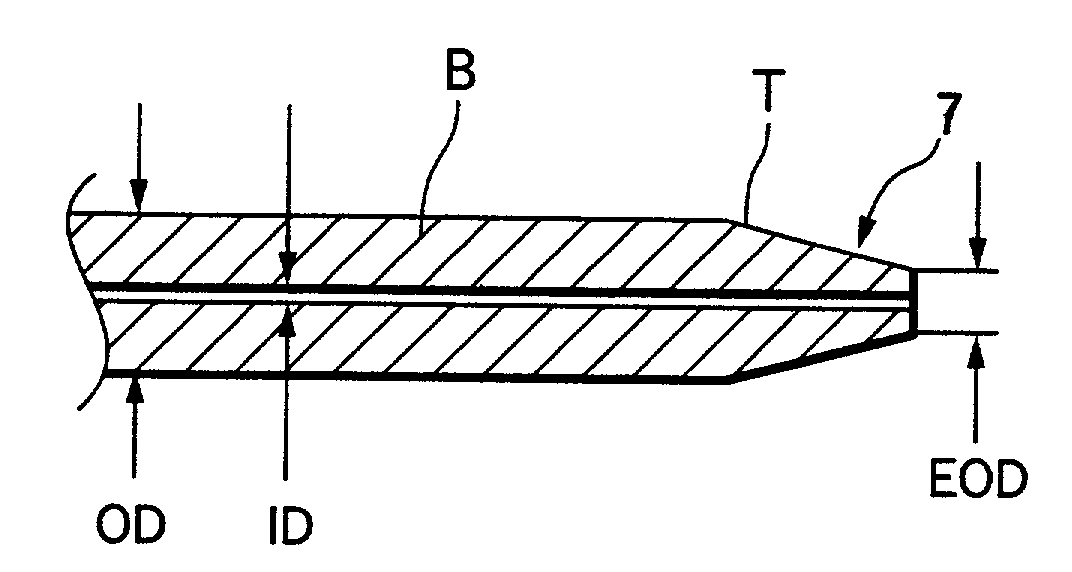

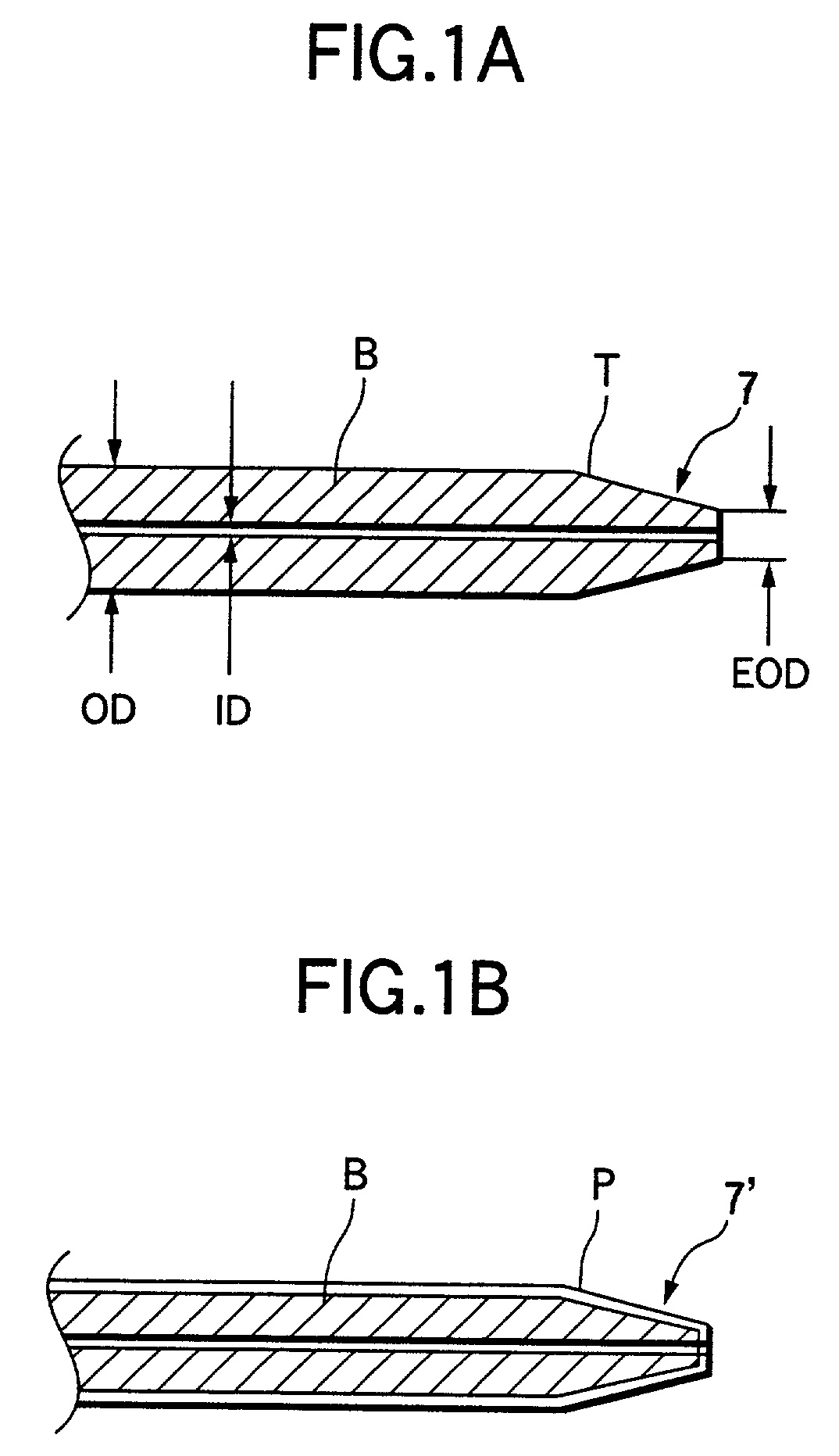

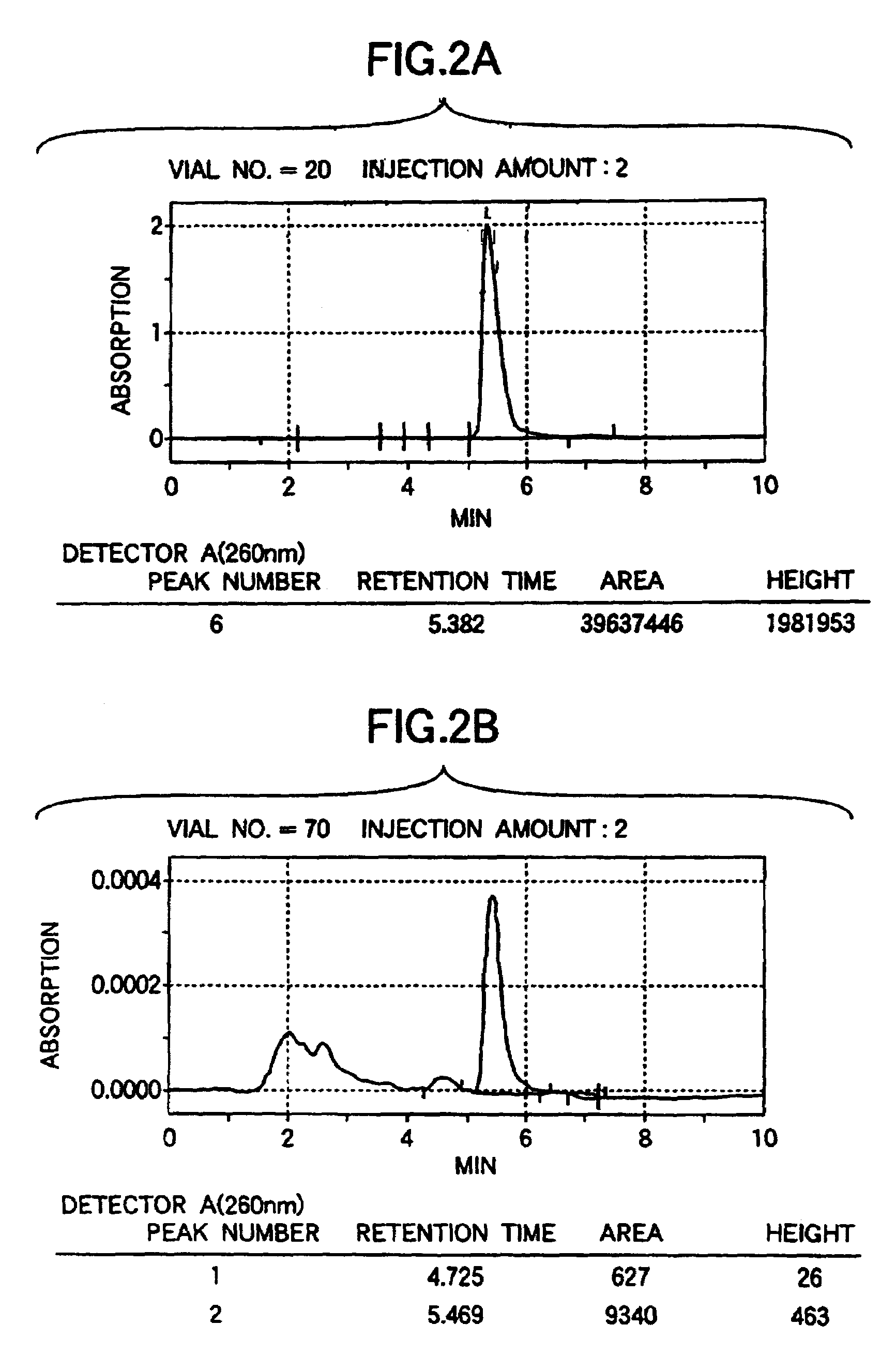

Automatic sampler and needle for the same

InactiveUS7175812B2Reduce chemisorptionLow chemical activityComponent separationWithdrawing sample devicesAutosamplerChemical adsorption

The surface of a needle for collecting samples is coated with a coating material lower in chemical activity than a base metal of the needle. More specifically, the surface of the needle may be coated with a layer of gold or platinum. Alternatively, the surface of the needle may be coated with a synthetic resin coating of, for example, PEEK which is superior in chemical resistance. As a result, it is possible to obtain a practically sufficient antifouling effect even on contamination coming from chemical adsorption. Such contamination could not be removed sufficiently only by related-art measures against physical contamination. Thus, it is possible to provide an automatic sampler which can perform highly sensitive analysis.

Owner:SHIMADZU CORP

High-temperature-resistant anti-oxidation coating

The invention discloses a high-temperature-resistant anti-oxidation coating, comprising the following components in percentage by weight: 50-60% of aluminate, 8-13% of silicate, 12-18% of ceramic micro powder, and the balance of water. The coating is prepared through the following steps of: crushing the prepared raw materials, fully stirring in a stirring machine, uniformly mixing into a paste, and taking out for later use. The components of the coating are simple and easy to collect, the coating is simple in preparation step and convenient to prepare and cannot cause harms to human bodies, and a brushing operation process is simple and safe. The components of the coating are stable in chemical property, and have strong oxidation resistance at high temperature to reduce oxidation burning loss, so that damages caused by high-temperature oxidation to a container are reduced, a cooled coating layer is easy to clean, the working efficiency is improved, and the production cost is reduced.

Owner:河北海丽特种石墨制造有限公司

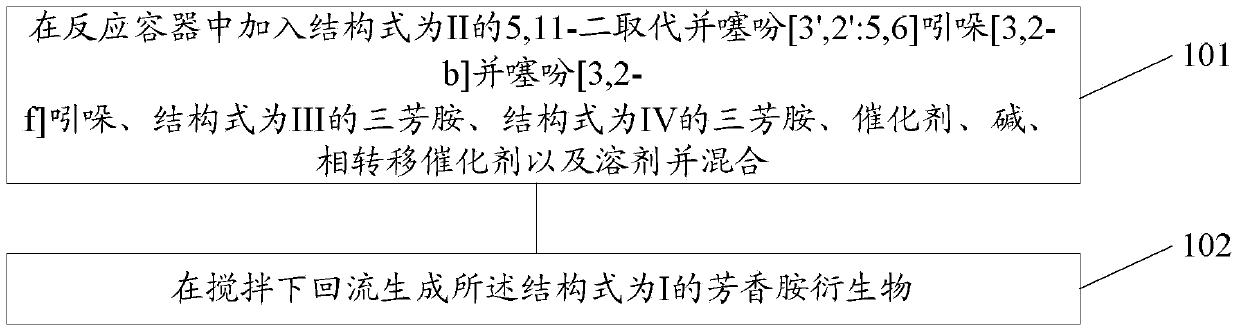

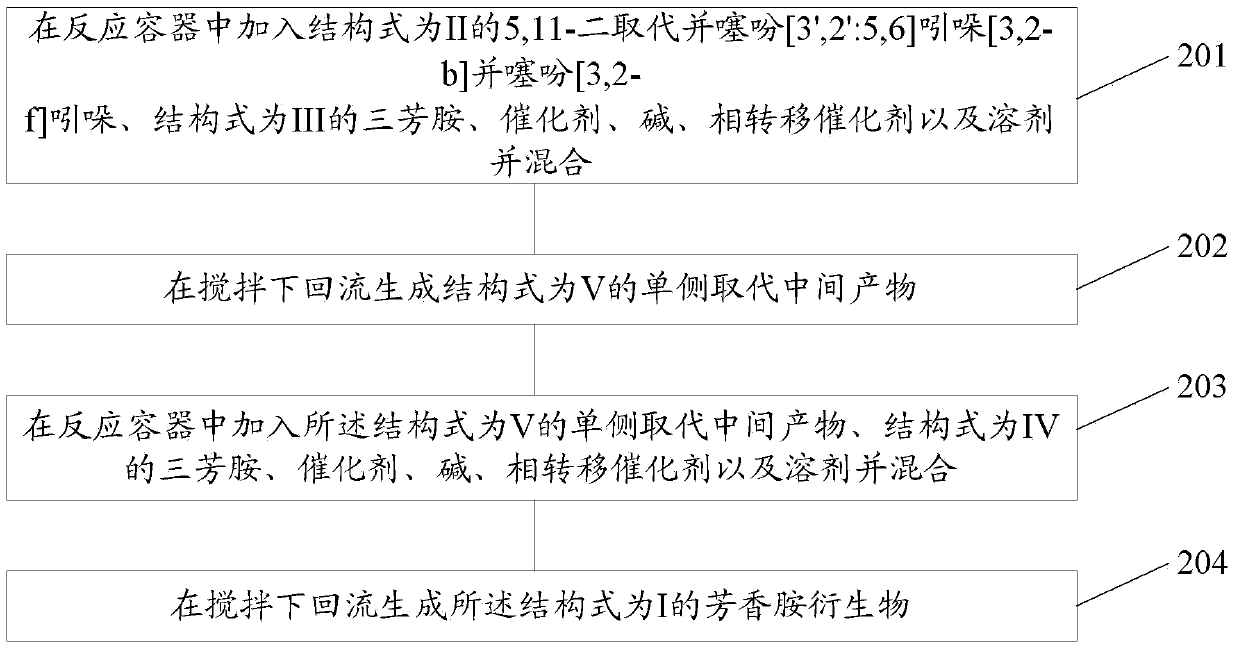

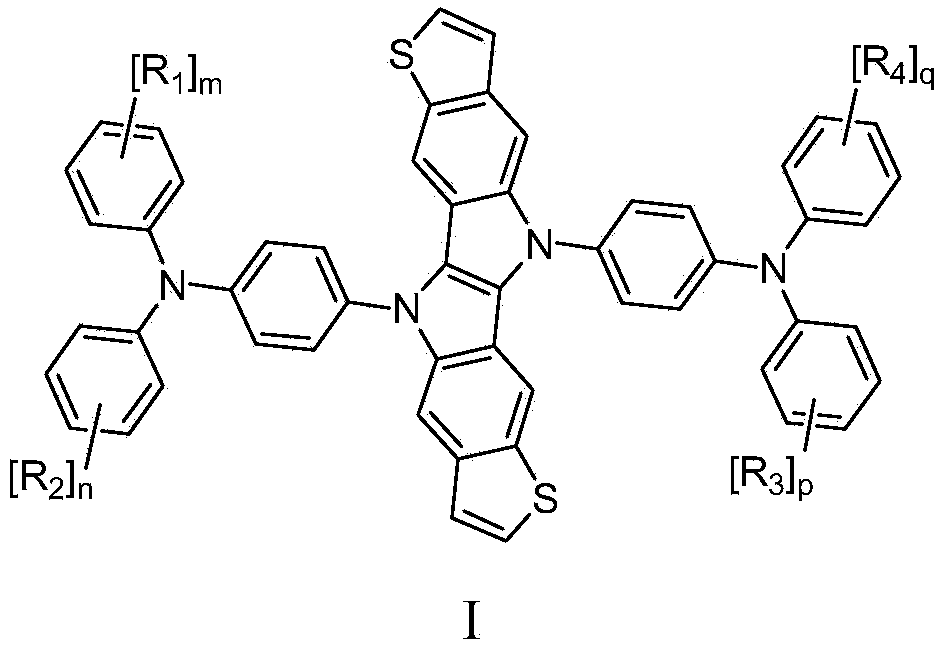

Aromatic amine derivative, and preparation method, use and organic electroluminescent device thereof

ActiveCN103992335AHigh molecular weightHigh glass transition temperatureOrganic chemistryElectroluminescent light sourcesArylHydrogen

The embodiment of the invention provides an aromatic amine derivative, and a preparation method, a use and an organic electroluminescent device thereof, and relates to the technical field of organic electroluminescence. The aromatic amine derivative is invented to improve the film forming ability and the redox repetition stability. The structural general formula I of the aromatic amine derivative is shown in the specification; and in the formula I, R1, R2, R3 and R4 respectively independently represent hydrogen, substituted or unsubstituted C1-C40 alkyl groups, substituted or unsubstituted C1-C40 alkyloxy groups, substituted or unsubstituted C3-C40 cycloalkyl groups, substituted or unsubstituted C6-C50 aryl groups, substituted or unsubstituted C3-C50 heteroaryl groups containing one or two selected from hetero atoms of N, O or S, or substituted or unsubstituted C10-C40 fused aryl groups, m, n, p and q respectively independently represent 0, 1, 2, 3, 4 or 5, and substituent can be one or more groups selected from halogens, C1-C10 alkyl groups, C1-C10 alkyloxy groups, C3-C20 cycloalkyl groups, C6-C20 aryl groups or C4-C20 heteroaryl groups. The aromatic amine derivative can be used in the organic electroluminescent device.

Owner:BOE TECH GRP CO LTD

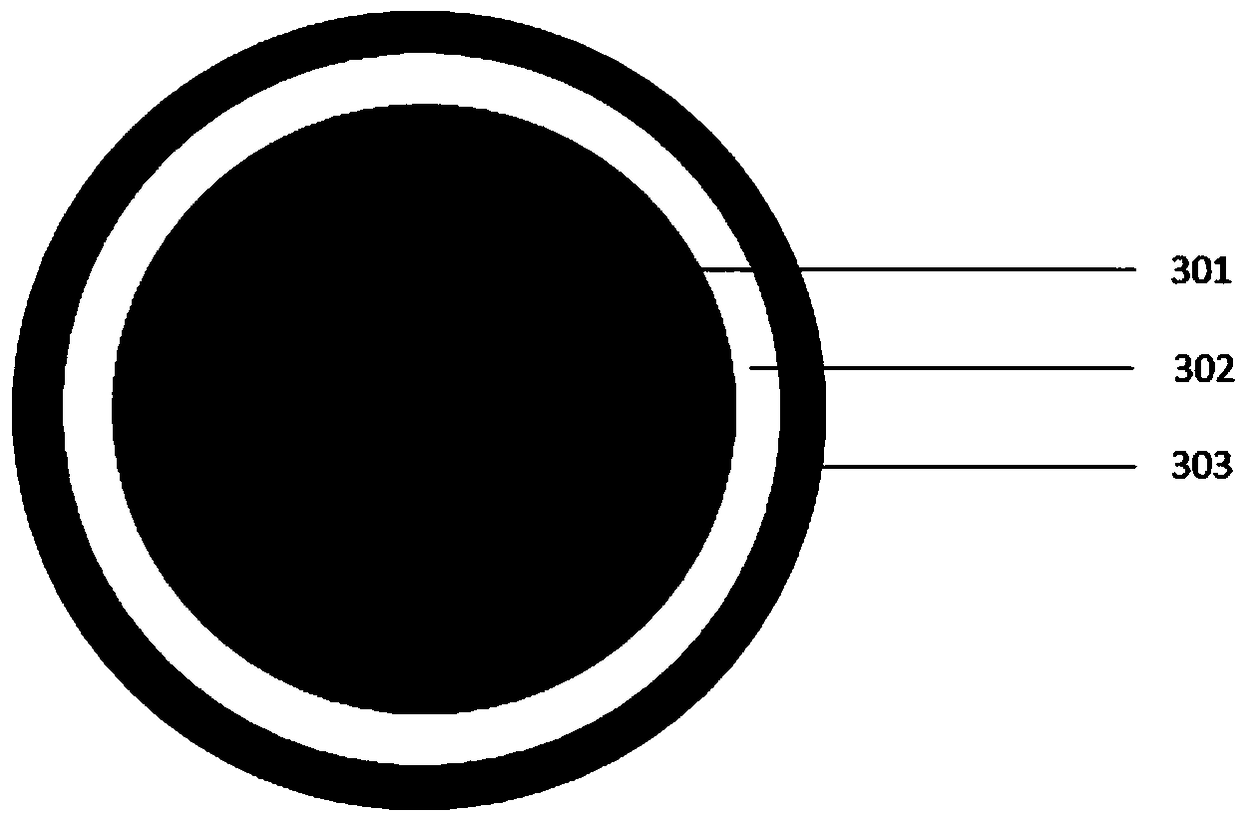

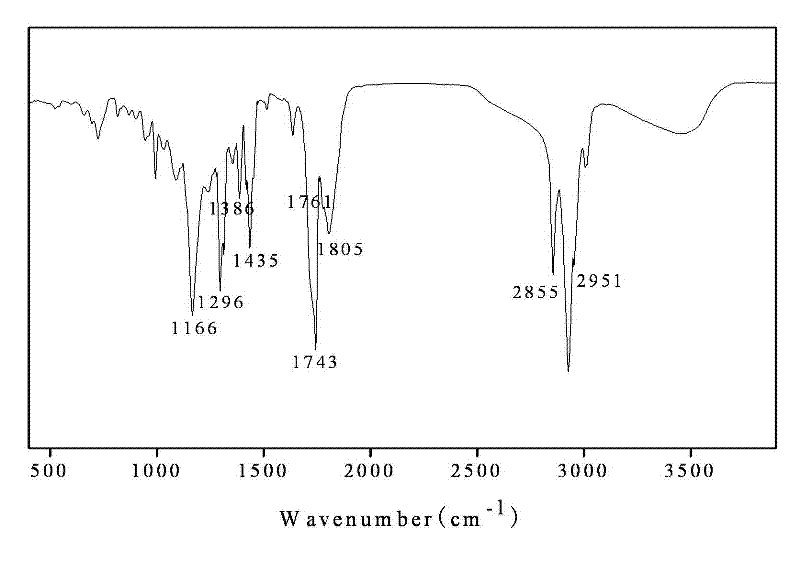

Medical degradable zinc-based alloy intravascular stent product

The invention relates to the fields of a medical material and an apparatus thereof, and provides an in-vivo degradable implantable intravascular stent product. The product comprises 1) an in-vivo degradable implantable zinc-based metal material; 2) the intravascular stent product produced by the zinc-based alloy material in the step 1) is in a pipenet structure; 3) a magnesium metal film coating is uniformly distributed and deposed at the surface of the pipenet stent product; and 4) the magnesium film coating is coated with a degradable polymer coating, and the polymer coating can contains therapeutic drugs. The zinc based alloy has the advantages of excellent mechanical properties, strong corrosion controllability, and excellent compatibility. According to the intravascular stent product,surface special arrangement is benefit for keeping a complete initial structure, is benefit for stent endothelialization, reduces an inflammatory reaction, and reduces local inflammation, restenosisand thrombus risk in the stent after stent implantation.

Owner:LEPU MEDICAL TECH (BEIJING) CO LTD

Stable compositions of uncomplexed iodine and methods of use

ActiveUS20170208814A1Good storage stabilityHigh activityAntibacterial agentsOrganic active ingredientsHigh concentrationDisinfectant

The present invention is directed to a composition in solution (often, an aqueous solution) which comprises a combination of molecular iodine (I2) and an acceptable source of iodate (IO3), and an acid (inorganic or organic), wherein iodide and iodate are present in the composition at a molar ratio of about 0.1 to about 25, the concentration of uncomplexed molecular iodine is a disinfectant, biocidal and / or antimicrobial (depending upon the end use of the composition) effective amount the concentration of acid in the composition is effective to provide a buffering pH in the composition ranging from about 1.5 to about 6.5. Compositions according to the present invention are storage stable for unexpectedly long periods of time (up to about 5 years), and find use as disinfecting solutions, as germicides and / or biocides (e.g. antiviral, antibacterial, antifungal, antispore etc.) for various surfaces and solutions including living and inanimate surfaces and are particularly useful because of their low cost, their reduced use of iodine, their activity (because of the high concentration of free molecular iodine in solution), their reduced environmental impact, their long term storage stability and their reduced toxicity. They also have particular utility in treating food surfaces to retard spoilage, increase useful shelf-life and minimize the human and economic cost of food waste. The compositions inactivate viruses, bacteria (both gram negative and positive), spores and fungi. Compositions according to the present invention may be used and stored in a variety of materials, given the substantial absence of corrosion (non-corrosive) these compositions display. Dental compositions (e.g. preprocedure rinses and other compositions) and methods related thereto are also disclosed.

Owner:IOTECH INT INC

Heat resistant, high-strength and wear resistant ball with high hardness for ball grinder

InactiveCN104099532AEliminate internal stressReduce internal stressFurnace typesMetallic material coating processesWear resistantBall mill

The invention discloses a heat resistant, high-strength and wear resistant ball with high hardness for a ball grinder. The heat resistant, high-strength and wear resistant ball comprises the following components: C, Mn, Si, Ni, Cr, Mo, V, Nb, Ca, Zr, Cu, S, P, balance of Fe and inevitable impurities; the ultrasonic auxiliary laser-cladding technology is adopted to modify the surface of the wear resistant ball, wherein parameters of the ultrasonic auxiliary laser-cladding technology are as follows: a laser is a CO2 laser, the power is 1450-1650 W, the powder feeding rate is 0.4-0.5 g / min; the scanning speed is 3-5 mm / s, the layering thickness is 0.4-0.6 mm, the overlapping rate is 20-28%, the supersonic frequency is 17-19 kHz, the ultrasonic power supply current is 0.02-0.08 A and the applied cladding powder comprises 20-30 parts of WO3 powder, 30-50 parts of V2O5 powder, 50-80 parts of C powder, and 300-500 parts of Ni 60 self-melting powder. The wear resistant ball provided by the invention has excellent impact strength, hardness, heat resistance and wearing resistance.

Owner:宁国市宁武新材料科技有限公司

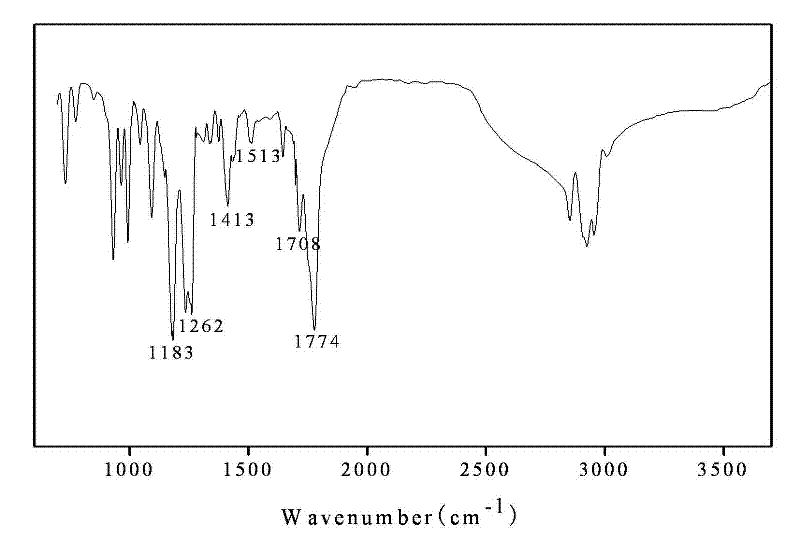

Light-cured tetrahydrophthalic anhydridized tung oil acrylate resin and preparation method thereof

ActiveCN102391123ALarge range of performance adjustmentLow toxicityOrganic compound preparationCarboxylic acid esters preparationWeather resistancePolymer chemistry

The invention discloses light-cured tetrahydrophthalic anhydridized tung oil acrylate resin and a preparation method thereof. The preparation method comprises the followings steps: tung oil and a tetrahydrophthalic anhydride monomer are subjected to the Diels-Alder reaction so as to produce an intermediate product, namely, tetrahydrophthalic anhydridized tung oil; and the tetrahydrophthalic anhydridized tung oil and an acrylic hydroxy ester monomer are subjected to an esterification reaction so as to prepare the product, wherein the mass ratio of the used raw materials is that the tung oil / the tetrahydrophthalic anhydride monomer / the acrylic hydroxy ester monomer is equal to 100:(45 to 55):(10-40). The product disclosed by the invention has a main chain which is a longer flexible chain, and the structural characteristics of a bonded rigid double six-membered ring; and the light-cured tetrahydrophthalic anhydridized tung oil acrylate resin is applied to the fields, such as light-cured solvent-free inks and coatings and the like as matrix resin, the rigidity, the toughness, the glossiness, the adhesive force to a base material, the weather-resisting property and the like of the inks, the coatings and the like can be adjusted within a wider range, so that the application performance is convenient to optimize and the fossil resources can be saved.

Owner:JINYU HENAN PACKAGING +1

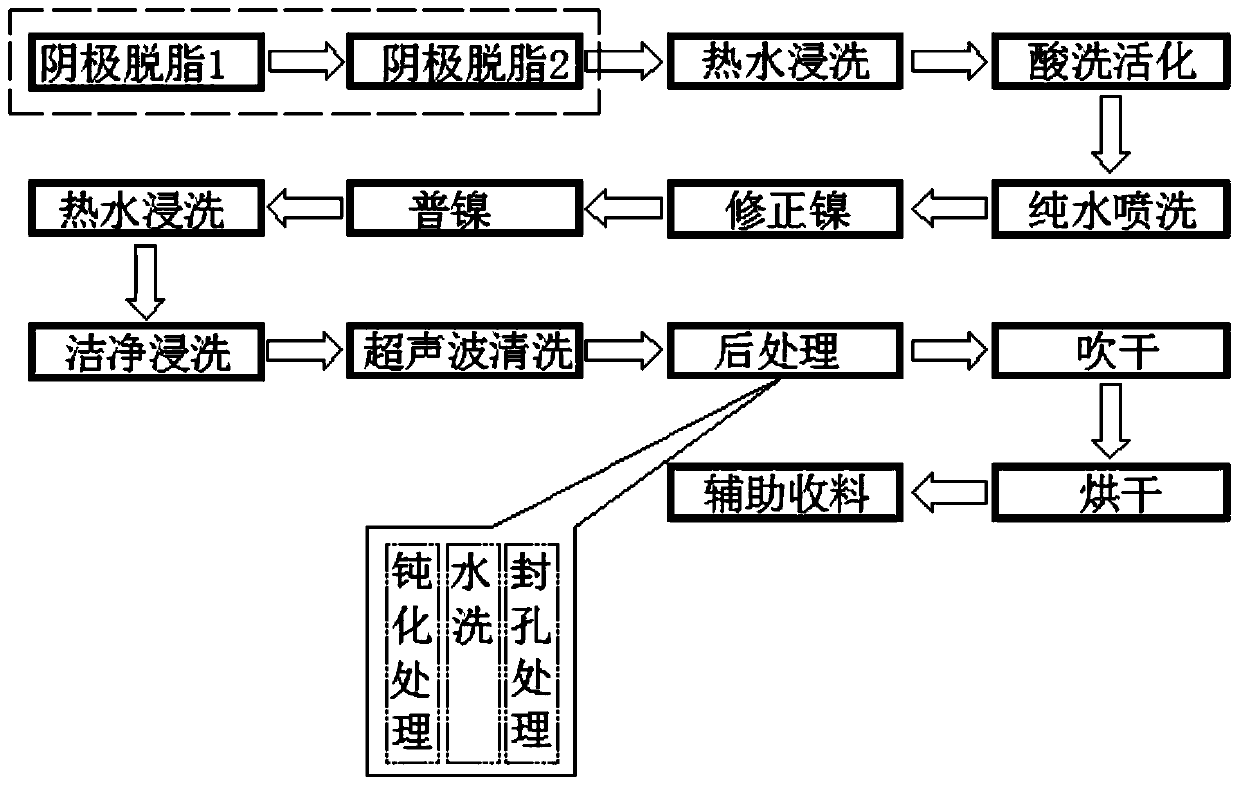

Copper alloy electroplating technology

ActiveCN109957822AImprove appearance cohesionReduce porosityMetallic material coating processesPorosityWater immersion

The invention discloses a copper alloy electroplating technology, and belongs to the technical field of electroplating. The copper alloy electroplating technology comprises the following steps of: step one. degreasing; step two. carrying out hot water immersion; step three. carrying out pickling activation; step four. carrying out spray rinsing by using pure water; step five. correcting nickel; step six. common nickel; step seven. carrying out hot water immersion; step eight. carrying out cleaning immersion; step nine. carrying out ultrasonic cleaning; step ten. carrying out post-processing; step eleven. drying; step twelve. drying; and step thirteen. carrying out auxiliary receiving. By extending and optimizing the pre-treatment process line, the copper alloy electroplating technology canprovide an electroplating plane of follow-up coating deposition and increases the appearance binding force of a coating. Crystal lattices of the nickel coating are significantly improved by using thecorrecting nickel for priming in the electroplating process, so that the structure is tight, the crystal lattices are refined, the porosity of the coating is reduced, thus, the uniformity and glossiness of the common nickel layer appearance are ensured; and a perfect cleaning process is developed and led to cooperate with passivation treatment and hole sealing treatment, so that the corrosion resistance of the coating is greatly enhanced.

Owner:东莞市康圣精密合金材料有限公司

Methods and compositions for passivating heat exchanger systems

InactiveUS20130099169A1Low chemical activityOther chemical processesHeat-exchange elementsPhosphateEngineering

Owner:CHEVROU USA INC

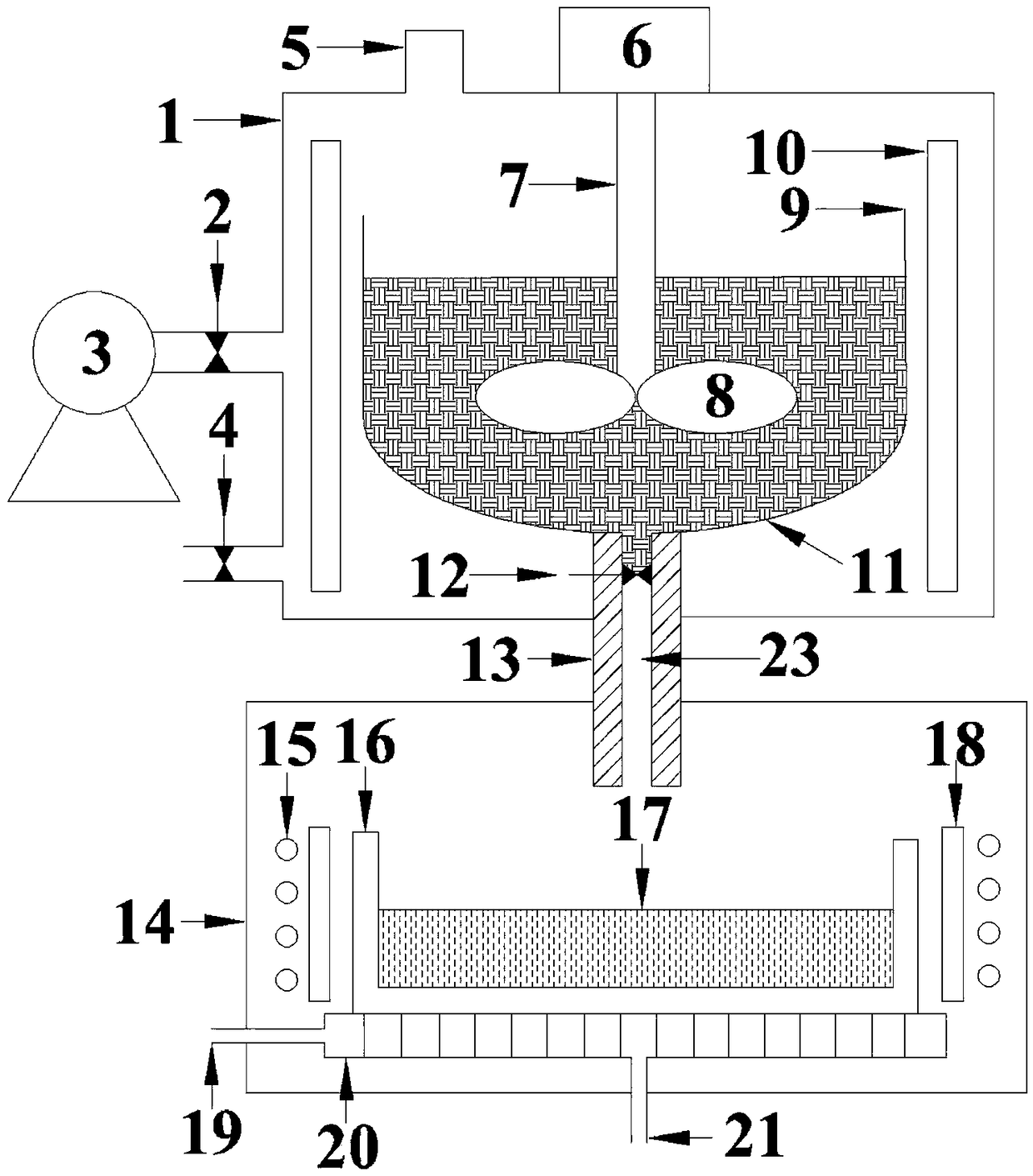

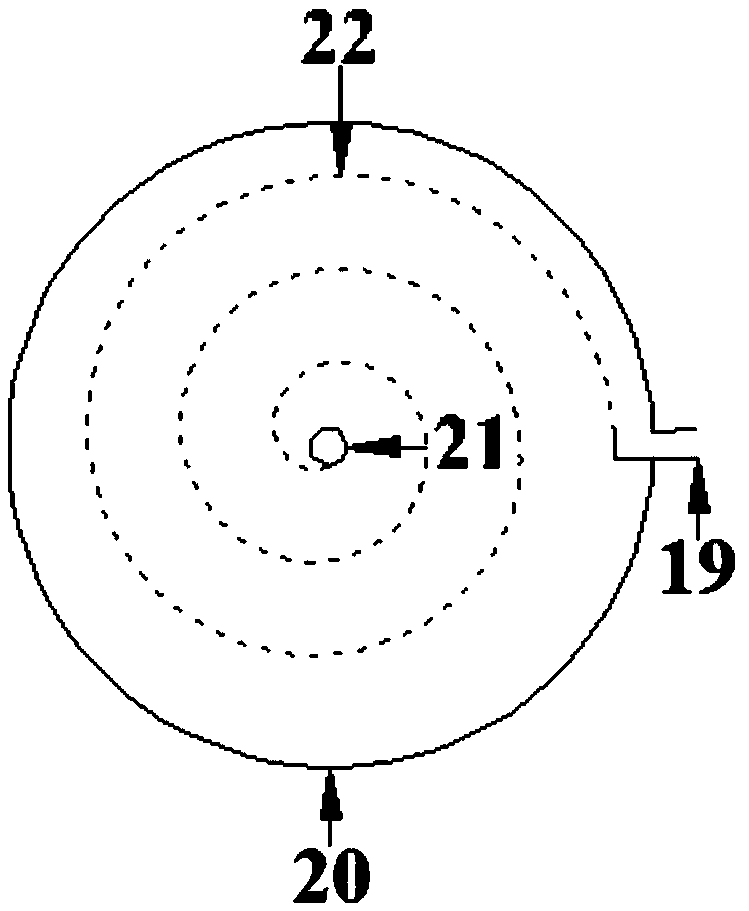

Oriented-arrayed graphenemagnesium-base alloy with ultra-high thermal conductivity and preparation method and device

The invention belongs to the technical field of materials, and relates to an oriented-arrayed graphene magnesium-base alloy with ultra-high thermal conductivity and a preparation method and a preparation device. The oriented-arrayed graphene magnesium-base alloy is composed of magnesium alloy matrix and graphene nano-sheets arranged in the matrix, wherein the graphene nano-sheets are oriented-arranged in the matrix. The preparation method comprises the following steps that (1), the graphene, magnesium and alloy mixed with metal are mixed and smelted; and (2), a smelted graphene alloy body is cooled, heat preservation is conducted and a magnetic field is externally applied, and the inside graphene is oriented-arranged and is solidified to obtain the oriented-arrayed graphene magnesium-basealloy with ultra-high thermal conductivity. According to the oriented-arrayed graphene magnesium-base alloy, diamagnetism of the two-dimensional graphene is adopted, so that the graphene is oriented-arrayed in the magnesium alloy matrix, high thermal conductivity of the material is achieved, and chemical activity of the magnesium is reduced with the graphene.

Owner:厦门十一维科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com