Patents

Literature

33results about How to "Achieve "wetting"" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

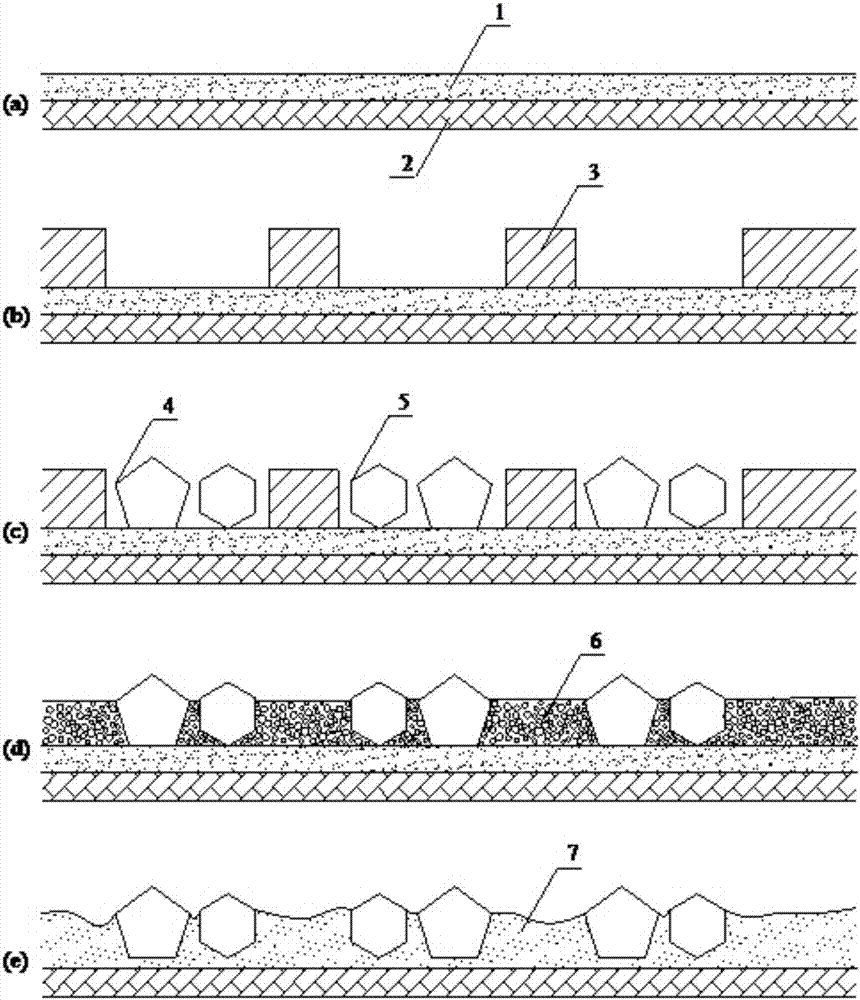

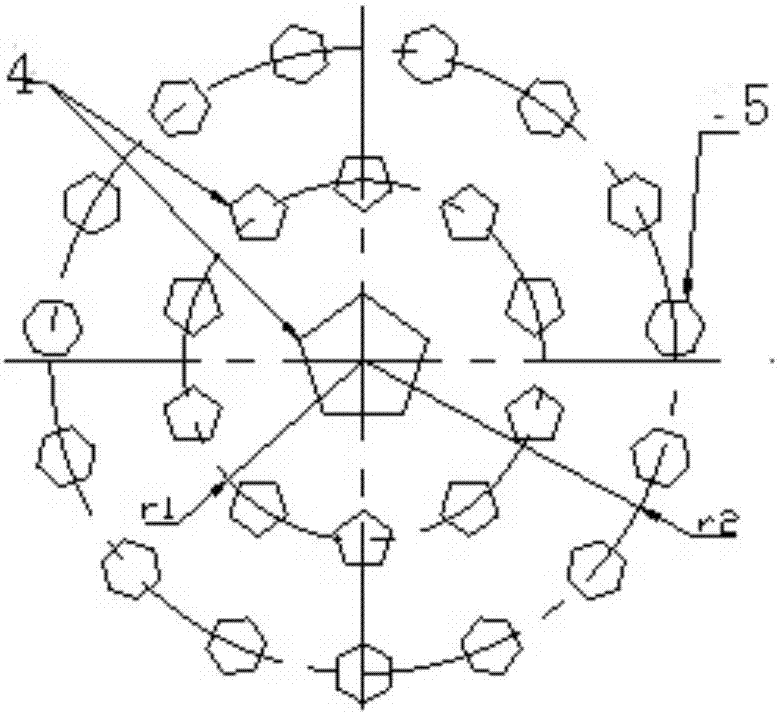

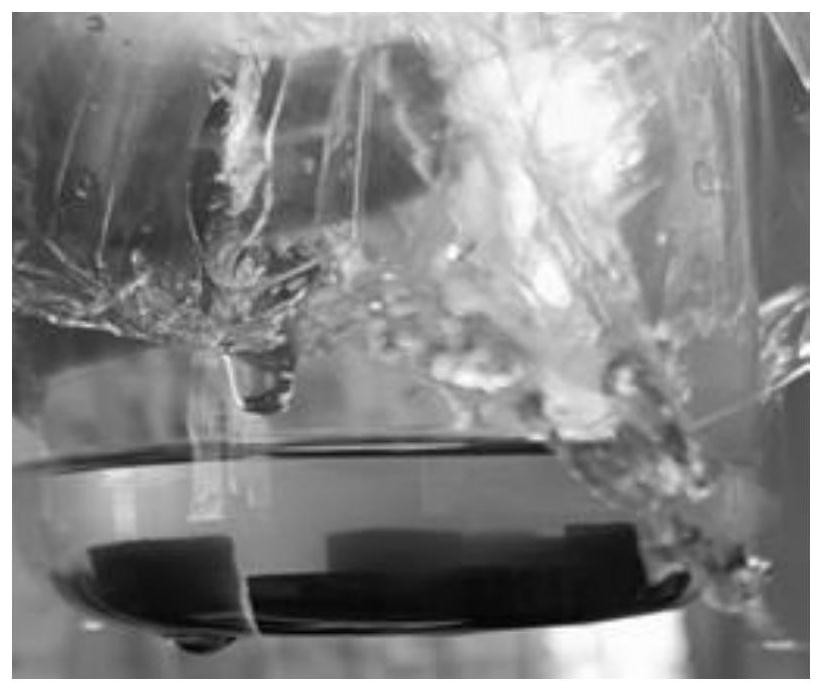

Method for manufacturing abrasive tool with abrasive particle collaborative configuration by virtue of brazing

The invention discloses a method for manufacturing an abrasive tool with abrasive particle collaborative configuration by virtue of brazing, which comprises the following steps: 1) carrying out pretreatment on abrasive materials and a steel substrate; 2) smearing binder onto the surface of the steel substrate uniformly; 3) configuring two kinds of abrasive materials on the surface of the binder according to a corresponding geometric structure; 4) covering the surroundings of the abrasive materials with brazing filler metal, putting into a vacuum furnace, heating at a high temperature, and cooling so as to obtain the abrasive tool. According to the method, diamond and cubic boron nitride are preferably adopted as abrasive materials for manufacturing the brazing tool with abrasive material collaborative configuration by virtue of high-temperature brazing; the excellent thermal expansion performance of the brazing filler metal (Ag-Cu-Ti brazing filler metal and Cu-Sn-Ti brazing filler metal) is utilized to make up the thermal expansion difference of the steel substrate, the alloy brazing filler metal and the abrasive materials, the brazed connection of the abrasive materials and the steel substrate is successively realized, and the application field of the brazing abrasive tool is broadened.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

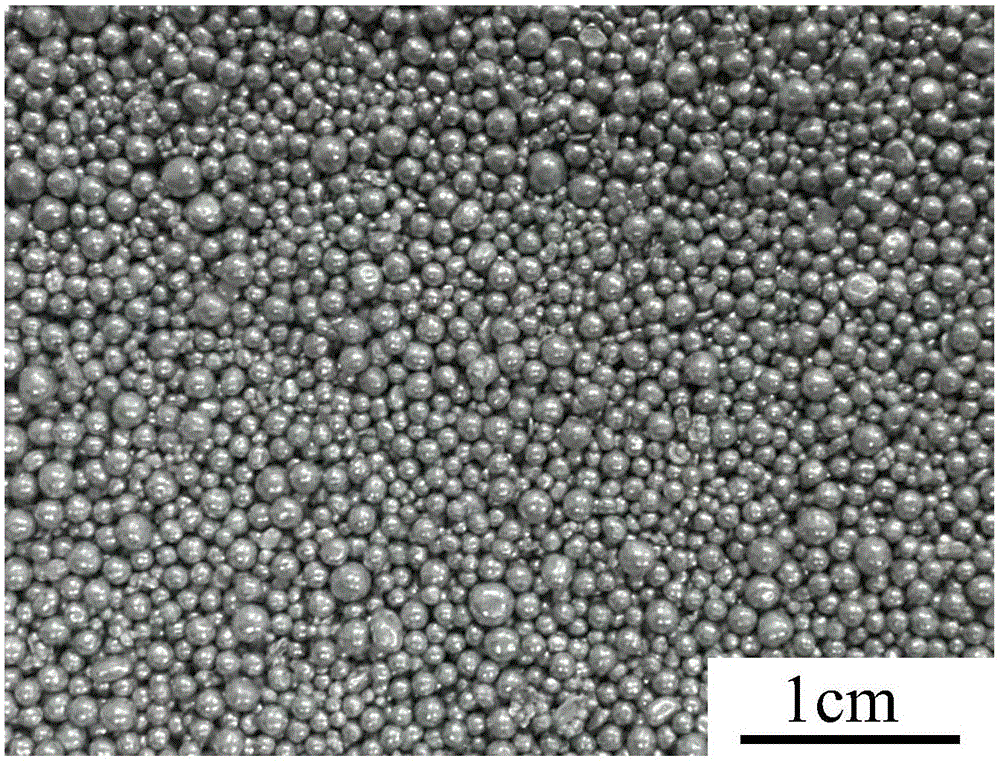

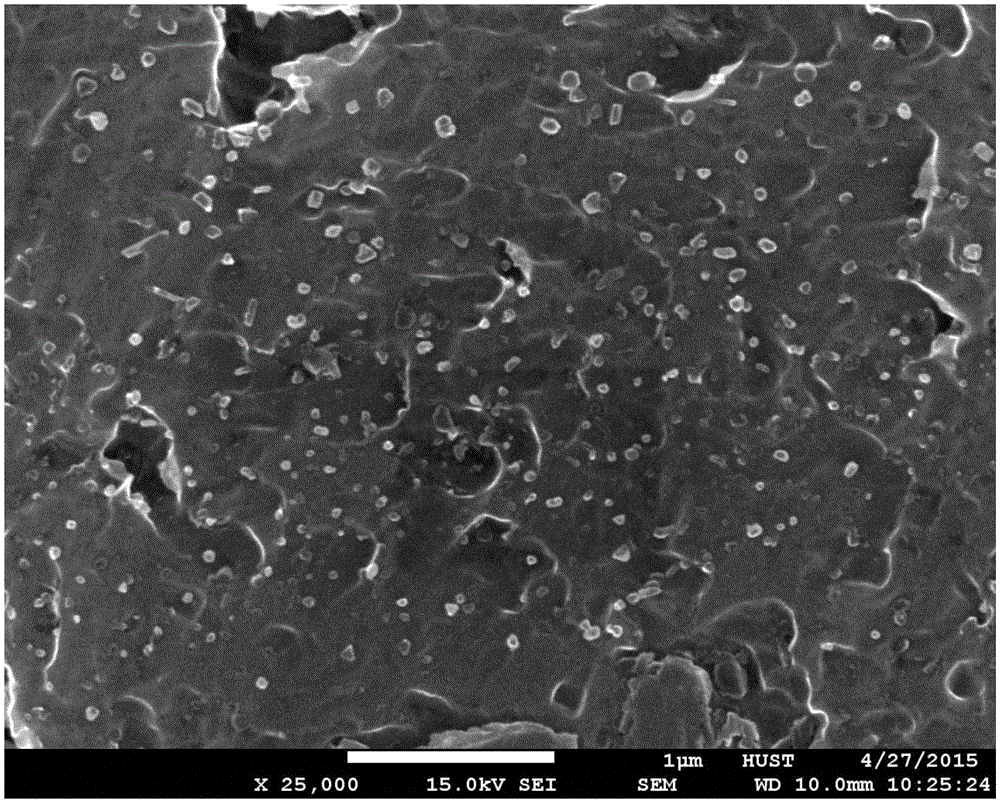

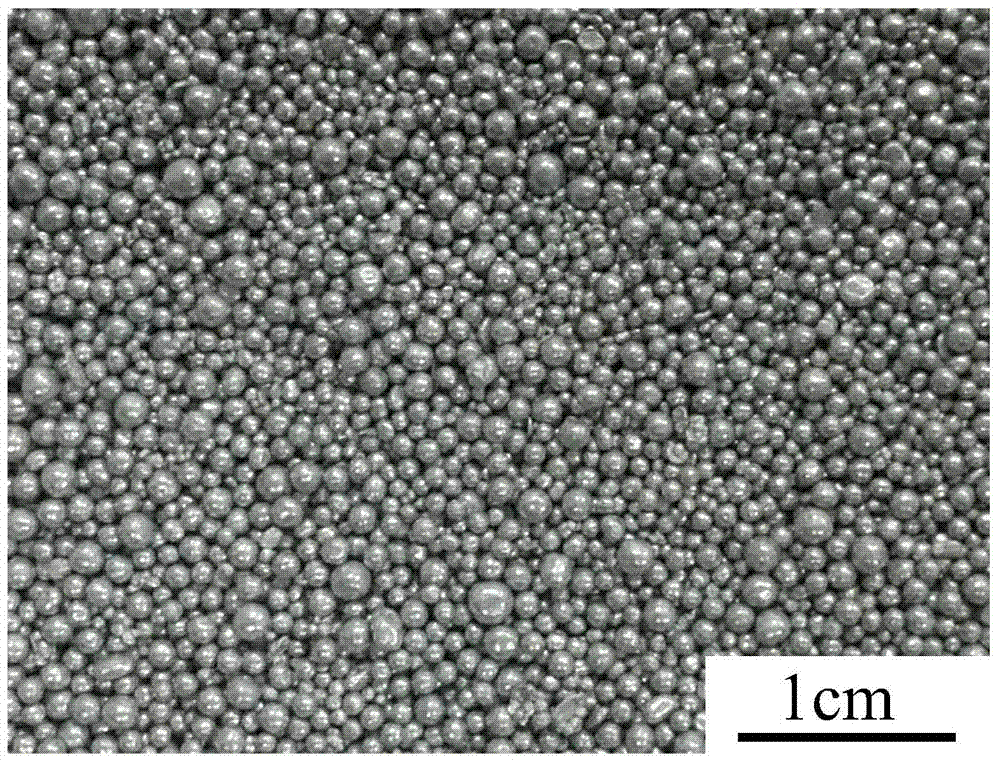

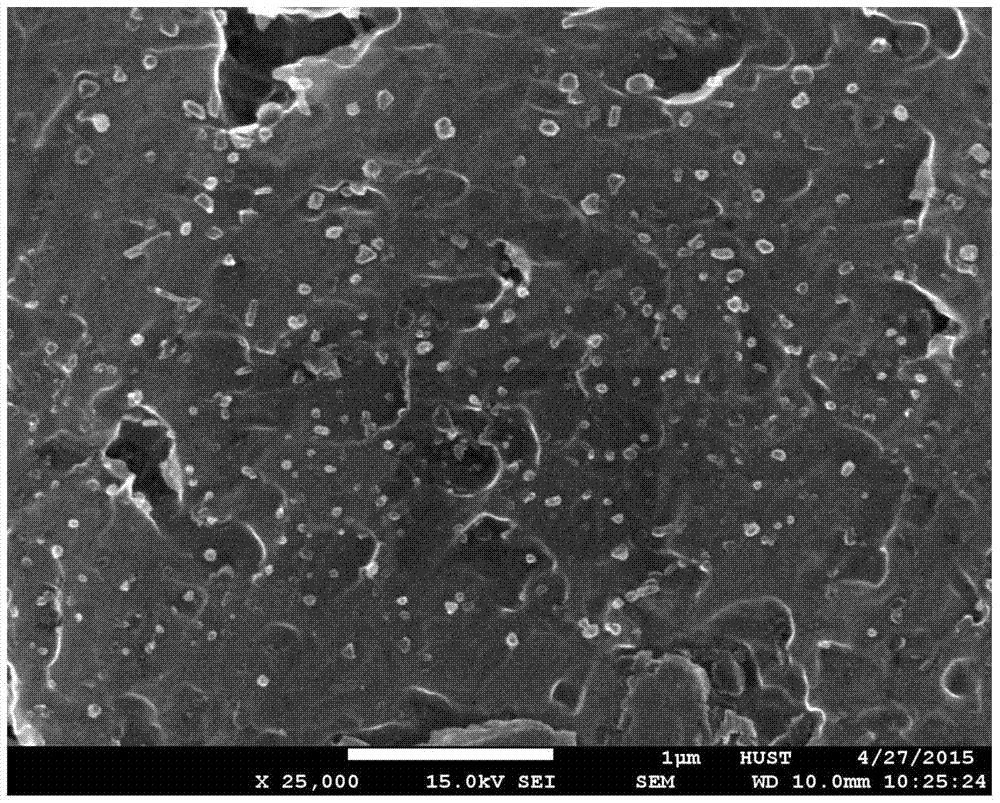

Method for preparing nano particle reinforced aluminum matrix composites

The invention discloses a method for preparing nano particle reinforced aluminum matrix composites. The method comprises the steps that firstly, mixed powder of nano ceramic powder and micron-sized aluminum or aluminum alloy powder is used for preparing millimeter-sized composite particles through a dry high-energy ball mill under the protection of vacuum or argon, wherein the volume fraction of nano ceramic particles in the millimeter-sized composite particles is 10-50%; and secondly, the millimeter-sized composite particles are melted directly or added into aluminum or aluminum melt, and supersonic vibration is applied, so that the nano ceramic particles are promoted to be uniformly dispersed in the metal melt, and the nano particle reinforced aluminum matrix composites are prepared. According to the method for preparing the nano particle reinforced aluminum matrix composites, the millimeter-sized composite particles prepared through a dry milling method can be added into the metal melt easily and completely, the problems that the wettability between the nano ceramic particles and matrix metal is poor, and adding of the particles is difficult are solved, and the advantage of low cost of a casting method for preparing metal matrix composites is given to play; the nano particles in the prepared composites are distributed uniformly, and the material performance is high.

Owner:HUAZHONG UNIV OF SCI & TECH

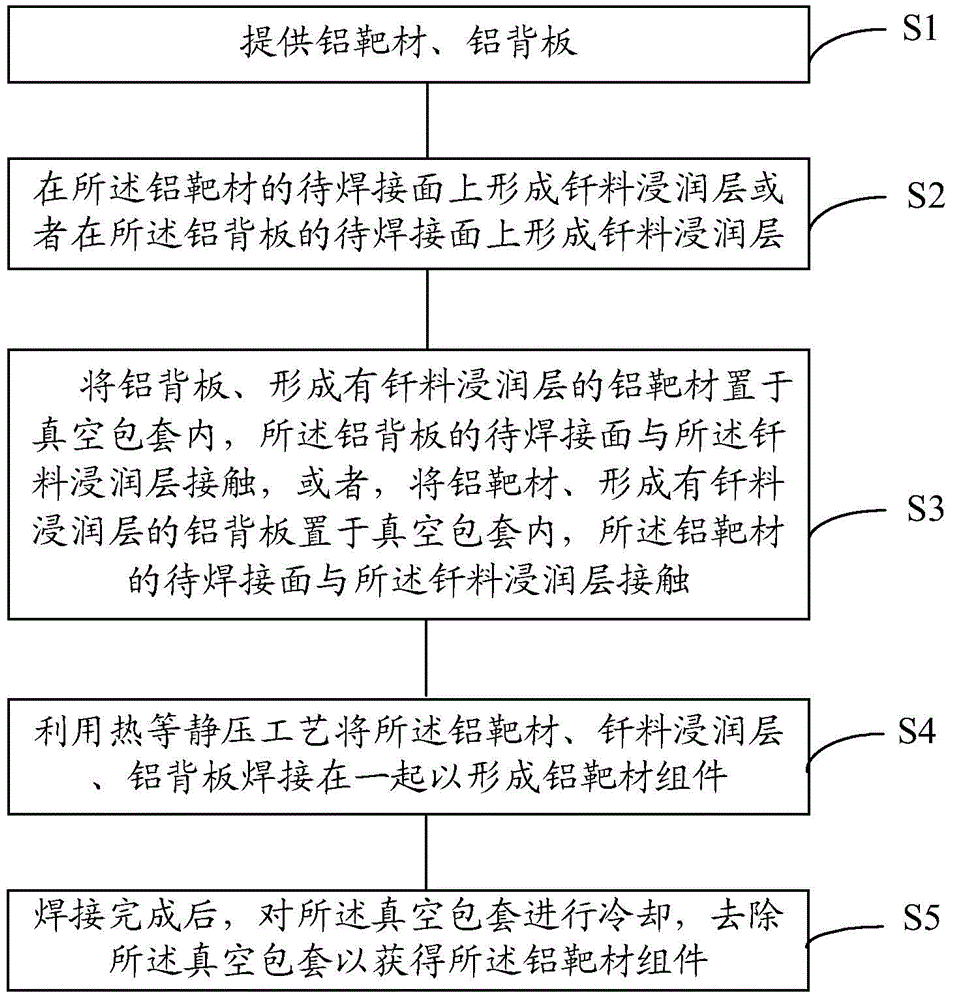

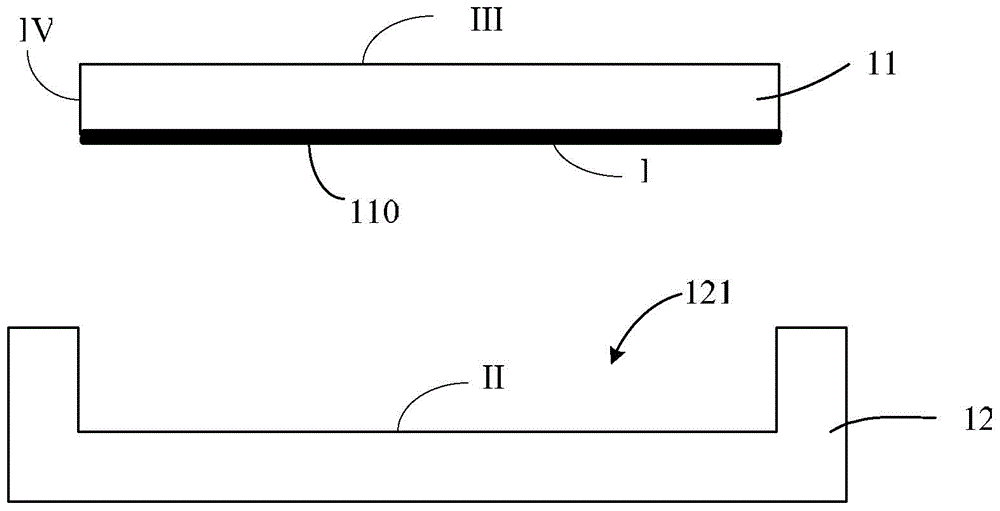

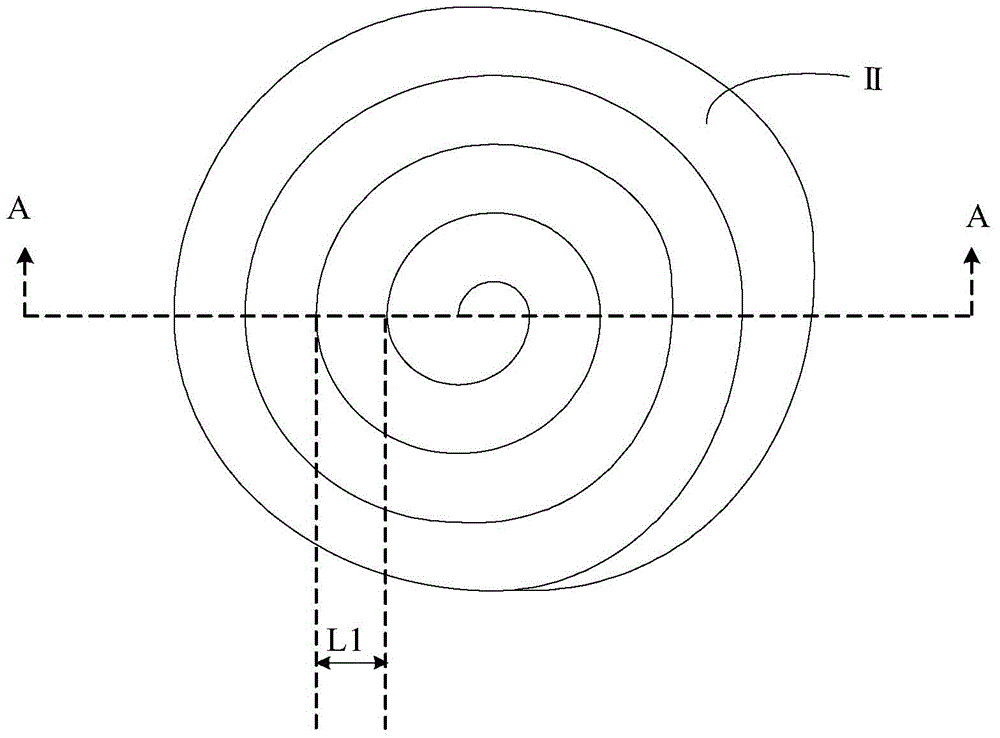

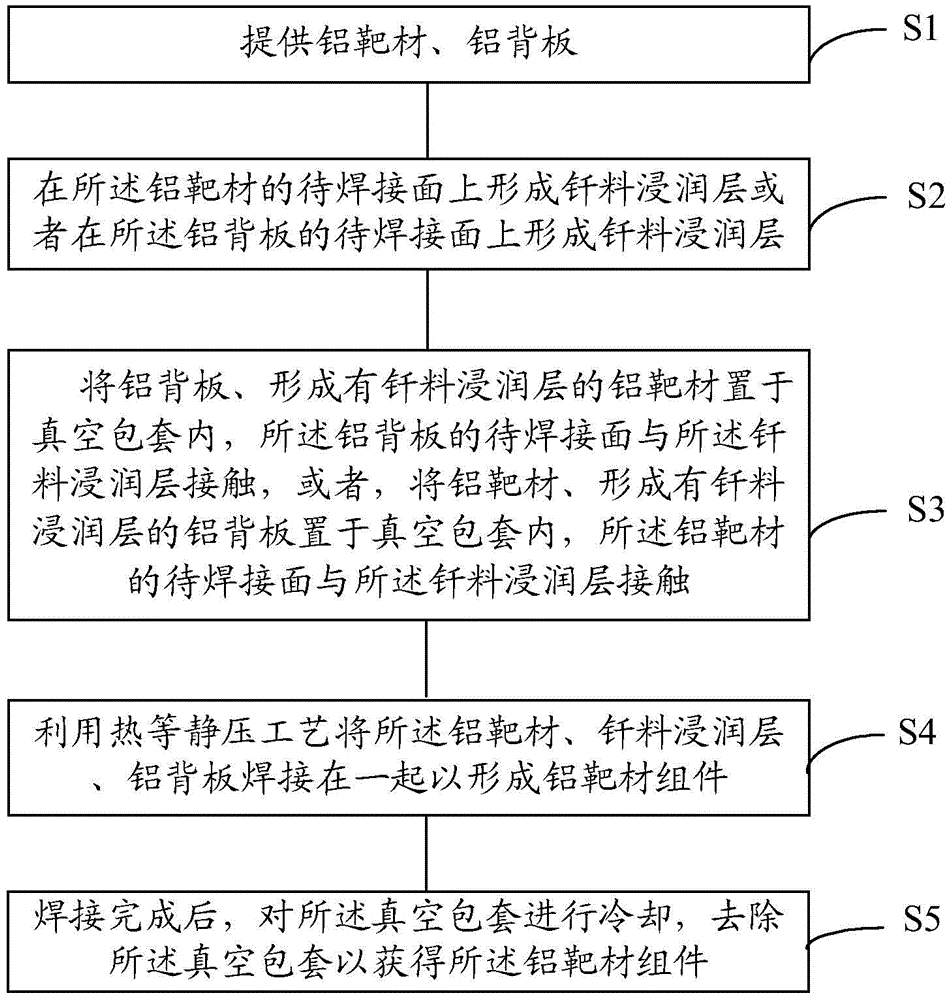

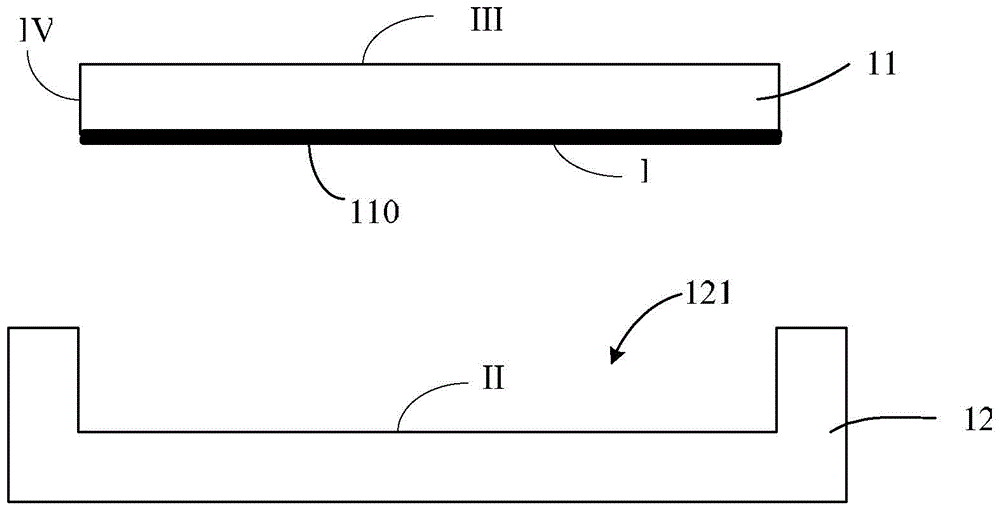

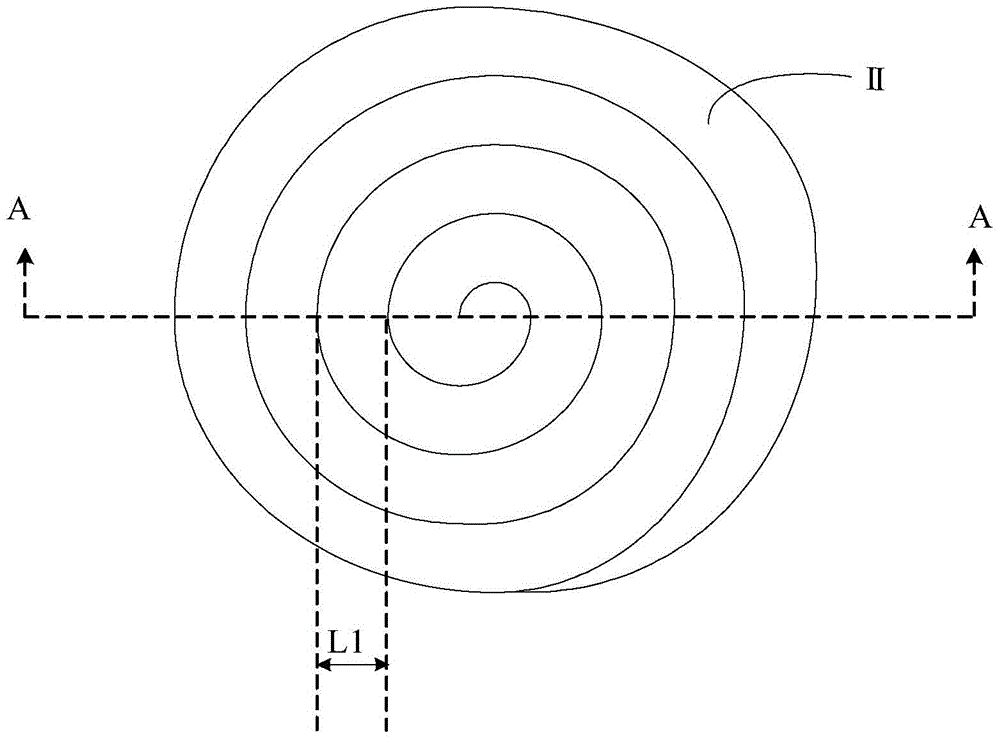

Welding method of aluminum target assembly

ActiveCN104588810AImprove welding efficiencyImprove welding strengthSoldering apparatusWelding/soldering/cutting articlesHot isostatic pressingAluminium

The invention provides a welding method of an aluminum target assembly. The welding method comprises the steps that an aluminum target and an aluminum back plate are provided; a brazing filler metal wetting layer is formed on the surface, to be welded, of the aluminum target or the surface, to be welded, of the aluminum back plate; the aluminum back plate and the aluminum target with the formed brazing filler metal wetting layer are placed in a vacuum packaging sleeve, and the surface, to be welded, of the aluminum back plate makes contact with the brazing filler metal wetting layer, or, the aluminum target and the aluminum back plate with the formed brazing filler metal wetting layer are placed in the vacuum packaging sleeve, and the surface, to be welded, of the aluminum target makes contact with the brazing filler metal wetting layer; the aluminum target, the brazing filler metal wetting layer and the aluminum back plate are welded together through a hot isostatic pressing technology so as to form the aluminum target assembly; after welding is accomplished, the vacuum packaging sleeve is cooled and removed to obtain the aluminum target assembly. By means of the welding method, welding between the aluminum target and the aluminum back plate can be achieved, the welding efficiency is high, the formed aluminum target assembly is high in welding strength and low in deformation, and the demand of long-term stable production and usage of targets can be met.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

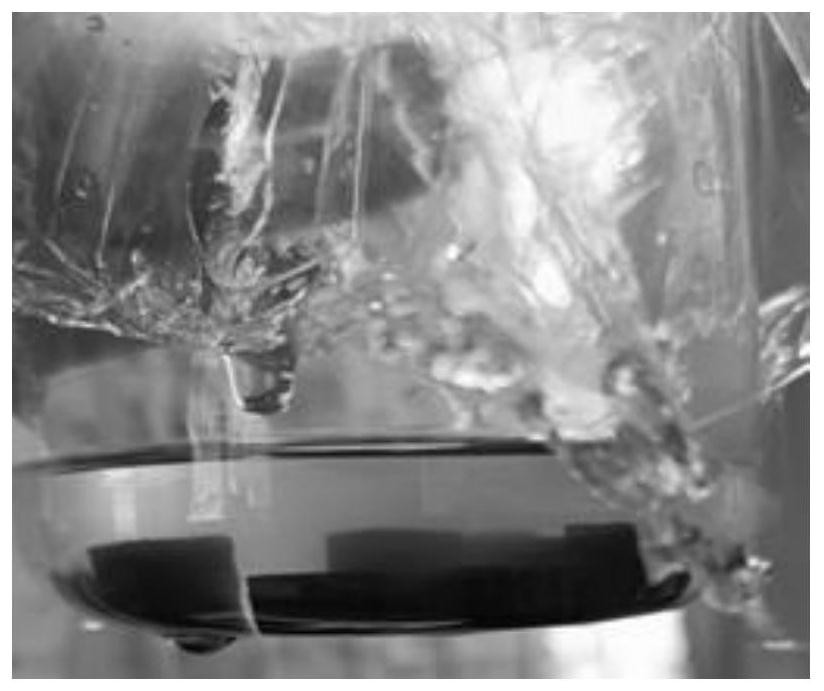

Non-contact ultrasonic brazing connection method for preparing quartz glass connector

ActiveCN111215714AAchieve wettingFirmly connectedSoldering auxillary devicesUltrasonic vibrationFiller metal

The invention relates to a non-contact ultrasonic brazing connection method for preparing a quartz glass connector. The method comprises the steps that 1, a brazing filler metal foil sheet is processed until the width of the foil sheet is identical to that of quartz glass; 2, the surface of the brazing filler metal foil sheet is polished and cleaned through acetone, the portion between two to-be-welded surfaces of the quartz glass is filled with the brazing filler metal foil sheet, the temperature is increased to 100-400 DEG C at the speed of 1-5 DEG / min, then heat preservation is performed for 5-10 minutes, the quartz glass is placed in a static magnetic field in the vertical direction, the magnetic induction intensity of the static magnetic field is 1-12 T, a coil generates an alternating current magnetic field, the frequency of the alternating current magnetic field is 2-10 kHz, the pressure of 0.1-1 MPa is applied to the upper end of the quartz glass, brazing filler metal is spreadand moistened on the surface of the quartz glass under the combined action of the pressure and electromagnetic ultrasonic vibration, the quartz glass is cooled to the room temperature, and thus the quartz glass is brazed. The non-contact ultrasonic brazing connection method solves the problems that in an existing quartz glass connection method, low-temperature connection is difficultly performed,and the residual stress of the high-temperature connector is large.

Owner:NORTHEAST GASOLINEEUM UNIV

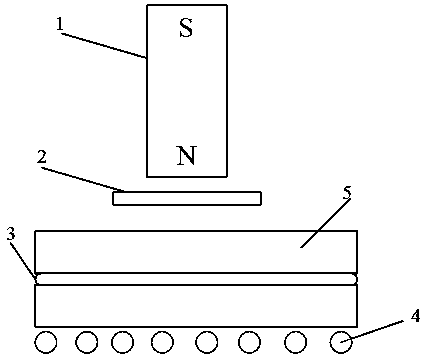

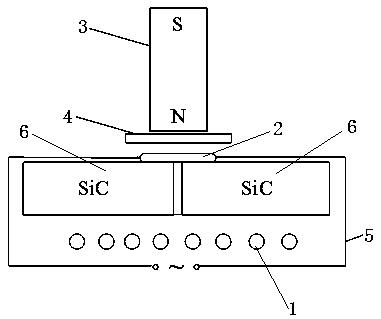

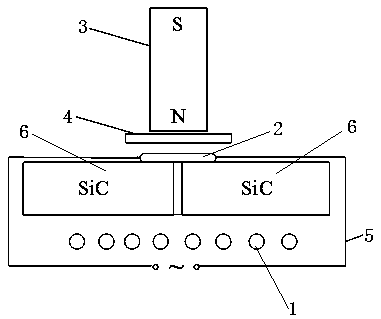

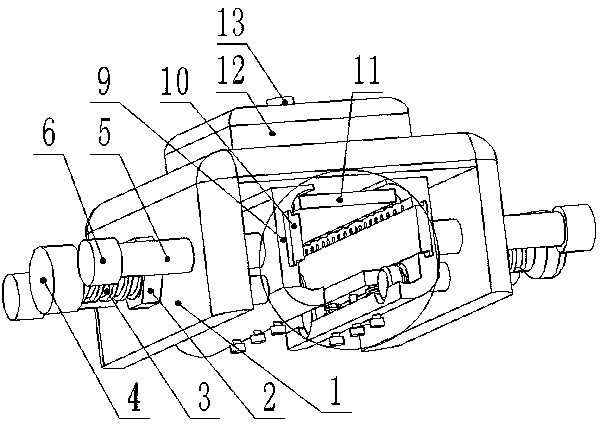

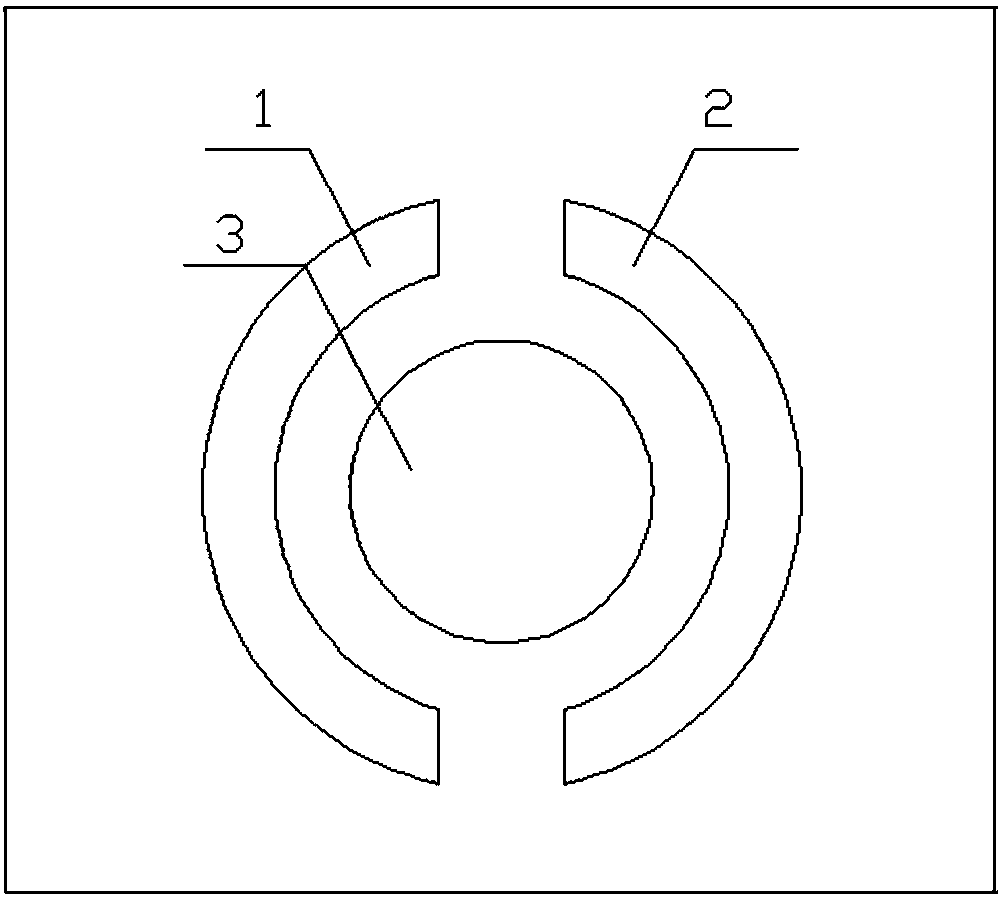

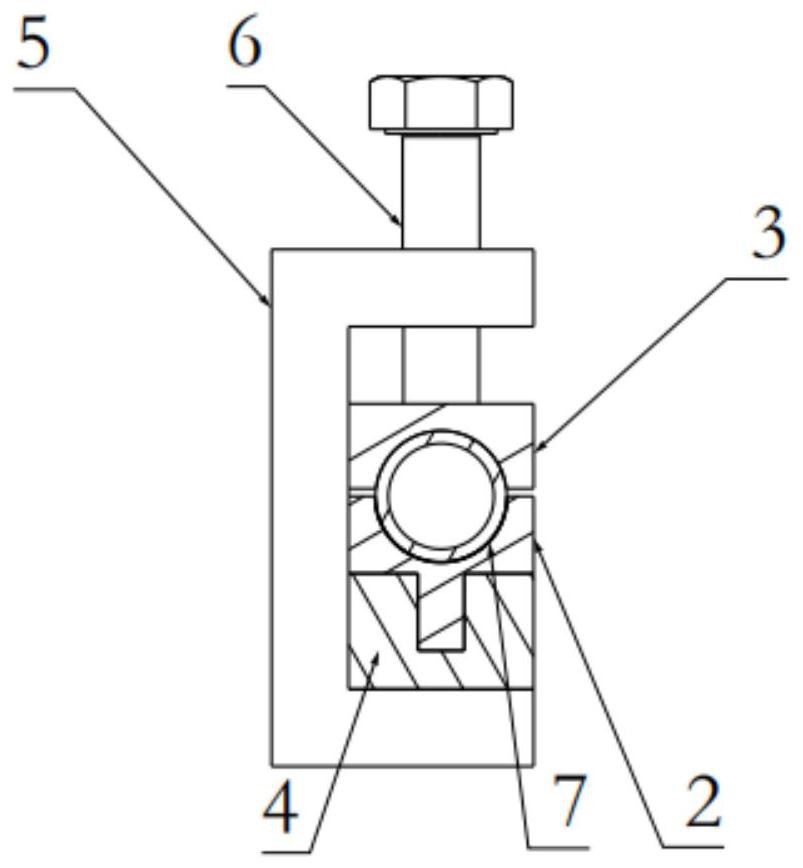

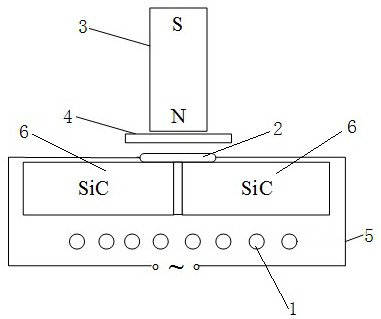

Electromagnetic ultrasonic brazing method for SiC ceramic

The invention relates to an electromagnetic ultrasonic brazing method for SiC ceramic, the method comprises the following operation steps: the width of a brazing filler metal foil sheet is processed to be completely consistent with the width and size of the SiC ceramic; the surface of the brazing filler metal foil sheet and the surface of the SiC ceramic are ground and cleaned; the treated brazingfiller metal foil sheet is filled between two to-be-welded surfaces of the SiC ceramic, two pieces of the SiC ceramic are horizontally placed side by side, another brazing filler metal foil sheet ishorizontally placed on the upper edges of the two to-be-welded surfaces, then is placed in a muffle furnace, and is then arranged in a static magnetic field in the vertical direction after being heated, a permanent magnet and a coil are positioned right above the horizontally-placed brazing filler metal foil sheet, the static magnetic field is generated by a superconducting magnet, current is introduced into the two ends of the brazing filler metal foil sheet, meanwhile, pressure is applied to the two ends of the SiC ceramic, the SiC ceramic is cooled to the room temperature along with the furnace, and the brazing of the SiC ceramic is completed. The electromagnetic ultrasonic method is adopted, no ultrasonic tool head is arranged, and the SiC ceramic cannot be directly contacted during ultrasonic application, so that the SiC ceramic cannot be subjected to ultrasonic vibration so as to cause cracking.

Owner:NORTHEAST GASOLINEEUM UNIV

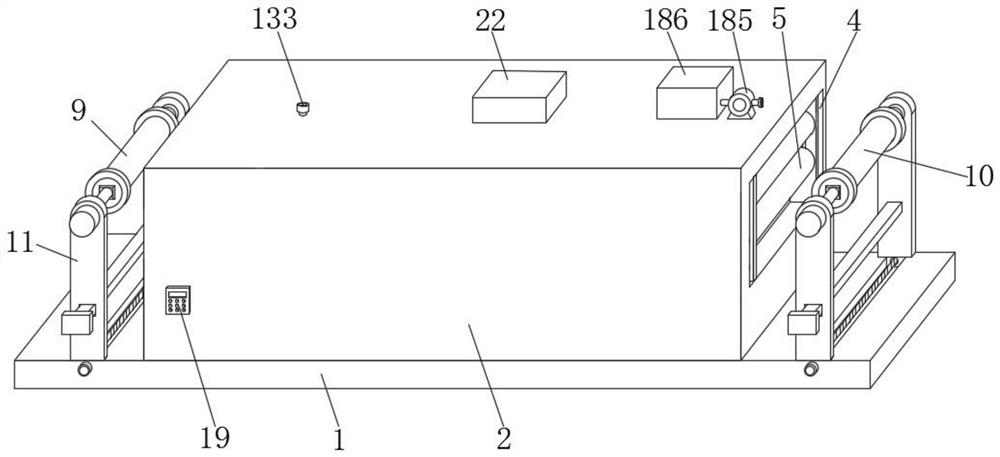

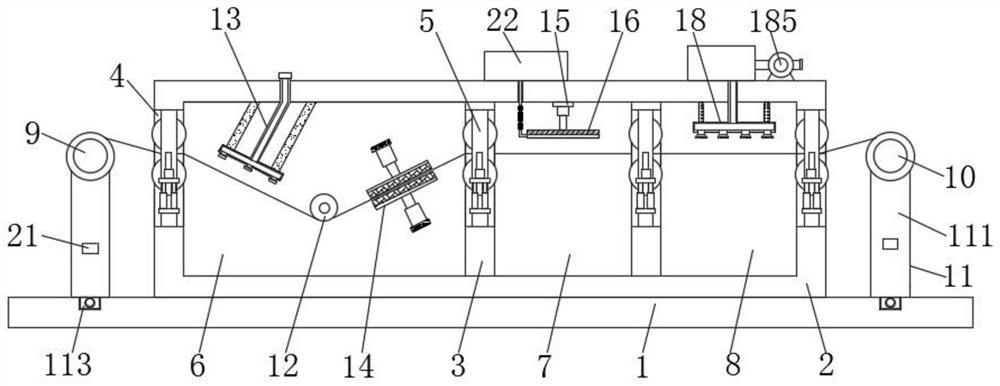

Textile fabric printing and dyeing device

PendingCN112323286APracticalRemove dustLiquid/gas/vapor removal by suctionTextile treatment machine arrangementsEngineeringTextile printer

The invention belongs to the technical field of textile printing and dyeing, and discloses a textile fabric printing and dyeing device. The device comprises a supporting plate, wherein a printing anddyeing box is fixedly connected to the top of the supporting plate, and two partition plates arranged left and right are arranged in the printing and dyeing box. According to the scheme, a cloth feeding winding drum and a cloth collecting winding drum with different lengths can be clamped, fixed, unwound and wound, textile fabrics with different thicknesses can be conveyed through a cloth feedingassembly with an adjustable interval, practicability is high, an auxiliary roller can assist in conveying the fabrics, the functions of automatic wetting, dust removing and excessive moisture absorbing through extrusion can be achieved through mutual cooperation of the auxiliary roller, a water spraying assembly and a water absorbing assembly in a wet spraying cavity, the automatic printing and dyeing function can be achieved through mutual cooperation of a hydraulic telescopic rod, a connecting block, a printing and dyeing module, a telescopic pipe and a dyeing agent box in a printing and dyeing cavity, automatic drying can be achieved through a drying assembly in a drying cavity, finally, winding is conducted through the cloth collecting winding drum, the automation degree is high, and the working efficiency is high.

Owner:陈扬辉

Clothes detergent capable of powerfully removing oil stains

InactiveCN108865533AGood dispersionImprove stabilityInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsHydrophobic polymerGlycerol

The invention relates to the technical field of daily chemical cleaning and in particular relates to a clothes detergent capable of powerfully removing oil stains. The clothes detergent is prepared from the following raw material components: a surfactant, glycerol, sodium tripolyphosphate, alkanolamide, potassium sorbate, a powerful oil removing agent, an aroma enhancer, a fluorescent brightener,a compound bacterium-inhibition agent and de-ionized water, wherein the powerful oil removing agent is a composition composed of an oleophilic polymer, a hydrophobic polymer and an adsorptive carriersubstance through compounding; the substance has a very good water repelling property and has remarkable selective adsorption performance on an oily substance and a relatively large adsorption capacity; the surfactant comprises an anionic surfactant and a non-ionic surfactant; the compound bacterium-inhibition agent comprises hydroxymethyl chitosan, seaweed polysaccharide and bacterium-inhibitionpeptide. The components of the detergent have good high-temperature-resisting performance and the detergent has a very excellent oil stain removing effect and can keep washed clothes clean and sanitary.

Owner:HEFEI YUANKE GARMENT DESIGN CO LTD

Preparation method of laser marking lubricant for ABS (acrylonitrile butadiene styrene) engineering plastics

ActiveCN107266717AImprove compatibilityImprove mechanical properties and laser marking resultsStearic acidNitrogen gas

The invention discloses a preparation method of a laser marking lubricant for ABS (acrylonitrile butadiene styrene) engineering plastics, and belongs to the technical field of a laser marking additive. According to the method, firstly, a Dopamine solution is used for soaking a modified laser absorbent; after filtering and drying are performed, the modified laser absorbent and a treating agent are mixed and react at high temperature, and are then dissolved in ethanediamine to prepare a laser absorbent ethanediamine solution; next, in a nitrogen protection state, heating is performed, so that stearic acid is melted and is then proportionally mixed with the laser absorbent ethanediamine solution for performing dehydration reaction; moisture in the system is taken out by nitrogen gas flow; finally, through extrusion pelletization, the laser marking lubricant for the ABS engineering plastics is obtained. The compatibility of the laser marking lubricant for the ABS engineering plastics with a plastic base body is good; the laser marking lubricant can be stably dispersed in the plastics; the mechanical strength of the product can be effectively improved; in the laser marking process, the formed marks are clear; the contrast is obvious; wide application prospects are realized.

Owner:常州可赛成功塑胶材料有限公司

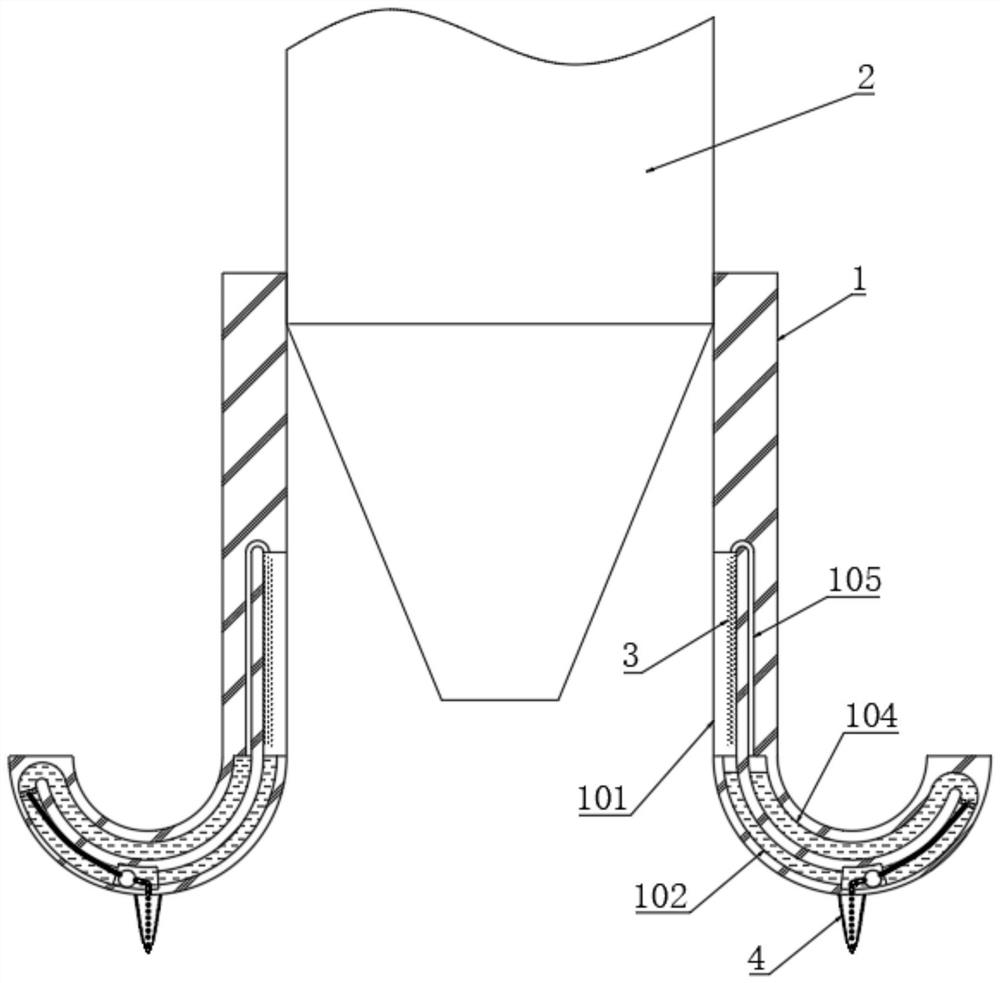

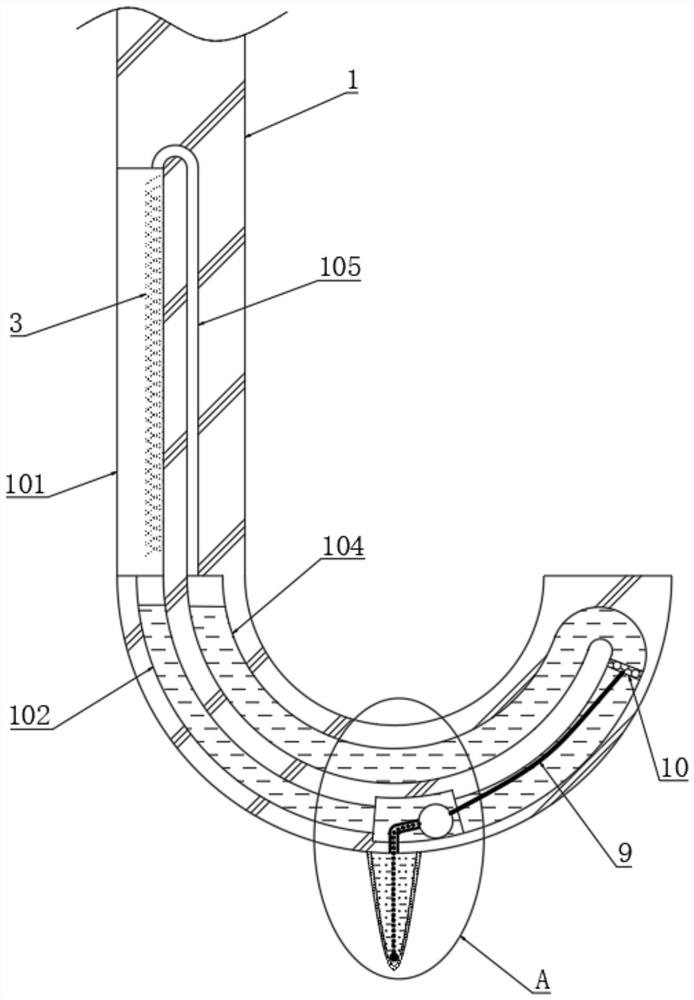

Stair handrail clearing robot

InactiveCN108903810AImprove adaptabilityAvoid shakingCarpet cleanersFloor cleanersAutomatic controlDrive wheel

The invention discloses a stair handrail clearing robot comprising a frame-shaped outer guard plate. Threaded sleeves are symmetrically fixed to the two sides of the frame-shaped outer guard plate, the interior of each threaded sleeve is in threaded connection with a threaded rod, a handle is fixed to one end of each threaded rod, and the other end of each threaded rod is fixedly connected with arotating block. According to the stair handrail clearing robot, arranged guiding rods have the guiding effect, thus arc-shaped inner clamping plates are prevented from shaking, consistency of the arc-shaped inner clamping plates and a handrail in direction is kept, and thus washing of the handrail in the later period is facilitated; a driving motor drives driving wheels to rotate, the rotating driving wheels make contact with the bottom of the handrail, thus the stair handrail clearing robot can automatically walk forwards, sponge layers wrapping the periphery of the handrail wash dust on thehandrail cleanly under the effect of a washing agent, in this way, manual washing is reduced, and the efficiency is greatly improved; and an arranged PLC controls the driving motor to drive the driving wheels to travel by the length, measured by a distance measuring instrument, of the handrail, the stair handrail clearing robot is prevented from falling and thus being damaged, and in this way, automatic control over the stair handrail clearing robot is achieved.

Owner:东莞市奇趣机器人科技有限公司

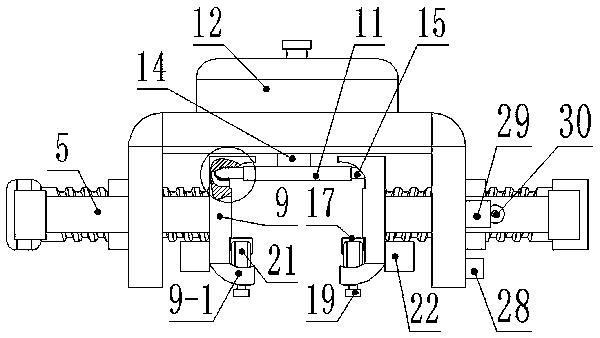

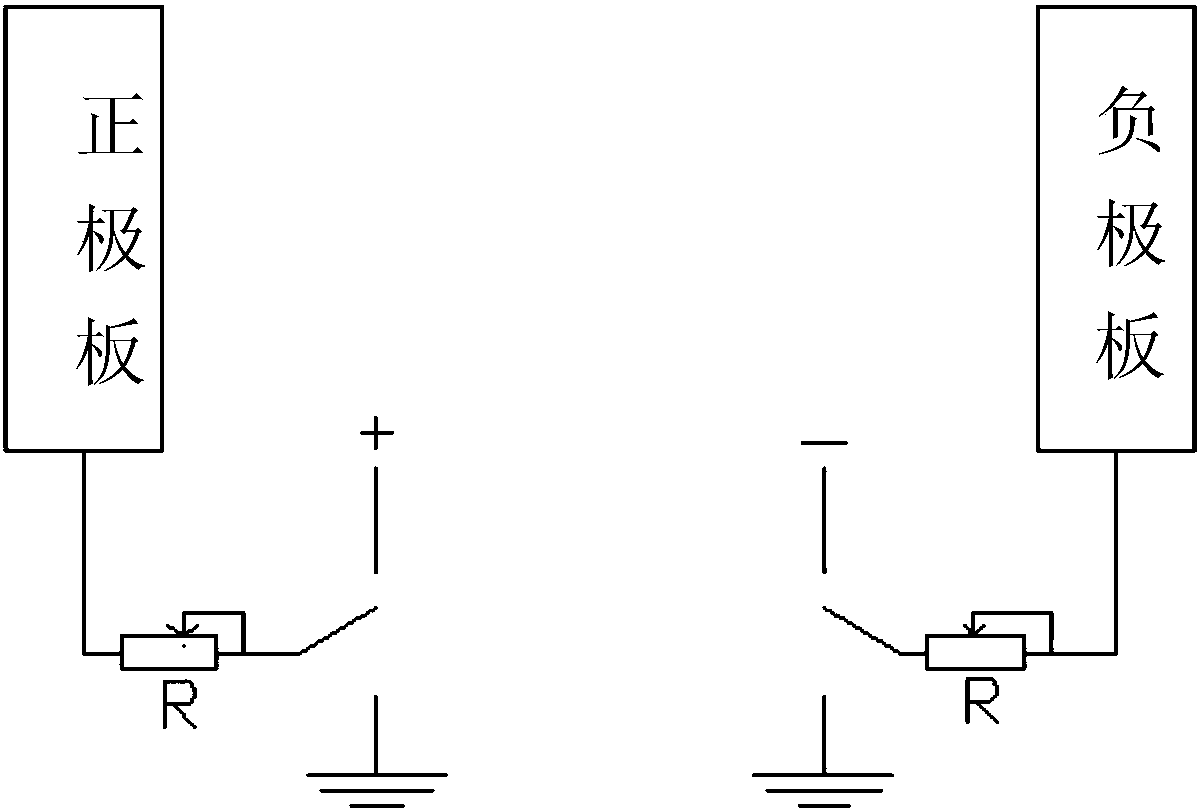

Welding method capable of driving solders by using electric field and application

ActiveCN108788355AHigh degree of homogenizationFacilitate directional flowSoldering apparatusMetallurgyWelding defect

The invention discloses a welding method capable of driving solders by using an electric field and application. The welding method comprises the following steps: base metal is preheated by 3-5 min at200-500 DEG C; brazing filler metal and the base metal are fixed according to a structure of base metal / brazing filler metal / base metal, and are heated to melt the brazing filler metal; after the brazing filler metal is molten, the heating is continued; meanwhile, liquid-state electrorheological fluid is filled in the brazing filler metal to obtain liquid-state mixed brazing filler metal; an electric field device is provided, and comprises an anode plate and a cathode plate; the anode plate and the cathode plate surround the base metal, and continuously apply the electric field to the base metal; meanwhile, the base metal is rotated; and the anode plate and the cathode plate are rotated around two base metal. The welding method facilitates film breakage, wetting and expansion of the liquid-state brazing filler metal on the surface of the base metal, promotes mutual dispersion and alloying of elements and components between the brazing filler metal and the base metal, improves the uniformity degree of welding lines, reduces the welding defects, and obtains high-strength welding joints.

Owner:河北宇天材料科技有限公司

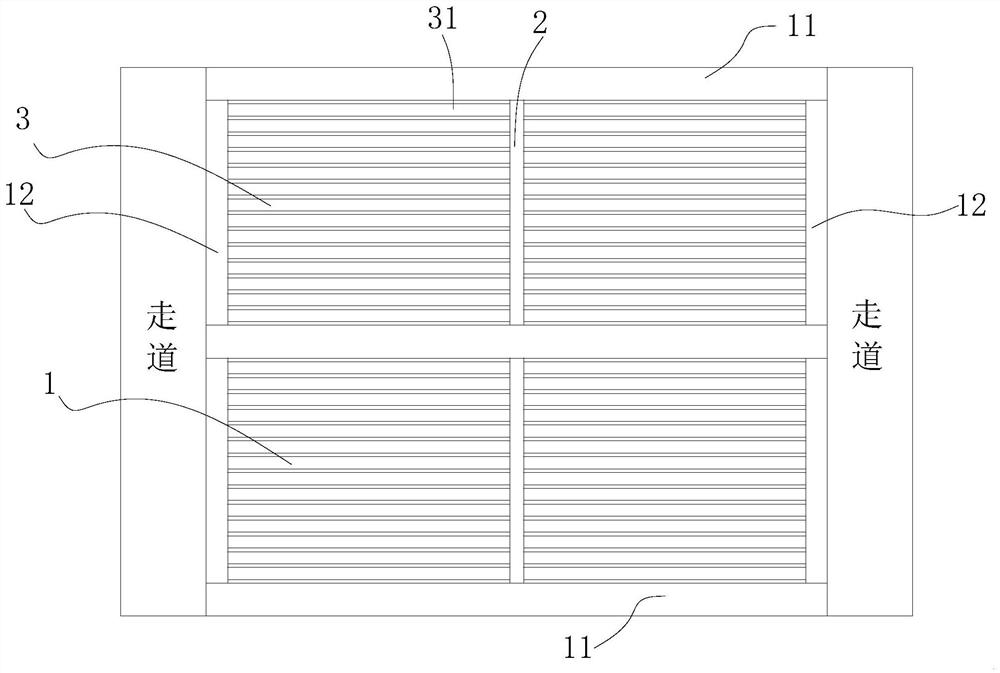

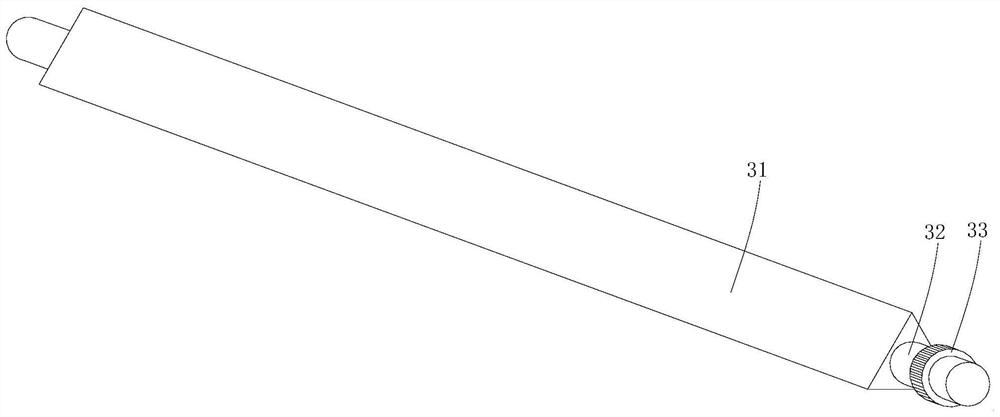

Pigsty of pig farm

PendingCN111789032AReduce the impactShorten the timeAnimal housingCleaning using liquidsPig farmsAnimal science

The invention discloses a pigsty of a pig farm. The pigsty comprises a captive area; a live pig activity space defined by a left side wall, a right side wall, a front grid and a rear grid; an area support, which is of a columnar structure, and of which two ends are connected to the side walls to divide the captive area into a front activity area and a rear activity area; turnover floors, respectively arranged in the two activity areas and dividing the captive area into an upper live pig activity area and a lower pollution discharge area; and brush bodies, arranged under the turnover floors andused for cleaning bottom surfaces of the turnover floors. The pigsty has the beneficial effects that through turning over the floors, a dry and clean surface is upward for live pigs to move, and a dirty surface is downward for cleaning and drying in the shade, so that influence of cleaning the floors on the live pigs is reduced, and pigsty cleaning efficiency is improved; in addition, a gentle cleaning device is provided, cleaning is completed while the live pigs move, and the life and the living environment of the live pigs are basically not affected in the cleaning process.

Owner:福建鑫锦宏农牧开发有限公司

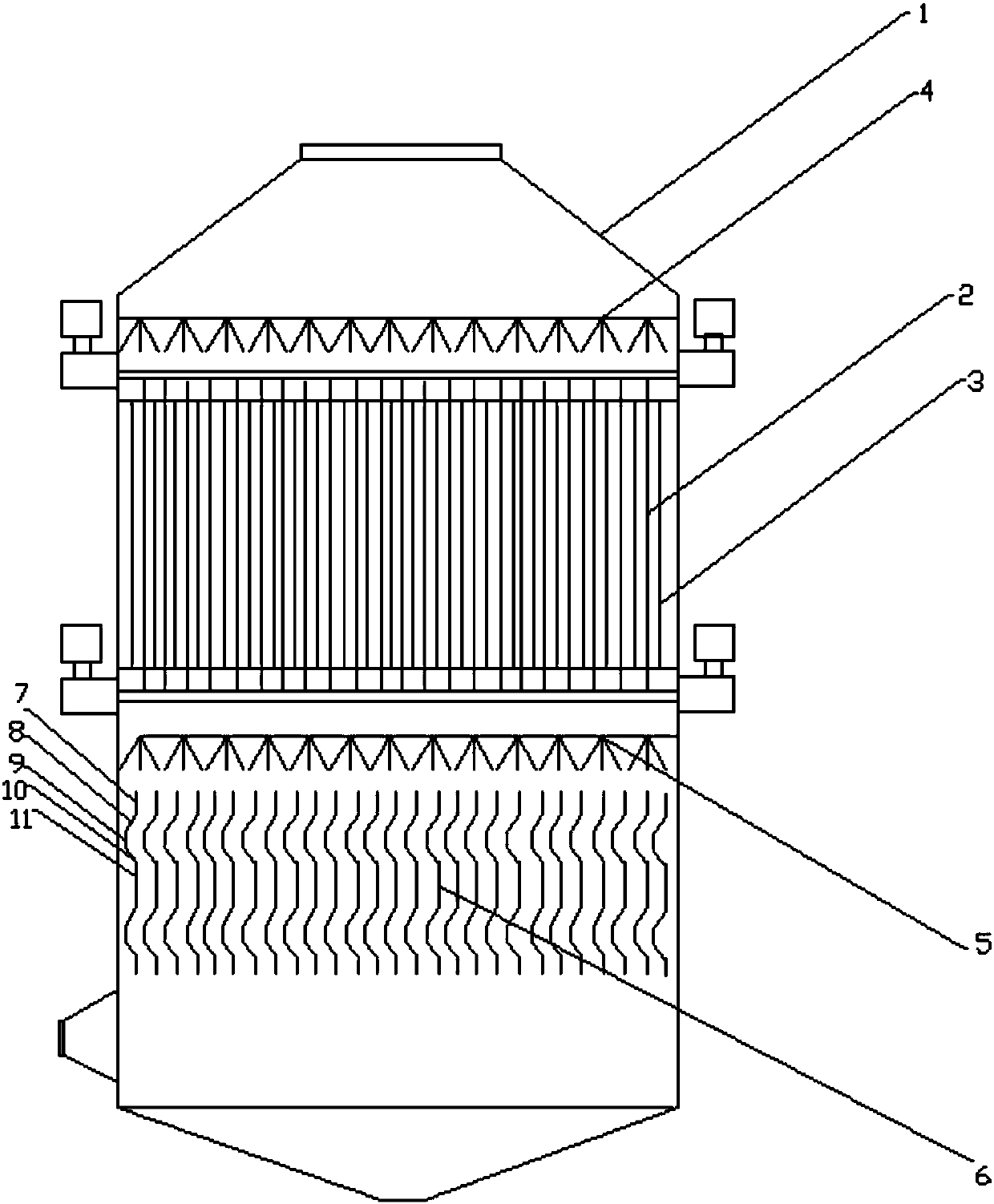

Hydroelectricity dust catcher

InactiveCN109590110AImprove dust removal efficiencyReduce dust concentrationExternal electric electrostatic seperatorElectrode constructionsPurified waterElectric field

The invention discloses a hydroelectricity dust catcher. An electric field region is arranged in an upper part of a box body, the electric field comprises multiple pairs of positive electrode dust collection plates and negative electrode lines, the multiple pairs of the positive electrode dust collection plates are arranged at intervals and in parallel, the negative electrode lines are arranged between each pair of positive electrode dust collection plates, spraying devices are arranged above the electric field region and are used for spraying purified water to the positive electrode dust collection plates, an atomizing humidification layer is arranged below the electric field region, a turbulence region is arranged below the atomizing humidification layer, a smoke inlet is higher than a position of the turbulence region, the turbulence region comprises bending plates which are arranged in parallel, each bending plate comprises a plurality of repeated units, each repeated unit is formed by connecting a first vertical plate, a left inclination plate, a second vertical plate, a right inclination plate and a third vertical plate in an end-to-end way, the lengths of the first verticalplate, the left inclination plate, the second vertical plate, the right inclination plate and the third vertical plate are equal, and angles of bending positions of the bending plates are equal and are all 140-170 DEG C. The hydroelectricity dust catcher is high in dust removal efficiency.

Owner:盐城市吉盛达环保工程有限公司

Adsorbent for dioxins and heavy metals and preparation method thereof

PendingCN110860276AImprove adsorption efficiencyImprove practicalityGas treatmentOther chemical processesSodium bicarbonateSorbent

The invention discloses an adsorbent for dioxins and heavy metals and a preparation method thereof, relating to the technical field of pollutant adsorbents. The adsorbent comprises the following components: 70-75 parts of bentonite, 5-10 parts of wood charcoal, 2-5 parts of graphene, 2-5 parts of lignin, 10-15 parts of sodium bicarbonate and 2-5 parts of water. According to the adsorbent for the dioxins and the heavy metals and the preparation method thereof, the adsorbent has high adsorption efficiency, can process other acid gases, is cheaper than a traditional adsorbent, has a wide use temperature range and high adsorption efficiency, co-processes other acid gases in addition to adsorbing harmful substances such as the dioxins and the heavy metals, is lower in cost, and has a high domestic production degree in China, broad application prospects, and the effect of removing part of acid gases, the practicality of the adsorbent is greatly improved, and the adsorbent can be used for large-scale promotion and use and has higher practicability.

Owner:瀚蓝工程技术有限公司

Welding method of aluminum target components

ActiveCN104588810BPrevent oxidationEasy to weldSoldering apparatusWelding/soldering/cutting articlesWeld strengthFiller metal

The invention provides a welding method of an aluminum target assembly. The welding method comprises the steps that an aluminum target and an aluminum back plate are provided; a brazing filler metal wetting layer is formed on the surface, to be welded, of the aluminum target or the surface, to be welded, of the aluminum back plate; the aluminum back plate and the aluminum target with the formed brazing filler metal wetting layer are placed in a vacuum packaging sleeve, and the surface, to be welded, of the aluminum back plate makes contact with the brazing filler metal wetting layer, or, the aluminum target and the aluminum back plate with the formed brazing filler metal wetting layer are placed in the vacuum packaging sleeve, and the surface, to be welded, of the aluminum target makes contact with the brazing filler metal wetting layer; the aluminum target, the brazing filler metal wetting layer and the aluminum back plate are welded together through a hot isostatic pressing technology so as to form the aluminum target assembly; after welding is accomplished, the vacuum packaging sleeve is cooled and removed to obtain the aluminum target assembly. By means of the welding method, welding between the aluminum target and the aluminum back plate can be achieved, the welding efficiency is high, the formed aluminum target assembly is high in welding strength and low in deformation, and the demand of long-term stable production and usage of targets can be met.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

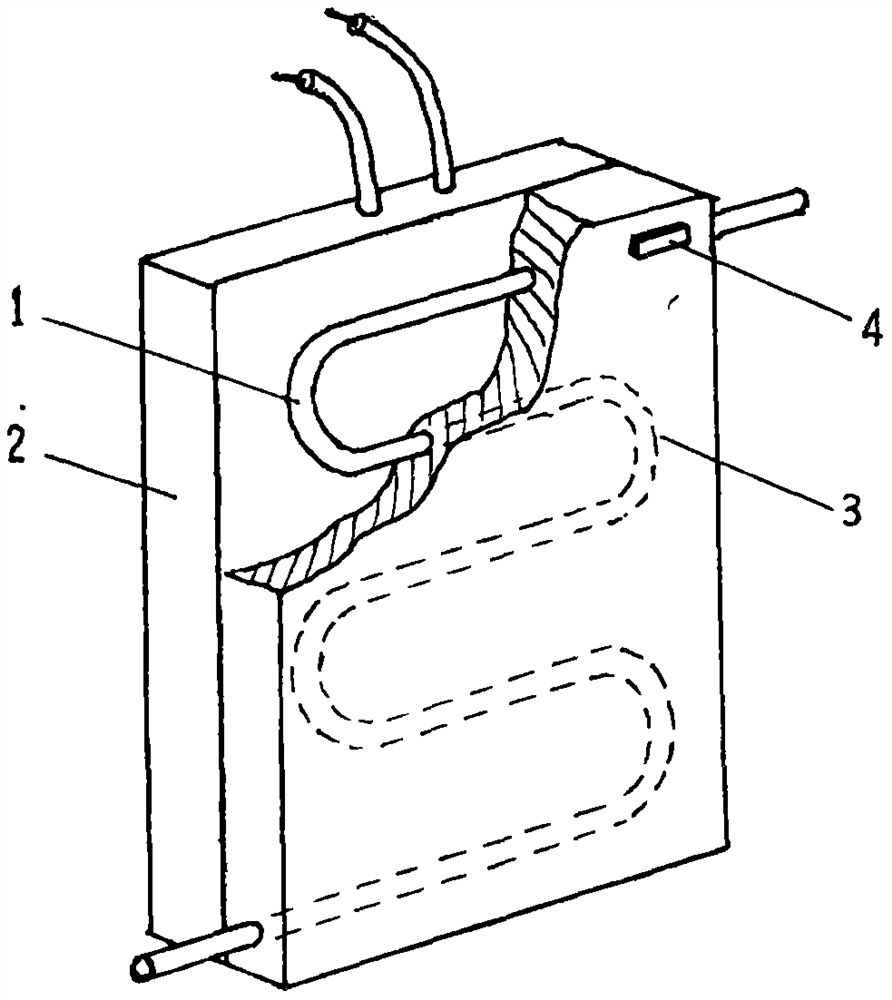

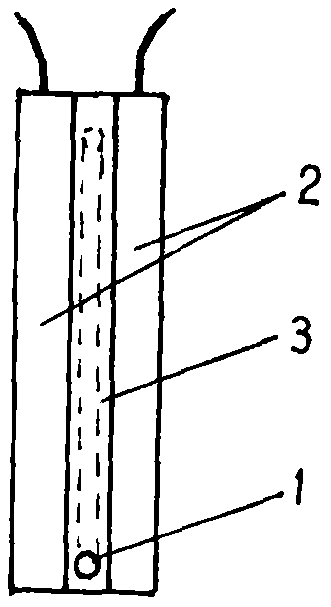

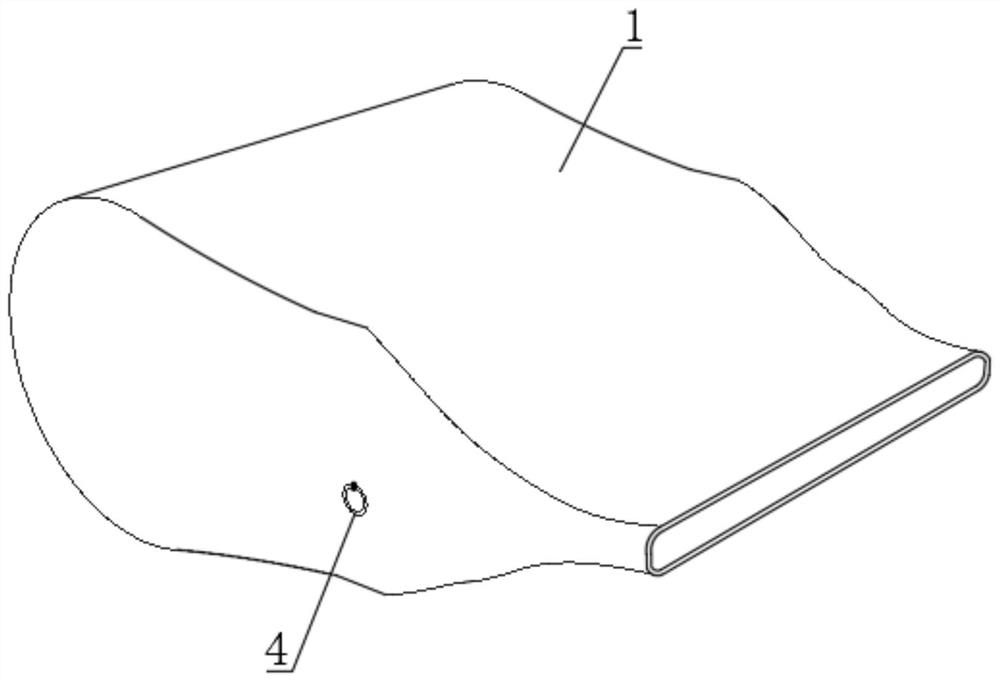

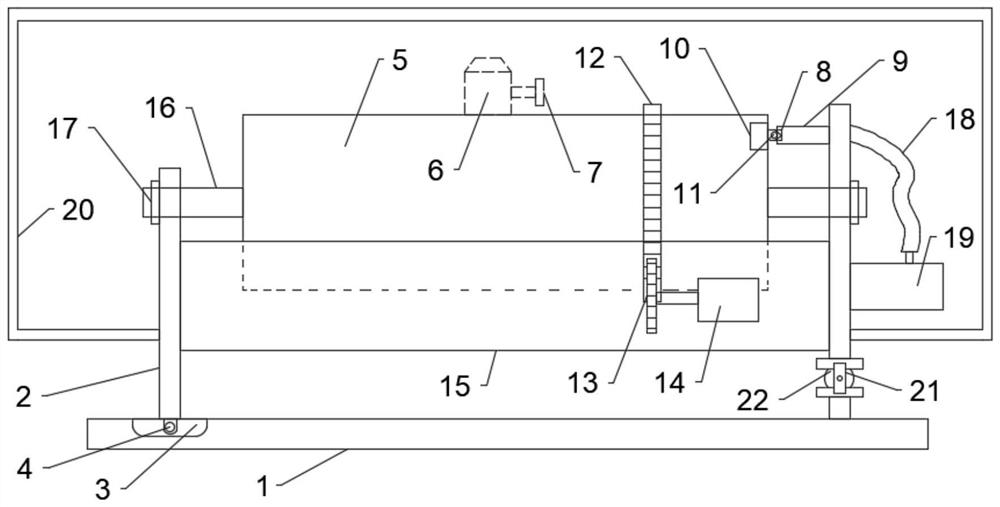

Rapid water sample heater

PendingCN112594920AAvoid defectsSolve the shortcomings of low heat exchange efficiency and low heatPreparing sample for investigationWater heatersThermodynamicsMetallic aluminum

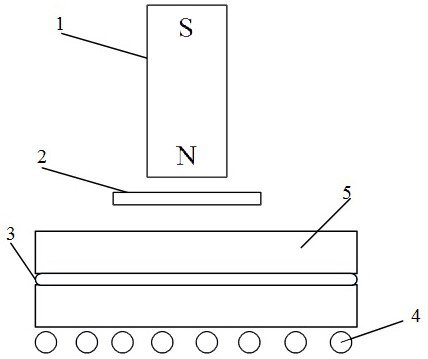

The invention discloses a rapid water sample heater. The rapid water sample heater is composed of a heat exchange tube 1 attached to the surfaces of heat sources 2 or clamped between the two heat sources, a heat conducting medium 3 filling all gaps between the heat exchange tube and the heat sources, and a temperature sensor 4, and the rapid water sample heater is characterized in that the heat conducting medium between the heat exchange tube and the heat sources uses tin-based alloy, and known heat conducting oil, or a metal aluminum casting method in which "thermal resistance" may exist is replaced.

Owner:大连科欣仪表研究所

A method for preparing nanoparticle-reinforced aluminum matrix composites

The invention discloses a method for preparing nano ceramic particles reinforced aluminum matrix composite material. Firstly, the mixed powder of nano-ceramic powder and micron-sized aluminum or aluminum alloy powder is prepared by dry-type high-energy ball milling under vacuum or argon protection to prepare millimeter-sized composite particles with a volume fraction of nano-ceramic particles of 10-50%. Then the millimeter-scale composite particles are directly melted or added to the aluminum or aluminum alloy melt, and ultrasonic vibration is applied to promote the uniform dispersion of the nano-ceramic particles in the metal melt, and the nano-ceramic particle-reinforced aluminum matrix composite material is prepared. The millimeter-scale composite particles prepared by the dry grinding method in the present invention can be easily and completely added to the metal melt, which solves the problem of poor wettability between the nano-ceramic particles and the base metal and difficulty in adding them. The low-cost advantage of composite materials. The nano particles are evenly distributed in the prepared composite material, and the material performance is high.

Owner:HUAZHONG UNIV OF SCI & TECH

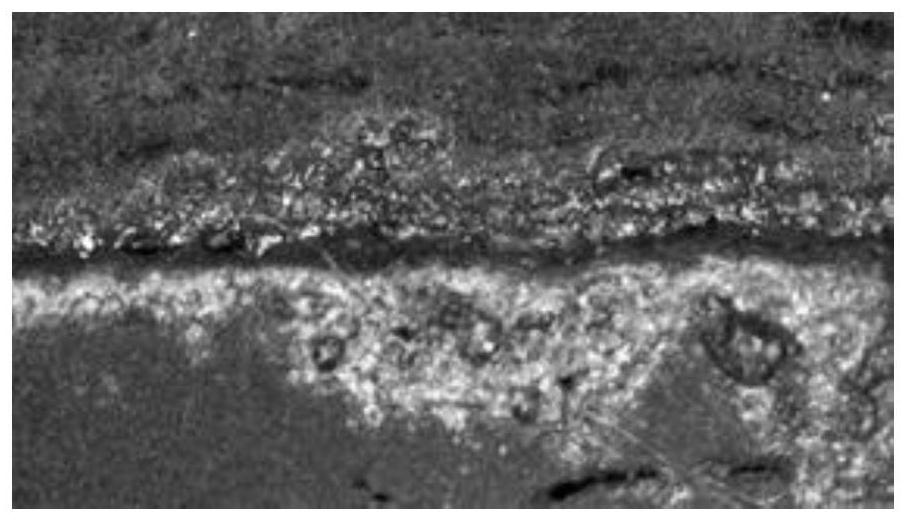

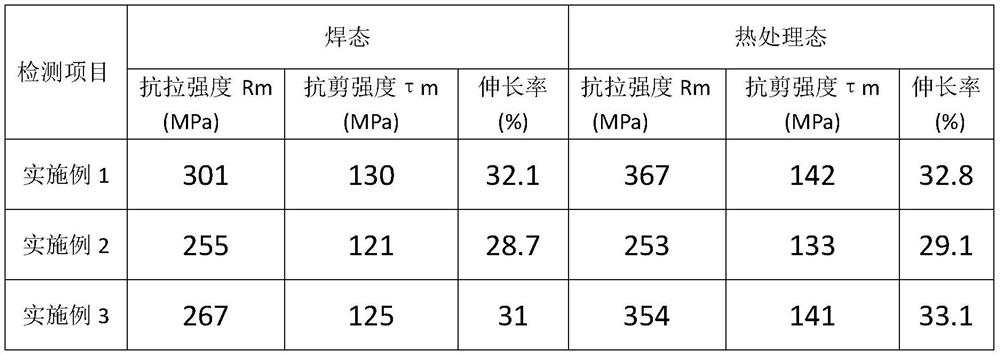

Flux for silicon carbide ceramic connection and preparation method thereof

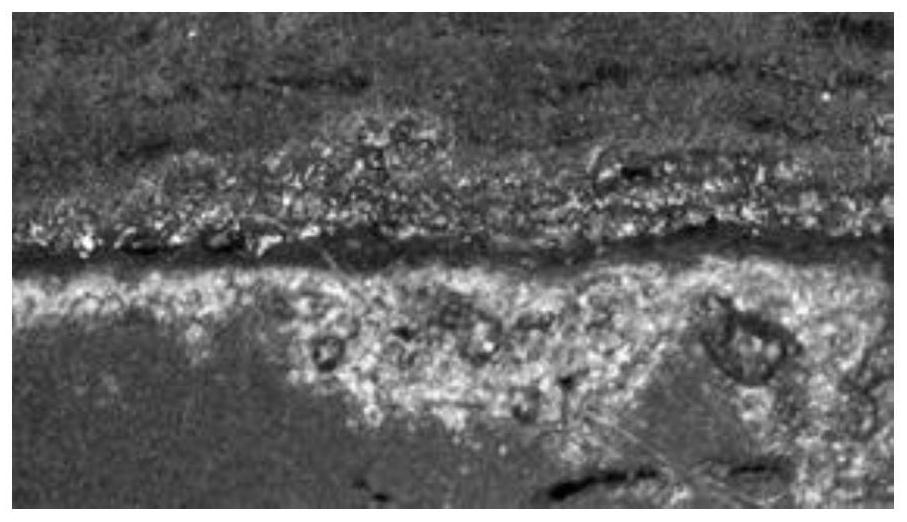

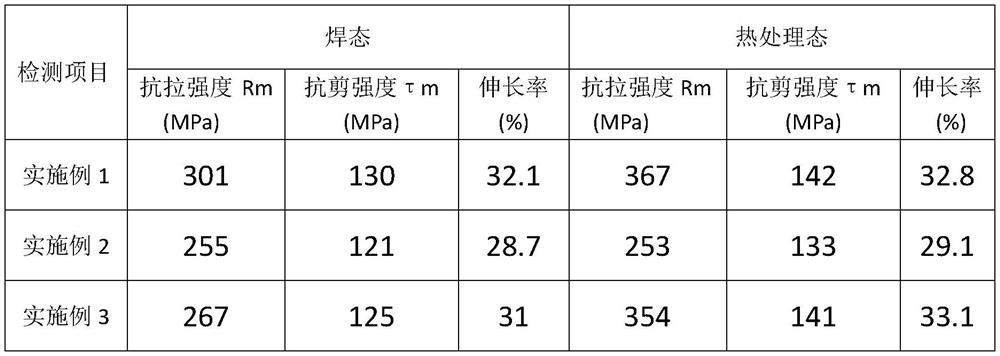

ActiveCN114346523AAchieve wettingFirmly connectedNuclear energy generationWelding/cutting media/materialsCarbide siliconUltimate tensile strength

The invention discloses a welding flux for silicon carbide ceramic connection and a preparation method of the welding flux. The welding flux is prepared from, by weight, 30-40 parts of Si powder, 1-3 parts of Ti powder, 1-4 parts of Zr powder, 10-15 parts of B powder, 1-2 parts of Fe powder, 5-10 parts of Cu powder and 1-5 parts of Hf powder. According to the flux, on one hand, oxide, carbide and nitride ceramics are effectively wetted, and on the other hand, the organization structure, strength and fracture morphology of a weld joint are affected.

Owner:成都成维精密机械制造有限公司

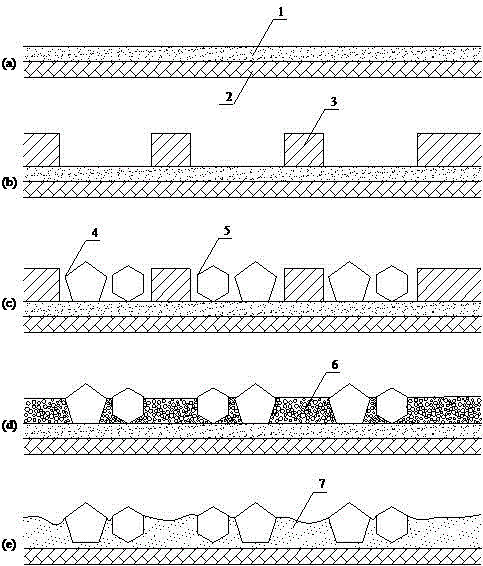

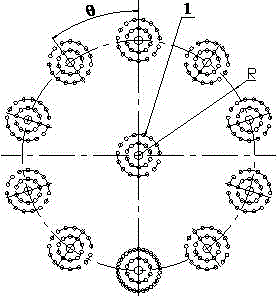

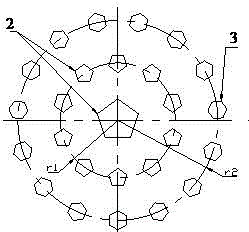

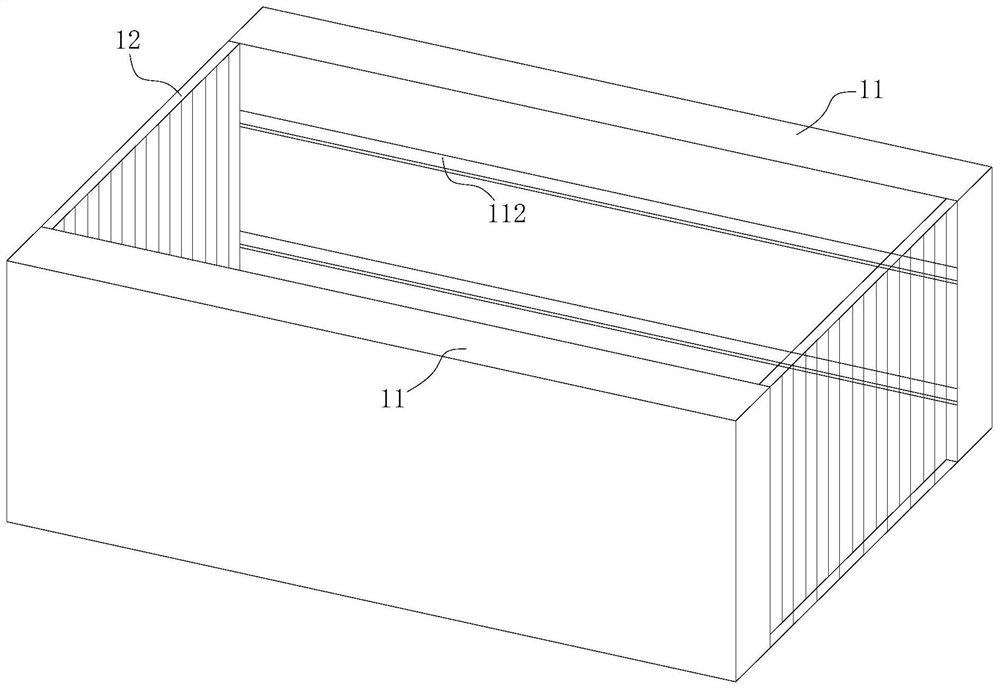

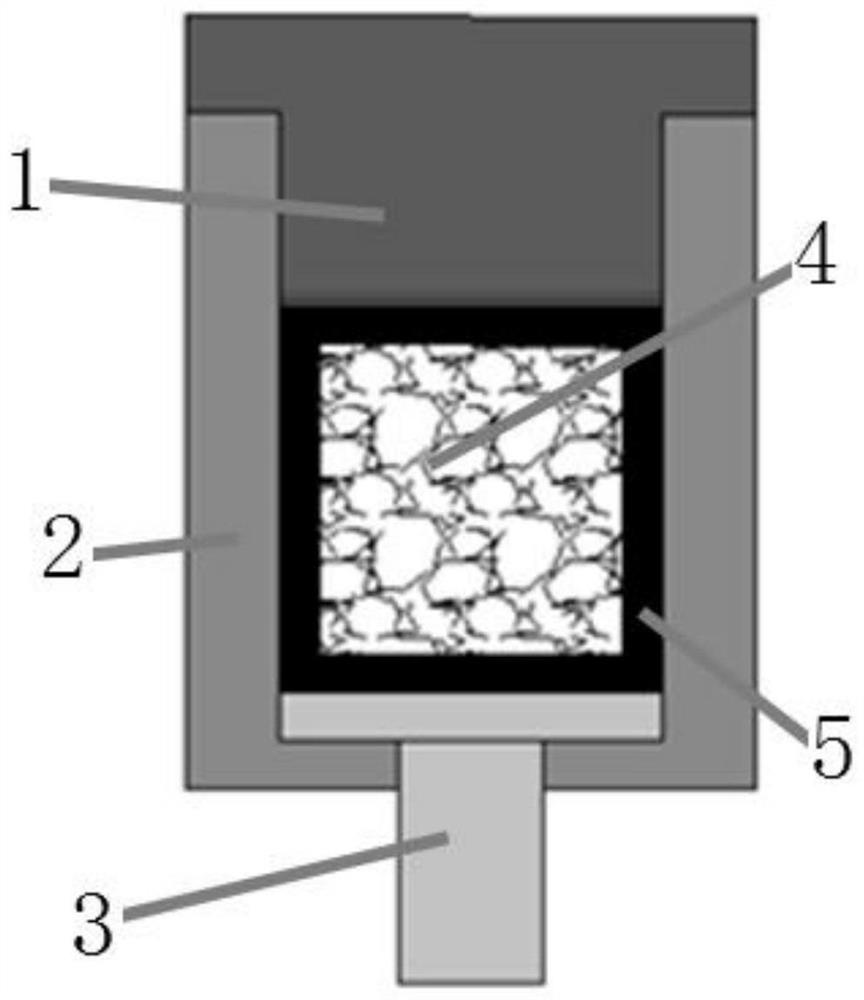

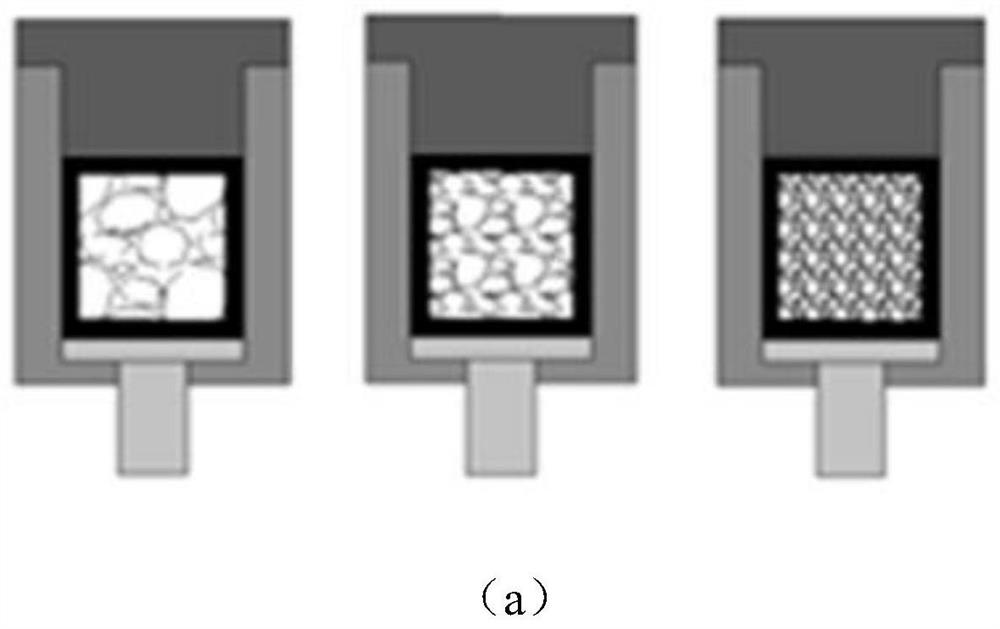

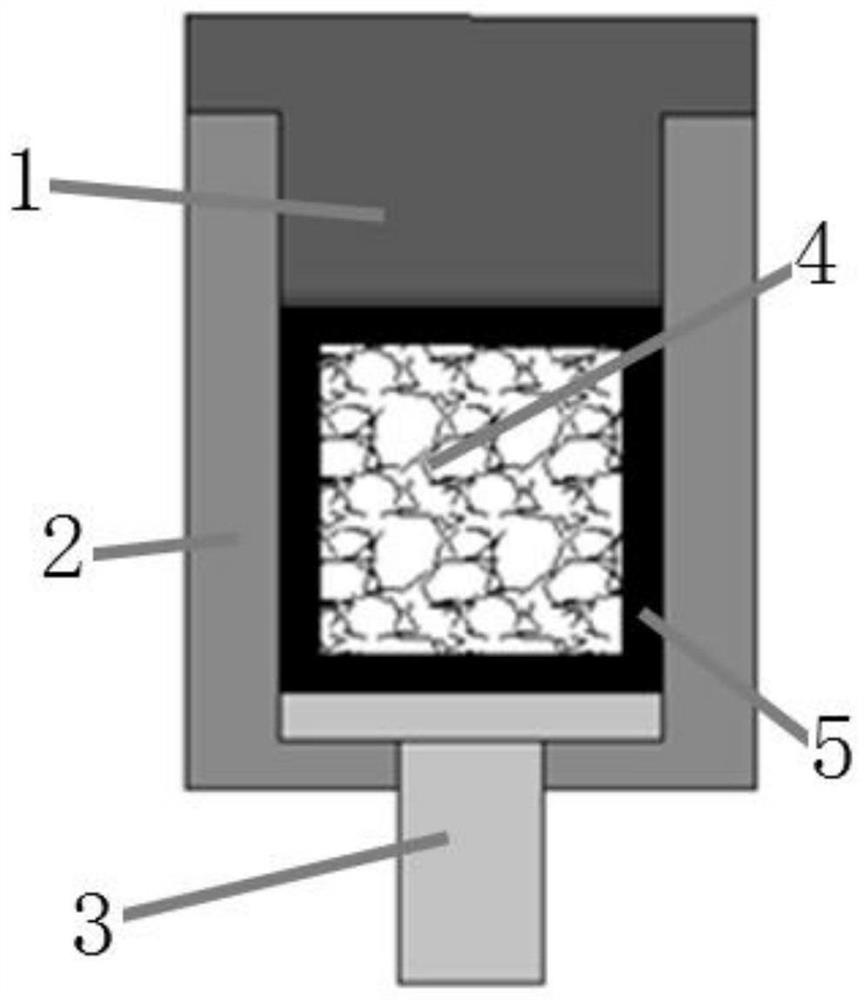

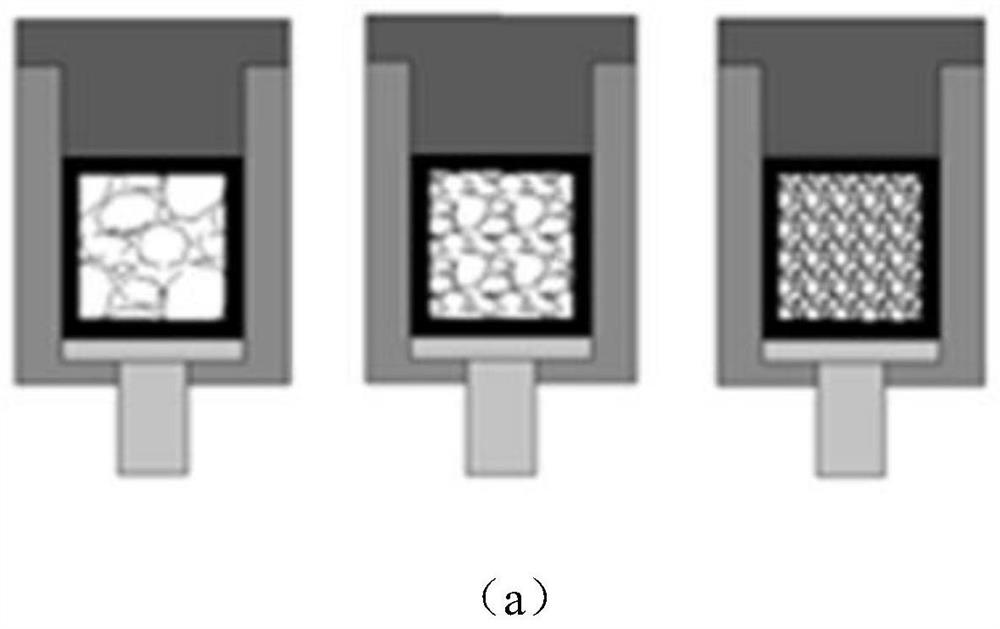

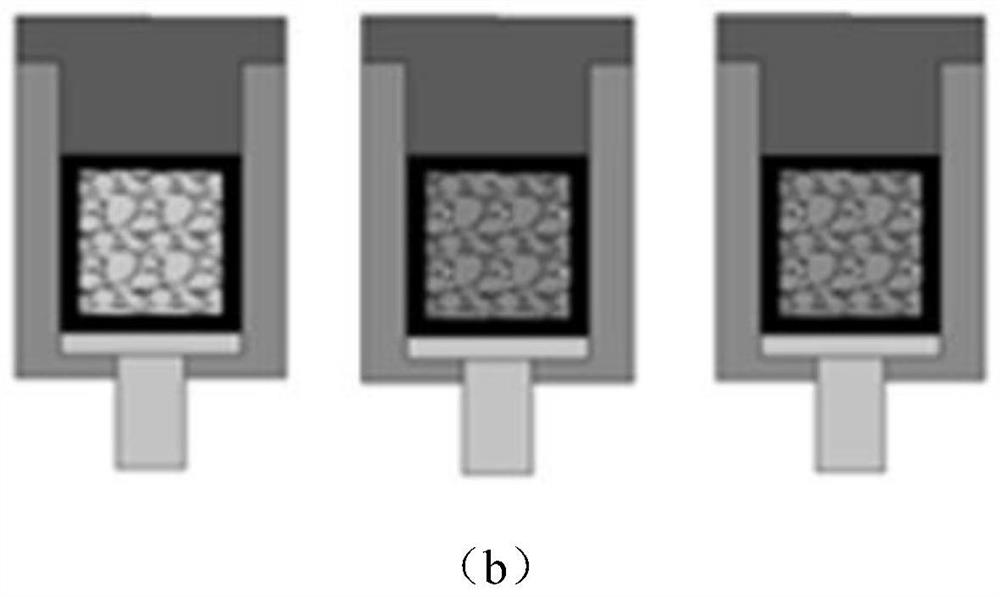

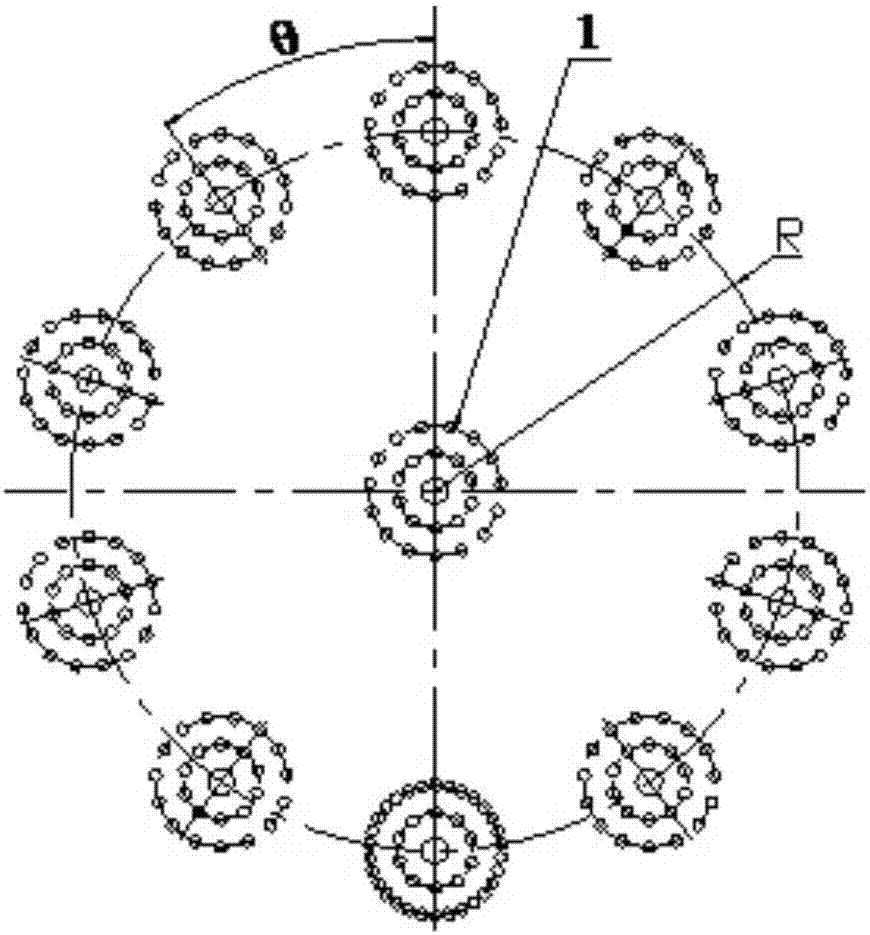

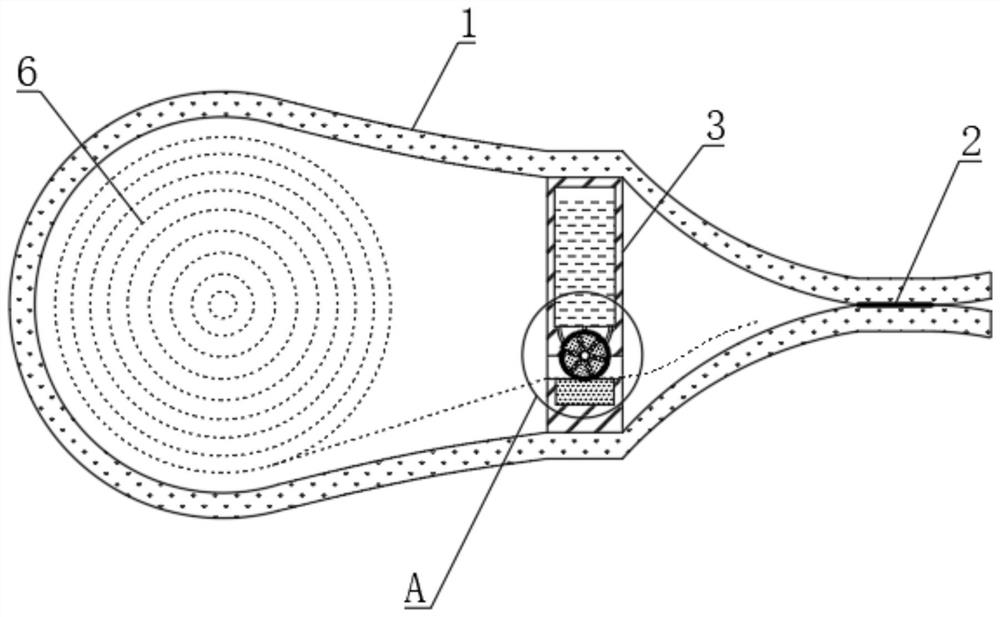

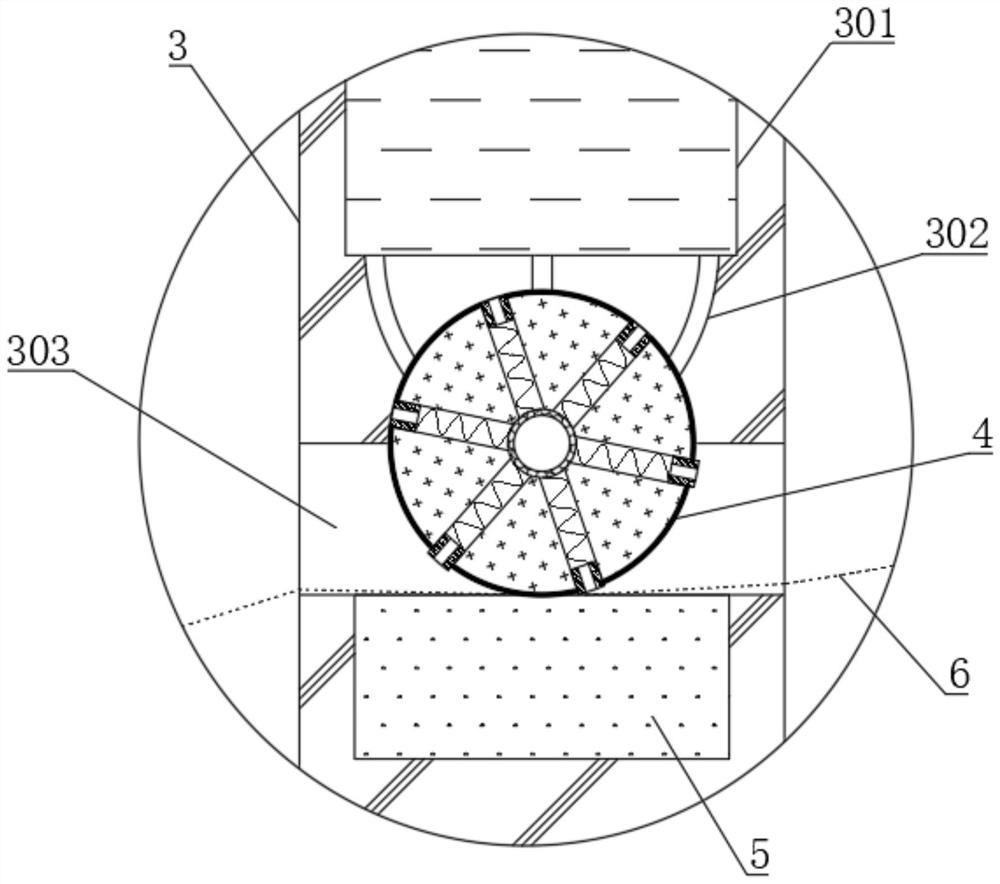

Array type ceramic preform sintering unit monomer and high-flux pressureless sintering method

ActiveCN112456980AImprove high temperature strengthHigh hardnessSurface modificationPressureless sintering

The invention discloses an array type ceramic preform sintering unit monomer and a high-flux pressureless sintering method. The method comprises carrying out surface modification on ceramic particles,mechanically mixing with alloy powder, placing in a graphite mold to be pre-pressed to form a sintering monomer, and then sintering in a high-flux vacuum pressureless sintering furnace. Single-batchand high-flux ceramic particle preforms are prepared by controlling ceramic particle components, sizes, surface modification methods, alloy powder components and addition amounts in ceramic preform sintering unit monomers. The prepared prefabricated body can be widely applied to preparation of wear-resistant layers required by wear-resistant composite materials such as grinding rollers, plate hammers, hammer heads, bucket teeth, lining plates, impellers and reamer heads, and has the advantages of being simple to operate, low in cost and high in efficiency.

Owner:XI AN JIAOTONG UNIV +1

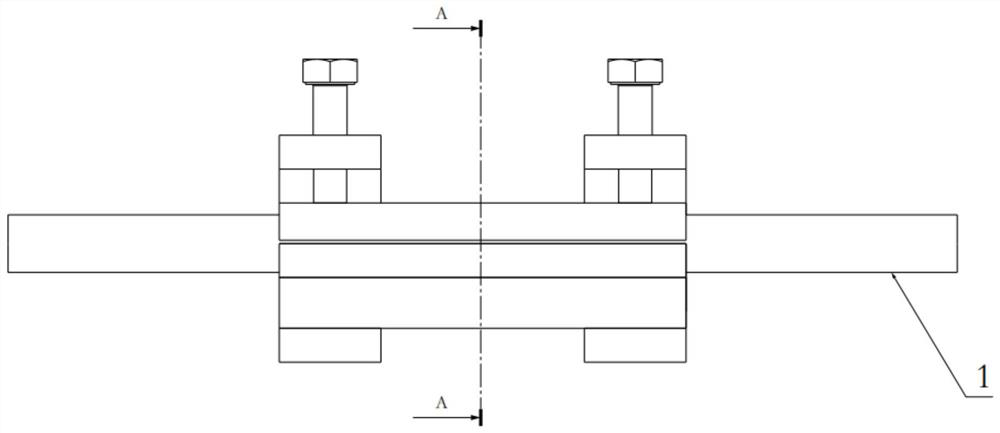

Preparation method of temperature measuring seat for superconducting feeder system

PendingCN114378387AOvercome physical propertiesFirmly connectedSoldering auxillary devicesSS - Stainless steelPipe

The invention relates to the technical field of welding, and discloses a preparation method of a temperature measuring seat for a superconducting feeder system, and the temperature measuring seat comprises a base and a circular tube which are welded with each other and are made of C10100 oxygen-free copper and 316L stainless steel. The preparation method comprises the steps that the round pipe is subjected to acid pickling, nickel plating is conducted after cleaning, an oxidation layer is removed from the base through an acid pickling method, the round pipe, the base and brazing filler metal are subjected to brazing assembly together through a welding device, the assembled welding device is integrally placed into a vacuum brazing furnace, and after the vacuum brazing step is executed, the furnace is opened, and the welding device is started. The welding device is simple in structure and convenient to use, contact between a base material and brazing filler metal can be guaranteed, the physical property that the difference between the base and the round pipe is large is effectively overcome, and reliable connection between the base and the round pipe is achieved.

Owner:合肥聚能电物理高技术开发有限公司

A kind of electromagnetic ultrasonic brazing method for sic ceramics

ActiveCN109836166BImprove mechanical propertiesEnhanced capillary actionSuperconducting CoilsUltrasonic vibration

Owner:NORTHEAST GASOLINEEUM UNIV

Array type ceramic preform sintering unit monomer and high-throughput pressureless sintering method

The invention discloses an array type ceramic prefabricated body sintering unit monomer and a high-throughput pressureless sintering method. The ceramic particles are surface modified, mechanically mixed with alloy powder, and placed in a graphite mold for pre-pressing to form a sintered monomer. . Then it is sintered in a high-throughput vacuum pressureless sintering furnace. The present invention realizes the preparation of a single-batch, high-throughput ceramic particle preform by controlling the ceramic particle components, dimensions, surface modification method, alloy powder composition and addition amount in the sintering unit of the ceramic preform. The prepared prefabricated body can be widely used in the wear-resistant layer required for the preparation of wear-resistant composite materials such as grinding rollers, blow bars, hammer heads, bucket teeth, liners, impellers, and reamer heads. At the same time, it has the advantages of simple operation, low cost, The advantage of high efficiency.

Owner:XI AN JIAOTONG UNIV +1

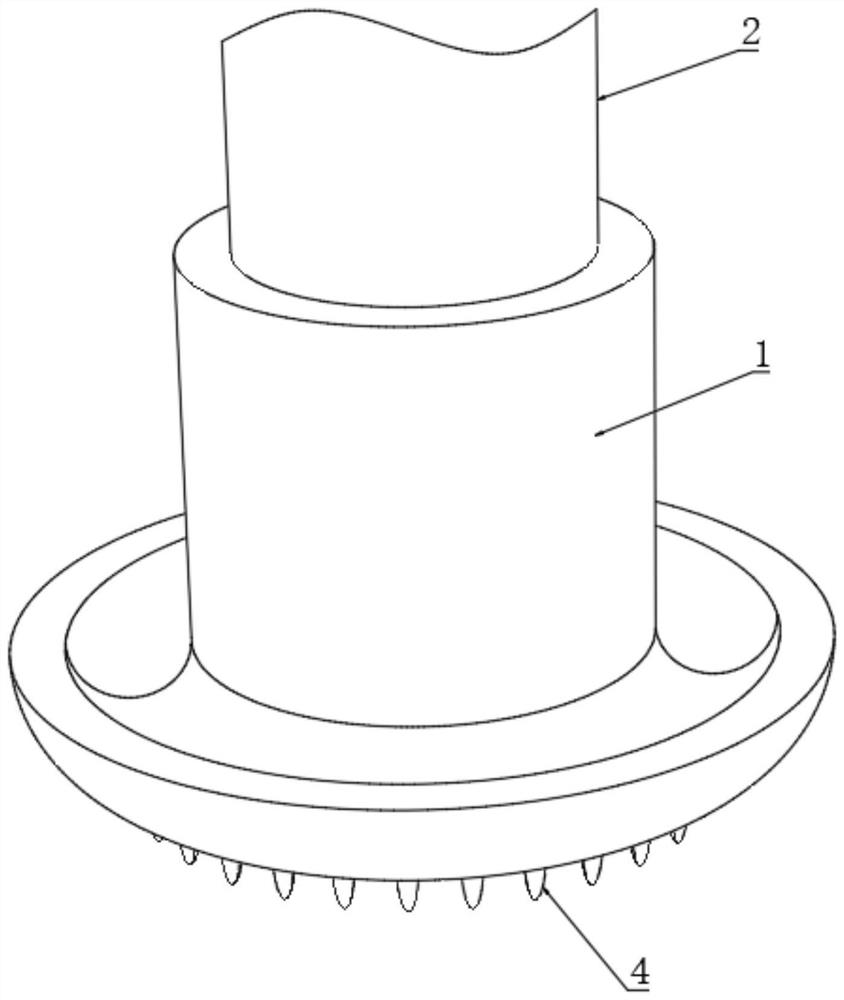

Fluid adsorption type laser cutting head

PendingCN113369704ARealize all-around surroundImprove adsorption capacityLaser beam welding apparatusWater flowLaser cutting

The invention discloses a fluid adsorption type laser cutting head, and belongs to the field of laser cutting heads. The fluid adsorption type laser cutting head comprises a cutting head body, and the outer end of the cutting head body is fixedly connected with a ring cylinder; and the inner surface of the ring cylinder is provided with a ring groove, and the inner wall of the ring groove is fixedly connected with an adsorption hair layer. According to the fluid adsorption type laser cutting head, when a workpiece is cut, splashing molten slag can be surrounded comprehensively, and therefore the molten slag adheres to the adsorption hair layer wetted by pure water; in the process of cutting the workpiece, a water propeller is gradually in contact with the surface of the workpiece, and is supported by the workpiece, and therefore a water pushing ball is moved along a liquid gathering flow channel; the pure water is pushed out, and sprinkled on the adsorption hair layer; on one hand, the adsorption hair layer is continuously soaked, and on the other hand, the molten slag adhering to the adsorption hair layer is cleaned, and enters a fluid inlet flow channel with water flow; and the molten slag is easy to adsorb by the adsorption hair layer continuously.

Owner:方志

Method for making abrasive tool with cooperative arrangement of abrasive particles by brazing

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Connection method of silicon carbide ceramics, silicon carbide ceramic connector and silicon carbide ceramics

The invention discloses a silicon carbide ceramic connecting method, a silicon carbide ceramic connector and silicon carbide ceramics, welding flux is welded on a welding surface of one silicon carbide ceramic unit and a welding surface of another silicon carbide ceramic unit, and the silicon carbide ceramic connecting method comprises the following steps: (1) pretreatment: polishing to-be-welded parts of two silicon carbide ceramics; then respectively carrying out acetone solution ultrasonic cleaning, alcohol ultrasonic cleaning and deionized water cleaning; (2) preparing soldering flux paste; (3) pasting: brushing the paste-made welding flux to the welding surfaces of the two silicon carbide ceramics; and (4) welding: putting the two silicon carbide ceramics into a clamping tool, and brazing in a heat treatment furnace, wherein the heating rate and the cooling rate are less than or equal to 5 DEG C / min. According to the method, good connection of SiC ceramics is achieved, and under the conditions that the temperature is 1400 DEG C, the heat preservation time is 10 min and the brazing filler metal thickness is two layers, the maximum shear strength of a SiC / welding flux / SiC connector is 150 MPa.

Owner:成都成维精密机械制造有限公司

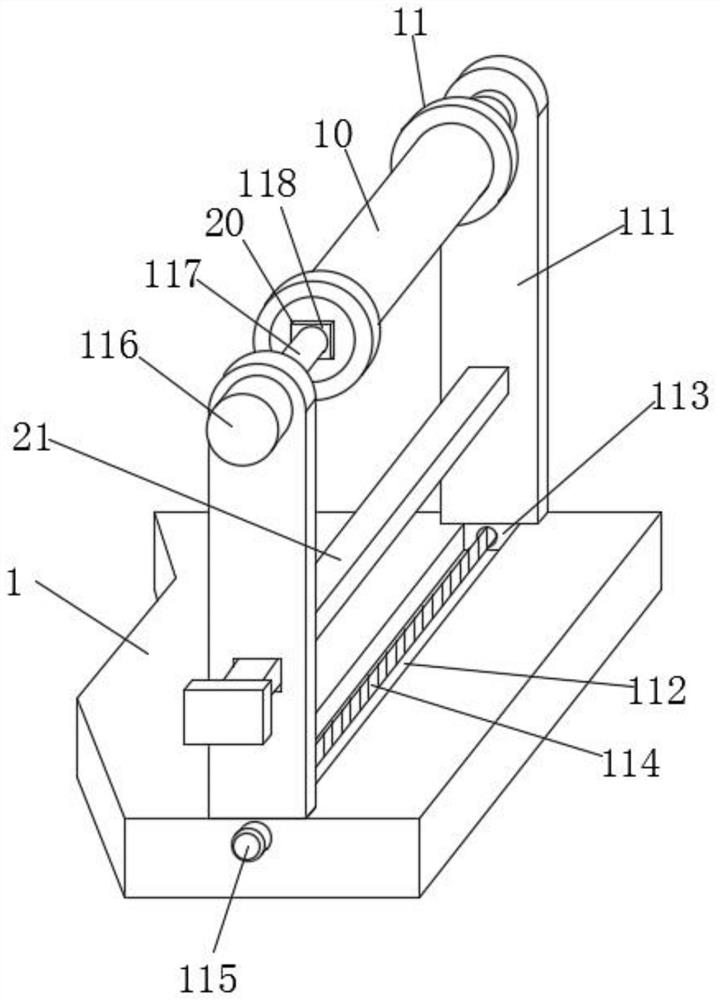

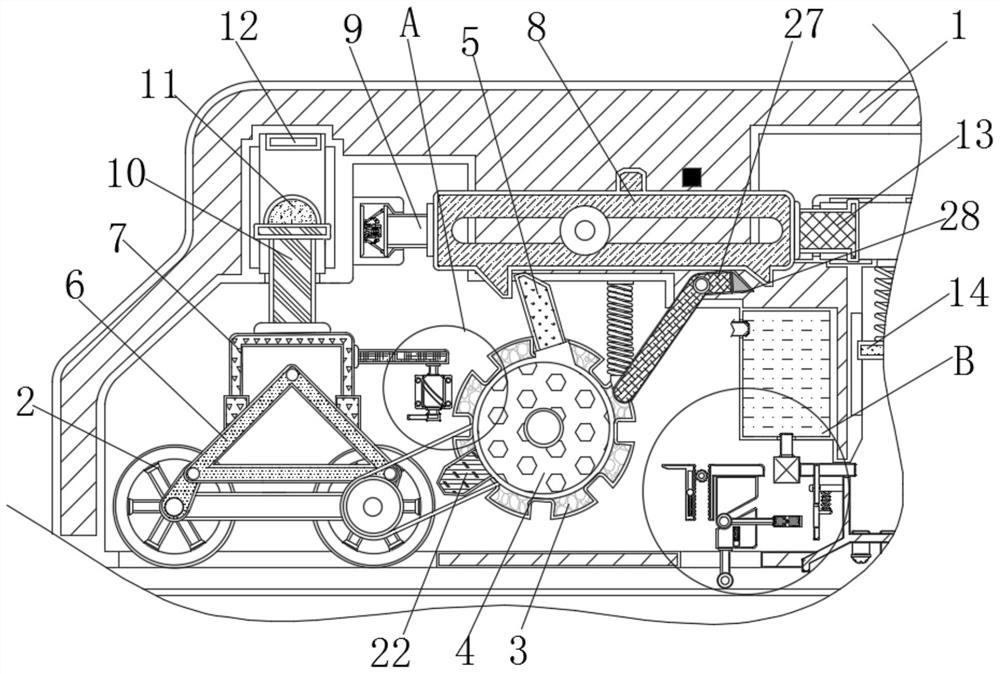

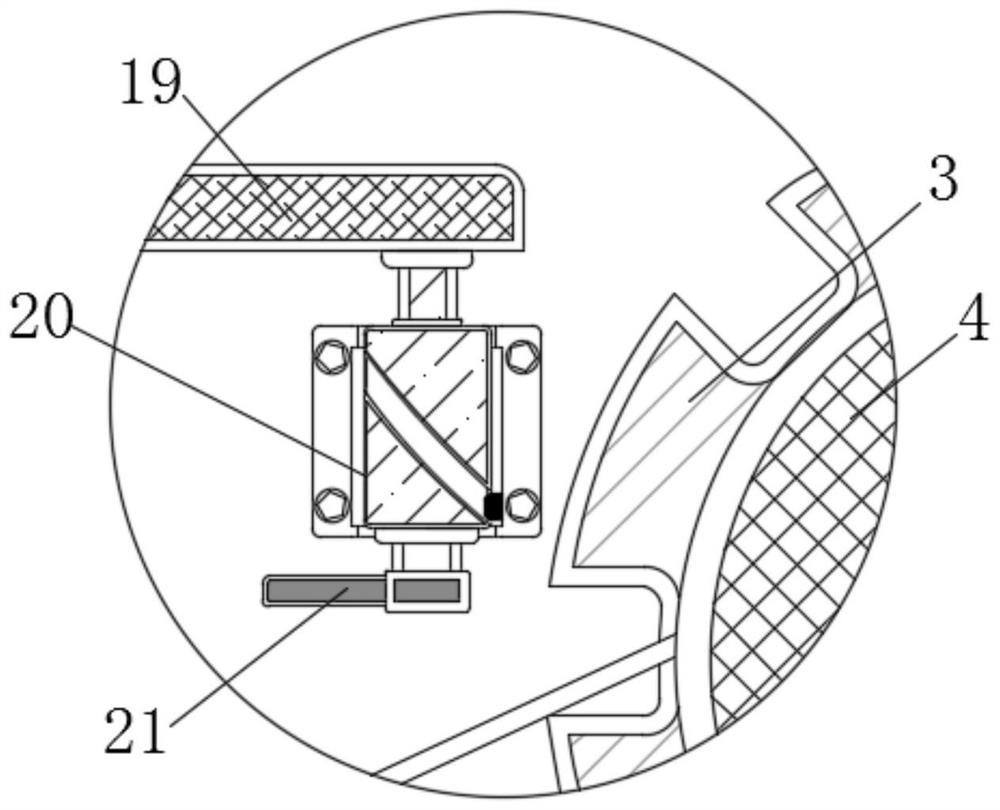

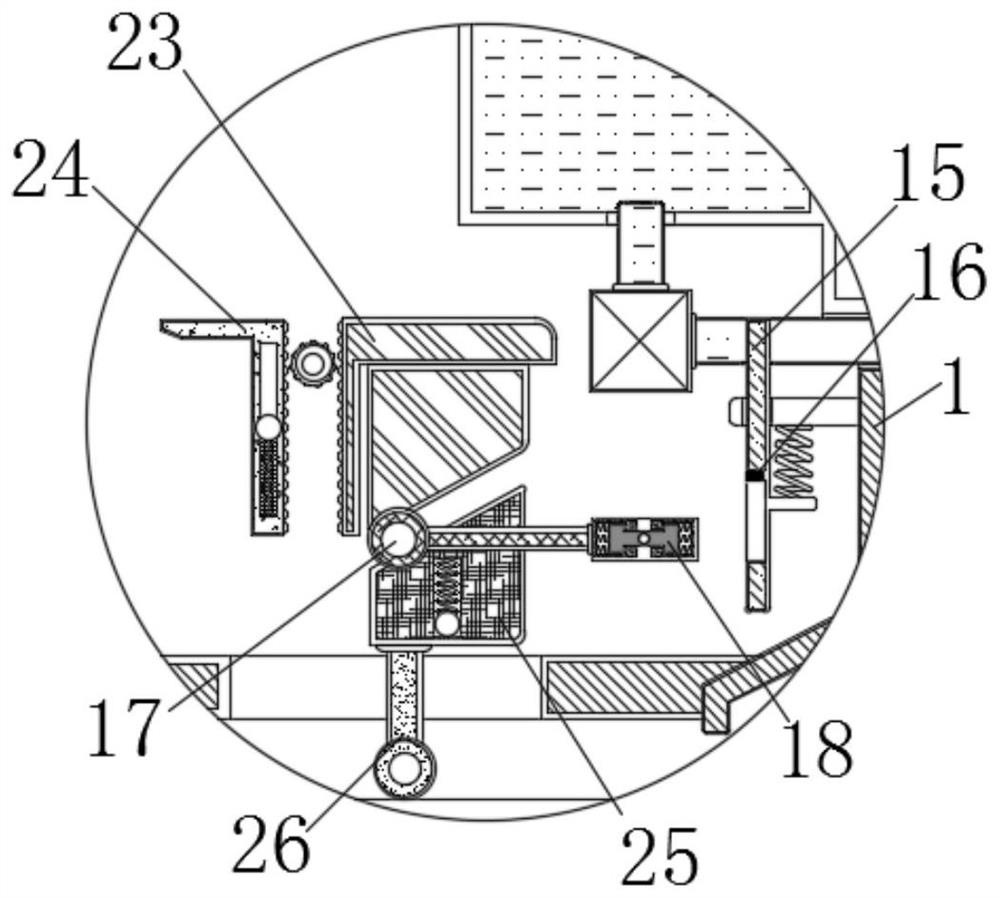

Intelligent textile industry electromechanical device capable of removing static electricity and automatically stretching

InactiveCN114197130AAchieve wettingReduce tensionTextile treatment by spraying/projectingStretchingControl engineeringEngineering

The invention discloses an intelligent textile industry electromechanical device capable of removing static electricity and automatically stretching, the intelligent textile industry electromechanical device comprises a machine shell and rollers, a control wheel is rotatably connected in the machine shell, a notch is formed in the surface of the control wheel, a first stop block corresponds to the notch in the surface of the control wheel, and an adjusting device is rotatably connected to the surface of the control wheel; the upper portion of the rolling wheel is fixedly connected with a connecting rod, and the upper end of the connecting rod is fixedly connected with a second push rod. According to the intelligent textile industry electromechanical device capable of removing static electricity and automatically stretching, a second check block loosens limitation on a first long plate clamping block, a reset device drives a first push block to slide through the first long plate, the first push block drives a sliding block to slide by extruding air, and therefore the first long plates on the two sides are intelligently controlled to slide, and the static electricity is removed; and the sliding block extrudes liquid to be sprayed to the surface of the textile material through the spray head, the surface of the textile material is wetted, and therefore the effect of removing static electricity on the surface of the textile material is achieved through water.

Owner:宁波精英纺织科技有限公司

A kind of preparation method of laser marking lubricant for ABS engineering plastics

The invention discloses a preparation method of a laser marking lubricant for ABS (acrylonitrile butadiene styrene) engineering plastics, and belongs to the technical field of a laser marking additive. According to the method, firstly, a Dopamine solution is used for soaking a modified laser absorbent; after filtering and drying are performed, the modified laser absorbent and a treating agent are mixed and react at high temperature, and are then dissolved in ethanediamine to prepare a laser absorbent ethanediamine solution; next, in a nitrogen protection state, heating is performed, so that stearic acid is melted and is then proportionally mixed with the laser absorbent ethanediamine solution for performing dehydration reaction; moisture in the system is taken out by nitrogen gas flow; finally, through extrusion pelletization, the laser marking lubricant for the ABS engineering plastics is obtained. The compatibility of the laser marking lubricant for the ABS engineering plastics with a plastic base body is good; the laser marking lubricant can be stably dispersed in the plastics; the mechanical strength of the product can be effectively improved; in the laser marking process, the formed marks are clear; the contrast is obvious; wide application prospects are realized.

Owner:常州可赛成功塑胶材料有限公司

Self-service moisturizing type wet tissue packaging bag and matched roll type wet tissue thereof

InactiveCN113460501ANot easy to evaporateNot easy to loseContainers for annular articlesBagsRolling paperPaper towel

The invention discloses a self-service moisturizing type wet tissue packaging bag and a matched roll type wet tissue thereof, and belongs to the field of wet tissue packaging. The self-service moisturizing type wet tissue packaging bag comprises a single-opening plastic bag, an adhesive layer is fixedly connected to the inner wall of the opening end of the single-opening plastic bag, and an inner plate is fixedly connected to the interior of the single-opening plastic bag. Through cooperative use of the inner plate, a semi-open liquid overflowing column and roll paper, when the roll paper needs to be used, the end of the roll tissue is pulled out of the single-opening plastic bag only by imitating the use mode of the roll tissue, and the roll tissue drives the semi-open liquid overflowing column to rotate while being pulled out, so that wet tissue liquid in a liquid storage cavity flows onto the roll tissue along the semi-open liquid overflowing column, the roll tissue becomes wet from dry and is pulled apart, the roll tissue can be normally used, when the tissue box is not used, the wet tissue liquid is stored in the liquid storage cavity in a sealed mode and is effectively isolated from the outside, it is guaranteed that the wet tissue liquid is not prone to evaporation and loss, and therefore the using effect of the self-service moisturizing type wet tissue packaging bag is effectively guaranteed.

Owner:刘飞

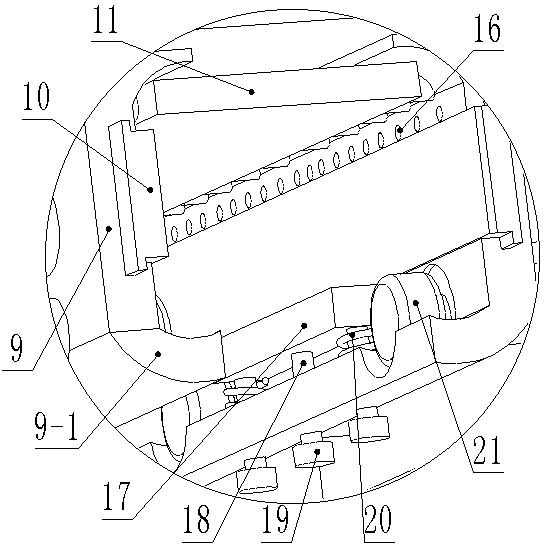

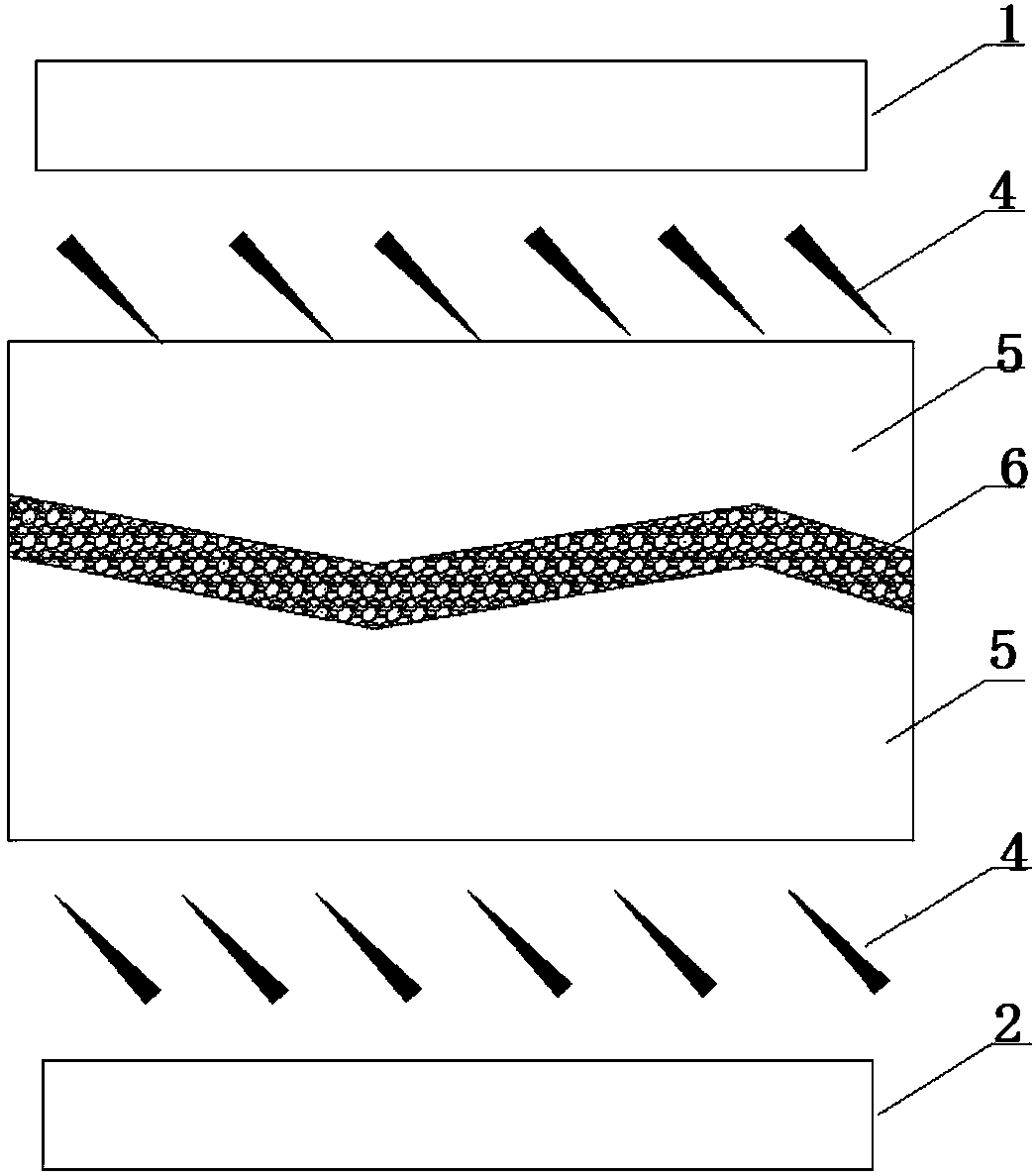

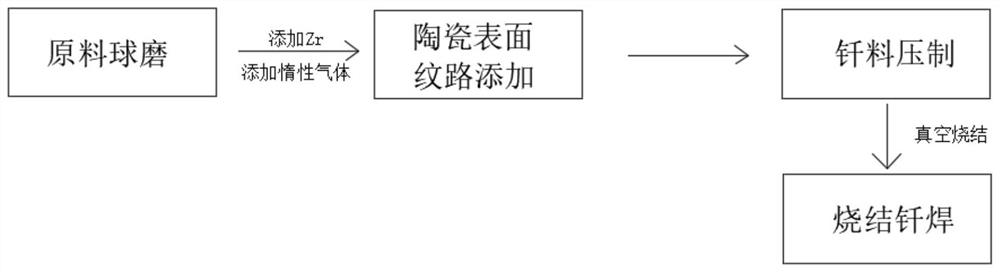

Raw material preparation method and equipment for preventing brazing layering of silicon nitride integrated circuit board

InactiveCN114105668AAchieve wettingSmall coefficient of thermal expansionThermal dilatationManufactured material

The invention discloses a raw material preparation method and equipment for preventing brazing layering of a silicon nitride integrated circuit board, relates to the technical field of circuit board brazing, and mainly solves the problem that after a circuit board of a silicon nitride ceramic substrate is brazed by an existing brazing raw material, the circuit board is easily subjected to insufficient soldering layering due to heating. According to the invention, an active element Zr is added mainly by improving brazing raw materials, the active element Zr can react with connected ceramic to realize wetting of the ceramic, the ceramic particles added with B4C can reduce the thermal expansion coefficient of the brazing filler metal, the thermal expansion coefficient of the brazing filler metal is better matched with the thermal expansion coefficient of a ceramic substrate, and the wetting effect is better. The physical lines are added to the silicon nitride ceramic substrate, so that the contact area is increased, the bonding force of the bonding surface is better improved, and the probability of brazing layering is greatly reduced when the brazed circuit board is in a heated state.

Owner:LIAONING YIFEI TECH

Silicone oil-free shampoo composition with softening and repairing effects as well as preparation method and application thereof

PendingCN112402301AIncrease the relative molecular massImprove adsorption capacityCosmetic preparationsHair cosmeticsPolymer scienceMeth-

The invention belongs to the field of cosmetics, and particularly relates to a silicone oil-free shampoo composition with softening and repairing effects as well as a preparation method and application thereof. The silicone oil-free shampoo composition is prepared from the following components in parts by mass: 0.1-0.5 part of acrylamide propyl trimethyl ammonium chloride / acrylamide copolymer, 0.1-0.5 part of polyquaternium-10, 1-5 parts of PEG-75 shea butter glyceride, 1-5 parts of keratin and hydrolyzed keratin, and 0.5-2 parts of myristyl amide propane dimethyl ammonium chloride phosphate.According to the invention, the cationic surfactant is used to drive more polymers / oil flocculants to be adsorbed to damaged parts of hair, meanwhile, protein is tightly combined with the polyquaternium substance, the attachment strength of the protein on the hair is improved, so that as many beneficial components as possible are attached to the hair, and then the purpose of wetting, softening andbrightening the hair is achieved.

Owner:TIANJIN YU MEI JING GRP

A non-contact ultrasonic brazing connection method for preparing quartz glass joints

ActiveCN111215714BAchieve wettingFirmly connectedSoldering auxillary devicesUltrasonic vibrationFiller metal

The invention relates to a non-contact ultrasonic brazing connection method for preparing quartz glass joints, which includes: 1. Processing the width of the solder foil to be consistent with the size of the quartz glass; 2. Grinding the surface of the solder foil , cleaned with acetone, then filled the solder foil between the two surfaces of the quartz glass to be welded, and then raised the temperature to 100-400°C at a rate of 1-5°C / min, kept it for 5-10min, and placed it on In the static magnetic field in the vertical direction, the magnetic induction intensity is 1~12T, and the coil generates an AC magnetic field with a frequency of 2~10 kHz. At the same time, a pressure of 0.1~1MPa is applied to the upper end of the quartz glass. Under the joint action of pressure and electromagnetic ultrasonic vibration The brazing material is spread and wetted on the surface of the quartz glass, cooled to room temperature, and the brazing of the quartz glass is completed. The invention solves the problems of difficult low-temperature connection and large residual stress of high-temperature joints in the existing quartz glass connection method.

Owner:NORTHEAST GASOLINEEUM UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com