Method for manufacturing abrasive tool with abrasive particle collaborative configuration by virtue of brazing

A kind of abrasive, abrasive grain technology, applied in the field of high temperature brazing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

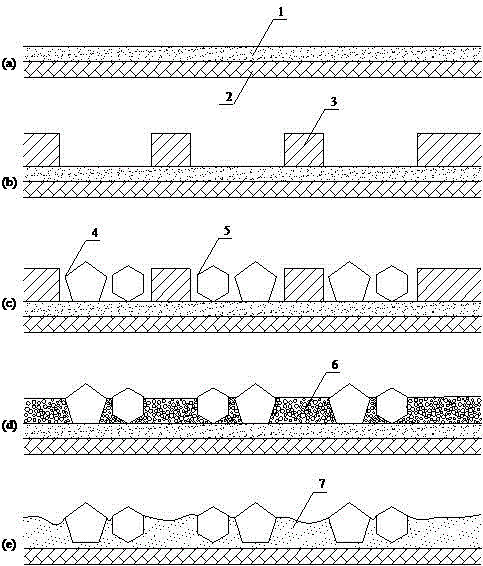

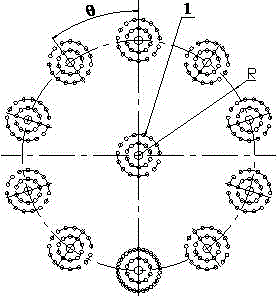

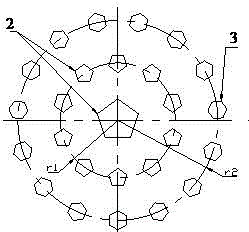

Method used

Image

Examples

Embodiment 1

[0047] Taking a circular saw blade carrier with a diameter of 230 mm as an example, its arrangement and brazing process are as follows:

[0048] The first step is to ultrasonically clean the diamond and cubic boron nitride respectively in a mixed solution of acetone and absolute ethanol, and dry them for later use. The volume ratio of acetone and ethanol used is 1.5:1; organic solvents such as gasoline are used to Clean the steel matrix on the outer edge of the saw blade, sandblast the brazing surface of the steel matrix on the outer edge of the circular saw blade after drying, clean the surface of the steel matrix on the outer edge of the circular saw blade with acetone, and dry it for later use;

[0049] The second step, according to the volume ratio of the pressure-sensitive adhesive to acetone is 1:1, configure the adhesive, mix and stir evenly, and apply the adhesive evenly on the surface of the steel substrate at the outer edge of the circular saw blade, with a thickness ...

Embodiment 2

[0054] The thickness of bonding agent described in the second step is 0.15mm; In the 4th step, the brazing filler metal particle size range is 220 orders, and the brazing filler metal thickness scope covered can be 45% of abrasive grain average size; Heating rate is 10 °C / min; the selection range of the brazing temperature can be 880 °C; the selection range of the holding time can be 15 min; the rest are the same as in Example 1.

Embodiment 3

[0056] The thickness of the binder described in the second step is 0.35 mm; in the fourth step, the size range of the solder particle size is 100 mesh, and the covered solder thickness range can be 90% of the average size of the abrasive particle diameter; the brazing temperature The selection range can be 950 ℃; The heating rate is 20 ℃ / min, and the cooling rate is 20 ℃ / min; the selection range for the holding time can be 30min; all the other are the same as embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com