Welding method capable of driving solders by using electric field and application

A welding method and electric field technology are applied in the welding method and application field in which the solder can be driven by an electric field, which can solve the problem of high oxide content, and achieve the effect of improving the degree of uniformity of the welding seam and reducing the welding defects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A welding method in which solder can be driven by an electric field, comprising the following steps:

[0041] 1) Prepare solder and two base metals to be welded. The two base materials to be welded are pure aluminum (99.6wt% Al content) (from Xuzhou Yuda Aluminum Products Co., Ltd.). The solder has conductive properties, and its It is Ag-Cu (atomic percentage: Ag:50.04Cu:34.28). Clean the surface of the base material to remove grease, stains and oxide film, and then dry it. Under atmospheric conditions, preheat the base metal at 350 °C for 5 min.

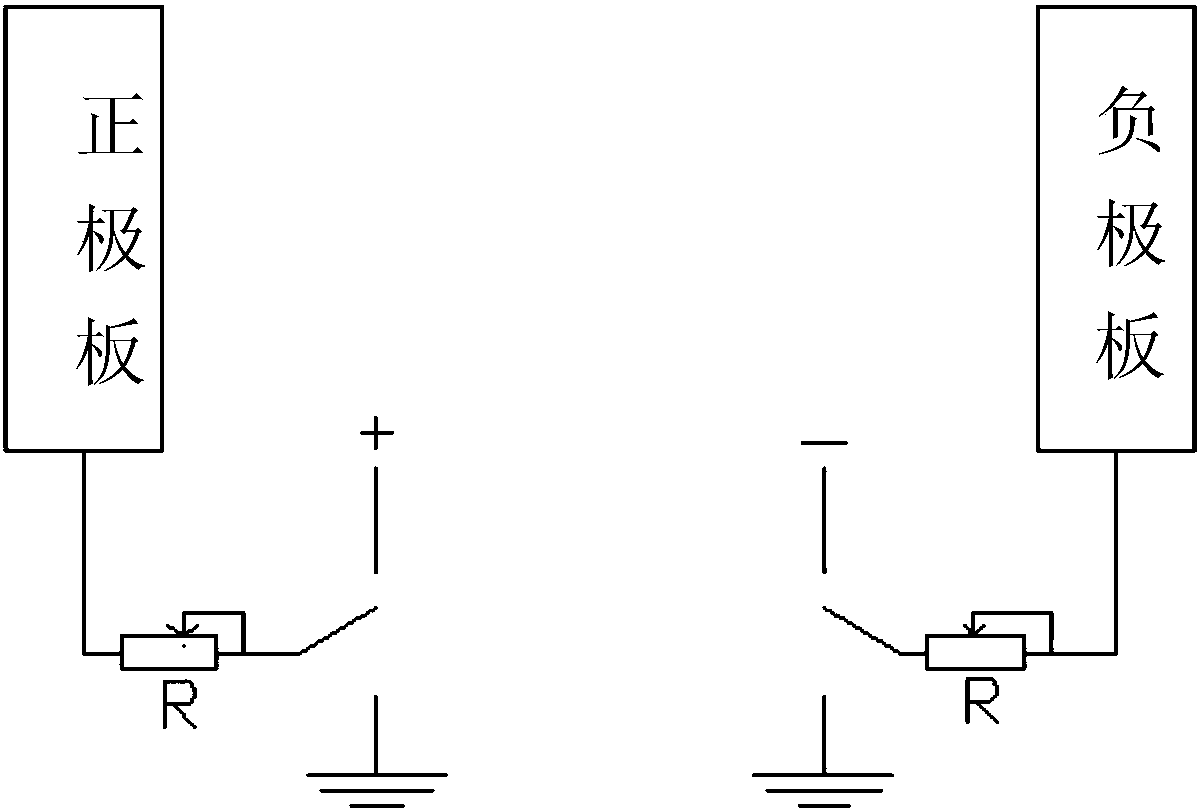

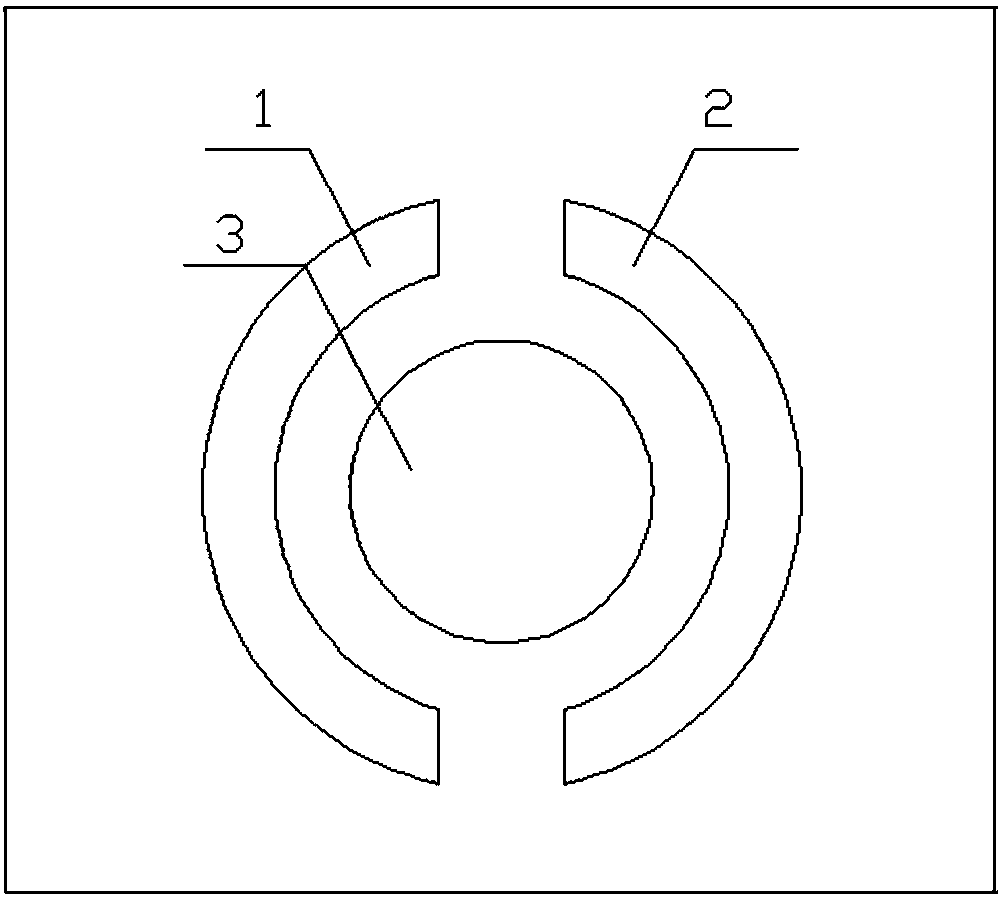

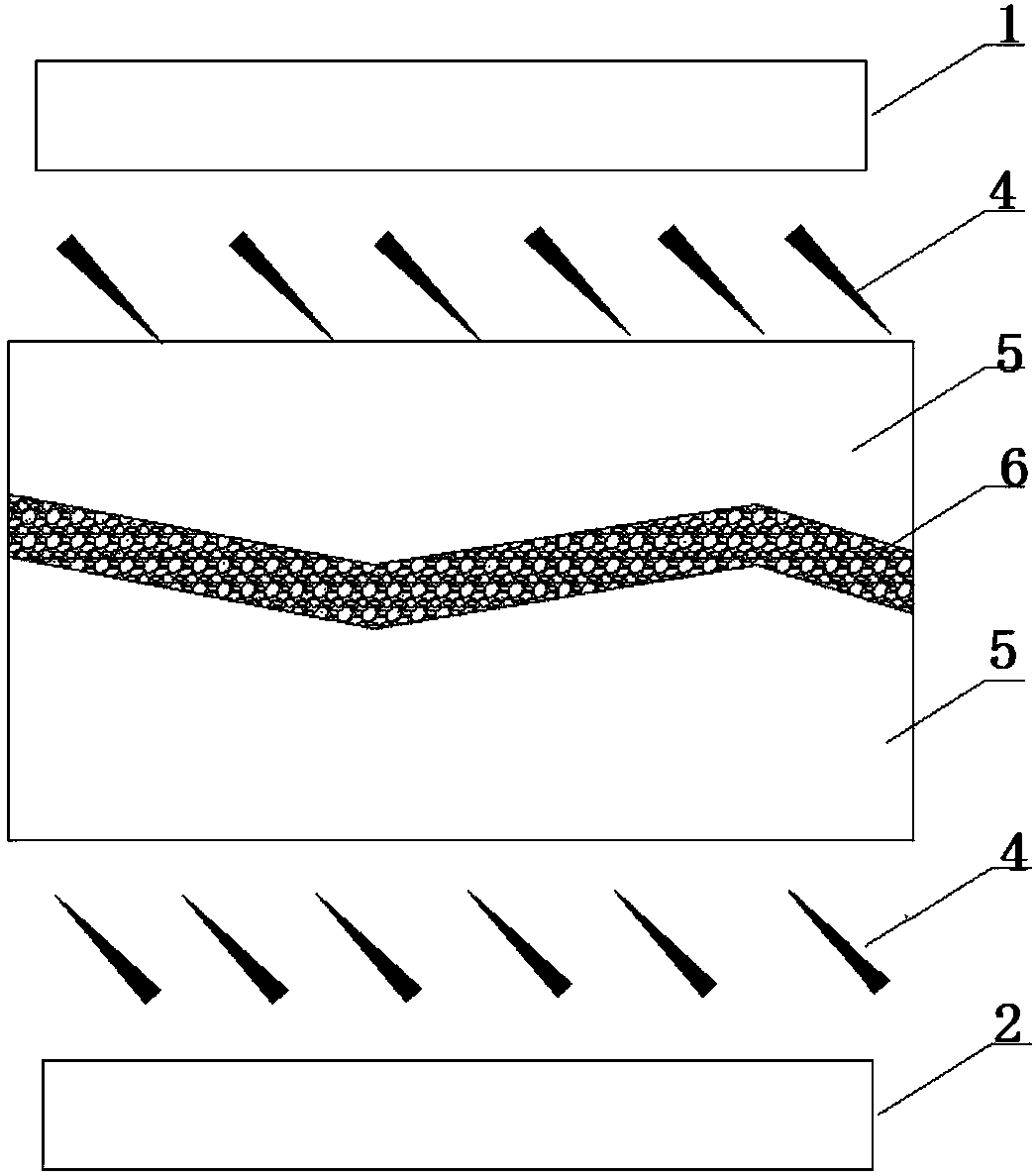

[0042] 2) The brazing filler metal and the base metal 5 in step 1) are fixed according to the structure of "base metal / brazing filler metal / base metal", the distance between the base metal and the brazing filler metal is less than 2cm, the present embodiment is 1 centimeter, heating In order to melt the brazing filler metal, the base metal is first fixed according to the structure, and after the base metal is fixed, the pos...

Embodiment 2

[0052] A welding method in which solder can be driven by an electric field, comprising the following steps:

[0053] 1) Prepare solder and two base metals to be welded, the two base metals to be welded are ME20M Mg (1.8wt% Mn, 0.3wt% Zn, 0.25wt% Ce, the balance is Mg), and the solder is Sn -9Zn (mass percentage: Sn91wt%, Zn9wt%). Clean the surface of the base material to remove grease, stains and oxide film, and then dry it. Under atmospheric conditions, the base metal was preheated at 350 °C for 4 min.

[0054] 2) Fix the brazing filler metal and base metal in step 1) according to the structure of "base metal / brazing filler metal / base metal", and heat to melt the brazing filler metal, wherein, the base metal is first fixed according to the structure, and the base metal After the material is fixed, the position and gap between the brazing parts are kept unchanged, and the brazing material is evenly put into the brazing seam.

[0055] 3) After the solder is melted, continue ...

Embodiment 3

[0065] A welding method in which solder can be driven by an electric field, comprising the following steps:

[0066] 1) Prepare solder and two base metals to be welded, both of which are 1060 aluminum (mass percentage: Al99.6wt%, Si, Cu, Mg, Zn, Mn, Ti, V, Fe content A total of 0.4wt%,), the solder is Zn-15Al (mass percentage: Al15wt%, Zn 85wt%). Clean the surface of the base material to remove grease, stains and oxide film, and then dry it. Under atmospheric conditions, the base metal was preheated at 340° C. for 5 min.

[0067] 2) Fix the solder and base metal in step 1) according to the structure of "base metal / brazing material / base metal", and heat to melt the solder, wherein the base metal is first fixed according to the structure, and the base metal is fixed After completion, ensure that the position and gap between the brazing parts remain unchanged, and put the brazing material evenly into the brazing seam.

[0068] 3) After the solder is melted, continue the heatin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com