Connection method of silicon carbide ceramics, silicon carbide ceramic connector and silicon carbide ceramics

A technology of silicon carbide ceramics and a connection method, which is applied in the field of aviation materials, can solve the problems of poor connection performance and lack of effective treatment of the parts to be connected, and achieve a good connection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

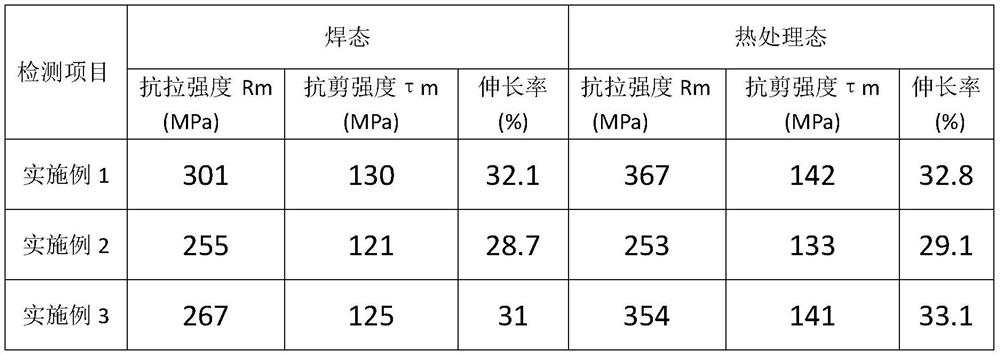

Embodiment 1

[0024] Mix 32.55kg Si powder, 2.45kg Ti powder, 2kg Zr powder, 12.3kg B powder, 1.1kg Fe powder, 6.5kg Cu powder, 2.5kg Hf powder in an agate mortar and grind them evenly, then place them in a graphite crucible for Sintering, the sintering condition is 1400°C / 2h, after the sintering is completed, place it in a planetary ball mill for fine grinding and sieving, and then the flux product can be obtained.

Embodiment 2

[0026] Mix 36.55kg Si powder, 2.5kg Ti powder, 2.5kg Zr powder, 12.5kg B powder, 1.5kg Fe powder, 8.5kg Cu powder, 1.5kg Hf powder in an agate mortar and grind them evenly, then place them in a graphite crucible for sintering , the sintering condition is 1400°C / 2h, after the sintering is completed, place it in a planetary ball mill for fine grinding and sieving, and then the flux product can be obtained.

Embodiment 3

[0028] Mix 40kg Si powder, 2.7kg Ti powder, 3.5kg Zr powder, 14.2kg B powder, 1.5kg Fe powder, 9.5kg Cu powder, 1.7kg Hf powder in an agate mortar and grind them evenly, then place them in a graphite crucible for Sintering, the sintering condition is 1400°C / 2h, after the sintering is completed, place it in a planetary ball mill for fine grinding and sieving, and then the flux product can be obtained.

[0029] The flux that embodiment 1-3 makes is respectively used in the welding between pottery and pottery, and welding mode is brazing, and welding method comprises the following steps:

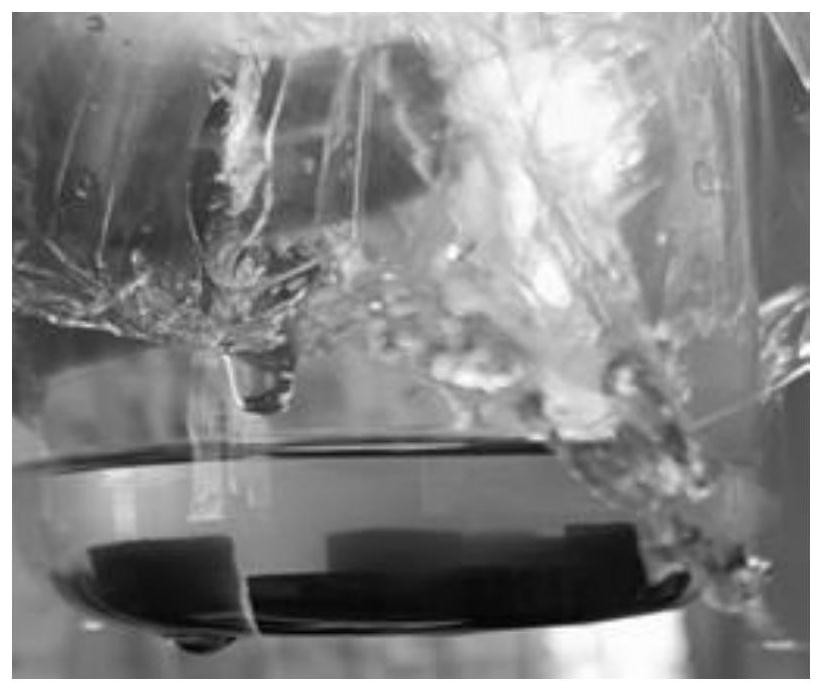

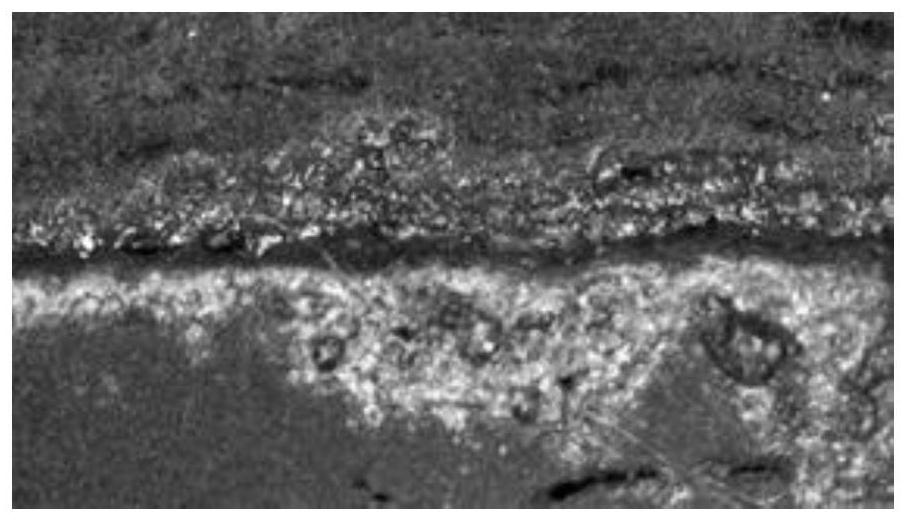

[0030] ①Pretreatment: Ceramic-10*10*3mm cut sample, 20*10*3mm stretched sample, polished with a brown brush (sequentially polished with water-based sandpaper with a roughness of 300-2000 mesh, each Grinding with roughness sandpaper for 30min)→silicon carbide coating (that is, coating the surface of the ceramic shear sample with a silicon carbide coating, coating the silicon carbide coating on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com