Patents

Literature

229results about How to "Reduce dust concentration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

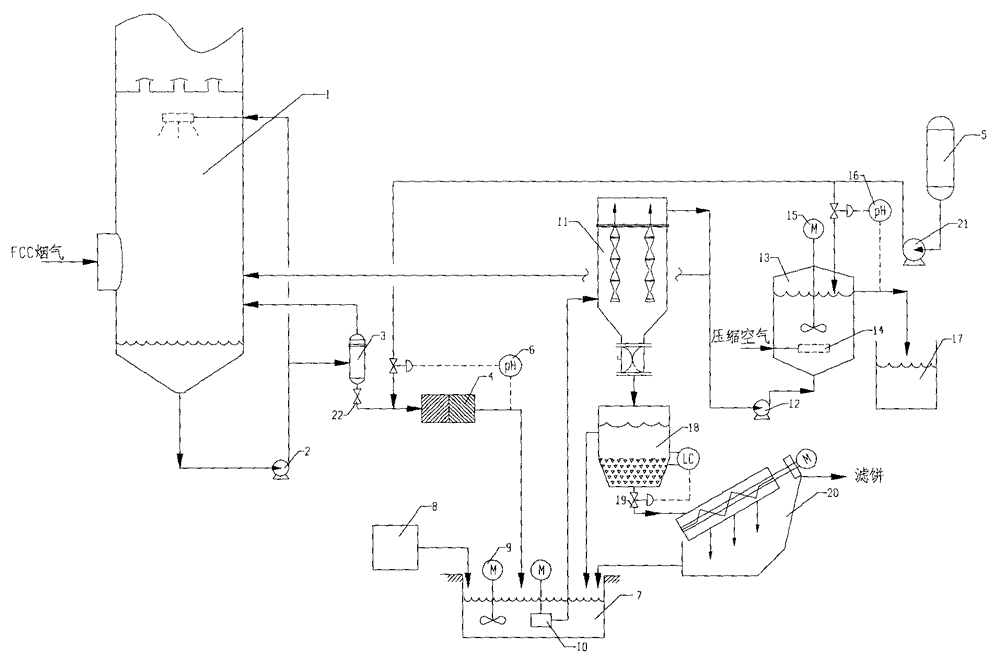

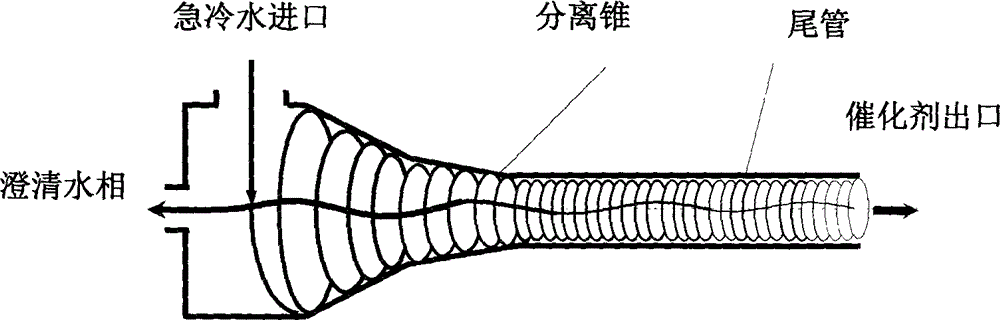

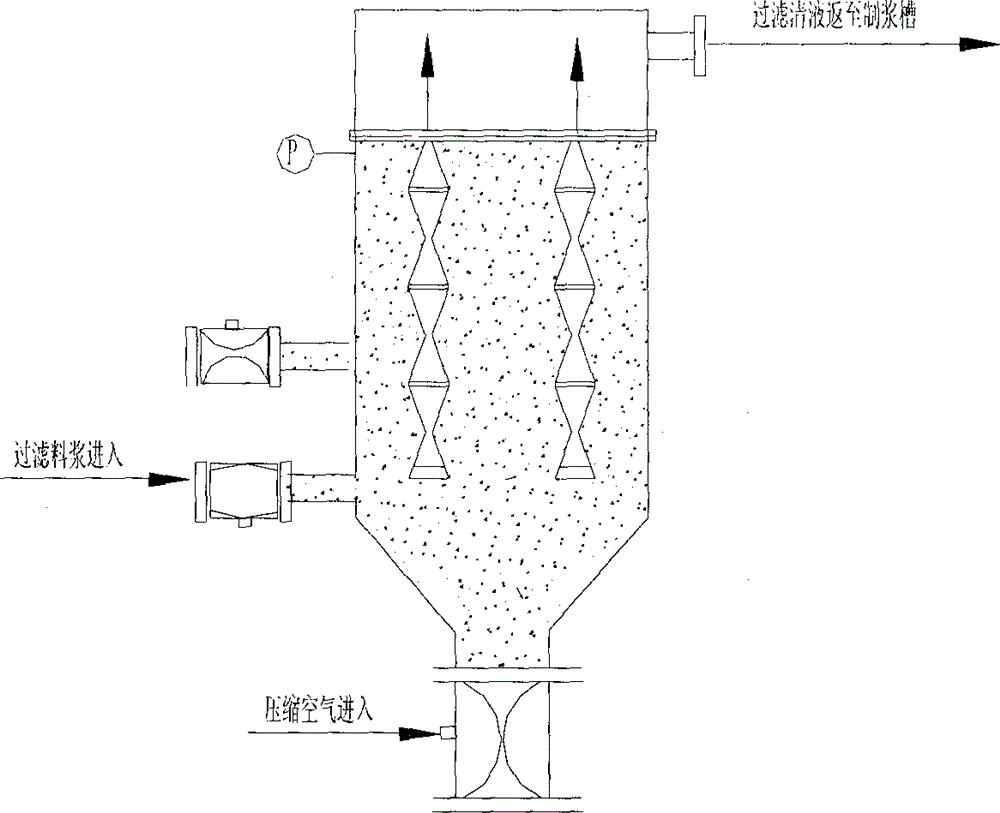

Process for treating waste liquid from catalytic cracking flue gas desulfurization

InactiveCN104418447AReduce dust concentrationReduce wearWater/sewage treatment by centrifugal separationSludge treatmentLiquid wasteSlurry

The invention provides a process for treating waste liquids from catalytic cracking flue gas desulfurization. The process comprises the following steps: enabling a part of waste liquids from a quenching washing tower to enter a hydraulic cyclone separator so as to be subjected to solid-liquid separation, returning the thin liquids to the quenching washing tower so as to be recycled, enabling the thick liquids to enter a neutralization reactor so as to be subjected to neutralization reaction, enabling the neutralized waste liquids to enter a slurry pond so as to be mixed with a flocculating agent uniformly, and enabling the mixture to enter an expansion-drum type filter so as to be subjected to solid-liquid separation with a thick slurry and a supernatant being obtained; returning part of the supernatant to the quenching washing tower so as to be recycled, discharging the remaining supernatant into an oxidation tank, removing the pseudo-COD containing sulfite roots and bisulfite roots by oxidizing, and directly discharging the qualified sewage; enabling the thick slurry to enter a settling pond from the bottom of the expansion-drum type filter so as to be further settled, feeding the thick slurry subjected to settlement into a dewatering machine so as to be concentrated and dewatered, directly transporting the filter cakes obtained by dewatering the thick slurry, returning the filtrate from the dewatering of the thick slurry to the slurry pond, and mixing the filtrate with the waste liquids so as to be retreated. The process provided by the invention has the advantages of a stable and efficient treatment effect, strong shock resistance, low investment and small floor area occupation and convenience of operation.

Owner:CHINA PETROLEUM & CHEM CORP +1

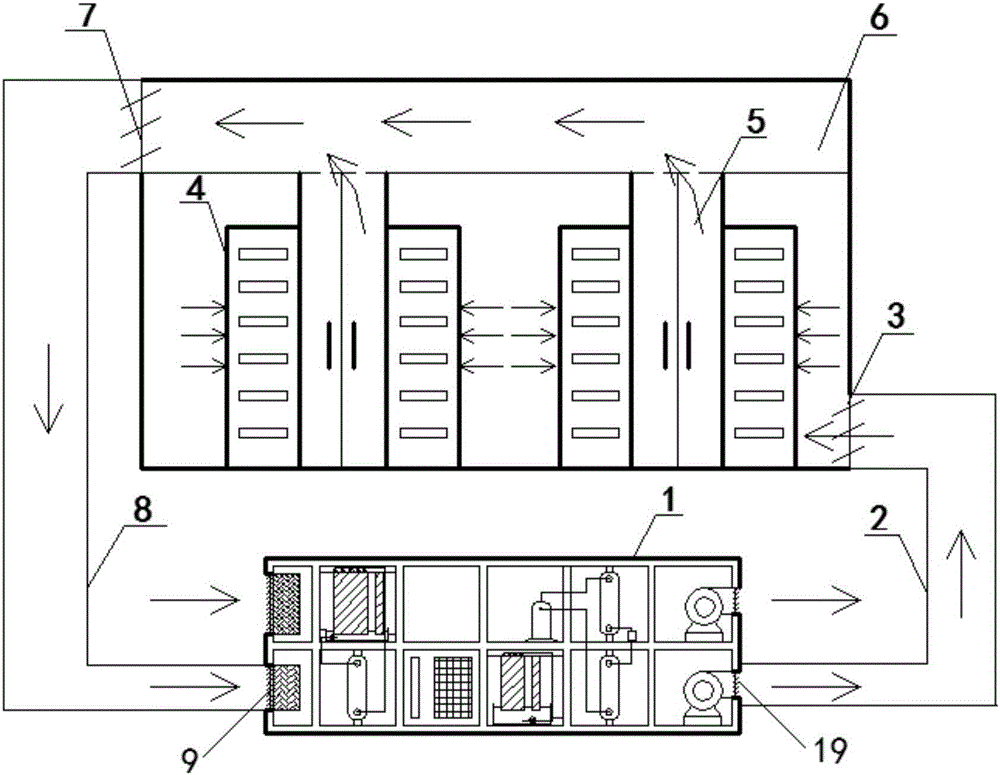

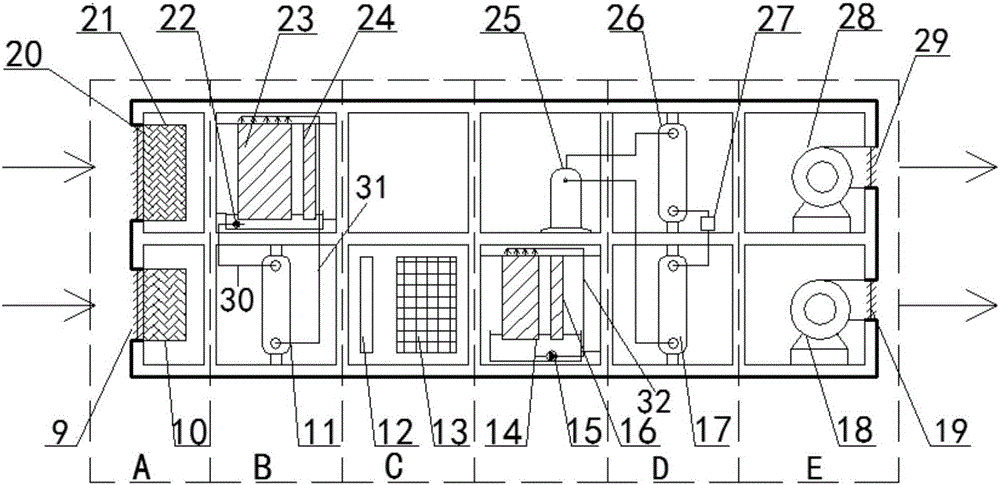

Sealed hot channel-full air returning dried-air energy central air conditioning system for data center

InactiveCN106247501ASimple structureLow costDucting arrangementsLighting and heating apparatusData centerOperation mode

The invention discloses a sealed hot channel-full air returning dried-air energy central air conditioning system for a data center. The sealed hot channel-full air returning dried-air energy central air conditioning system comprises a dried-air energy central air conditioning unit; the dried-air energy central air conditioning unit is connected with the data center through an air returning pipe and can recycle return air in the data center and process the return air so that the return air can become air meeting the air supply condition; and the dried-air energy central air conditioning unit is further connected with the data center through an air supply pipe, and the air meeting the air supply condition can be fed into the data center through the air supply pipe and a machine room air supply outlet. According to the sealed hot channel-full air returning dried-air energy central air conditioning system for the data center, the full year cool supply requirement of the data center can be effectively ensured, the phenomenon that disordered air distribution occurs in the data center can be avoided, and meanwhile reasonable adjustment of three operation modes can be achieved according to different weather conditions.

Owner:XI'AN POLYTECHNIC UNIVERSITY

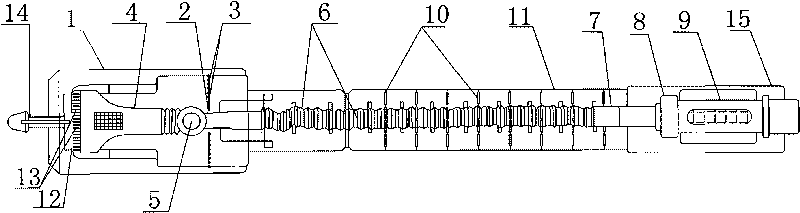

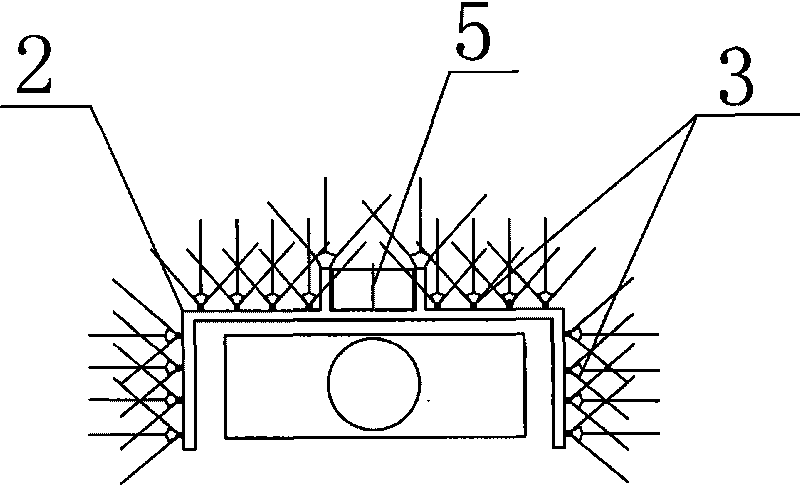

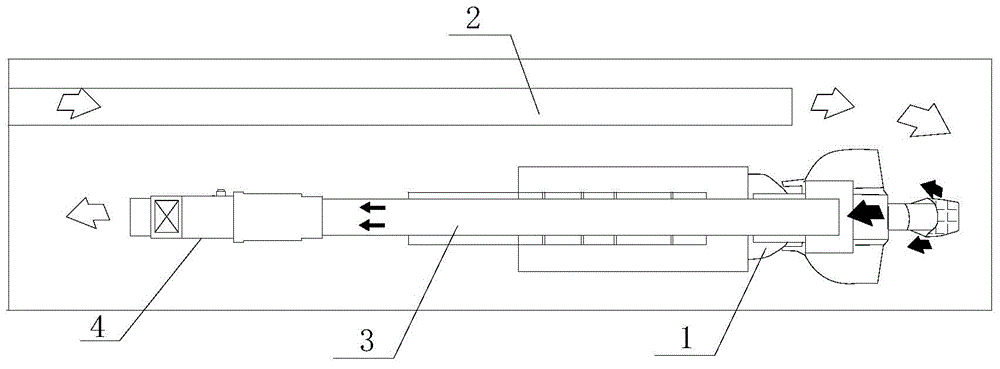

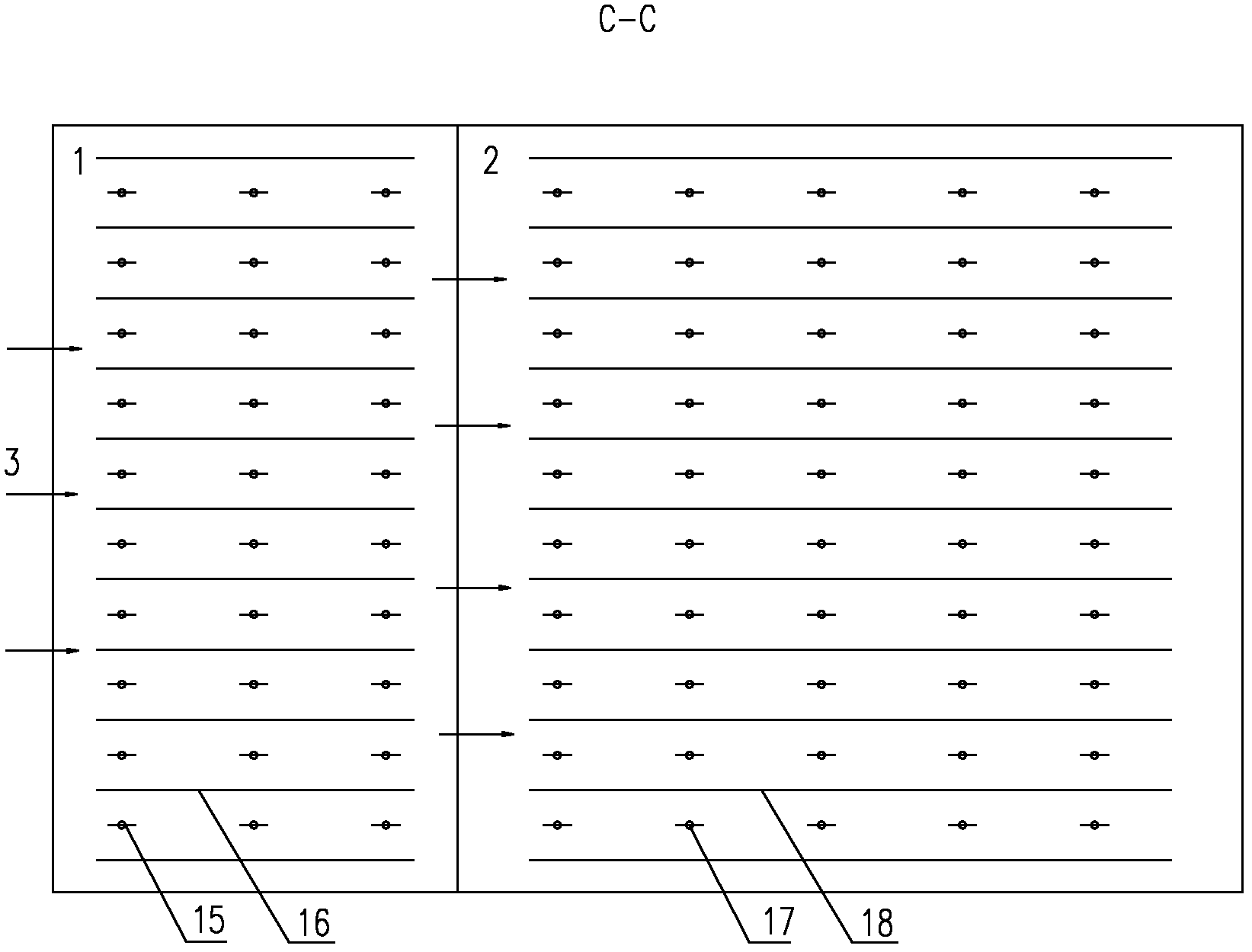

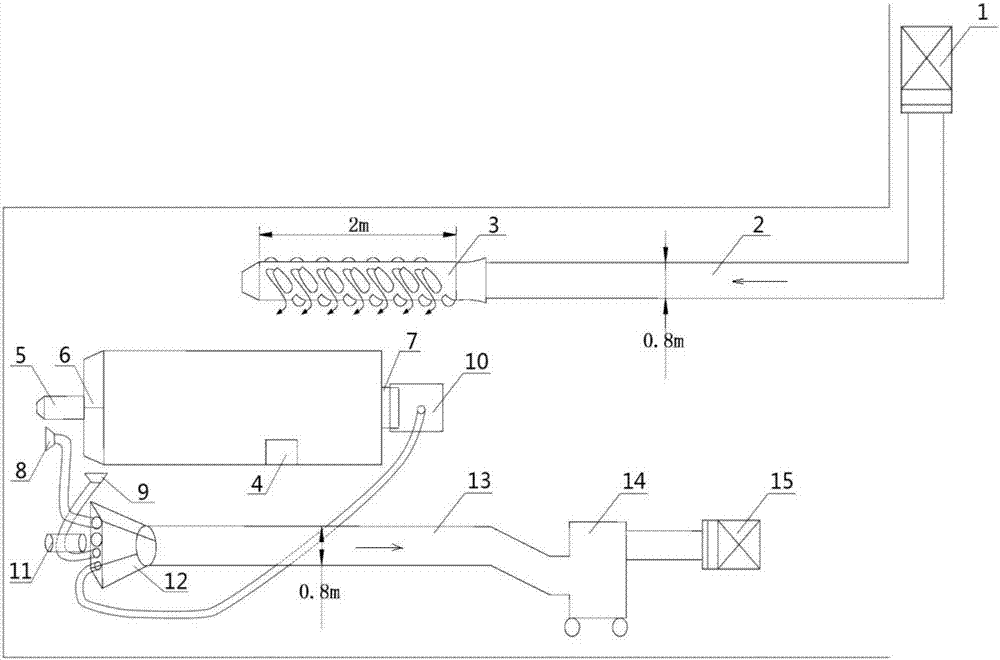

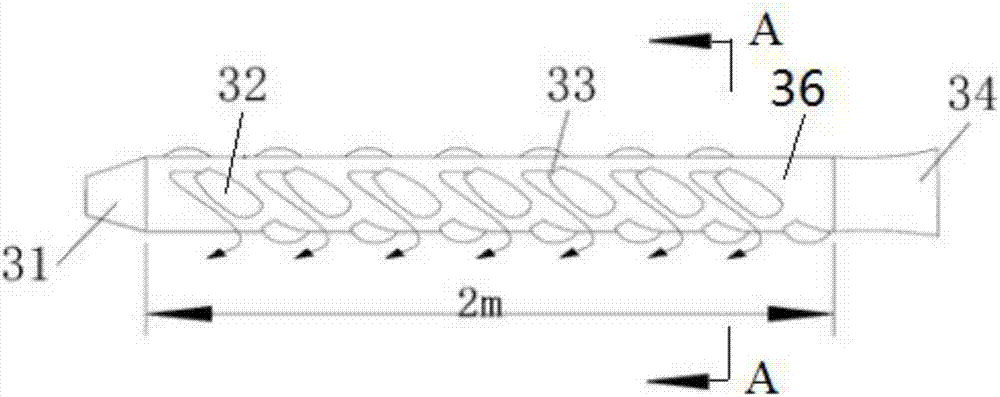

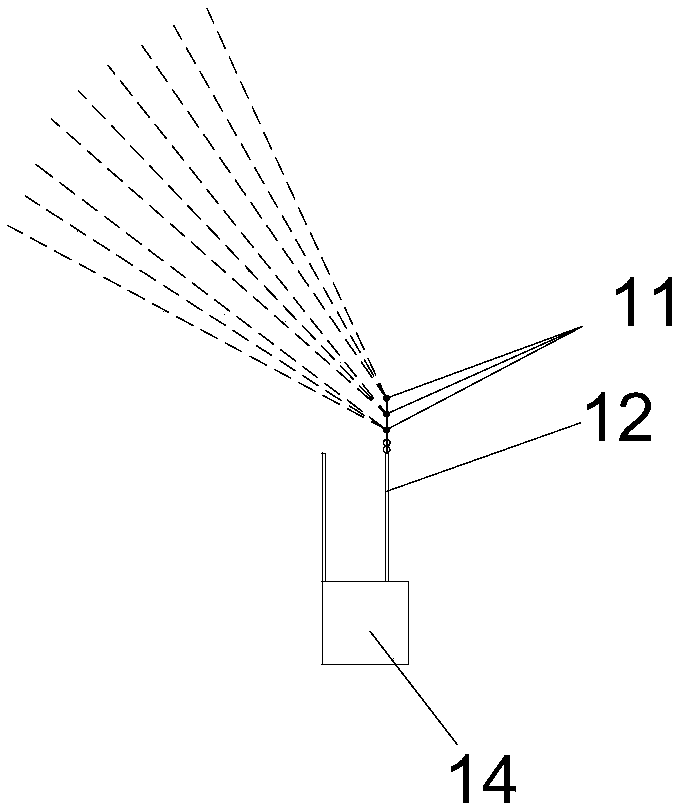

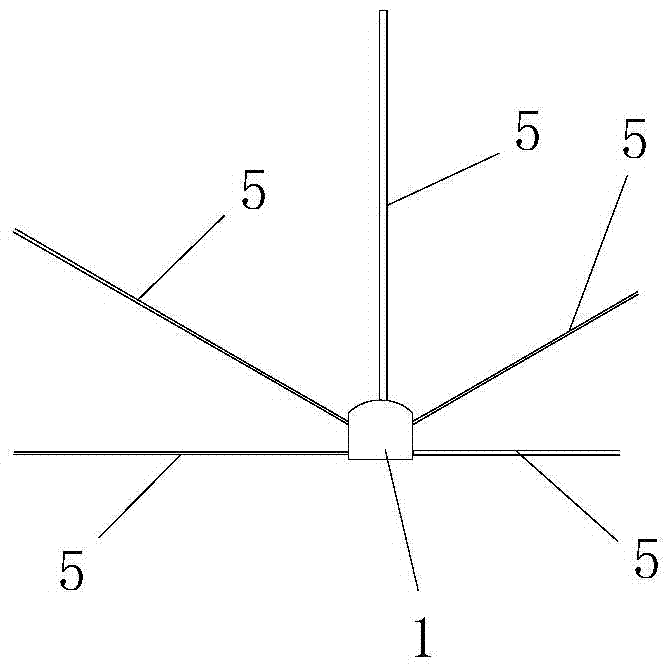

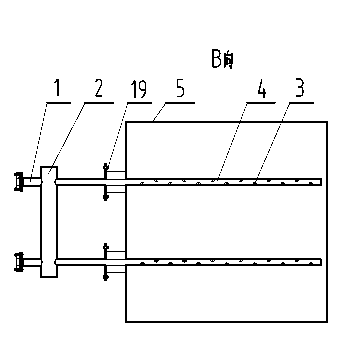

Air curtain sealing dedusting system on fully-mechanized excavating face

InactiveCN101761337AReduce spreadReduce dust concentrationDust removalFire preventionEngineeringOperation safety

The invention discloses an air curtain sealing dedusting system on a fully-mechanized excavating face, comprising a fully-mechanized roadheader body. The fully-mechanized roadheader body is provided with an air curtain generating device; the air curtain generating device is positioned between an excavating head and a driver of the fully-mechanized roadheader body and can spray air flows to the left side and the right side of the fully-mechanized roadheader body in an upright upward direction so as to form a closed air curtain perpendicular to the excavating direction of a fully-mechanized roadheader; a closed space used for accommodating dust generated when the fully-mechanized roadheader body excavates is formed by the closed air curtain and the excavating face of the fully-mechanized roadheader body; and the fully-mechanized roadheader body is also provided with a dedusting device used for absorbing the dust inside the closed space. By arranging the ari curtain generating device on and the dedusting device on the fully-mechanized roadheader to effectively seal the dust in a space with unattended operation, the invention enhances the dust absorption efficiency of the dust positioned on the excavating head, reduces the influence on a visual line of an operator and enhances the operation safety because the operator can clearly view evacavating.

Owner:SHANDONG UNIV OF SCI & TECH

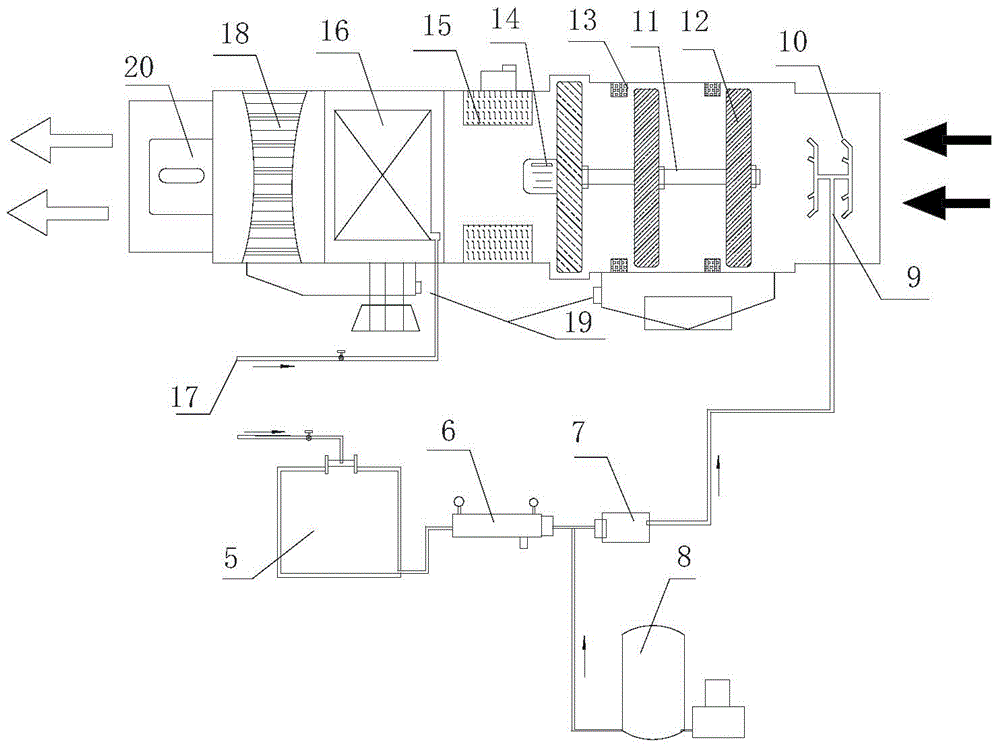

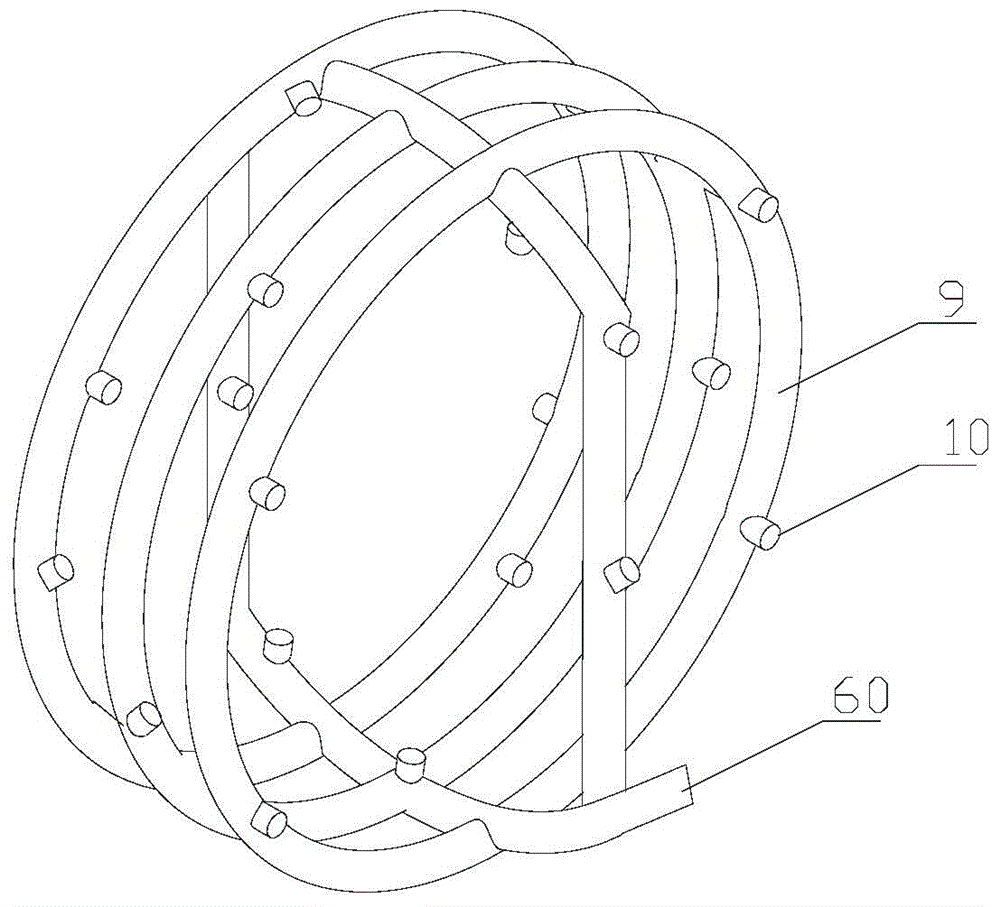

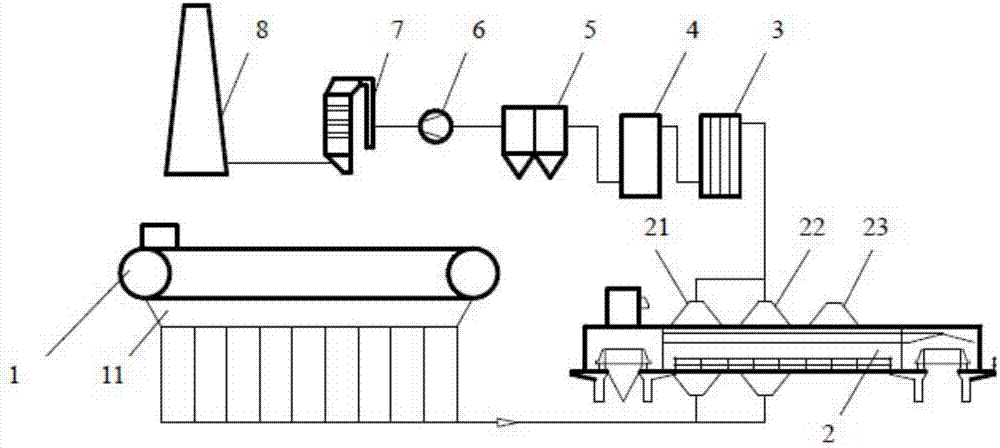

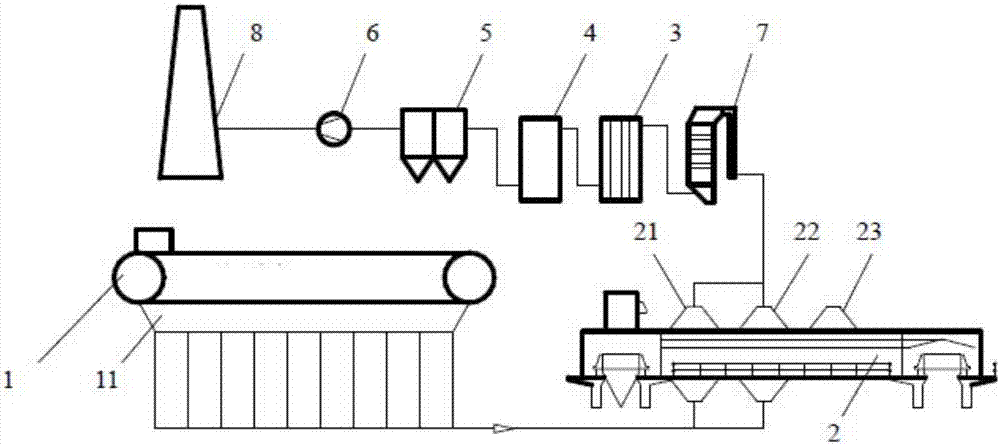

Wet-type dust-capturing wind current cooling device

ActiveCN104474819ACompact structureReduce volumeCombination devicesTemperature controlWorking environment

The invention provides a wet-type dust-capturing wind current cooling device mounted at a head-on rear position of a mining working face mining machine, connected with an outlet end of a polluted wind pumping canister and comprising a cover shell, and a spray dedusting device, a cyclone centrifugal dedusting device, a dust screen filtering device, an air cooling type heat exchanger and a baffle plate demister which are connected in order inside the cover shell; positions of the cover shell walls below the cyclone centrifugal dedusting device and the baffle plate demister are respectively provided with drainage pipe ports. Fully-mechanized excavating working face dust capturing and wind current cooling works are combined together, with a treatment mode of firstly dust capturing and then wind current cooling, polluted wind is firstly subjected to multi-stage dust capturing treatment and then is demisted and cooled, the working face wind current temperature is controlled in a suitable temperature, a safe and comfortable working environment of the down-hole working face is ensured, and the problems of high temperature and high dust of the mine mining working face are better solved.

Owner:SHANDONG UNIV OF SCI & TECH

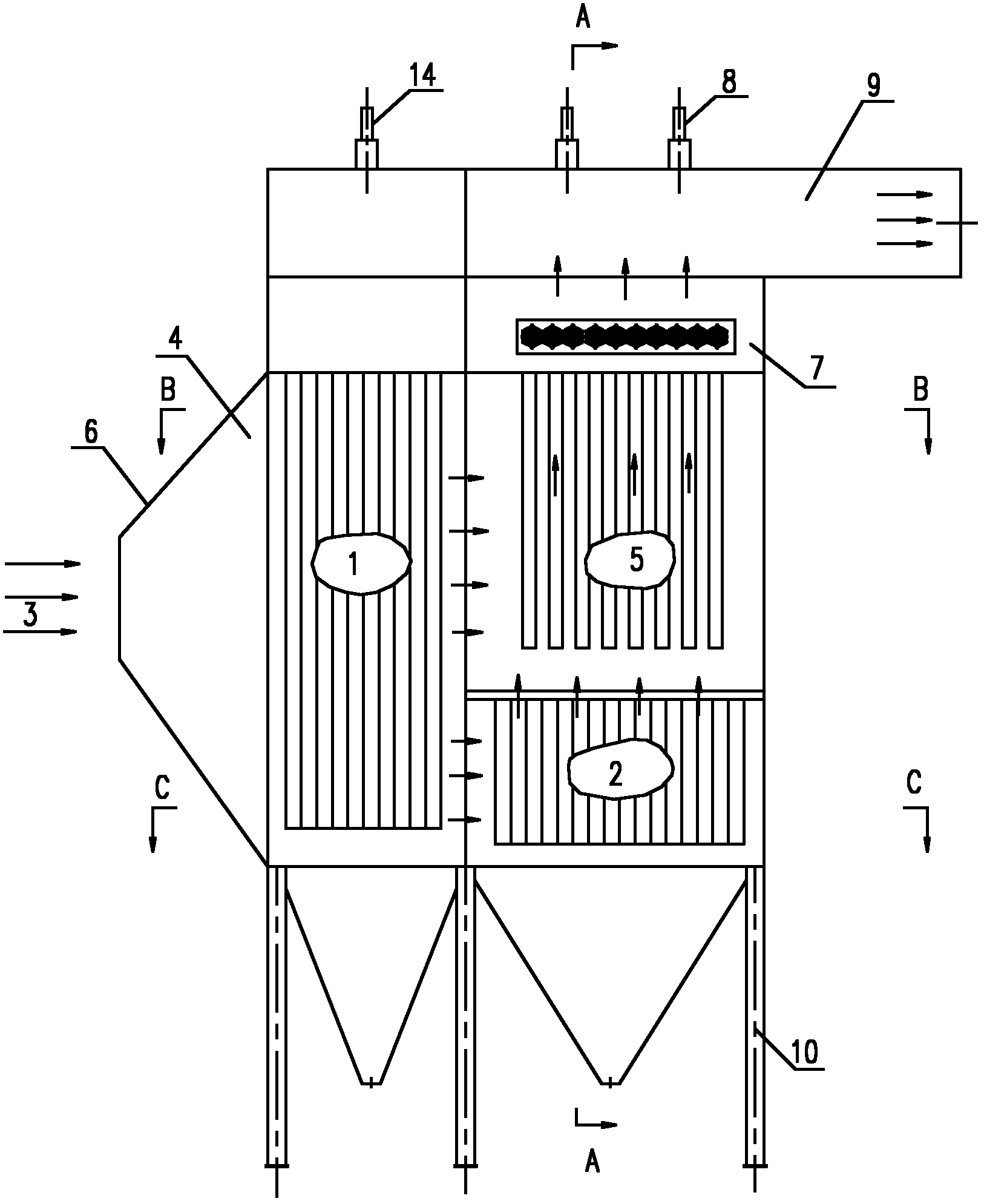

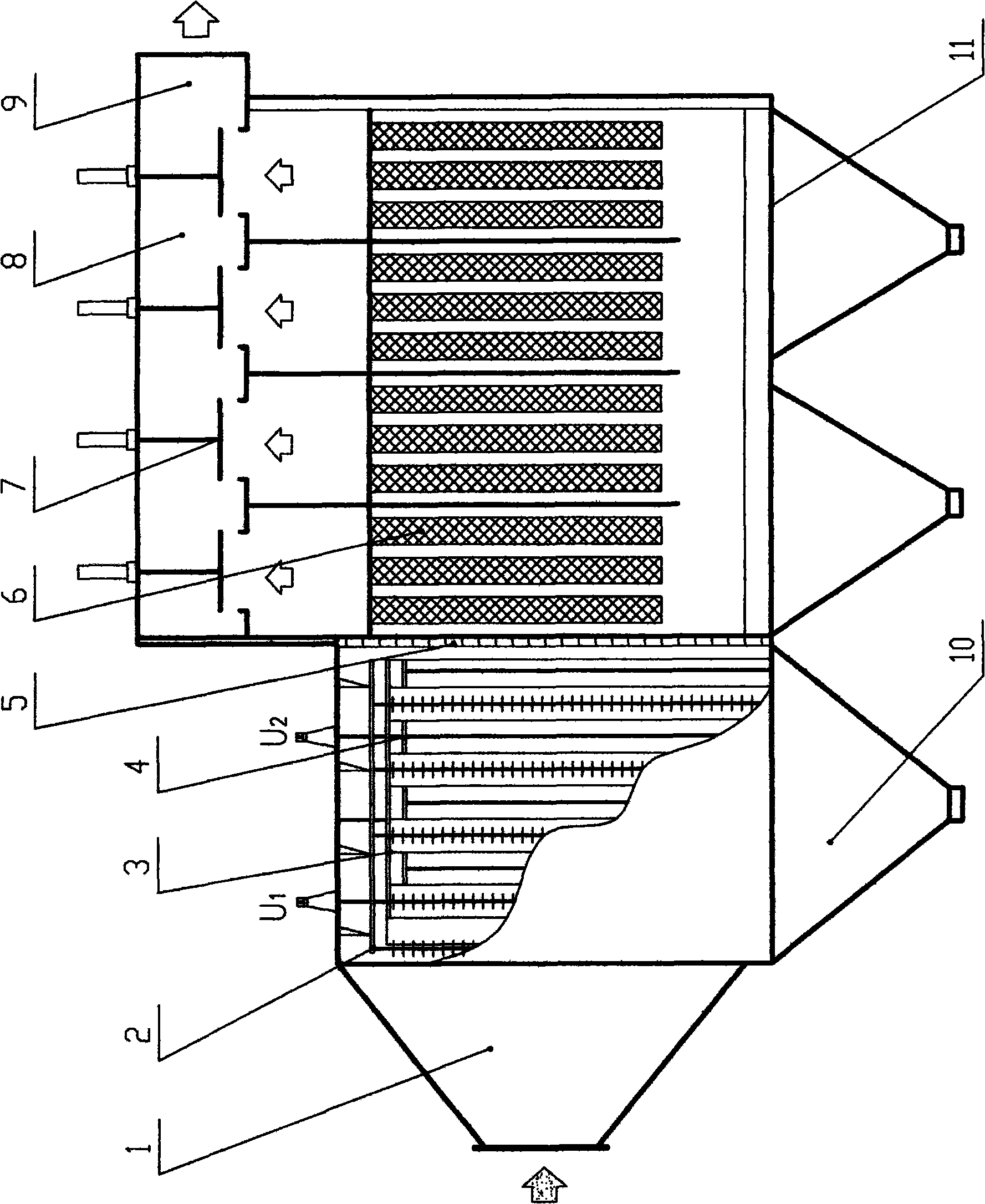

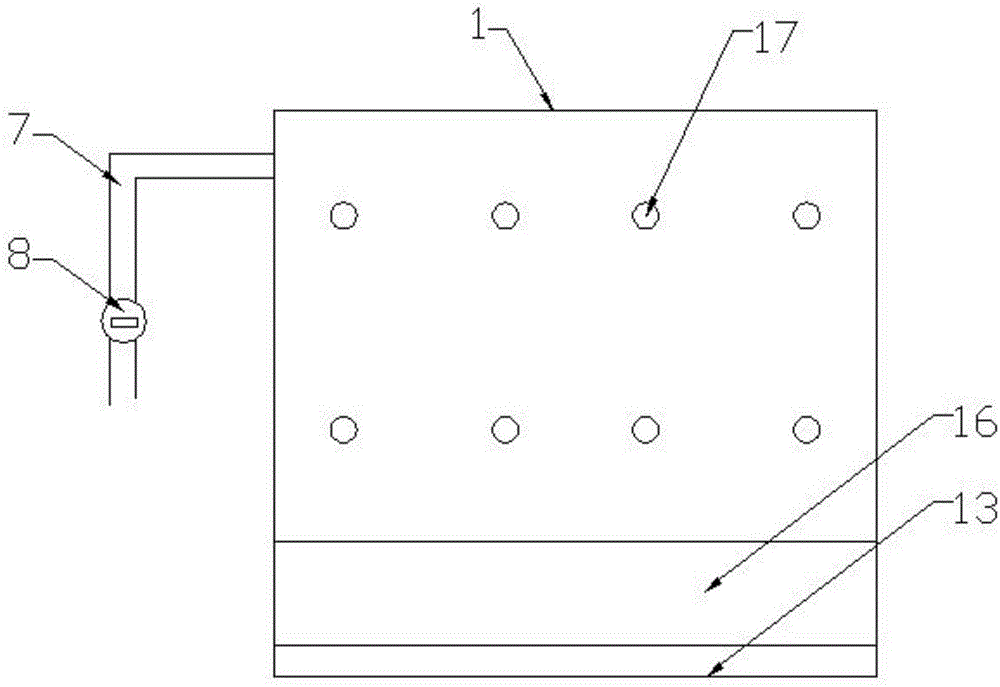

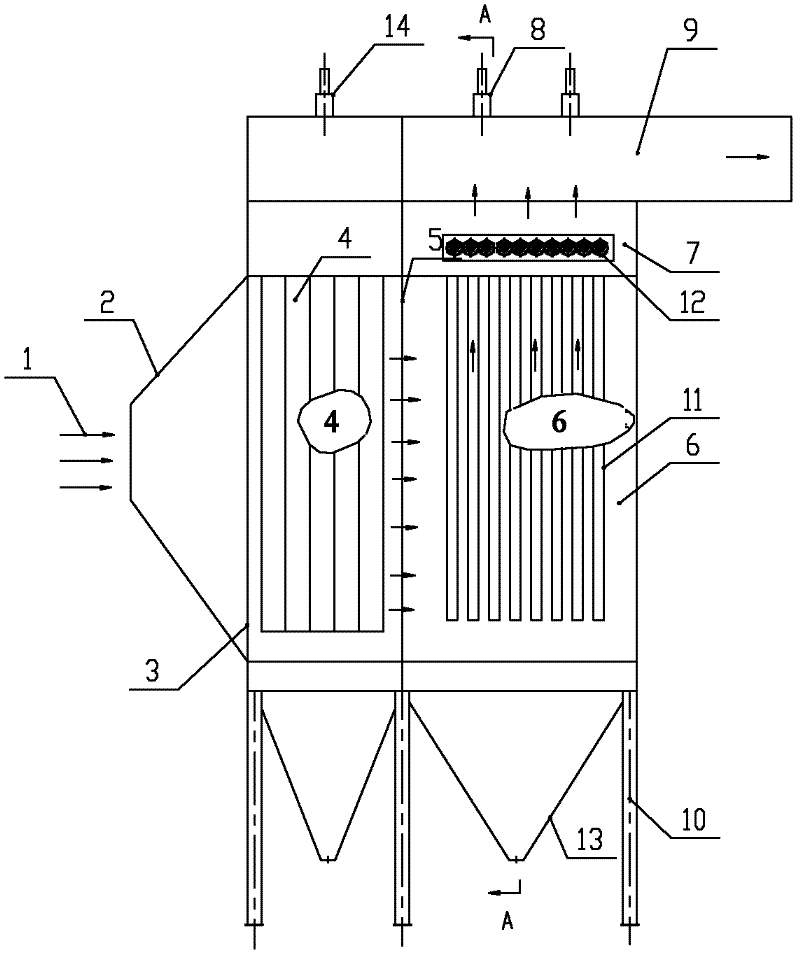

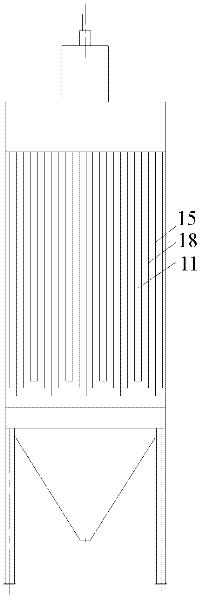

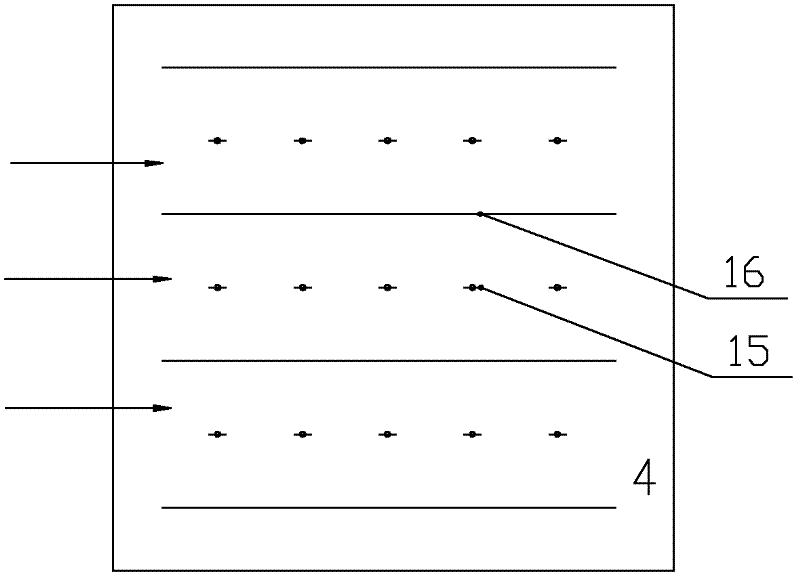

Electric-bag composite dust collector

ActiveCN102327724AIncrease the filtration speedReduce processingCombination devicesEngineeringDust emission

The invention discloses an electric-bag composite dust collector. The electric-bag composite dust collector comprises a composite dust collecting region in a housing, wherein the composite dust collecting region comprises an electric bag dust collecting region and a first electric field dust collecting region; the electric bag dust collecting region comprises a filter bag region and a second electric field dust collecting region; a filter bag dust collecting device is arranged in the filter bag region, and located on the upper end of the electric bag dust collecting region; an electric field dust collecting device is arranged in the second electric field dust collecting region, which is communicated with the filter bag region and located on the lower end of the electric bag dust collecting region; and an electric field dust collecting device is arranged in the first electric field dust collecting region, which is communicated with the electric bag dust collecting region and located onthe front end of the electric bag dust collecting region. In the electric-bag composite dust collector provided by the invention, the second electric field dust collecting region is arranged on the lower end of the electric bag dust collecting region, so that the dust can be recharged when a portion of smoke flows from the first electric field dust collecting region to the second electric field dust collecting region, thereby enhancing the dust charging strength. Additionally, the second electric field dust collecting region can effectively collect dust dropping from the filter bag region when the dust is removed, thereby reducing secondary dust emission, prolonging dust removal period, prolonging the service life of the filter bag, reducing the whole dust removing resistance, and improving the overall performance of the dust collector.

Owner:FUJIAN LONGKING

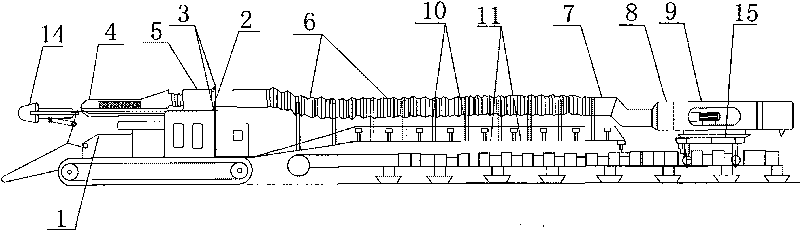

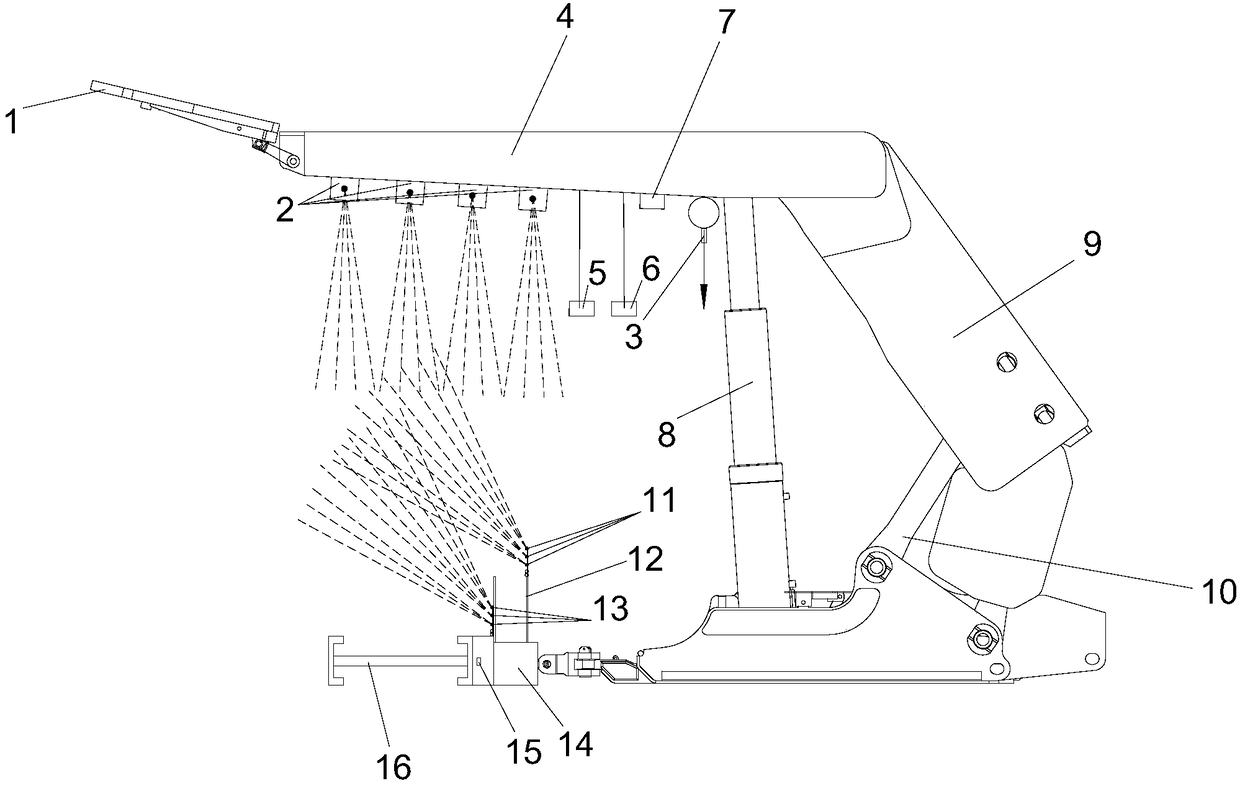

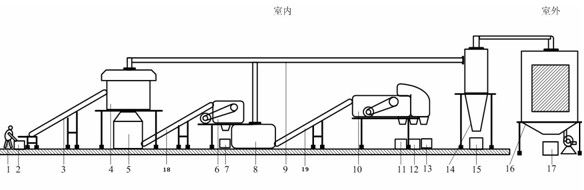

Dust removing system for fully-mechanized coal mining workface

PendingCN107218074AImprove working environmentReduce dust concentrationDust removalFire preventionMining engineeringDust control

The invention discloses a dust removing system for a fully-mechanized coal mining workface. The system includes a dust control system installed on one side of a roadheader, a dust suction system and a dust collecting system installed on the other side of the roadheader, wherein the dust control system comprises a press-in type fan, a press-in type air duct and a wall-attached air duct which are connected with each other in turns; the dust suction system comprises a first suction hood for sucking dust on the cutting head position of the roadheader, a second suction hood for sucking dust on the insertion board position of the roadheader, a third suction hood for sucking dust on the break-of-bulk-point position of a scraper conveyor and belt conveyor, a dust suction air duct and a suction hood assembly box, and the first suction hood, the second suction hood, the third suction hood and the dust suction air duct are all connected to the suction hood assembly box; the dust collecting system comprises an extraction type air duct, a dust remover and an extraction type fan which are connected with each other in turns, and the extraction type air duct is connected to the suction hood assembly box. The dust removing system for the fully-mechanized coal mining workface can effectively control diffusing and spreading of dust in underground roadways, has a good dust suction effect and high dust collecting efficiency, and can greatly reduce the dust concentration of the fully-mechanized coal mining workface.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

Lens electric-bag complex dust collector

InactiveCN101310822AReduce turbulence intensityExtended service lifeCombination devicesDispersed particle filtrationElectric fieldSpecific resistance

The invention relates to a lens-type electric bag composite dust collector which utilizes the characteristics that a lens-type electric dust collector has higher dust collecting efficiency of a dust collecting space than a wire-plate electric dust collector and better adaptability to high specific resistance dust and superfine dust, an electric field of the pre-stage lens-type electric dust collector collects the most of the dust containing the high specific resistance dust and the superfine dust in advance and reduces the high specific resistance dust and the superfine dust in the dust which enters a post-stage bag dust collector to the utmost extent, thus ensuring the gathered dust to have better looseness and permeability, reducing the running resistance and the working load of the post-stage bag dust collector, further reducing the comprehensive cost of the dust collector and prolonging the service life.

Owner:FUJIAN DONGYUAN ENVIRONMENTAL PROTECTION

Method of using high-pressure water injection to prevent and treat gas coal dust

InactiveCN106703871AIncrease moisture contentLess gushSurveyDust removalWorking environmentHigh pressure water

The invention provides a method of using high-pressure water injection to prevent and treat gas coal dust, and relates to a method of using coal seam water injection to prevent and treat the gas coal dust. The method comprises the steps of constructing a bedding drainage borehole, inserting a drainage tube into the borehole, sealing a hole sealing section of the borehole, and beginning to conduct drainage of the gas in the coal seam; regarding a second borehole as a water injection hole, dismantling a second drainage pipeline and a second orifice plate flowmeter which are connected to the second drainage tube, and inserting an expansion hole packer into the second drainage tube; connecting the expansion hole packer with a high-pressure valve, a water injection flowmeter, a high-pressure water injection pump and an underground water supply pipe sequentially through a high-pressure rubber hose; utilizing the high-pressure water injection pump to inject water into a second borehole implement coal seam; turning off the high-pressure valve. According to the method, injection-drainage boreholes are utilized to alternately arrange and implement the coal seam water injection, the gas drainage amount of adjacent drainage boreholes can be increased, the gas gushing amount during digging is reduced, the water content of the coal seam is increased, the dust concentration during digging is reduced, the working environment of working staff is improved, and mine gas coal dust disasters are effectively prevented and treated.

Owner:NORTH CHINA INST OF SCI & TECH

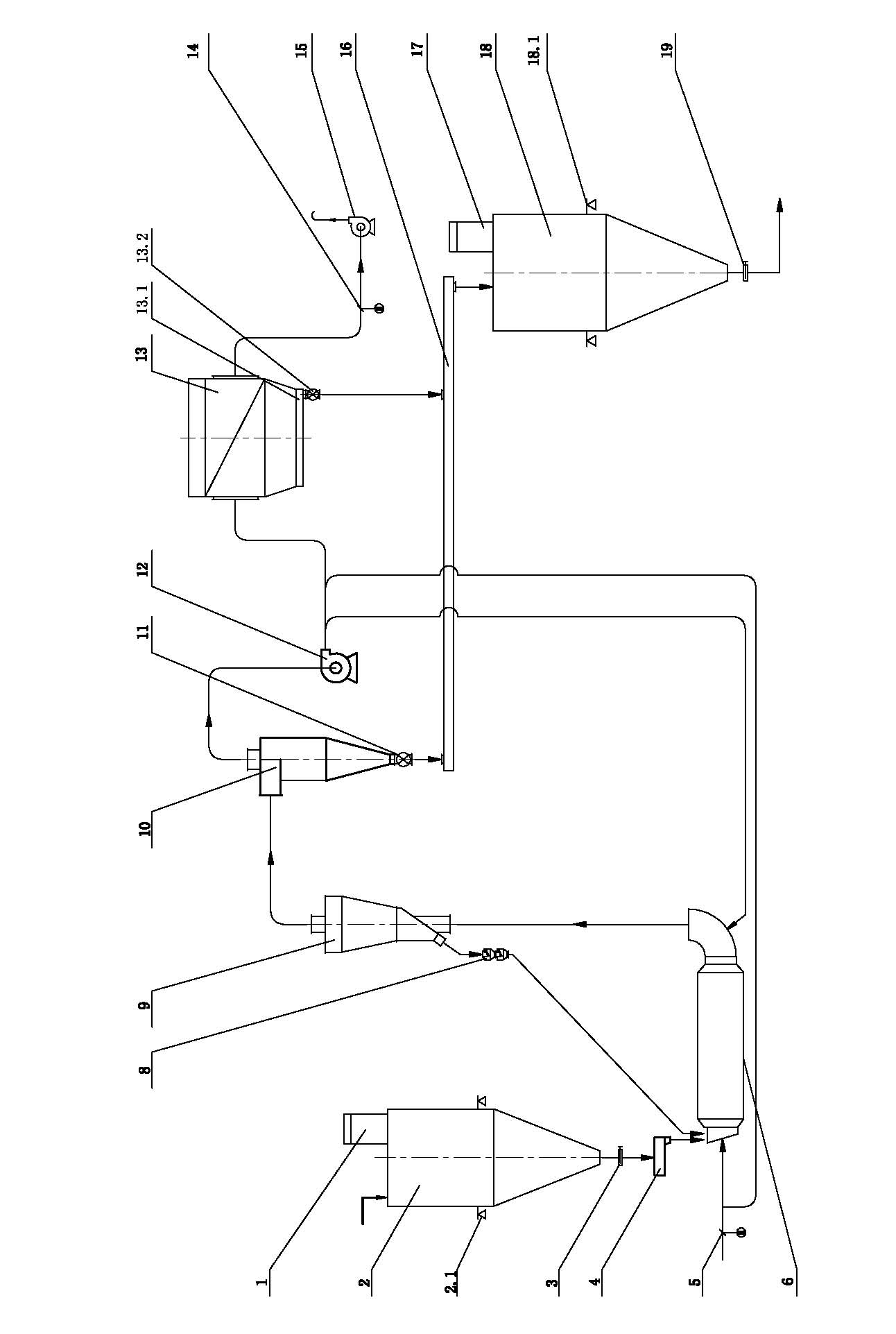

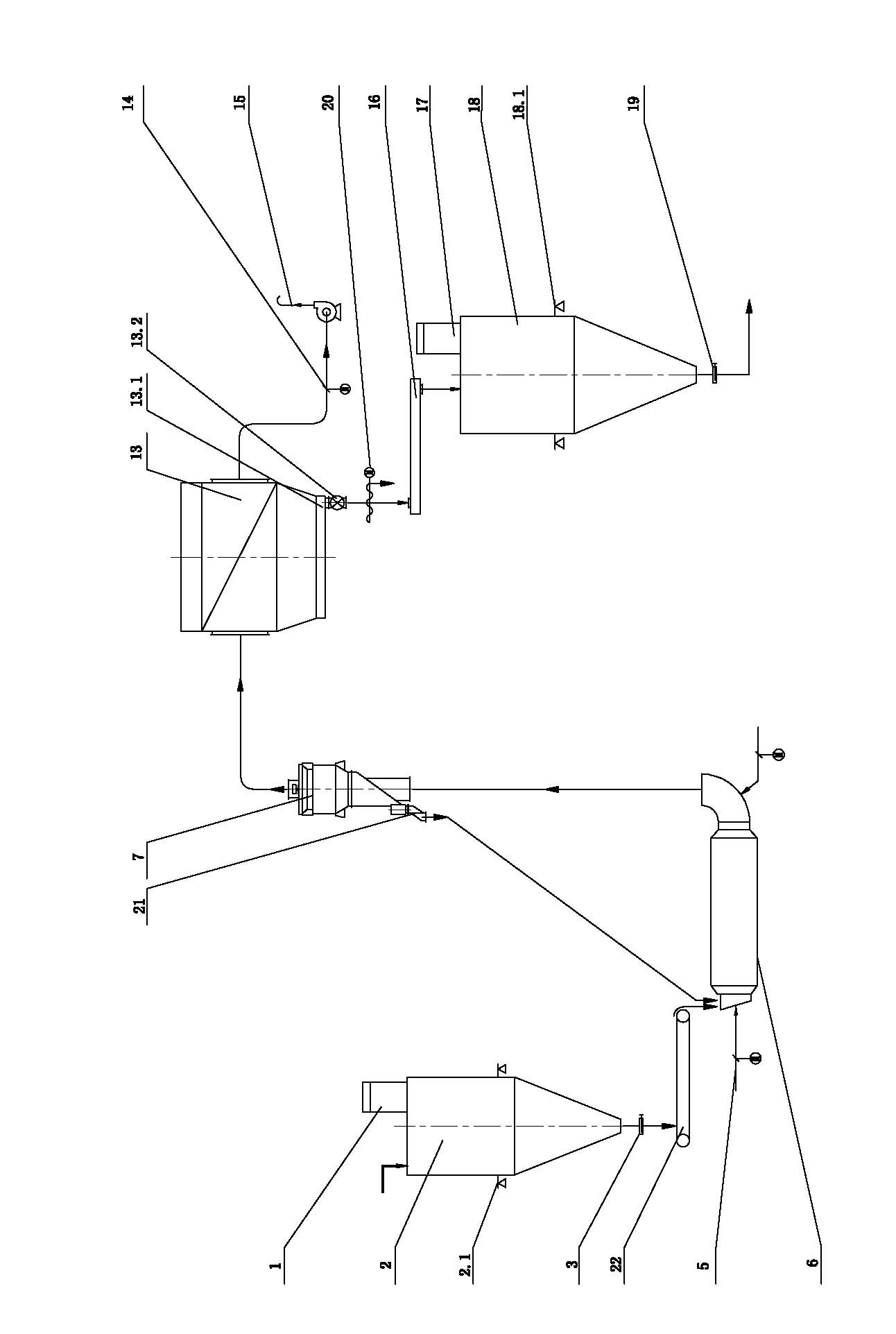

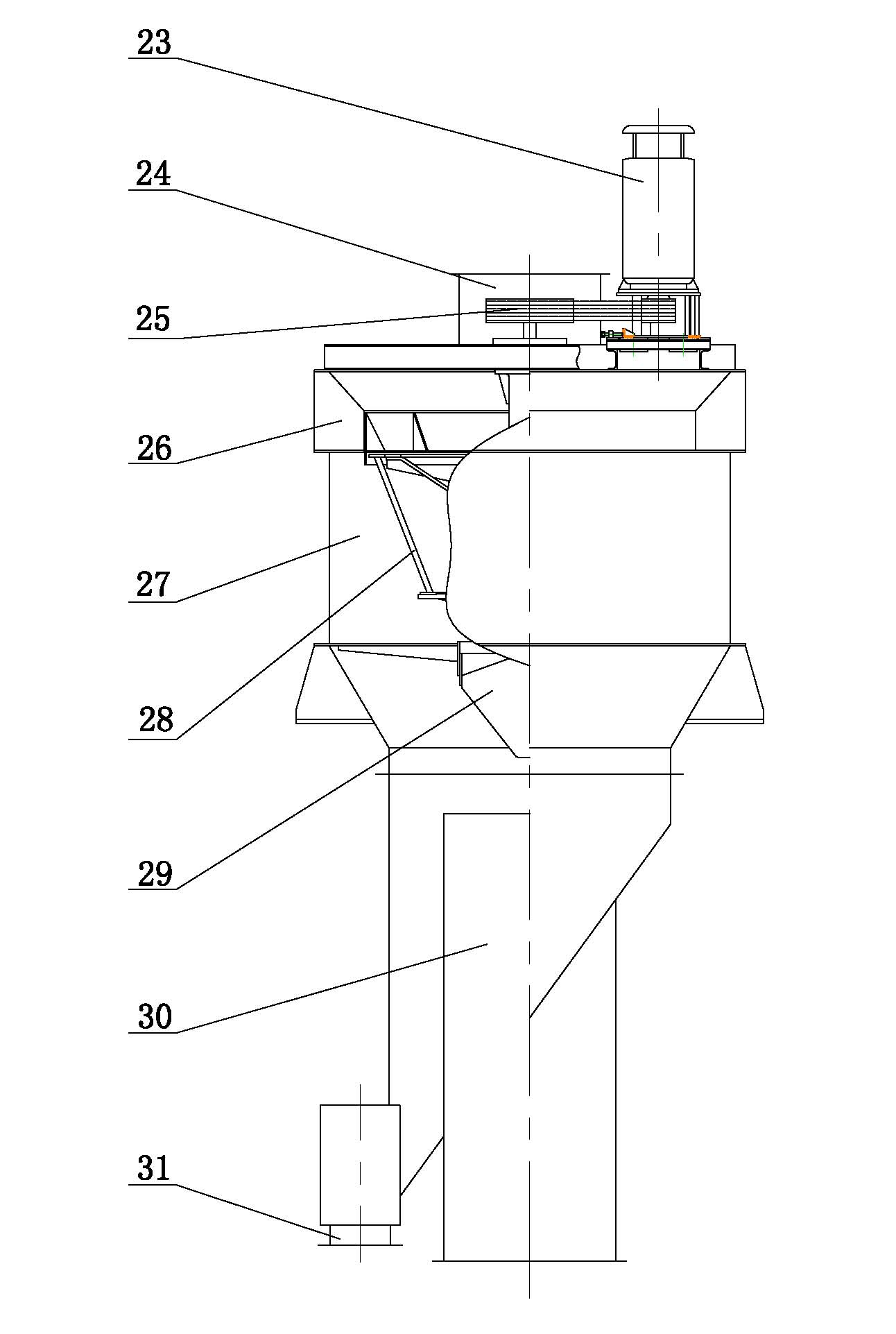

Process for preparing carbon forming powder

InactiveCN101972687AImprove dust carrying capacityReduce power consumptionGrain treatmentsProcess engineeringBall mill

The invention relates to a process for preparing carbon forming powder, in particular to a new process for preparing carbon forming powder by adopting an air swept type ball milling system. In the invention, equipment mainly comprises a raw material bin, an air swept type ball mill, a high-efficiency rotor type grader, a gas tank pulse bag type dust collector, a main exhaust fan and a finished powder bin. In the main work process of the invention, a raw material is fed and added to the air swept type ball mill through a feeder and is subjected to rough and fine powder grading through the high-efficiency rotor type grader, rough particles are returned to the ball mill for pulverizing once again, and fine particles enter the gas tank pulse bag type dust collector for collection. The invention has the technological performance advantages of high systemic force supply, low power consumption for unit product, high finished powder purity, and good uniformity and stability, and completely eliminates the phenomena of air leakage and ash flying in the traditional process because of the operation in a negative pressure state. The process is not only suitable for the optimization and technological improvement on the traditional process in the production process of the carbon forming powder, but also suitable for new projects of a carbon forming powder preparation system.

Owner:NANJING UNIV OF TECH

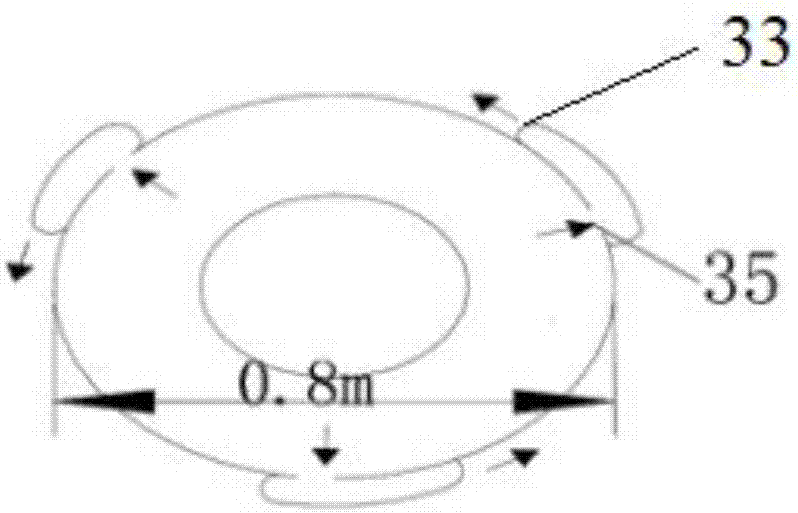

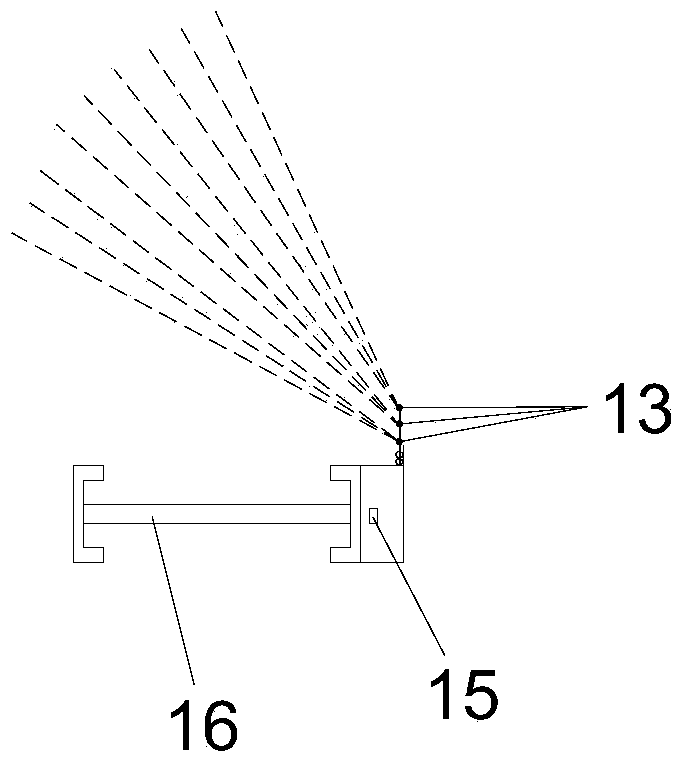

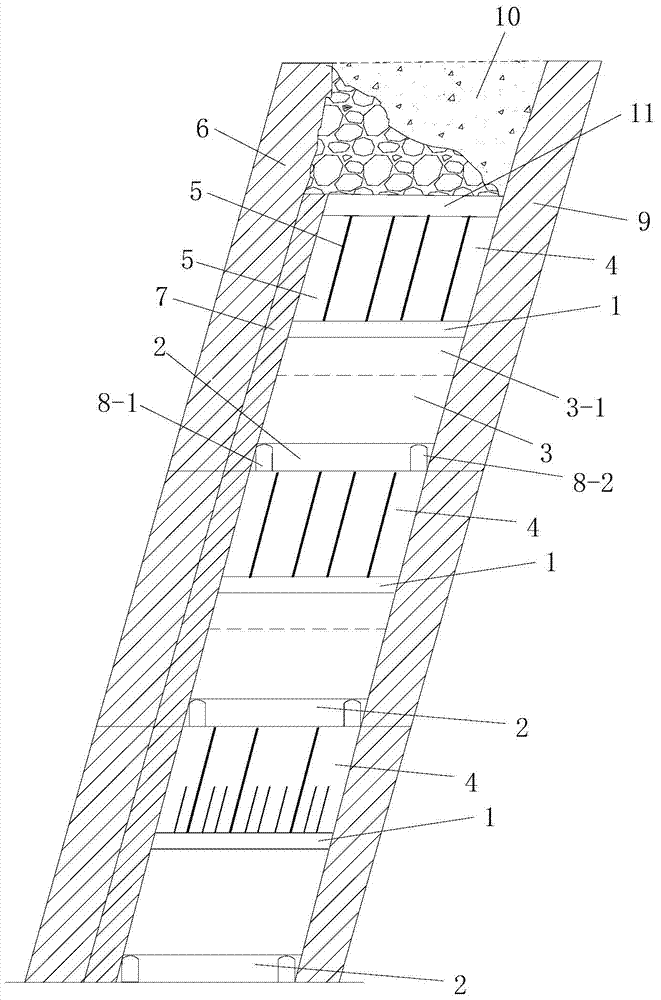

Space three-dimensional dust control and removal method for dust produced during bracket moving of fully mechanized mining face

ActiveCN108930549APrevent escapeReduce dust concentrationMining devicesDust removalHigh concentrationWireless transmission

The invention discloses a space three-dimensional dust control and removal method for dust produced during bracket moving of a fully mechanized mining face. Different dust-proof measures are conductedon the upper, middle and lower spaces of the fully mechanized mining face, an air curtain machine or different kinds of nozzles is / are utilized to form a gas-water double-curtain closed space and a single fog filed closed space, a sensor sends a signal to a central processing system, thus fully-automatic spraying dust-reduction in the bracket moving process of column descending, bracket advancing, column ascending and the like is conducted, and the high-concentration dust is concentrated in the closed space to be treated in a concentrated mode, or the high-concentration dust is blocked outside the closed space; by utilizing closed dust-isolation and spraying dust-reduction modes, a wireless transmission system is adopted, a remote control device is utilized to send a radio signal, a signal processor receives the signal and transmits the signal to the controller, thus the controller can adjust the air volume of the air curtain machine, the spraying range of the nozzles and the water passing pressure, the dust reduction efficiency in the bracket moving process is improved to 95% or above, coal dust explosion accidents are avoided, and the operation environment of workers is also greatly improved.

Owner:SHANDONG UNIV OF SCI & TECH

Recovery method and recovery device for waste toner cartridges

InactiveCN102279552AImprove work efficiencyReduce manual separation processElectrography/magnetographyRecovery methodHigh concentration

The invention relates to a method and device for recovering waste and old selenium drums. The method comprises the steps of: firstly, crushing waste and old selenium drums into scraps of 5mm-15mm by adopting a roll crusher and a hammer crusher; secondly, separating carbon powder from the waste and old selenium drums by adopting a negative-pressure type cyclone separating system, and collecting dust in the waste and old selenium drums by using a bag-type dust collector; thirdly, separating magnetic metal particles from the crushed waste and old selenium drums by adopting a magnetic separator; and finally, separating copper, aluminum and plastic particles from the crushed waste and old selenium drums by adopting a vortex separation method. According to the method and device provided by the invention, the working efficiency of recovering the waste and old selenium drums is improved, effective separation of carbon powder from dust is realized, meanwhile, the concentration of particles in the bag-type dust collector is reduced, and the hazard of explosion due to over-high concentration of the carbon powder and the dust in a cyclone separator during the treatment process is avoided.

Owner:SHANGHAI JIAO TONG UNIV

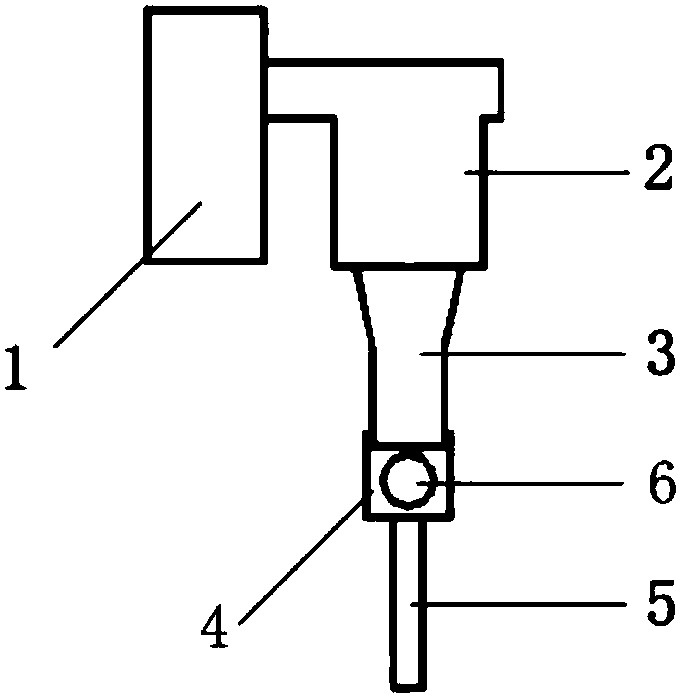

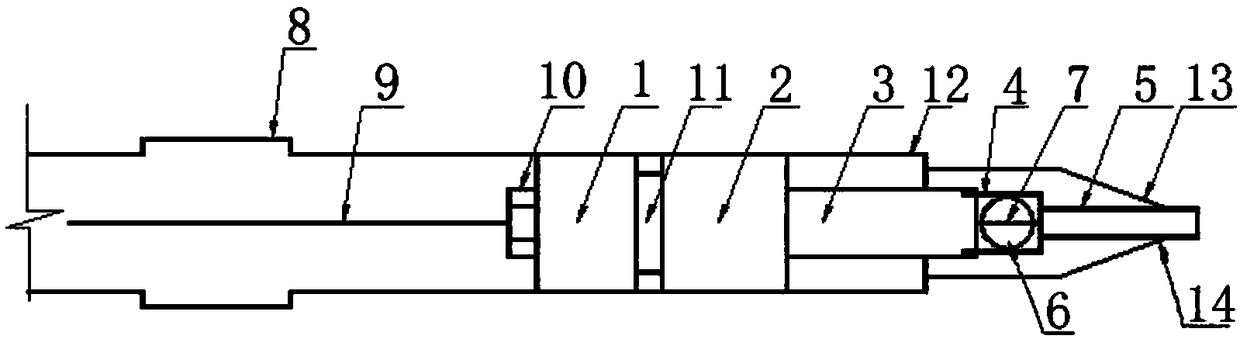

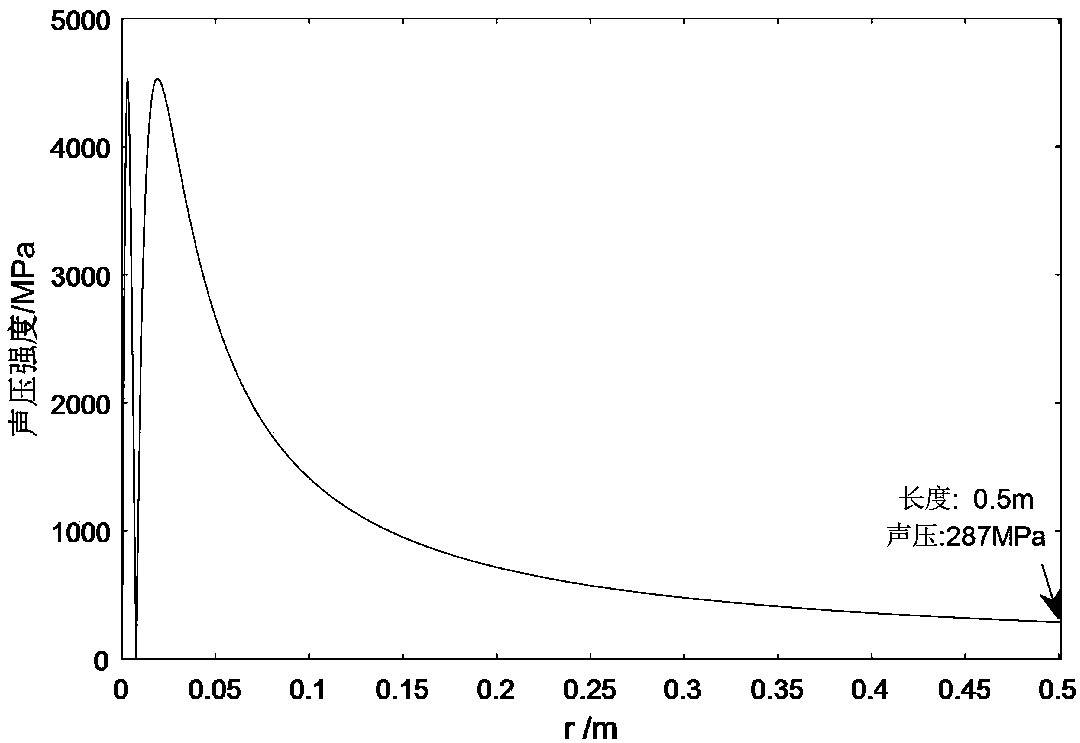

Mine ultrasonic rock breaking equipment

InactiveCN108316861AImprove drilling efficiencyReduce concentrationSlitting machinesFlushingVertical vibrationGeneral Fatigue

The invention provides mine ultrasonic rock-breaking equipment. The mine ultrasonic rock-breaking equipment comprises an ultrasonic generation module, an amplitude rod, a hollow connecting piece, a free-mass sphere, an ultrasonic drill pipe. The tail end of the amplitude rod is fixed to the front end of the ultrasonic generation module, the two ends of the hollow connecting piece are connected with the amplitude rod and the ultrasonic drill pipe separately, and the free mass sphere can oscillates back and forth in the hollow connecting piece. According to the mine ultrasonic rock-breaking equipment, an ultrasonic driver is driven by the high-frequency alternating current excitation voltage with ultrasonic frequency to produce vertical vibration with ultrasonic frequency according to the inverse piezoelectric effect, and the high-frequency vibration is transmitted to the rock surface through the amplitude rod, the free mass sphere and the ultrasonic drill pipe to generate high-frequencydynamic loads with ultrasonic frequencies to break rocks. Ultrasonic vibration has the characteristics of high frequency, high vibration and low amplitude, so that the cumulative growth speed of rockdamage is higher than that caused by general fatigue load, the time for rocks to reach the fatigue failure limit is short, and the rock-breaking efficiency is higher.

Owner:CHINA UNIV OF MINING & TECH

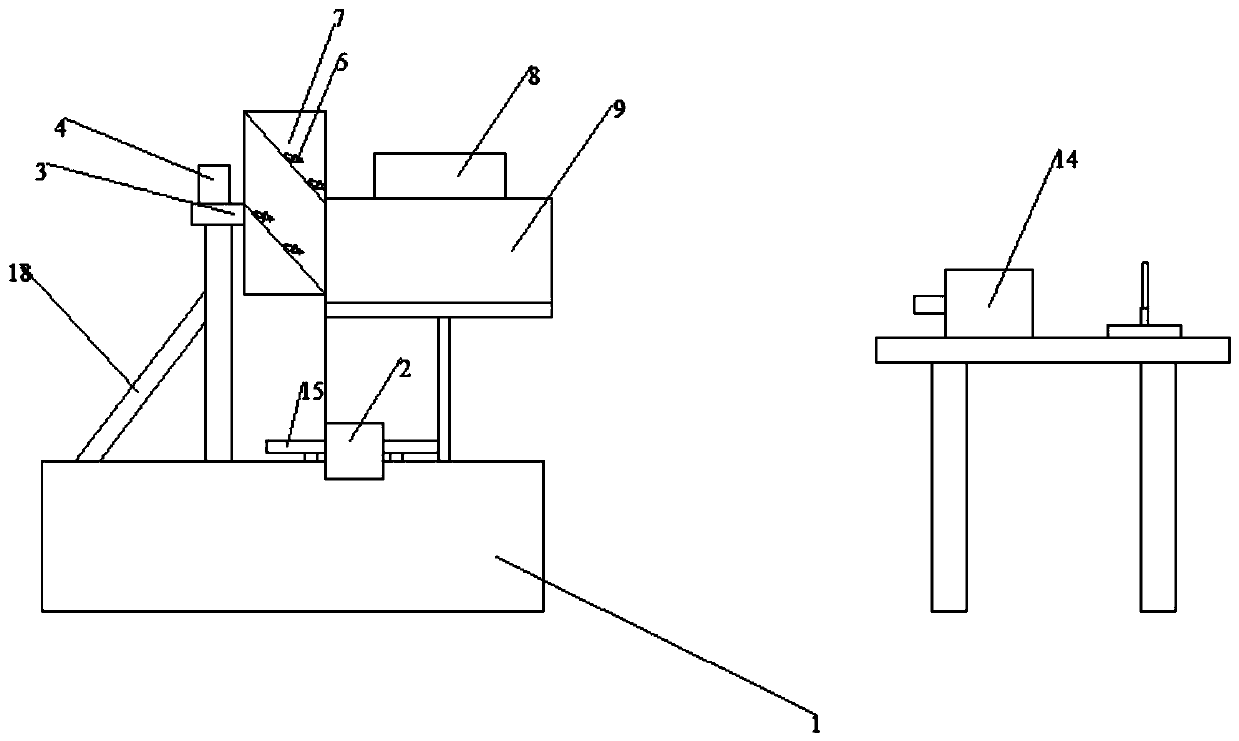

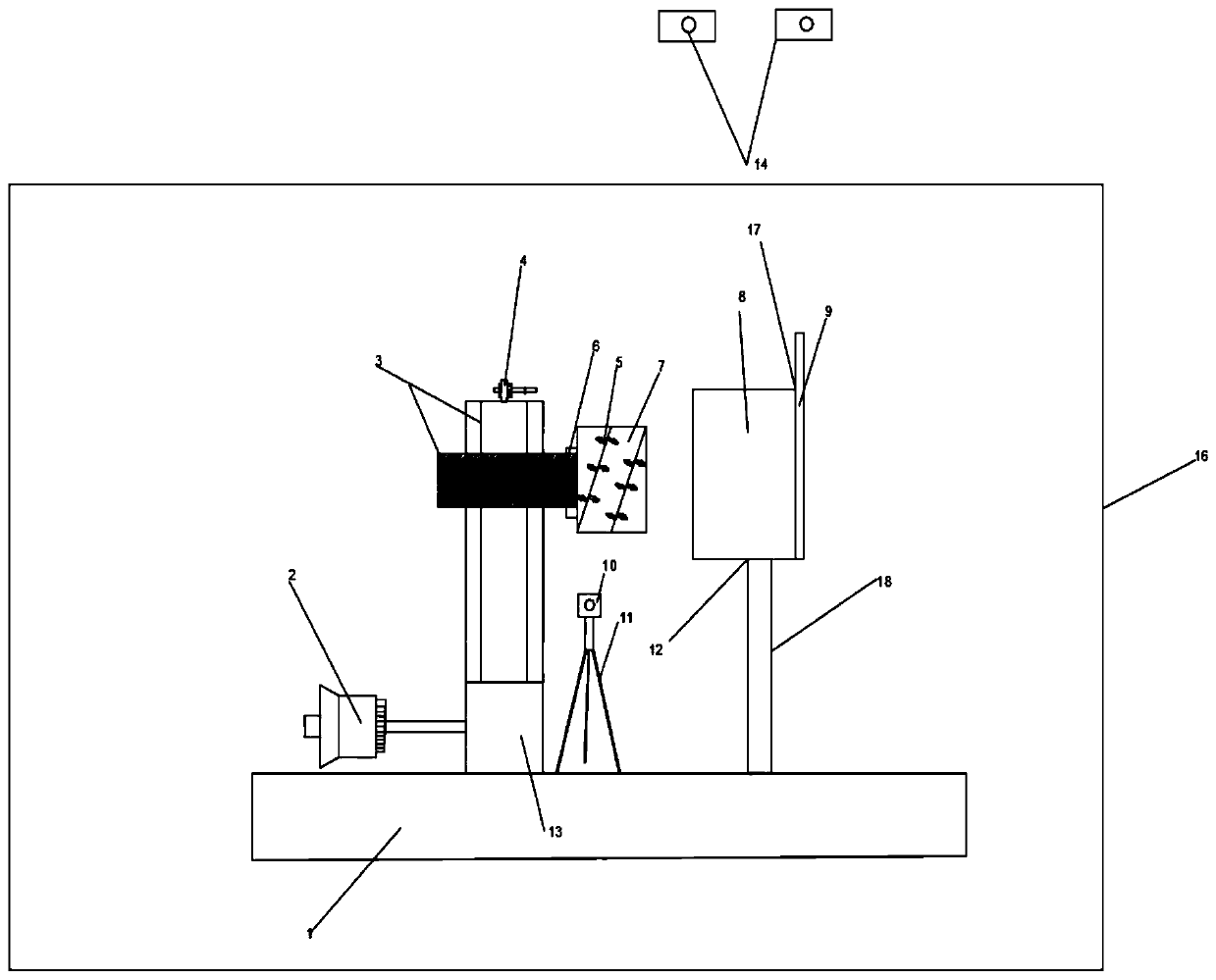

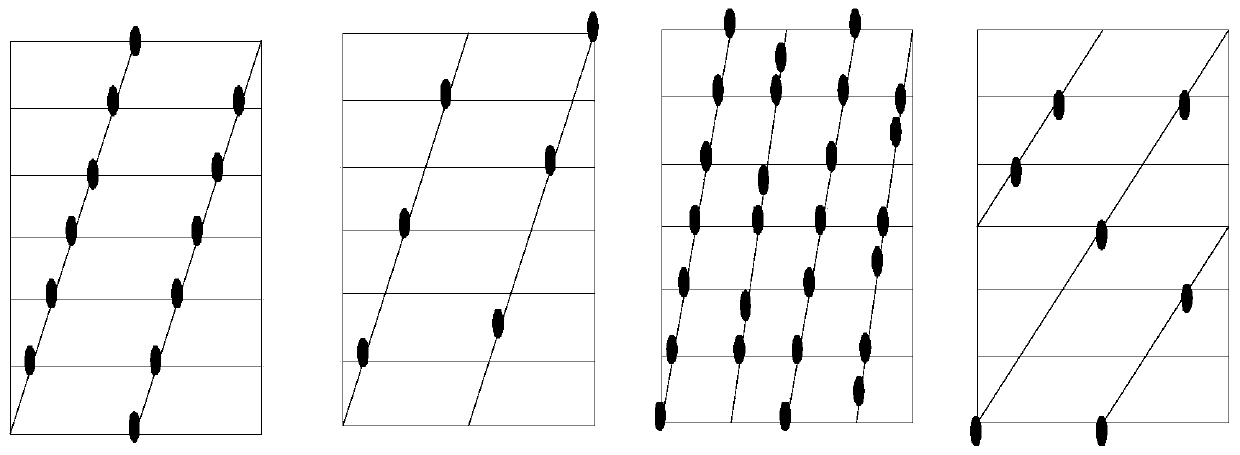

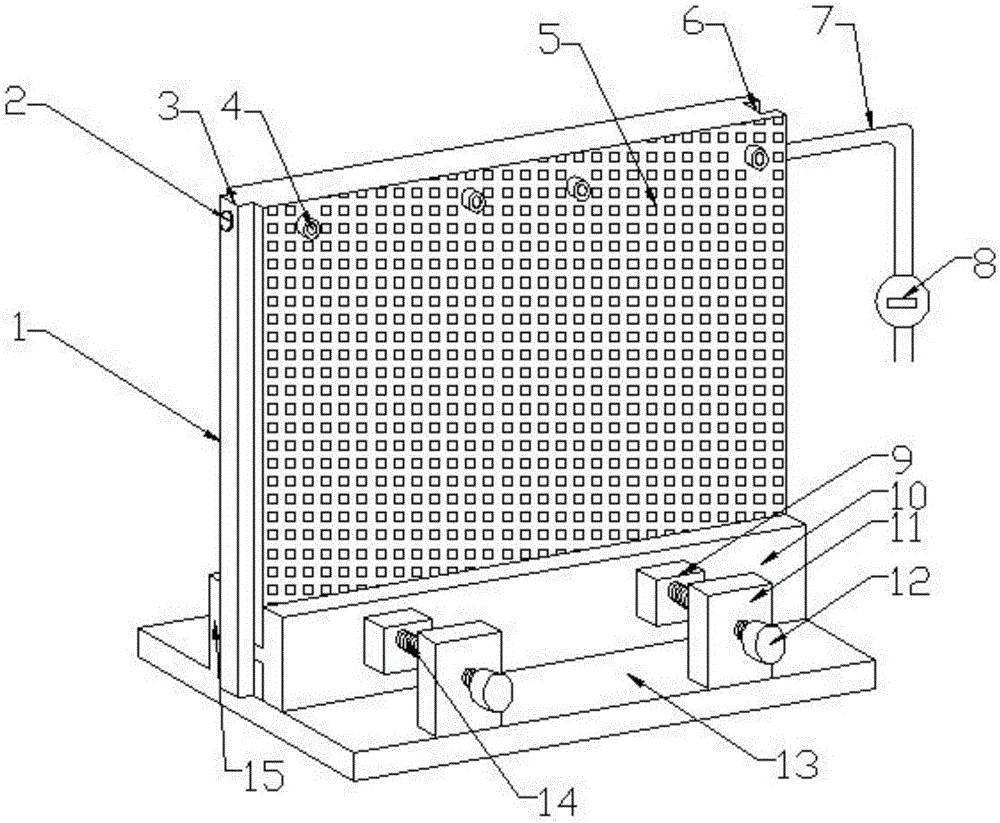

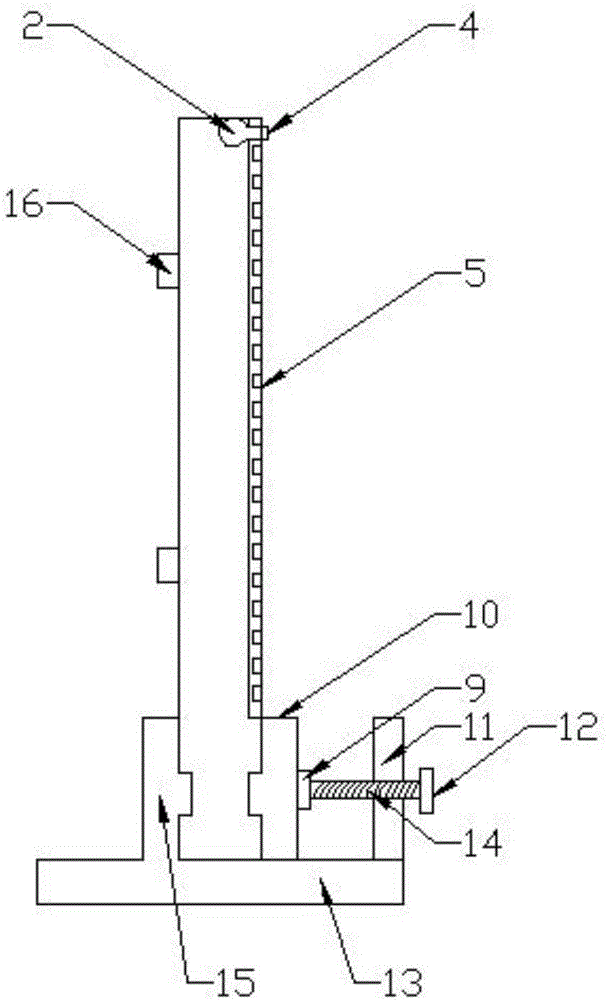

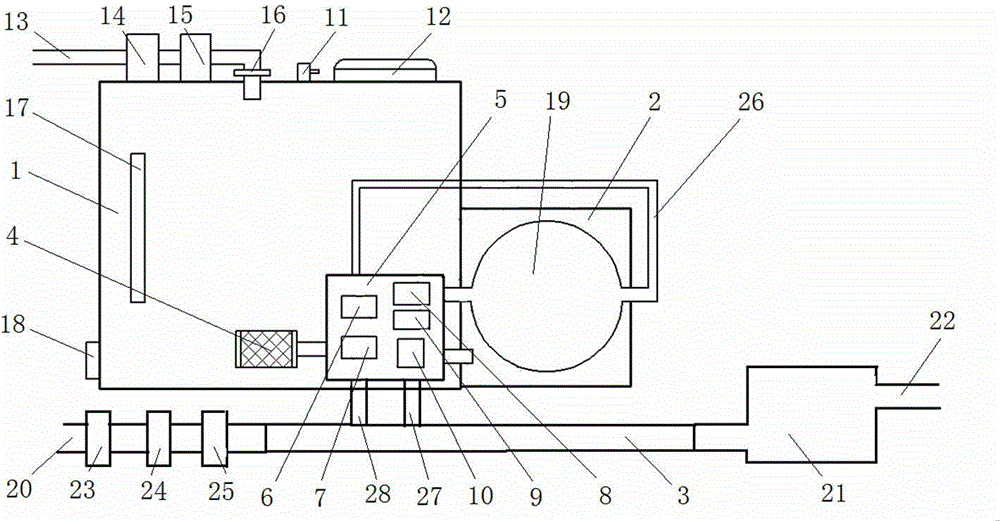

Simulation experiment system and experiment method for simulating cutting dust production of coal and rock mass

InactiveCN110006771AReduce dust concentrationRealize simulationParticle suspension analysisElectromagnetic wave reradiationCoal briquetteControl system

The invention discloses a simulation experiment system and method for simulating coal and rock mass cutting dust production. A cutting experiment device is arranged on the experiment platform; the device is provided with a coal briquette sample, a loading device for loading loads at will, a traction speed loading device, implementation devices of various constraint modes, a roller rotating speed control device, a cutting pick switching device, a mechanical monitoring device and a dust monitoring device, and the experiment system controls all subsystems to complete experiment requirements through a central control system. According to the experimental system disclosed by the invention, simulation analysis on dust produced by cutting of the underground coal mining working face and the tunneling working face can be realized; simulation of dust production caused by cutting damage of different cutting picks under different ground stresses in excavation work can be carried out, mechanical analysis of the cutting picks in the cutting process can be carried out, and research on the influence of different cutting pick types on dust concentration, particle sizes, speeds and microscopic characteristics in the cutting process can be carried out. Theoretical and technical support is provided for dust prevention and control of a mine excavation working face.

Owner:SHANDONG UNIV OF SCI & TECH

Separating wallboard for building construction

InactiveCN107524338AReduce dust concentrationProtect your healthGas treatmentUsing liquid separation agentPipingControl switch

The invention discloses a separating wallboard for building construction. The separating wallboard for building construction comprises a wall and a fixing base. A first protruding block is arranged on one side of the wall, and a first groove corresponding to the first protruding block is formed in the other side of the wall. The walls can be assembled together through the first protruding blocks and the first grooves and fixed through the fixing bases. Rotating handles are rotated to drive screws to rotate, so that the wall is clamped through movable plates and fixed plates, the wall is fixed, and the wall is conveniently assembled, dismounted and mounted and can be repeatedly used. A water valve is opened, water is sprayed from four spraying openings through a water pipe, dust suppression by spraying is conducted on a construction site through the four spraying openings, the concentration of dust is reduced, and the physical health of constructors is guaranteed. Noise of the construction site is reduced through noise reduction sponge laid on the wall and noise reduction grooves, so that the influence of the noise on nearby residents is reduced. Turn-on and turn-off of eight symmetrical warning lamps on the wall are controlled through an external control switch, so that passing vehicles and people are warned, and the life safety of people is guaranteed.

Owner:叶雨玲

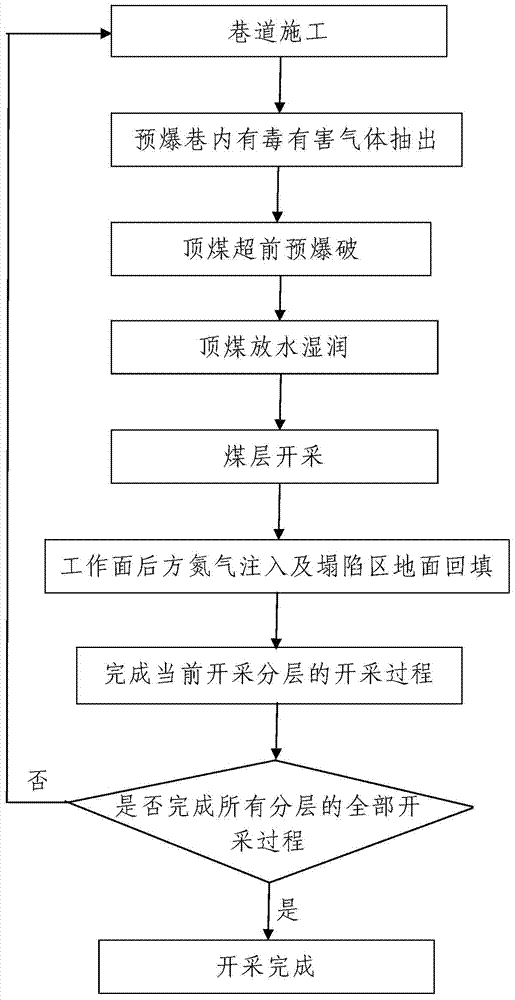

Three-dimensional roof controlling method for fully mechanized caving of steeply inclined and extremely thick coal seam

InactiveCN104847351AThe method steps are simpleReasonable designUnderground miningBlastingMining engineeringCombined use

The invention discloses a three-dimensional roof controlling method for fully mechanized caving of a steeply inclined and extremely thick coal seam. The steeply inclined and extremely thick coal seam is mined in multiple sections from back to front along the trend of the coal same, each of the mining sections is cut into multiple sub-layers from top to bottom, and the uppermost sub-layer is a top sub-layer; when any mining section is mined, the multiple sub-layers of the mining section are respectively minted from top to bottom, and the process comprises the following steps: I, mining the top sub-layer: comprising the steps of tunnel construction, extraction of toxic and harmful gas in a pre-denotation roadway, advanced pre-blasting of top coal, drainage to wet the top coal, coal mining and nitrogen injection behind a working face and ground backfill of a subsidence area; II, mining the next sub-layer; and III, repeating the step II once or multiple times till the mining processes of all sub-layers of the mining section are completed. The method disclosed by the invention is simple in step, reasonable in design, convenient to implement and good in using effect, and various protective measures are combined in use, so that the potential safety hazards such as roof caving, gob fire and the like can be effectively eliminated.

Owner:XIAN UNIV OF SCI & TECH

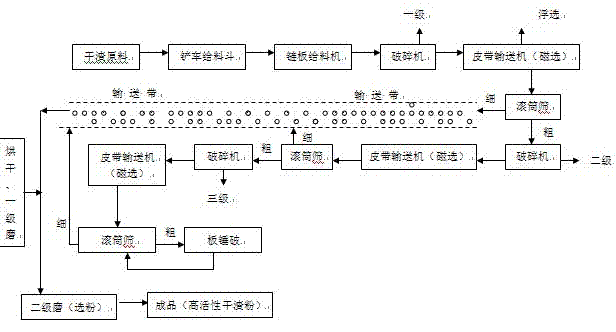

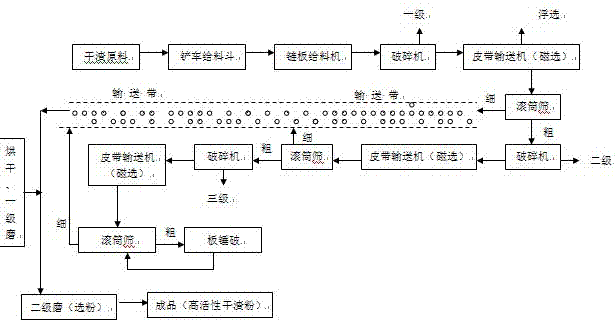

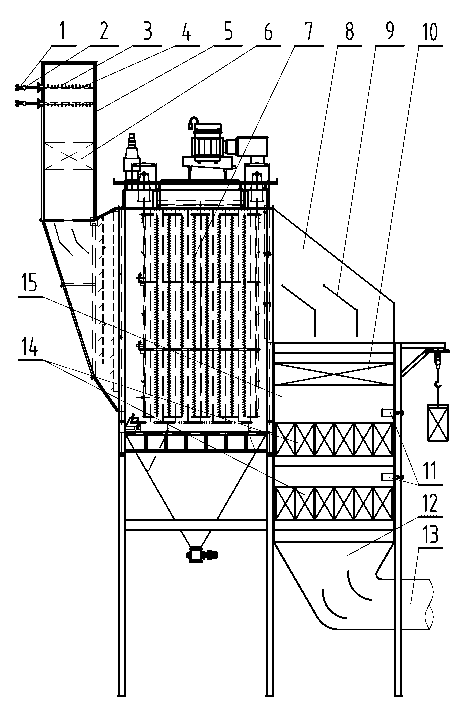

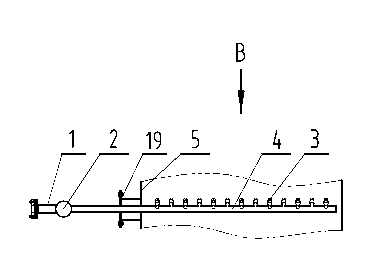

Method for preparing high-activity powder by using dry blast furnace slag

InactiveCN102417939AReduce dust concentrationEfficient purificationRecycling and recovery technologiesProcess efficiency improvementSlagResource recovery

The invention provides a method for preparing high-activity powder by using dry blast furnace slag. The method comprises the following steps of: crushing the slag, screening, performing magnetic separation, drying, performing primary pulverizing (adding a pulverizing aid) and secondary pulverizing (adding a pulverizing aid and an active agent), selecting the powder, discharging, and thus obtaining the high-activity powder. The physical and mechanical properties of the high-activity powder totally meet the requirements of cement mortar and concrete aggregate; and the method has the characteristics of achieving high resource recovery rate, saving the consumption of raw materials, reducing environmental pollution caused by the dry slag and realizing resource recycle.

Owner:韶关市柏林再生资源开发有限公司

SCR (silicon controlled rectifier) denitration system of cement kiln gas

InactiveCN103120899AReduce dust concentrationPromote denitrification reactionCombination devicesElectricitySilicon-controlled rectifier

The invention discloses an SCR (silicon controlled rectifier) denitration system of cement kiln gas. The SCR denitration system comprise an ammonia spraying device, a reactor box body, a wind evening rectifying device, catalysts and sound wave soot blowers, wherein the wind evening rectifying device and the catalysts are respectively arranged on the upper part and the lower part in the reactor box body; and the sound wave soot blowers are arranged in the reactor box body. The SCR denitration system also comprises an electrofilter and a mixing device, wherein the electrofilter comprises a gas inlet and a gas outlet; and the gas inlet of the electrofilter is provided with a gas inlet pipeline. The ammonia spraying device and the mixing device are respectively arranged on the gas inlet pipeline, the mixing device is positioned on the down stream of the ammonia spraying device, an exit of the electrofilter is connected with the upper end of the reactor box body by a gas collection cover, the lower end of the reactor box body is provided with a lower cone bucket, and the lower cone bucket is connected with a gas outlet channel. The SCR denitration system of the cement kiln gas is long in service life and low in use cost.

Owner:YANCHENG LANFENG ENVIRONMENTAL ENG TECH

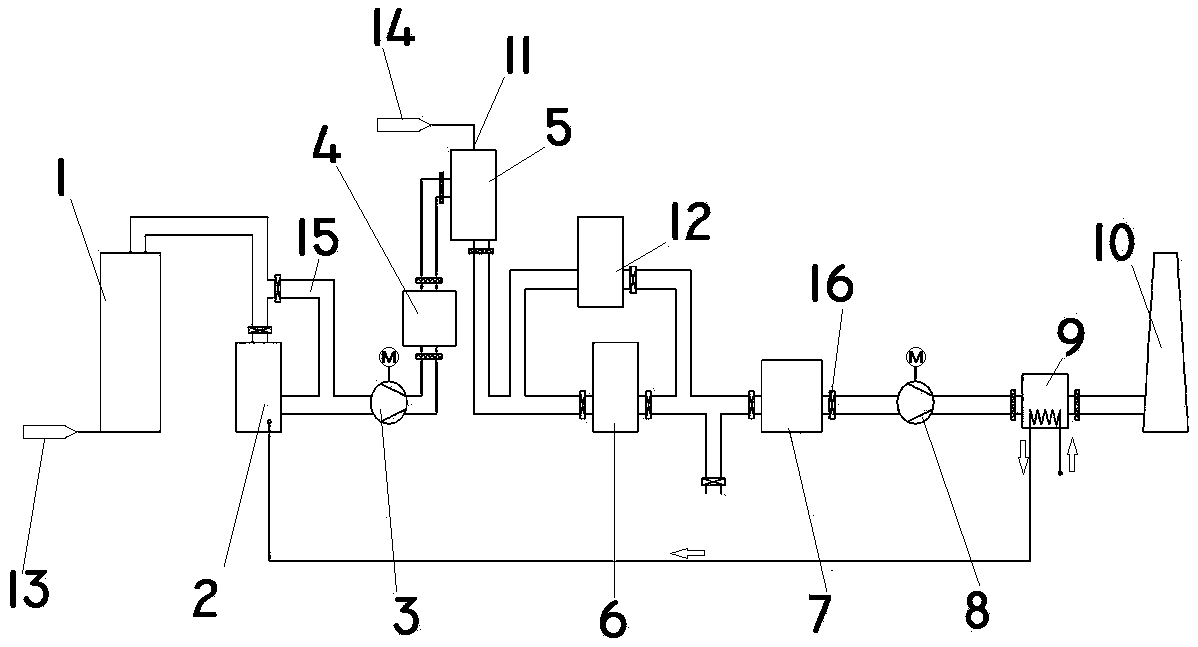

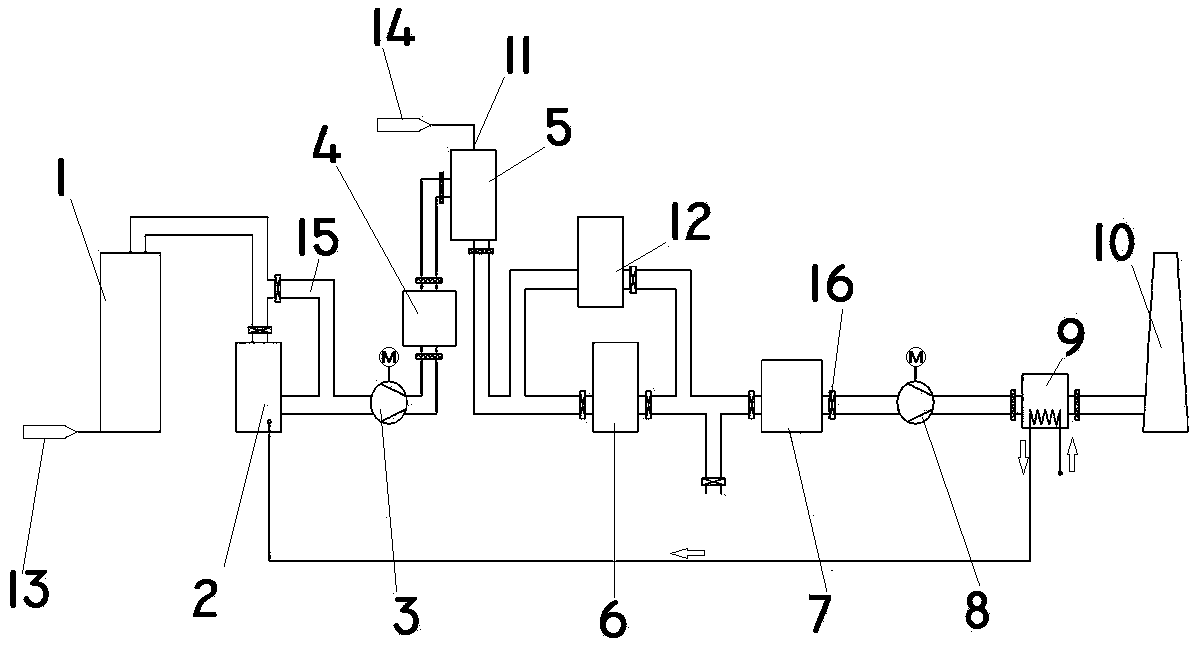

Denitration system and method which are capable of realizing direct utilization of agglomerate heat energy

PendingCN106984169AHigh flexibility in operationLess investmentDispersed particle filtrationIncreasing energy efficiencyEmbrittlementProcess engineering

The invention provides a denitration system and a method which are capable of realizing direct utilization of agglomerate heat energy. The denitration system comprises a sintering machine, a cooling equipment, a waste heat recycling device, a dry desulfurization device, a dust collector, a blower fan, a denitration reactor, and a chimney; an exhaust gas outlet of an air bellow of the sintering machine is connected with an exhaust gas outlet of a first segment air bellow and an exhaust gas outlet of a second segment air bellow; the exhaust gas outlet of the first segment air bellow and the exhaust gas outlet of the second segment air bellow are connected with the waste heat recycling device, and then the waste heat recycling device is connected with the dry desulfurization device, the dust collector, the blower fan, and the chimney via pipelines in series connection successively; when the denitration reactor is a low-temperature denitration reactor, the denitration reactor is arranged between the blower fan and the chimney; and when the denitration reactor is a middle-temperature denitration reactor, the denitration reactor is arranged among the exhaust gas outlet of the first segment air bellow, the exhaust gas outlet of the second segment air bellow, and the waste heat recycling device. The denitration system and the method are capable of realizing direct utilization of agglomerate heat energy, low temperature denitration reaction of sintering exhaust gas is realized without consumption of extra energy, high efficiency conversion of NOx is realized, denitration rate is as high as 80 to 90%, agglomerate embrittlement is not caused, and agglomerate waste heat is recycled.

Owner:MCC CAPITAL ENGINEERING & RESEARCH

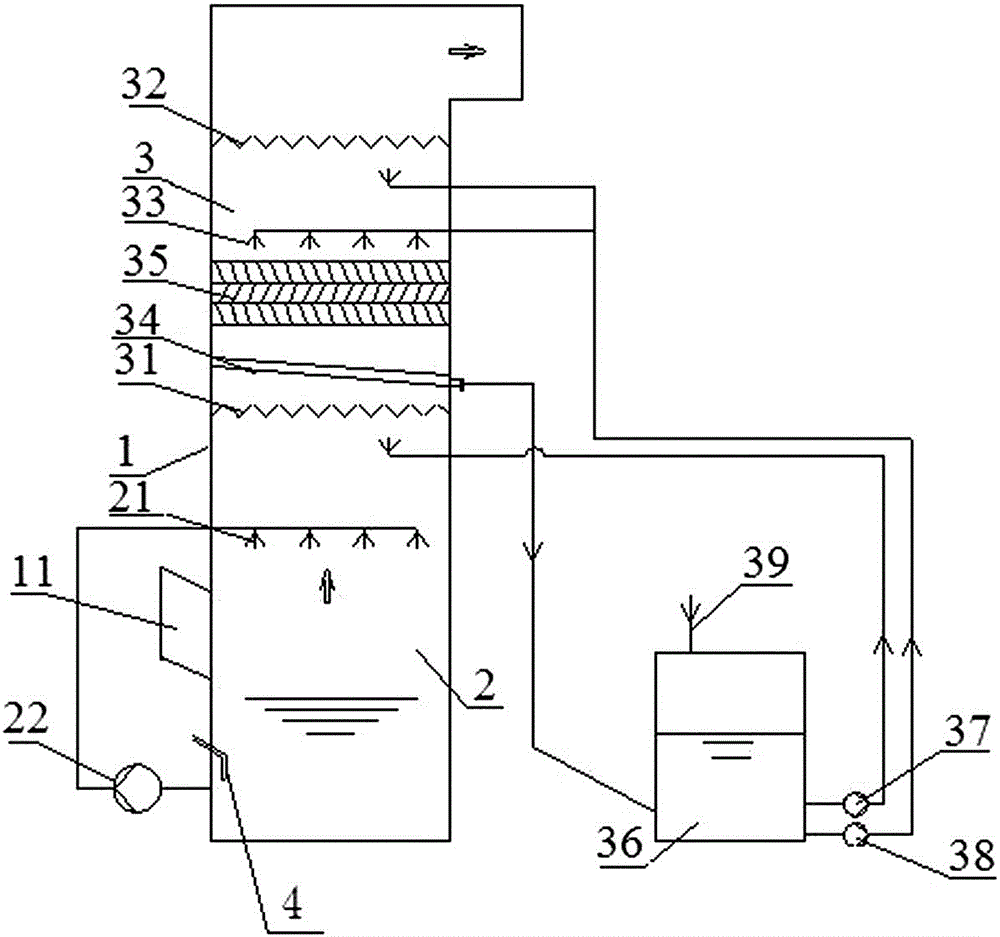

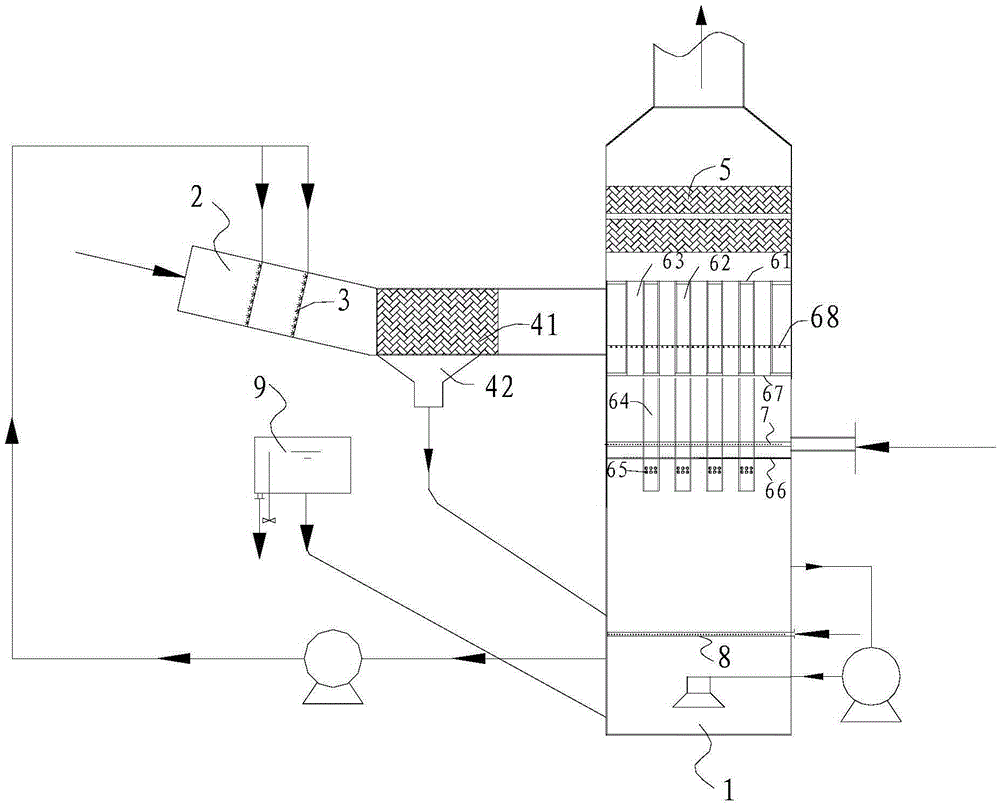

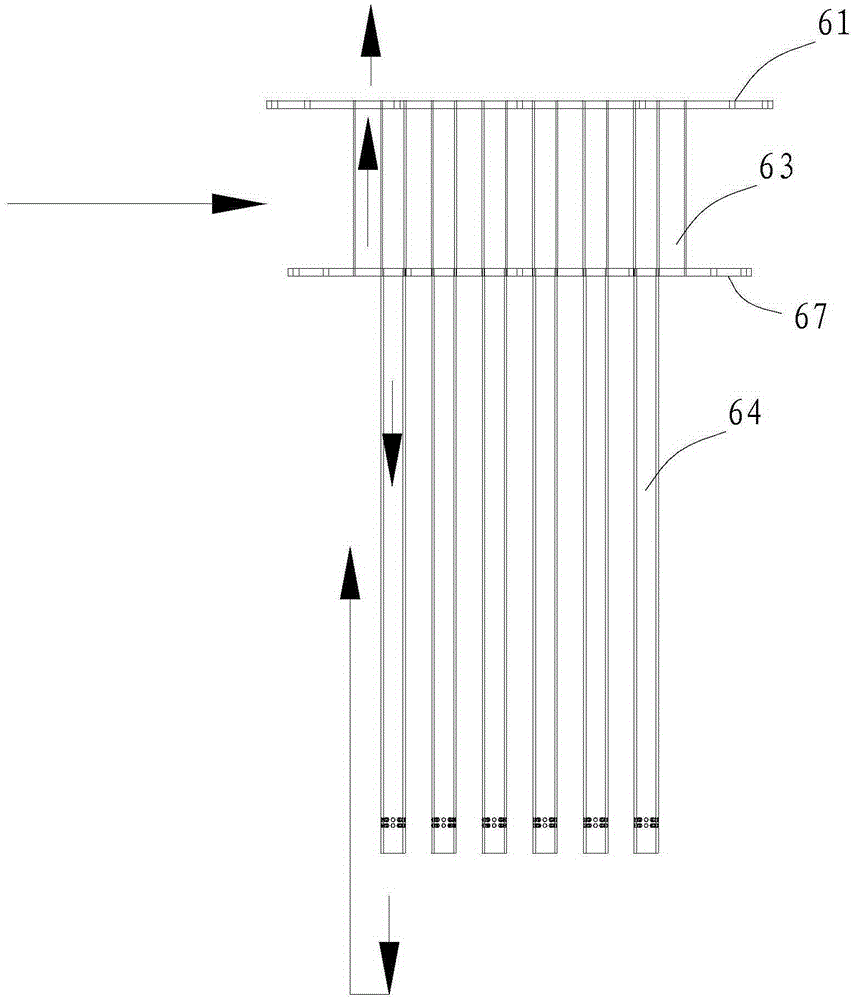

Desulphurization and dust removal integrating flue gas purification device and method

InactiveCN104984633AReduce dust concentrationReduce dissolved salt concentrationUsing liquid separation agentPurification methodsFlue gas

The invention relates to a desulphurization and dust removal integrating flue gas purification device and a desulphurization and dust removal integrating flue gas purification method. The device comprises an absorption tower, wherein a wet desulphurization system and a water-washing deep dedusting system are sequentially arranged in the flue gas flowing direction in the absorption tower. The glue gas enters the absorption tower; after being desulphurized by the wet desulphurization system, the flue gas enters the water-washing deep dedusting system to be deeply cleaned and washed, so that dust concentration in the flue gas and the concentration of dissolving salt in outlet fog drops are reduced, and SO2 and SO3 are also removed to certain degree; finally, the flue gas enters a chimney, cleaning emission is realized, desulphurization and dust removal are integrated, and the flue gas is exhausted without causing pollution.

Owner:BEIJING GUODIAN LONGYUAN ENVIRONMENTAL ENG

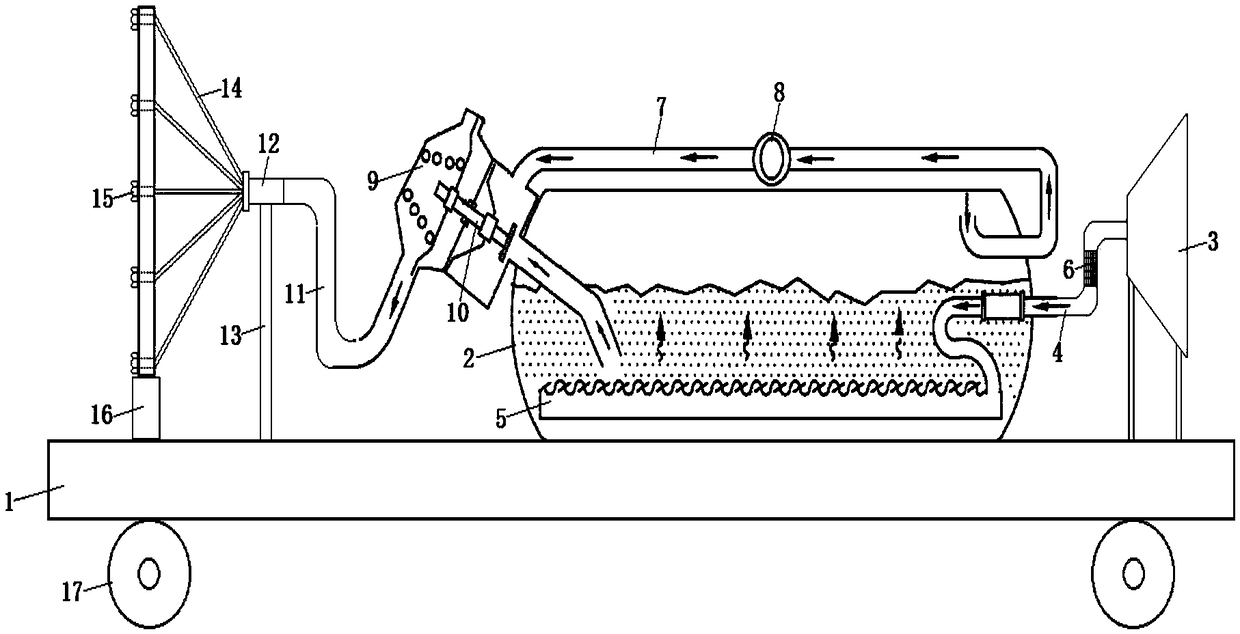

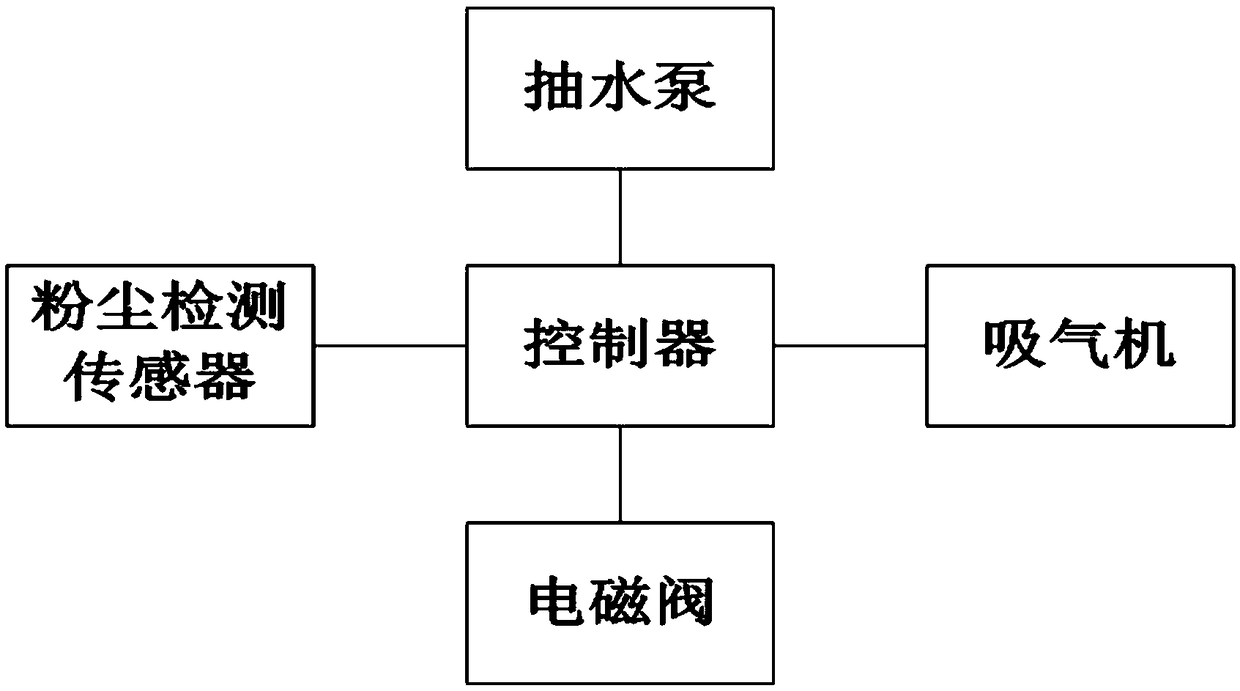

Moveable mist spray and dust removal device in coal mine shaft

InactiveCN108843375AReduce dust concentrationImprove the effectMining devicesDust removalWater pipeCoal

The invention discloses a moveable mist spray and dust removal device in a coal mine shaft. The device comprises a base, wherein a dust removal box is arranged on the base, one side of the dust removal box is provided with an aspirated engine, the aspirated engine is provided with an aspirator pump, and the aspirator pump is communicated with a dust collection box arranged in the dust removal boxthrough an air suction pipeline; the dust removal box is communicated with an air exhaust pipeline, the air exhaust pipeline is connected with an air suction port of the aspirator pump on the dust collection box, and an air outlet of the aspirator pump is connected with a mixing box through a pipeline; the inner portion of the mixing box is provided with a water suction pump, and the water suctionpump is connected with a water storage tank arranged on the dust collection box through a water pipe; the mixing box is further provided with an outlet, and the outlet is connected with an atomizingnozzle. The moveable mist spray and dust removal device in the coal mine shaft detects the dust concentration in the mine shaft through a dust detection sensor, when the detected dust concentration exceeds a preset value, the aspirated engine absorbs the dust in the mine shaft into the dust collection box; and a controller controls the aspirator pump and the water suction pump to work simultaneously, thereby further reducing the dust concentration in the mine shaft.

Owner:肥城矿业集团矿业管理服务有限公司

Bubble tower and method for wet flue gas desulphurization

ActiveCN105381703AImprove desulfurization efficiencySmall volumeCombination devicesGas treatmentFlue gasProcess engineering

The invention discloses a bubble tower and method for wet flue gas desulphurization. The bubble tower comprises an absorbing tower, a bubbling mechanism is arranged in the absorbing tower, the bubbling mechanism is connected to an inlet flue, a humidifying spray mechanism and a dust pre-removal mechanism are orderly arranged in the inlet flue along a flue gas flow direction, the bubbling mechanism comprises a sealed flue gas inlet zone formed from an upper separation plate, a lower separation plate and inner walls of the absorbing tower, the sealed flue gas inlet zone is communicated with the inlet flue, the bubble tower also comprises several vertical bubbling pipes, the upper ends of the bubbling pipes go through the lower separation plate and are communicated with the flue gas inlet zone, the lower ends of the bubbling pipes stretch into the tower bottom, the bubble tower also comprises several vertical flue gas discharge pipes, the flue gas discharge pipes go through the upper separation plate and the lower separation plate, the flue gas discharge pipes and the bubbling pipes are staggered, the bubble tower comprises a flushing pipe network, the flushing pipe network is arranged in the flue gas inlet zone and is located above inlets of the bubbling pipes, and the flushing pipe network is provided with several atomizing nozzles. The bubble tower and method are used for wet flue gas desulphurization and mainly solve the problem that the existing bubble tower easily produces scale in the bubbling pipes so that the bubbling pipes are blocked and bubbling tower normal operation is influenced.

Owner:ZHEJIANG TIANLAN ENVIRONMENTAL PROTECTION TECH

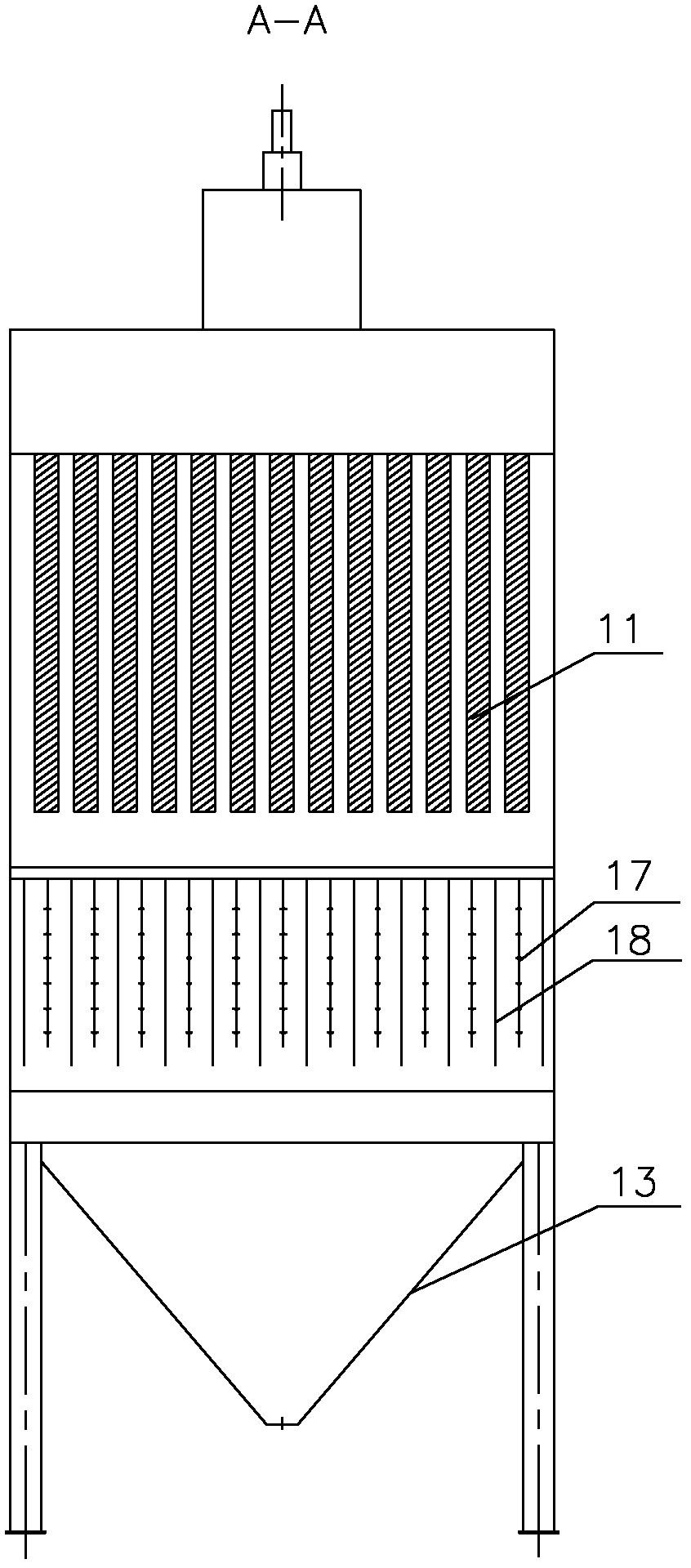

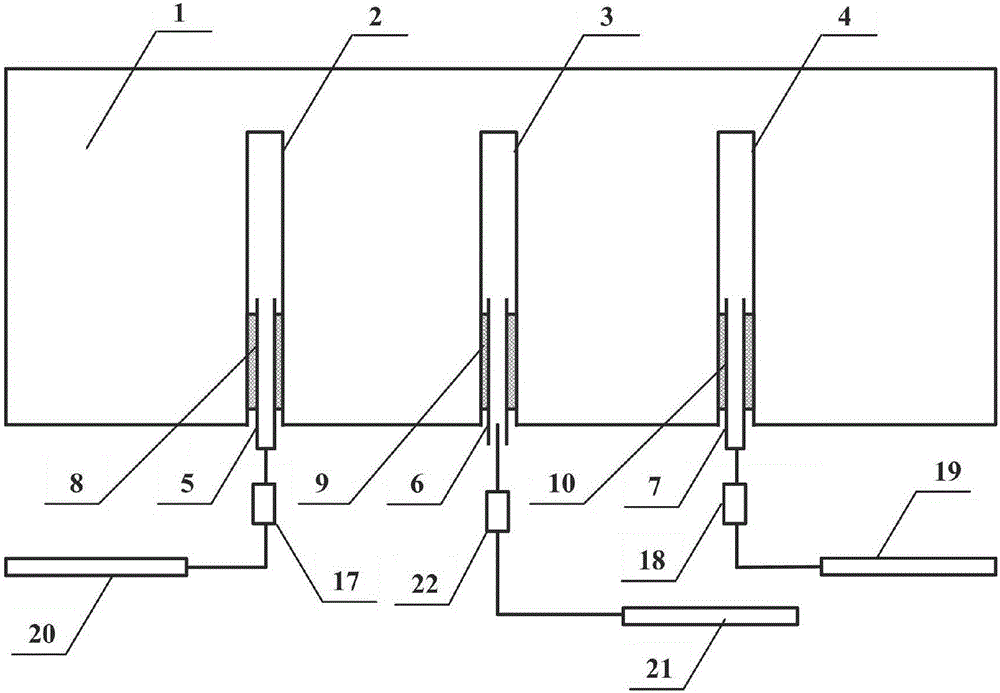

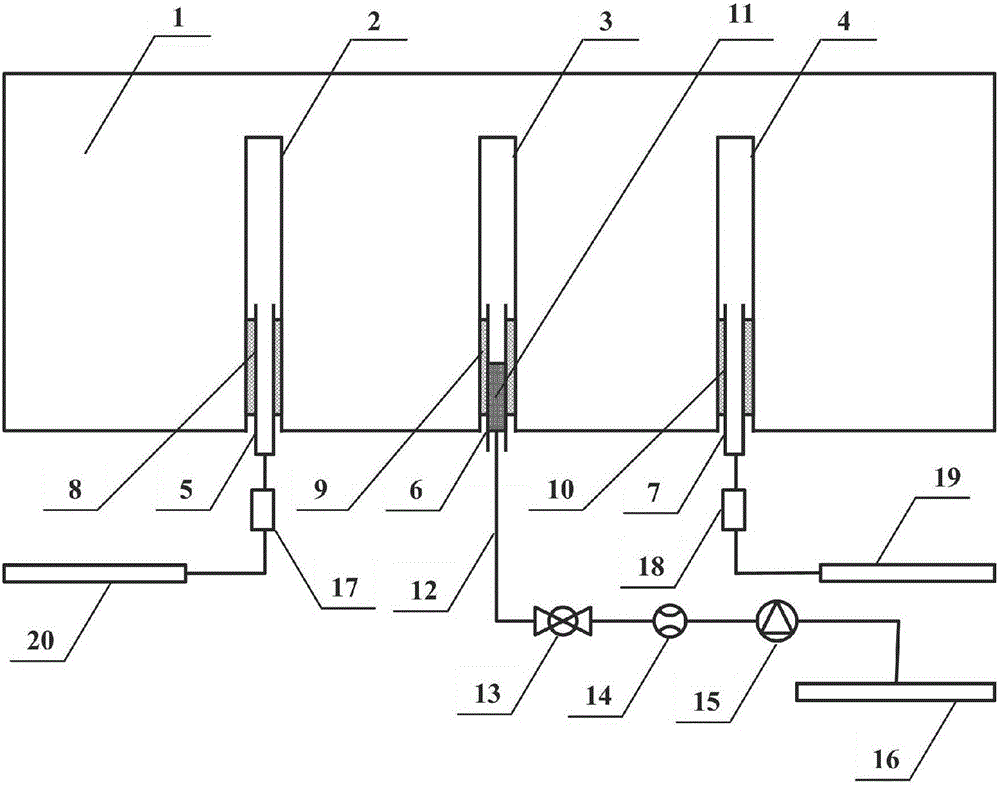

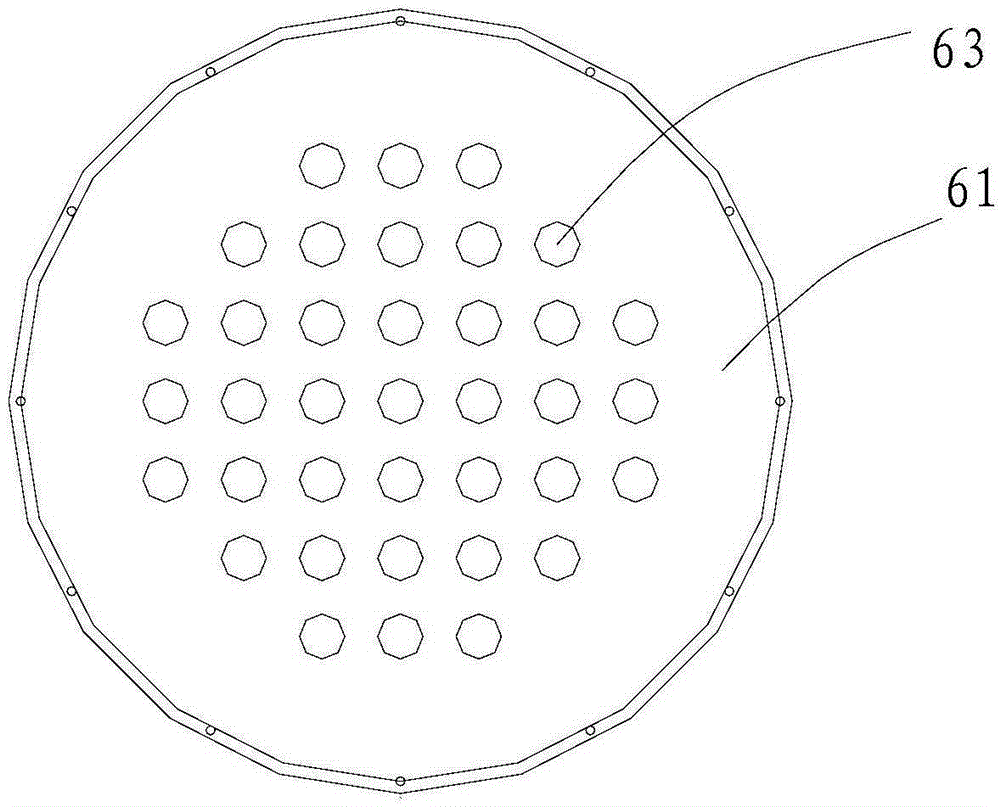

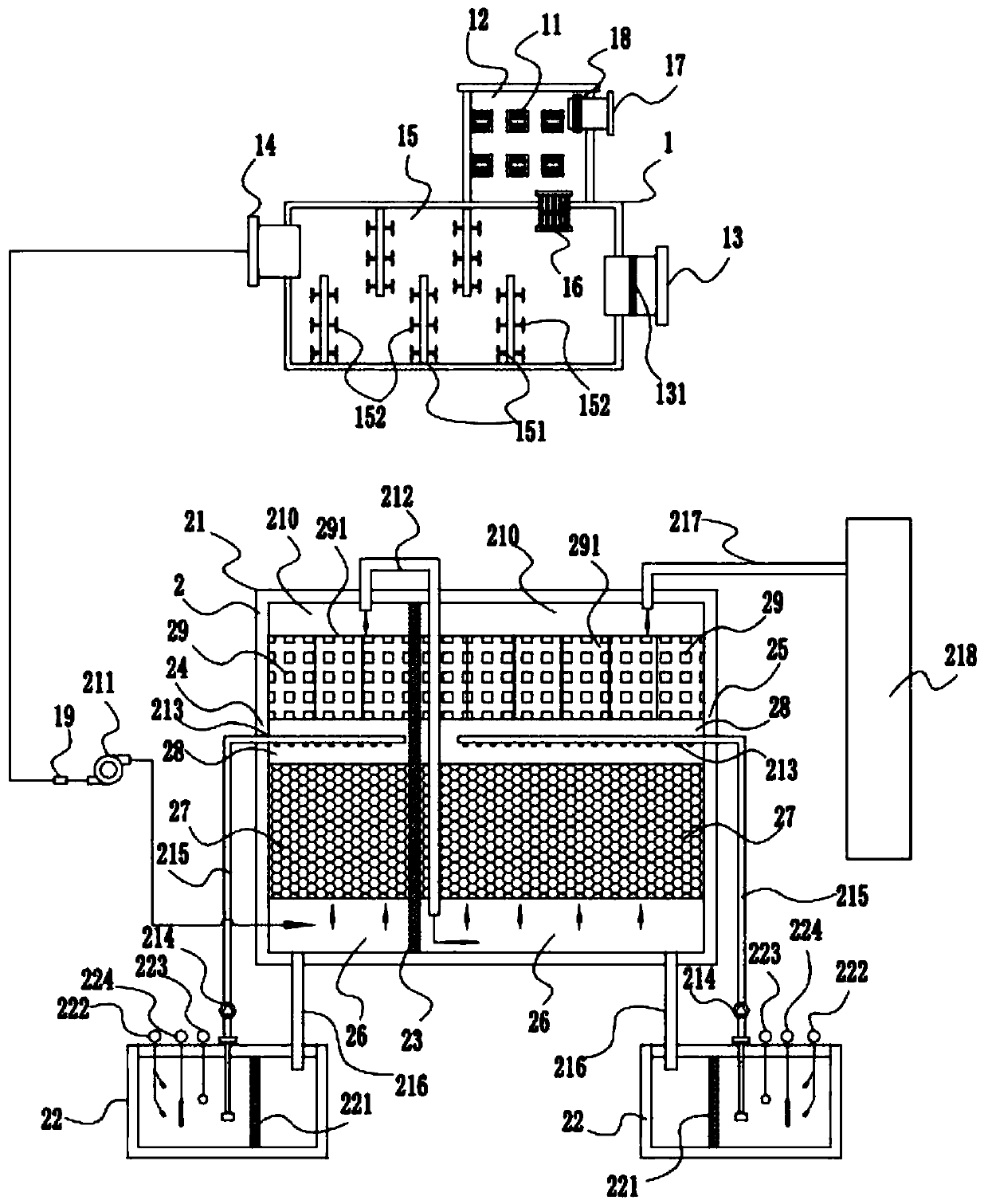

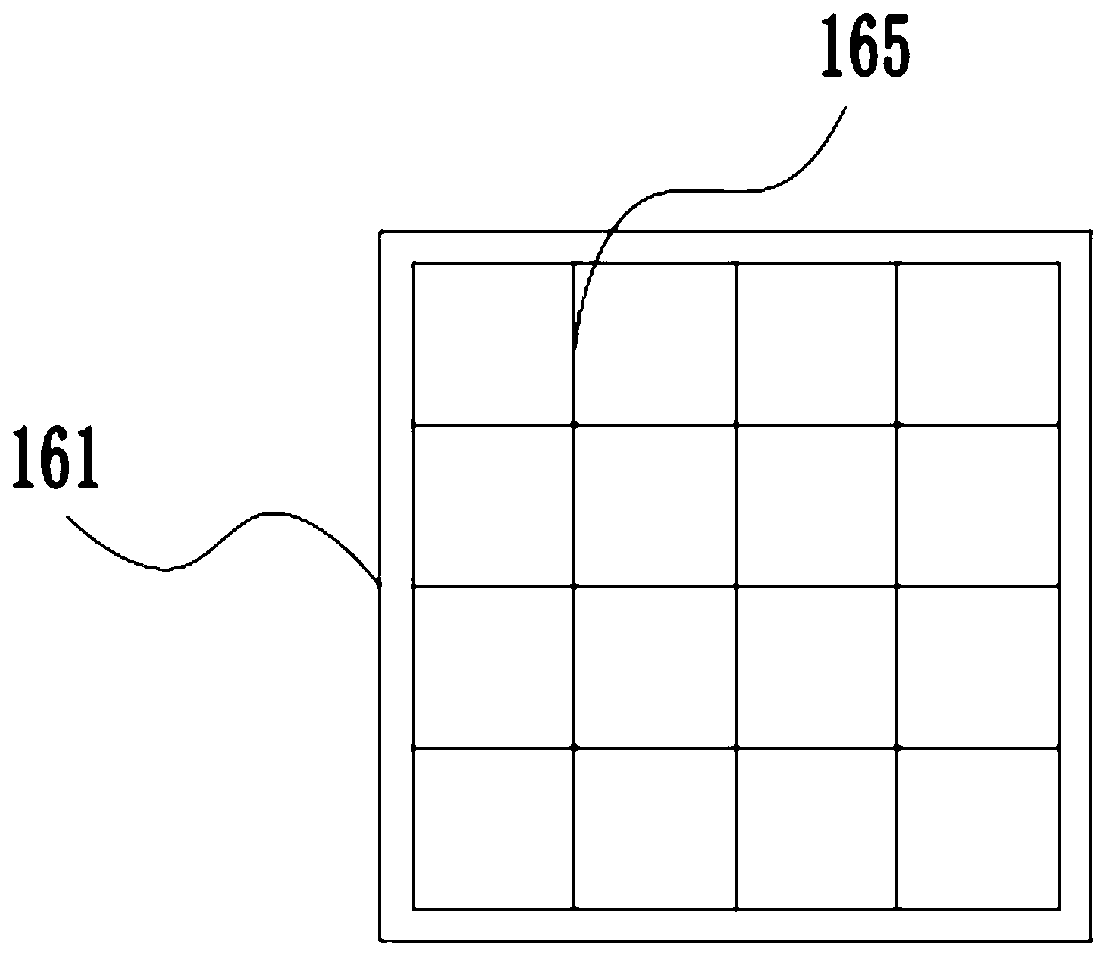

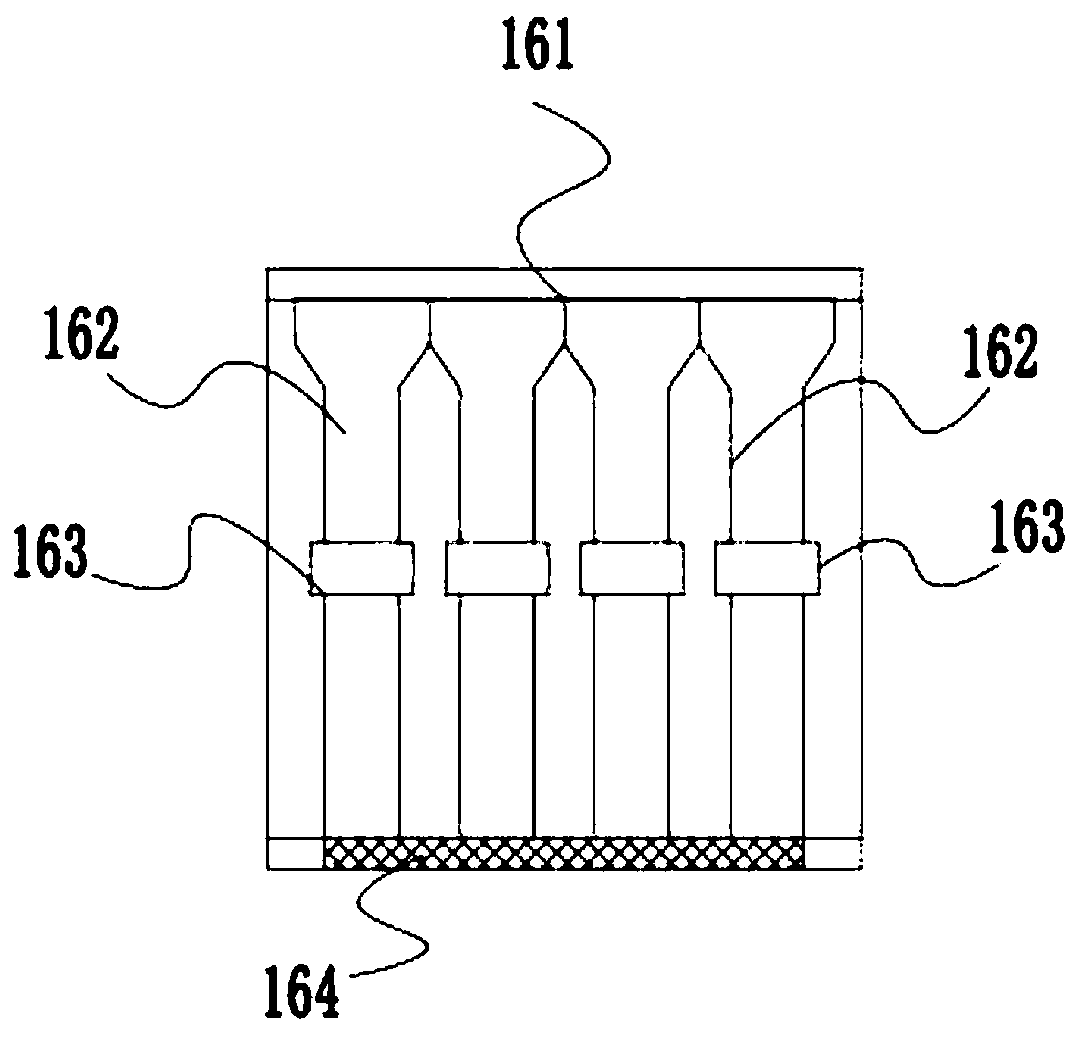

Double-row filter bag embedded type electric bag compound dust catcher with electric field area at front stage

ActiveCN102553382AExtended service lifeAchieve emission standardsHuman health protectionCombination devicesEngineeringAir purification

The invention discloses a double-row filter bag embedded type electric bag compound dust catcher with an electric field area at the front stage, and relates to an industrial dust catcher. The dust catcher is provided with an inlet horn, a casing, a smoke duct, a filter bag, an ash cleaning system, an ash hopper, a discharge electrode, a dust absorbing polar plate, a rear discharge electrode and dust collecting pore plates; the front end and the rear end in the casing are provided with an electric field area at the front stage and an embedded electric bag dedusting area at the rear stage, an air inlet of the electric field area is connected with the inlet horn, and a flow guiding adjusting plate is arranged between an air inlet of the dedusting area and an air outlet of the electric field area; an air purification chamber is arranged at the upper part in the casing, and the air inlet of the air purification chamber is connected with an air outlet of the dedusting area; the air inlet ofthe smoke duct is connected with the air outlet of the air purification chamber, and a lifting valve device is arranged at the top of the smoke duct; the ash hopper is arranged at the bottom of the casing; a bypass valve device is arranged at the top of the electric field area of the front stage, the discharge electrode and the dust absorbing polar plate are arranged at the front end of the casing to form the electric field area of the front stage; the rear discharge electrode and the dust collecting pore plates are arranged at the rear end of the casing to form an electric field of the rear stage; the filter bag is arranged between the two dust collecting pore plates to form a filter area of the filter bag; and the electric field area of the rear stage and the filter bag area form the embedded electric bag dedusting area.

Owner:FUJIAN LONGKING

Working surface dust treating and preventing method based on working surface on-site coal dust diffusion regulation

InactiveCN109630187ASolve difficultySolve efficiency problemsMining devicesDust removalHigh concentrationCoal dust

The invention discloses a working surface dust treating and preventing method based on a working surface on-site coal dust diffusion regulation. A supporting frame negative pressure secondary dust removing device, a coal mining machine negative pressure secondary dust removing device and a wet-type rolling blind dust preventing net, wherein the supporting frame negative pressure secondary dust removing device and the coal mining machine negative pressure secondary dust removing device perform mist spraying dust reducing according to an entrainment mechanism of a water jet, a negative pressurearea can be formed to entrain high concentration dust aggregates in a working area to improve the dust reduction efficiency, the wet-type rolling blind dust preventing net sprays water mist onto a filter net to form a filter membrane under the action of the tension on the surface of water, the bumping probability between dust in air flows and the filter membrane is increased to improve the dust capturing efficiency, the location and manner of three dust reduction measures are designed according to on-site numerical simulation and the distribution of wind flows and the dust, and cooperative using is conducted to achieve the purpose of reducing the dust concentration of the working surface. The method has the advantages that the dust reducing efficiency is improved, and the dust concentration on large-mining-height comprehensive-mining working surface is reduced.

Owner:SHANDONG UNIV OF SCI & TECH

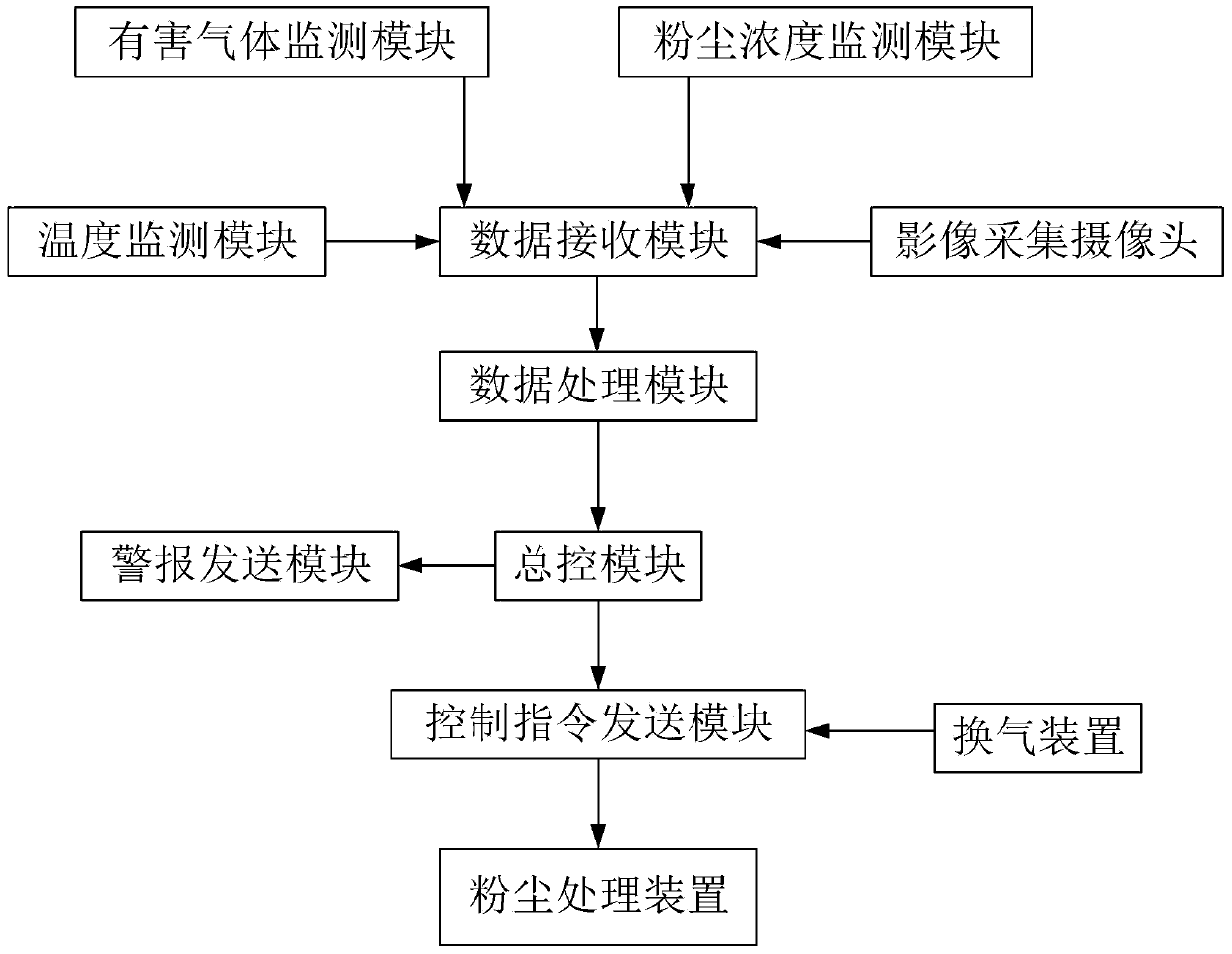

Safety monitoring system for renewable resource plant based on big data

ActiveCN110853291AAvoid casualtiesReduce the situation of absorbing excessive dustMeasurement devicesAlarmsEnvironmental resource managementProcess engineering

The invention discloses a safety monitoring system for a renewable resource plant based on big data. The system comprises a harmful gas monitoring module, a dust concentration monitoring module, a temperature monitoring module, an image acquisition camera, a data receiving module, a data processing module, a master control module, an alarm sending module, a control instruction sending module, a ventilation device and a dust processing device, wherein the harmful gas monitoring module is used to monitor the concentration of harmful gas in the plant, the dust concentration monitoring module is used to monitor the concentration of dust in the plant, the temperature monitoring module is used to monitor temperature information in the plant, and the image acquisition camera is used to collect image information in the plant; and the data receiving module receives the concentration information of harmful gas, the dust concentration, the temperature information, and the image information. The invention has the beneficial effects of being able to better perform safety monitoring, providing more functions and being able to handle the problems occurring during the monitoring.

Owner:ANHUI HUANJIA TIANYI RENEWABLE RESOURCES

System, technology and method for de-nitrating flue gas of cement kiln and recovering waste heat of flue gas of cement kiln

PendingCN109966812AAchieve clean emissionsReduce contentCombination devicesGas treatmentFlue gasProcess engineering

The invention discloses a system, technology and method for de-nitrating flue gas of a cement kiln and recovering the waste heat of flue gas of a cement kiln. The system comprises a preheater, a wasteheat boiler, a highly hot air blower, a high temperature bag deduster, an SCR denitration reactor, a raw mill, a kiln tail deduster, an induced draft fan, a heat exchanger, and a chimney. A flue gasoutlet in the tail part of a rotary cement kiln is communicated with an inlet in the lower part of the preheater through a pipeline. The outlet in the top of the preheater is communicated with the inlet in the top of the waste heat boiler through a pipeline. The outlet in the lower part of the waste heat boiler is communicated with the inlet of the high temperature bag deduster through a pipeline.The outlet of the high temperature bag deduster is communicated with the inlet of the SCR denitration reactor through a pipeline. The outlet in the bottom of the SCR denitration reactor is communicated with the inlet of the raw mill through a pipeline. The outlet of the raw mill is communicated with the inlet of the kiln tail deduster through a pipeline. The ultralow temperature waste heat utilization and ultralow pollutant discharge are effectively co-researched. The content of NOx in flue gas of a cement kiln is efficiently reduced, the energy consumption is low, and finally discharged fluegas meets the discharge requirements.

Owner:BEIJING GUODIAN LONGYUAN ENVIRONMENTAL ENG

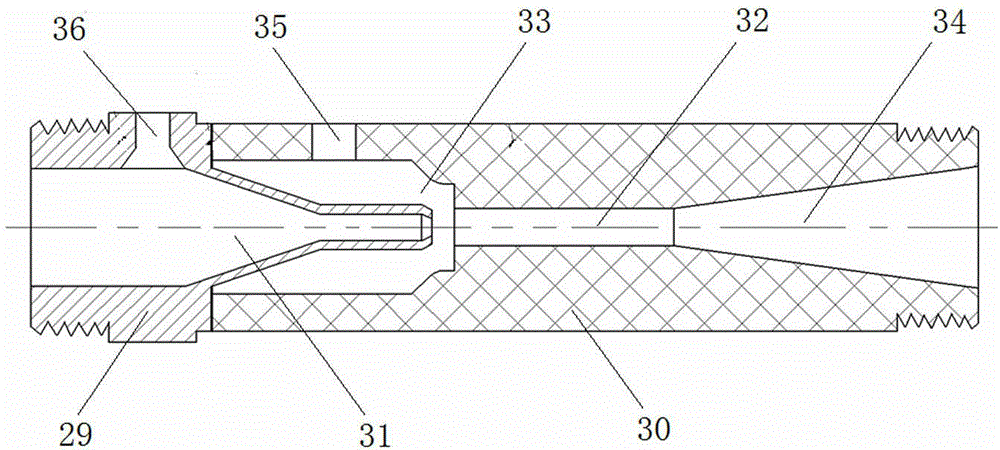

Low-concentration viscose wastewater and waste gas treatment system

ActiveCN110449002AReduce dust concentrationReduce the risk of explosionGas treatmentDispersed particle filtrationPollutionDisposal Technique

The invention discloses a low-concentration viscose wastewater and waste gas treatment system and belongs to the technical field of waste gas treatment. aiming at solving the problems that a single treatment technique is poor in effect, carbon disulfide is liable to combust and explode, and the like since a low-concentration waste gas which is generated in a viscose wastewater treatment process iscomplex in constitution (within carbon disulfide, hydrogen sulfide, volatile organic compounds and the like), the invention provides a novel treatment system which consists of plasma deodorization equipment and biological deodorization equipment in serial connection. A waste gas is fed into the plasma deodorization equipment, and a plasma generation chamber and a plasma reaction chamber are indirectly connected through a butt joint component, so that the problem that explosion is caused as a plasma pipeline group is in direct contact with flammable and combustible waste gases such as the carbon disulfide can be avoided; meanwhile, pollutants such as the carbon disulfide can be rapidly degraded and are fed into a biological deodorization system for secondary removal, so that the pollutantremoval efficiency, the removal rate and the operation security can be greatly improved; and in addition, the system has the advantages of being low in investment cost, free of secondary pollution, and the like.

Owner:恩宜瑞(江苏)环境发展有限公司

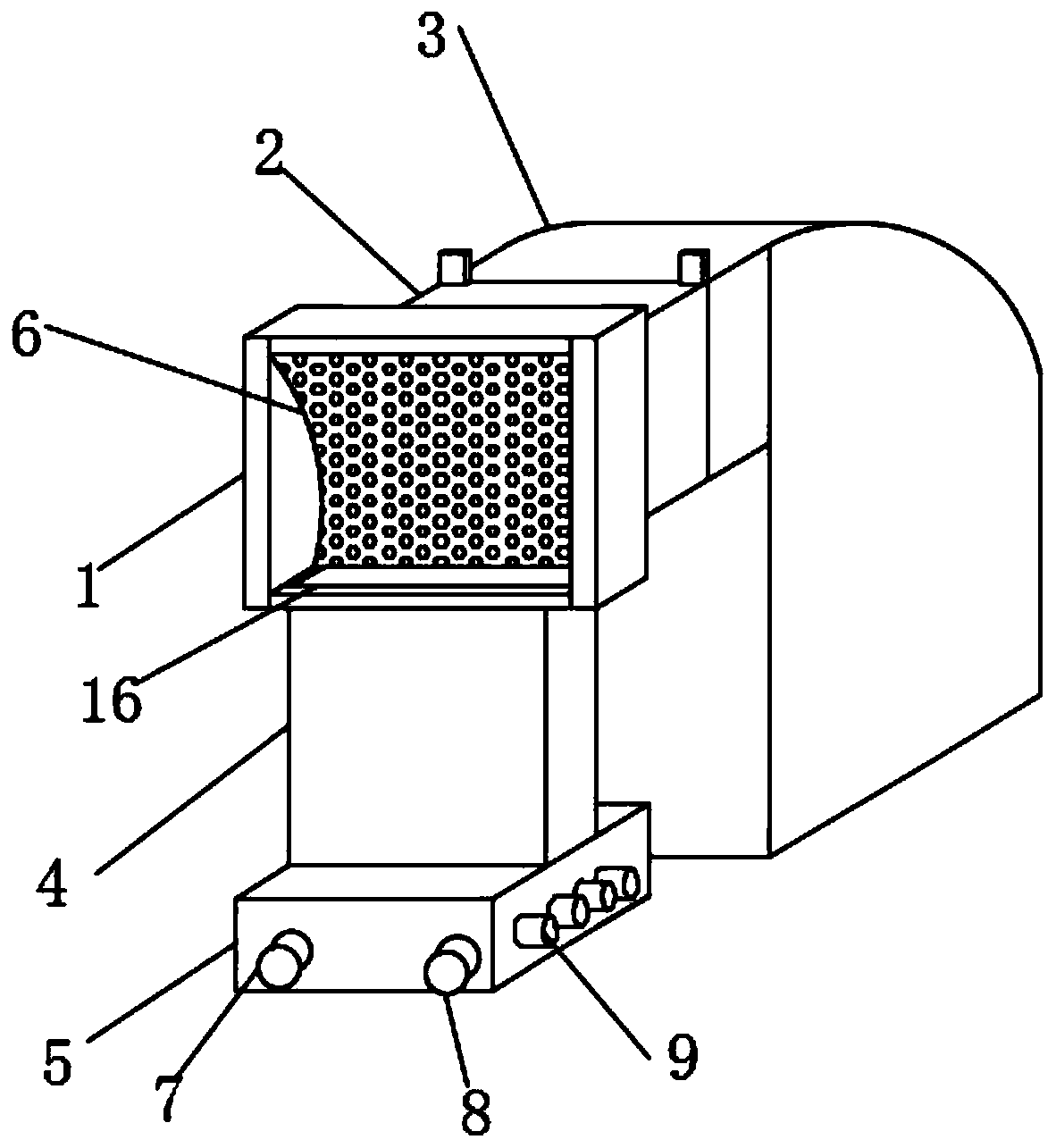

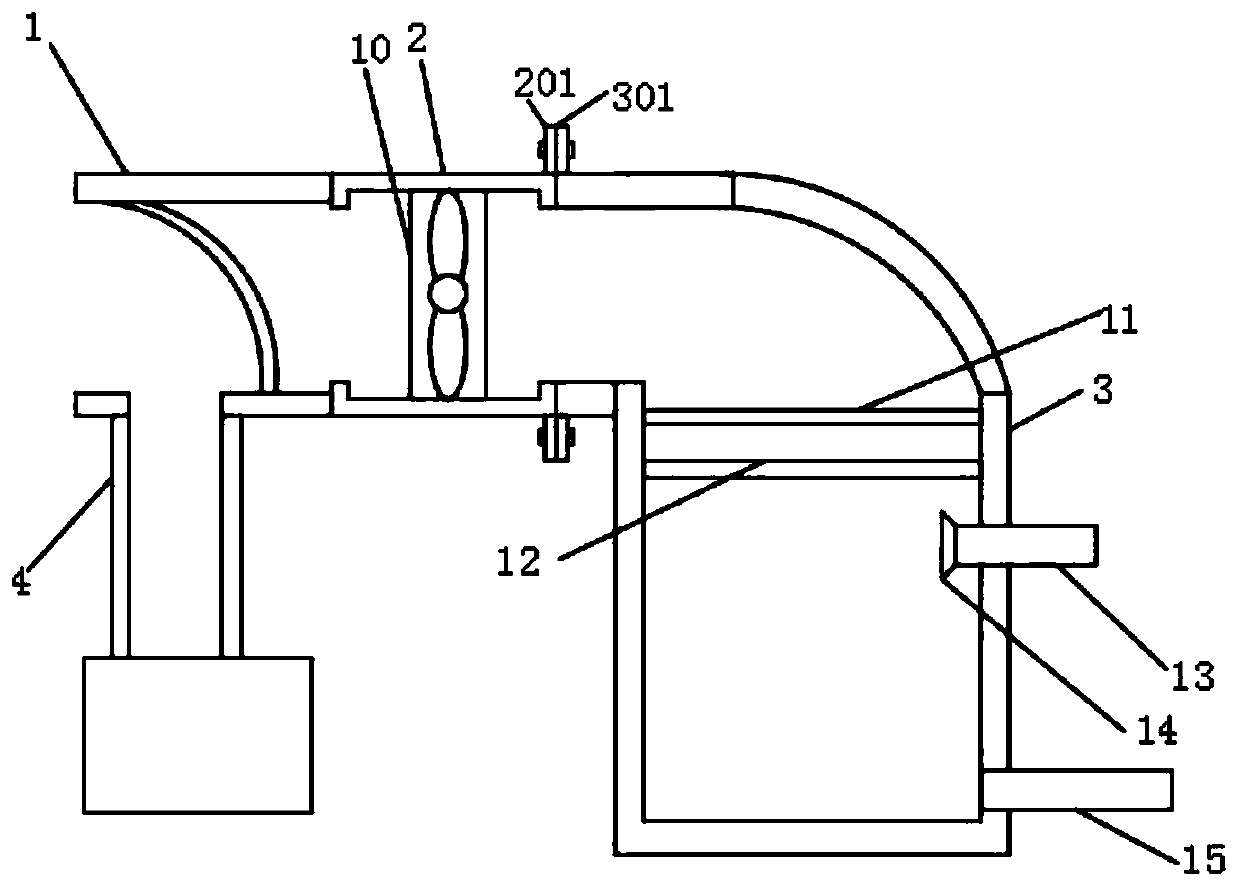

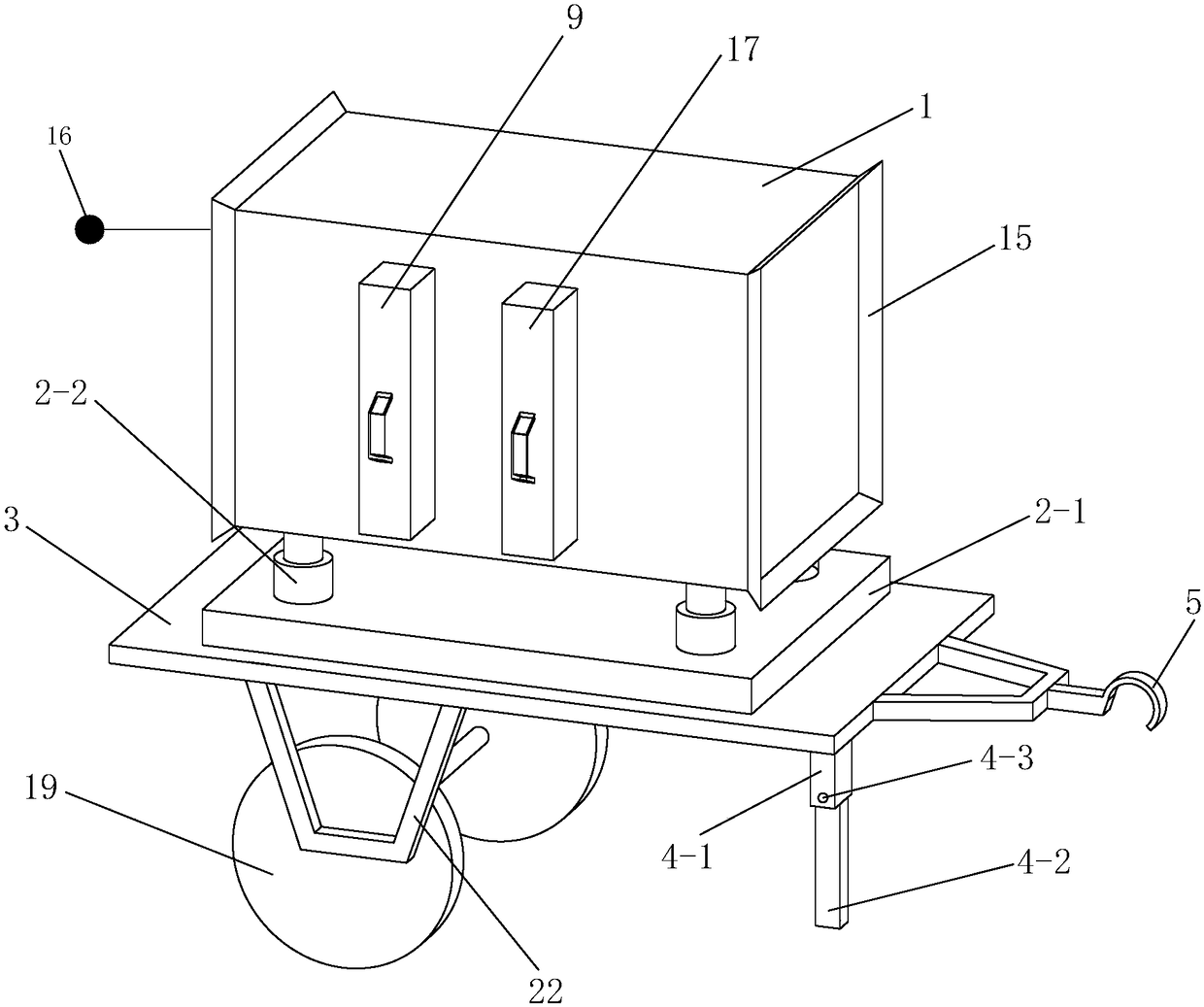

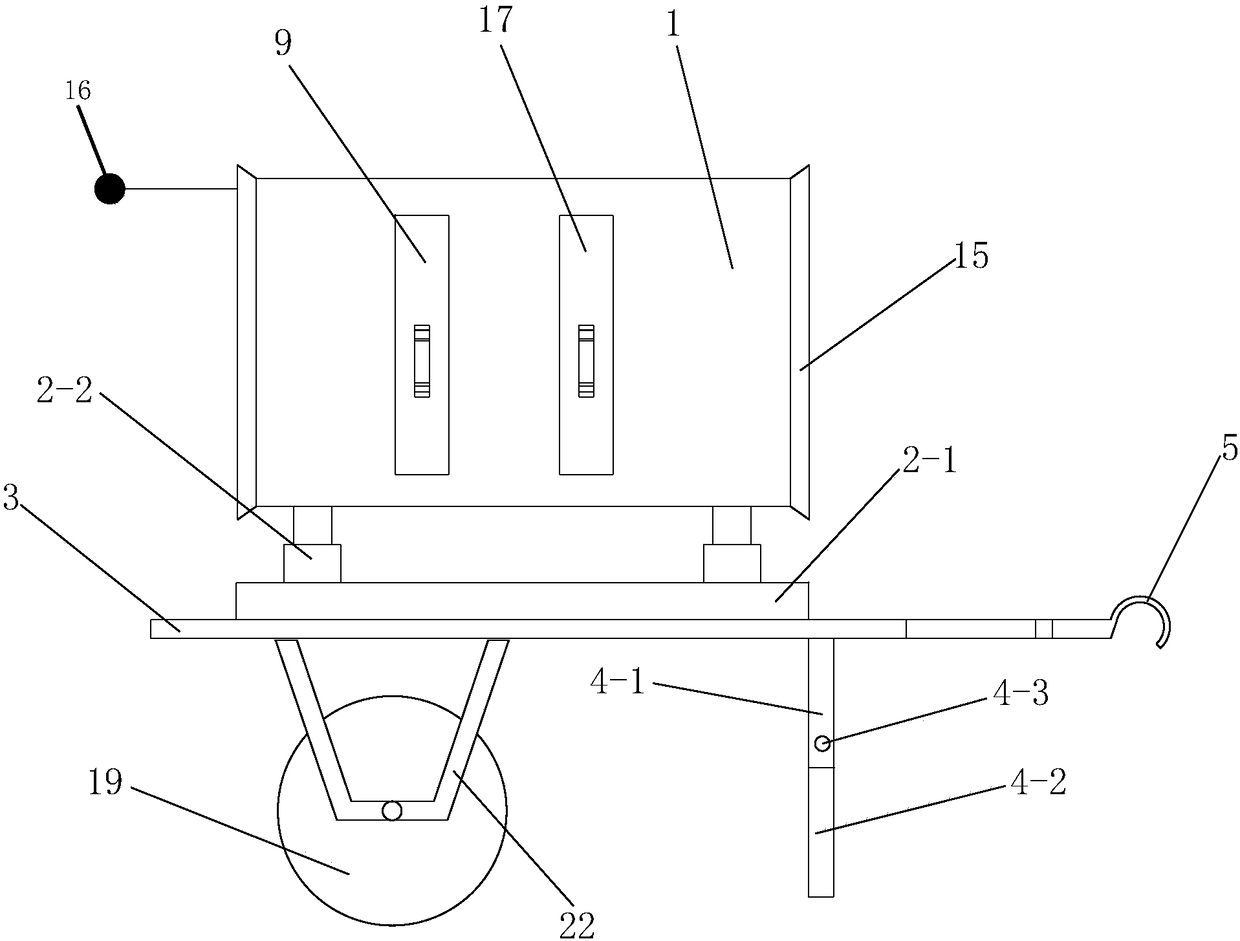

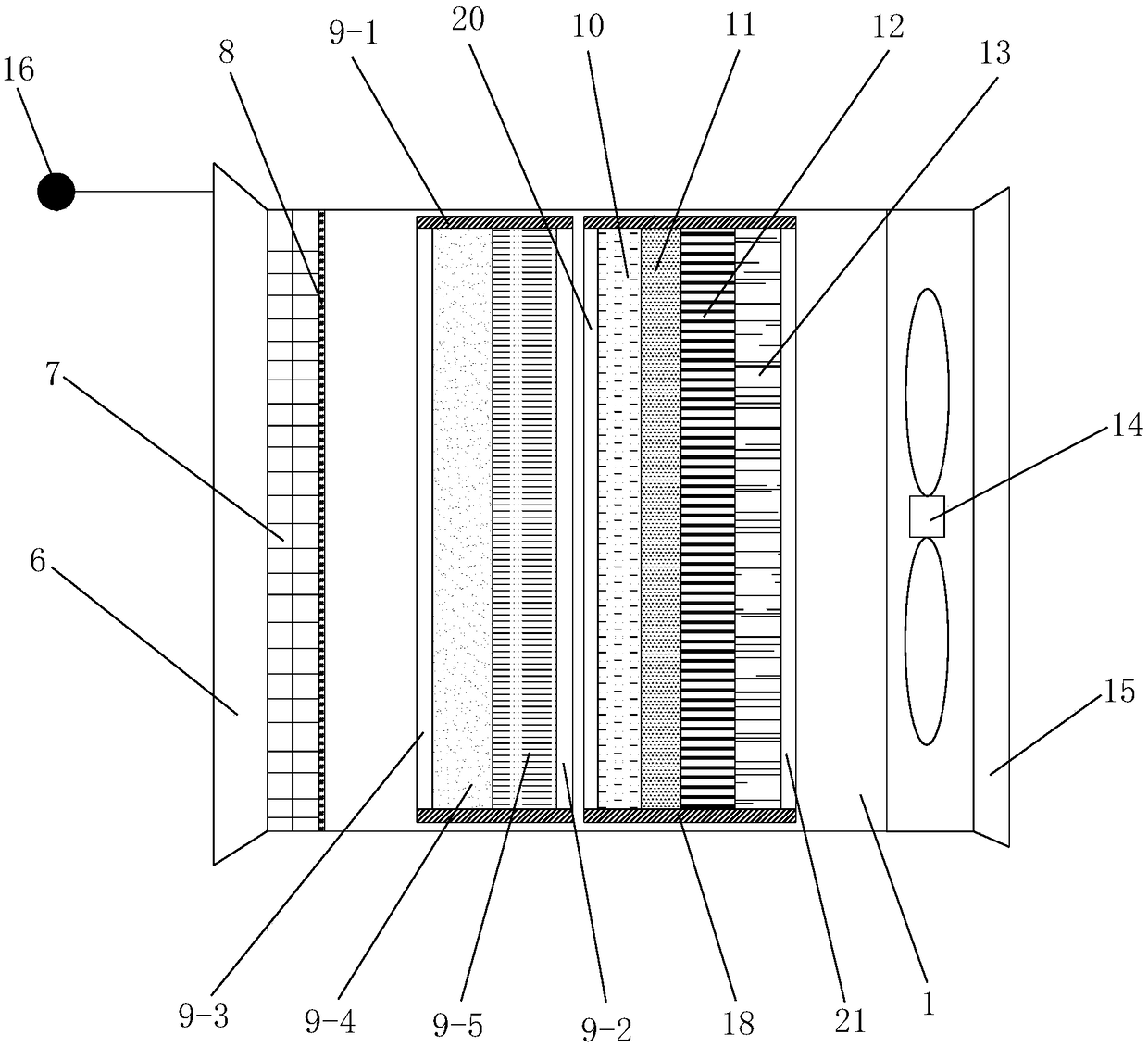

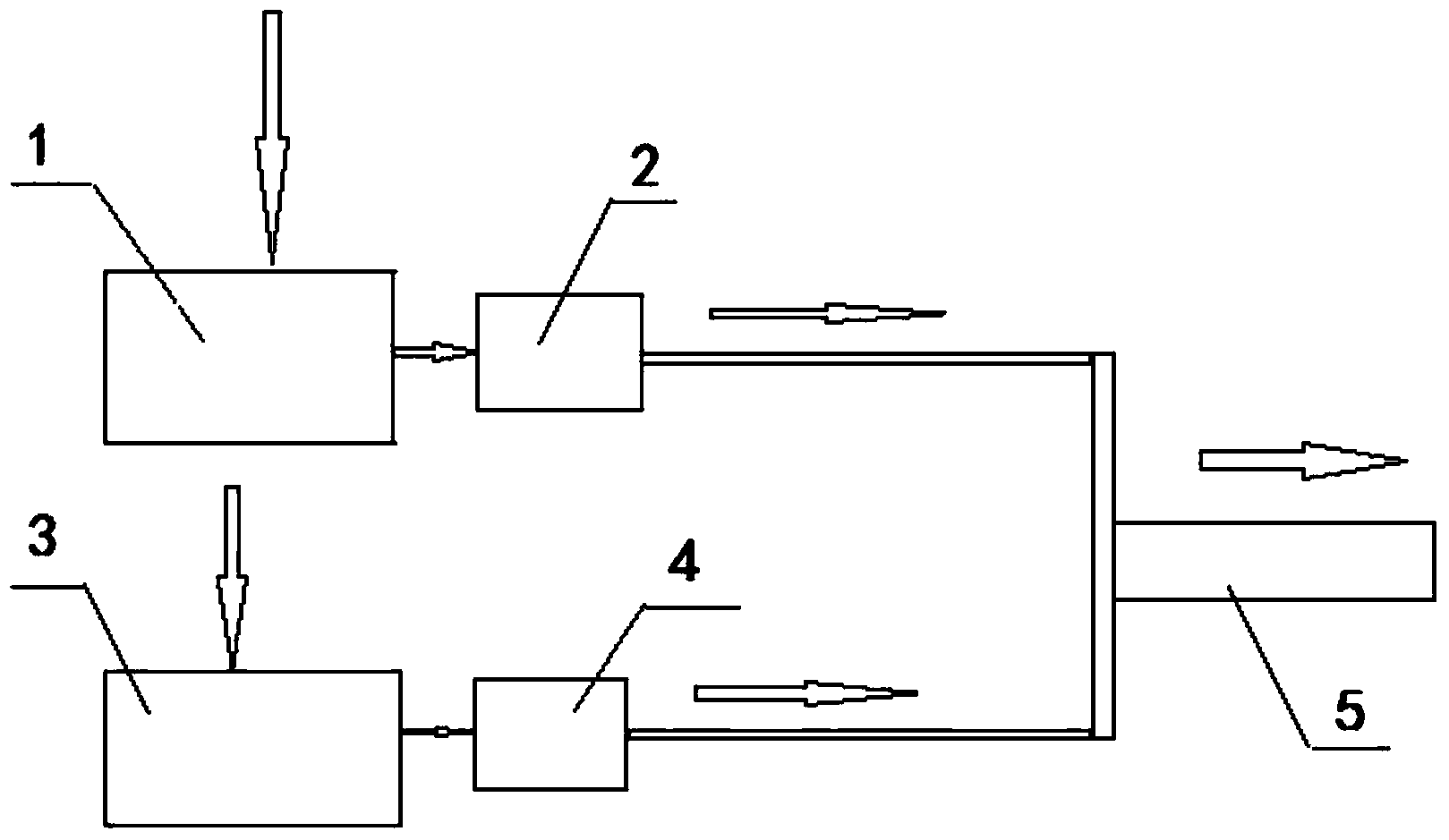

Movable mineral porous medium stage purification dust removing device and dust removing method

The invention discloses a movable mineral porous medium stage purification dust removing device. The movable mineral porous medium stage purification dust removing device comprises a movable mechanism, a lifting mechanism and a changeable porous medium stage purification main body; the lifting mechanism is arranged on the movable mechanism; the changeable porous medium stage purification main bodyis arranged on the lifting mechanism; the movable mechanism comprises a vehicle body; rubber wheels are arranged on the rear side of the bottom of the vehicle body; a telescopic support rod is arranged on the front side of the bottom of the vehicle body; the changeable porous medium stage purification main body comprises a casing; an air inlet is formed in the rear end of the casing; an air outlet is formed in the front end of the casing; a gas sensor is arranged at the air inlet; an air deflector, a dust retaining net, a replaceable prefiltering layer, a replaceable stage filtering layer anda fan are arranged in the casing from rear to front. The invention also provides a movable mineral porous medium stage purification dust removing method using the device. According to the movable mineral porous medium stage purification dust removing device and the movable mineral porous medium stage purification dust removing method disclosed by the invention, by adopting a dry type dust removing mode, the problem of forming a mud blockage filtering layer by wet dust removal is solved, and the demands of purification and dust removal of local air in an underground coal mine can be met.

Owner:XIAN UNIV OF SCI & TECH

Wet-type concrete spraying process

InactiveCN103527220AReduce dust concentrationReduce material reboundUnderground chambersTunnel liningCoalElectricity

The invention discloses a wet-type concrete spraying process and belongs to concrete spraying processes. According to the wet-type concrete spraying process, cement and gravel are conveyed to a spray gun respectively in two branches; after the gravel and a powdery accelerating agent are proportionally mixed and stirred through a stirring mechanism, one branch enters a conveying mechanism, and the gravel is conveyed to the spray gun; after the cement and water are proportionally mixed and stirred through a mixing and stirring mechanism, the other branch is conveyed to the spray gun through a grout conveying pump; after being mixed in the spray gun, the two branches are sprayed to a spray-receiving face through the spray gun. According to the technical scheme, the process can achieve the purposes of falling dust and being slight in springback, change the status quo that a liquid accelerating agent must be used in a traditional wet spraying process, reduce additive cost in wet spraying construction, and guarantee material conveying distances. The process can be widely applied to grout spraying construction in the various industries of coal mine, water and electricity, tunnels, municipal engineering and the like.

Owner:JIANGSU DINGJIA TECH

Differential pressure mining dust removing agent automatic adding device

InactiveCN104632269AReduce dust concentrationImprove working environmentFlow mixersTransportation and packagingImpellerWater pipe

The invention particularly relates to a differential pressure mining dust removing agent automatic adding device and solves problems of high energy consumption, complicated structure and high fault rate in terms of existing dust removing devices. A filtrate net and a valve body integrated box are arranged at the bottom inside a liquid storing tank, a vent valve, a liquid adding opening and a pressure ventilation pipe are arranged at the top of the liquid storing tank, a liquid bag is disposed inside an agent adding box, a water inlet pipe is disposed at one end of a jet flow negative pressure pipe, an impeller stirrer is mounted at the other end of the jet flow negative pressure pipe, a flow guide water pipe is arranged between the valve body integrated box and a liquid inlet of the liquid bag, a single-way throttling valve and a back pressure valve are disposed on the flow guide water pipe, an agent adding pipe is disposed between a liquid outlet of the liquid bag and the side wall of the jet flow negative pressure pipe, a flowmeter and a proportional valve are disposed on the agent adding pipe, a side pressure water inlet pipe is disposed between the agent adding box and the jet flow negative pressure pipe, and a water inlet control valve is disposed on the side pressure water inlet pipe. According to the differential pressure mining dust removing agent automatic adding device, automatic adding of an agent is achieved, dust concentration on an excavation surface is effectively lowered, and working environment of an excavation work face is greatly improved.

Owner:TAIYUAN UNIV OF TECH

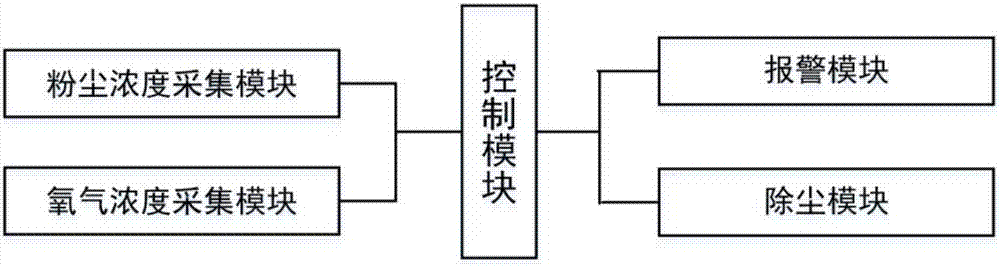

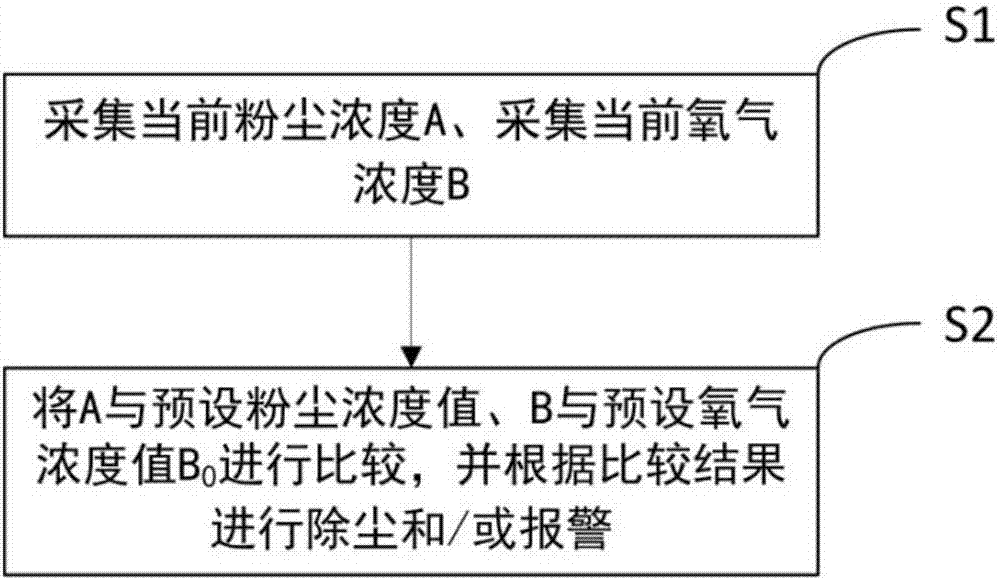

Safety monitoring system and method for flour processing

InactiveCN107045313AReduce dust concentrationAvoid safety hazardsProgramme controlComputer controlEngineeringOxygen

The invention discloses a safety monitoring system and method for flour processing. The system comprises a dust concentration collection module, an oxygen concentration collection module, an alarm module, a dust removing module, and a control module. To be specific, the dust concentration collection module is used for collecting the current dust concentration A; the oxygen concentration collection module is used for collecting the current oxygen concentration B; the alarm module connected with the control module is used for carrying out action based on an instruction from the control module to send out warning information; the dust removing module connected to the control module is used for carrying out action based on an instruction from the control module to remove dust; and the control module is in communication connection with the dust concentration collection module and the oxygen concentration collection module. The control module obtains the current dust concentration A by the dust concentration collection module, obtains the current oxygen concentration B by the oxygen concentration collection module, compares the A with a preset dust concentration value and compares the B and a preset oxygen concentration value B0, and controls the alarm module and the dust removing module to carry out processing by integration of two comparison results.

Owner:无为皖江粮食机械有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com