Wet-type concrete spraying process

A technology of concrete spraying and crafting, which is applied in earthwork drilling, wellbore lining, tunnel lining, etc. It can solve the problems of complex hydraulic system maintenance, inability to convey concrete, and short conveying distance, so as to improve the working environment and avoid occupational diseases. The effect of reducing the cost of additives

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

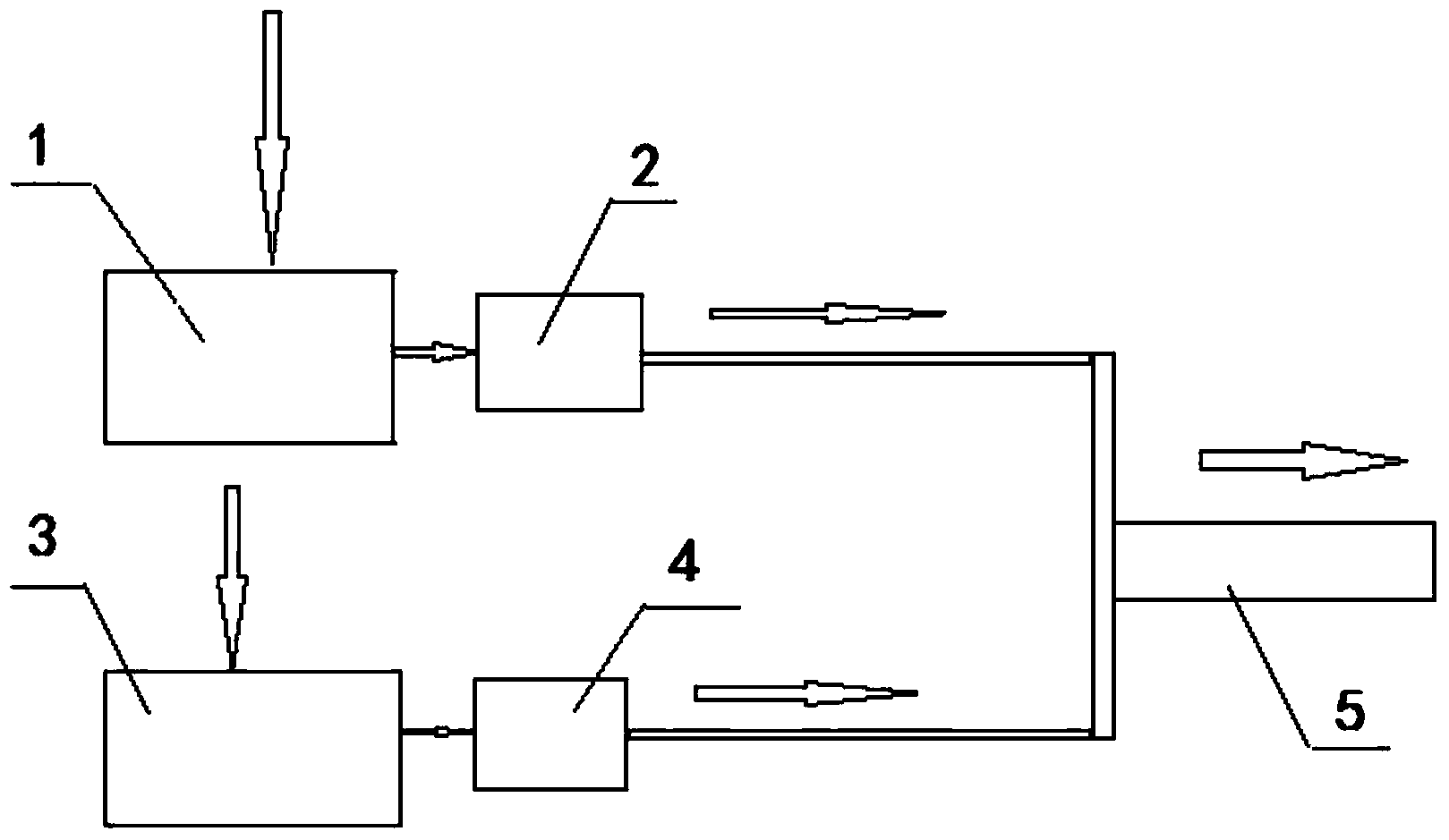

[0010] Equipment used: electric screw mixer, rotor concrete sprayer, pneumatic mixing mechanism and pneumatic slurry pump

[0011] Specific spraying method: one way: dry sand and powdery quick-setting agent are stirred by electric screw mixer 1, then sent to rotor concrete sprayer 2 and sent to spray gun 5; the other way: cement and water are mixed by pneumatic stirring mechanism 3 The cement slurry is transported to the spray gun 5 by the pneumatic slurry pump 4, mixed with sandstone and powdered quick-setting agent, and sprayed to the surface to be sprayed.

[0012] Such as figure 1 Shown, described stirring mechanism 1 for sandstone, quick-setting agent comprises any kind of stirring mechanism of any structural principle in manual, pneumatic, hydraulic, electric or other driving modes; The conveying mechanism 2 for quick-setting agent delivery includes any conveying mechanism of any structure in manual, pneumatic, hydraulic, electric or other driving modes; the cement and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com