Safety monitoring system and method for flour processing

A safety monitoring system and safety monitoring technology, applied in the field of grain processing, can solve problems such as excessive dust concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

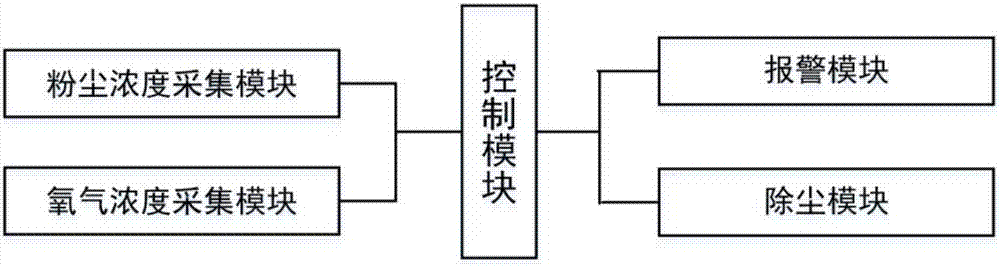

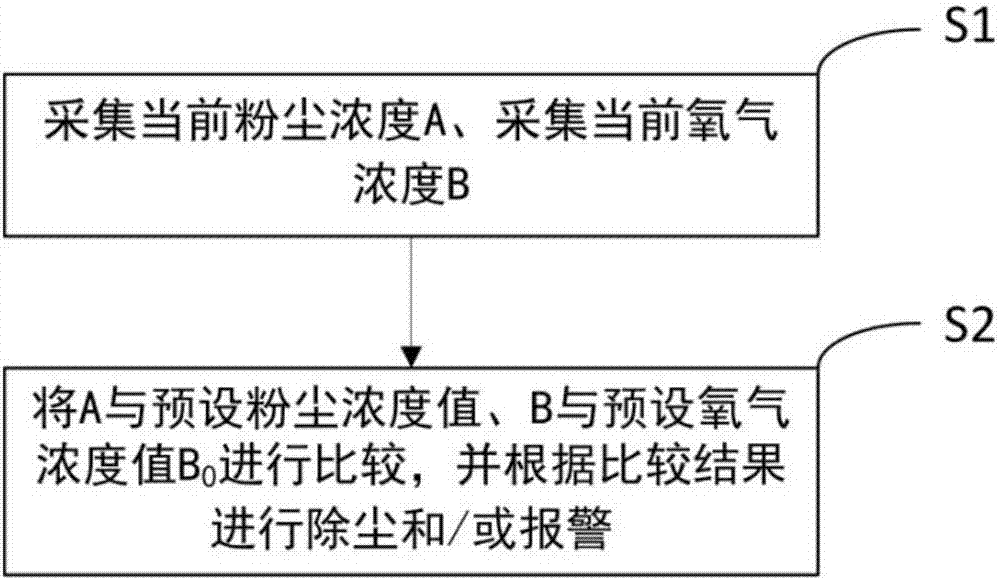

[0036] refer to figure 1 , a kind of flour processing safety monitoring system that the present invention proposes, and this system comprises:

[0037] The dust concentration collection module is used to collect the current dust concentration A;

[0038] The dust concentration collection module includes at least one dust concentration collection sub-module, and any dust concentration collection sub-module includes at least one dust concentration detector;

[0039] In this embodiment, a dust concentration detector is placed in the flour processing site to collect the dust concentration in the site. When multiple dust concentration detectors are used, the average value of the dust concentrations collected by all the dust concentration detectors is calculated. Get the current dust concentration A.

[0040] The oxygen concentration acquisition module is used to collect the current oxygen concentration B;

[0041] The oxygen concentration acquisition module includes at least one...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com