System, technology and method for de-nitrating flue gas of cement kiln and recovering waste heat of flue gas of cement kiln

A waste heat recovery and cement kiln technology, applied in the field of air pollutant control, can solve the problems of high energy consumption, complex control process of ultra-low nitrogen oxide emissions, easy blockage of catalysts, etc., and achieve ultra-low emission effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The technical solutions of the present invention are described in detail below through the examples, and the following examples are only exemplary, and can only be used to explain and illustrate the technical solutions of the present invention, but cannot be construed as limitations to the technical solutions of the present invention.

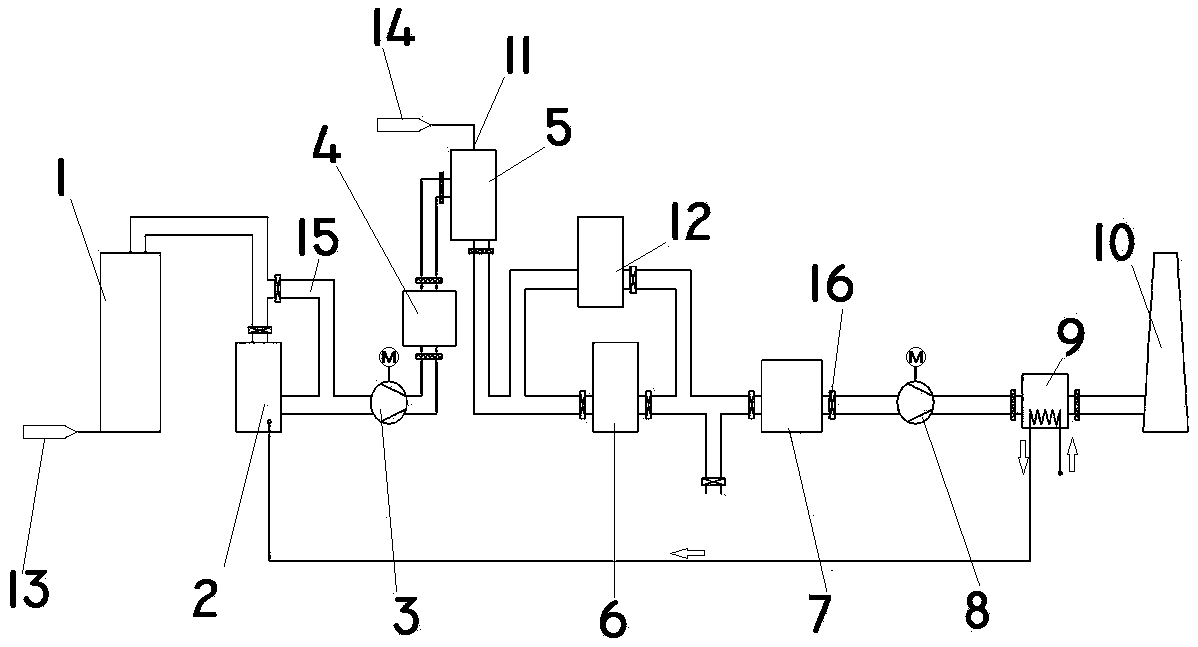

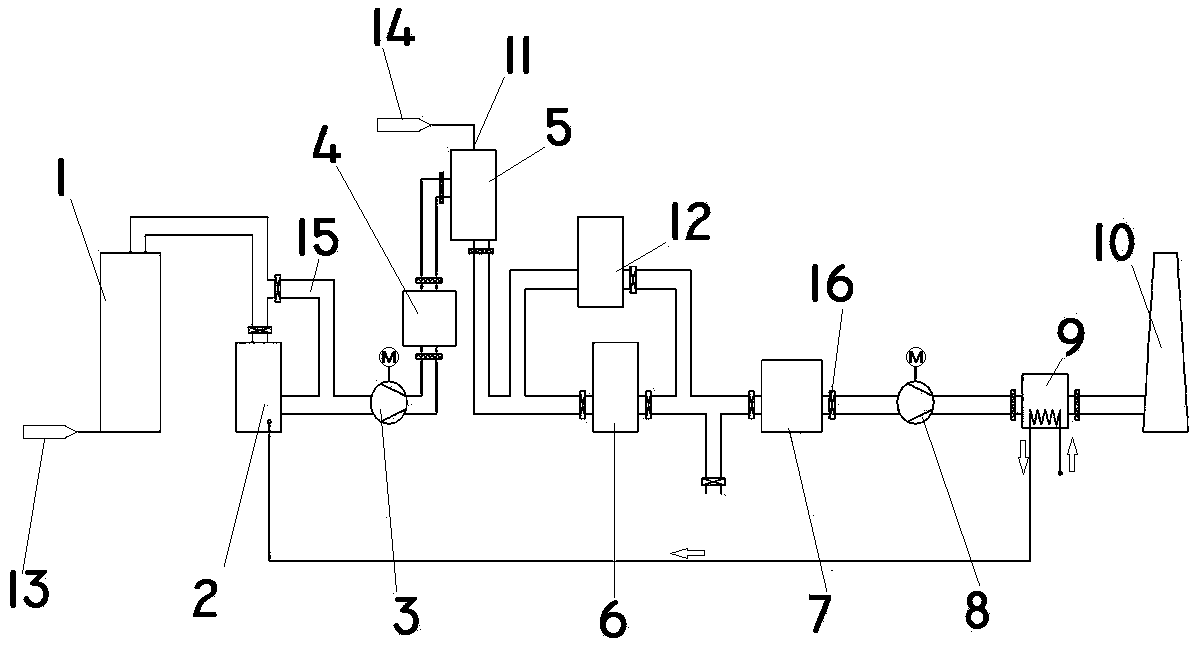

[0040] Such as figure 1 As shown, in view of the typical production process and emission characteristics of flue gas pollutants in the cement industry, combined with source process emission reduction and terminal collaborative control, the present invention provides a cement kiln tail flue gas denitrification and waste heat recovery system to realize nitrogen oxides Ultra-low emissions.

[0041] Specifically, it includes preheater 1, waste heat boiler 2, high-heat fan 3, high-temperature bag filter 4, SCR denitrification reactor 5, raw meal mill 6, kiln tail dust collector 7, induced draft fan 8, heat exchanger 9, booster Wet tower 12 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com