Patents

Literature

63results about How to "No need to increase the size" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

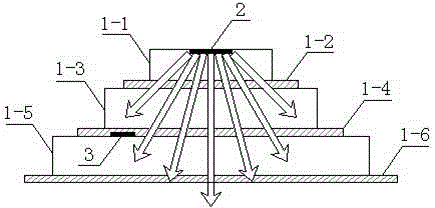

PACT (powdered activated carbon treatment) process and device, and activated carbon-microbial zoogloea culture method using same

ActiveCN103086503AImprove settlement performanceProportionally largeSustainable biological treatmentWater/sewage treatment by sorptionZoogloeaWater treatment system

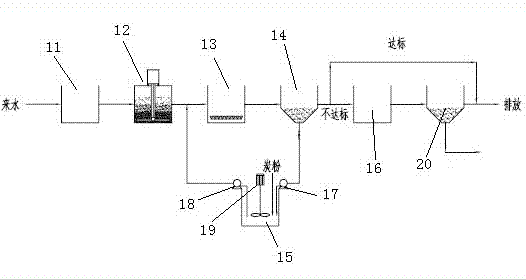

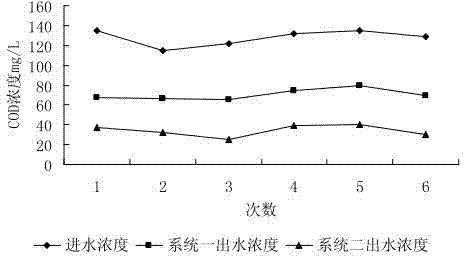

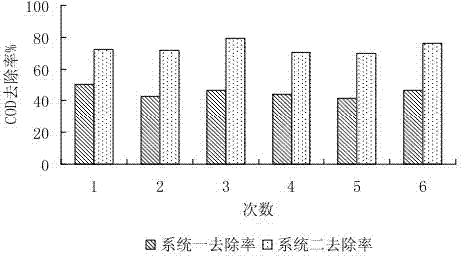

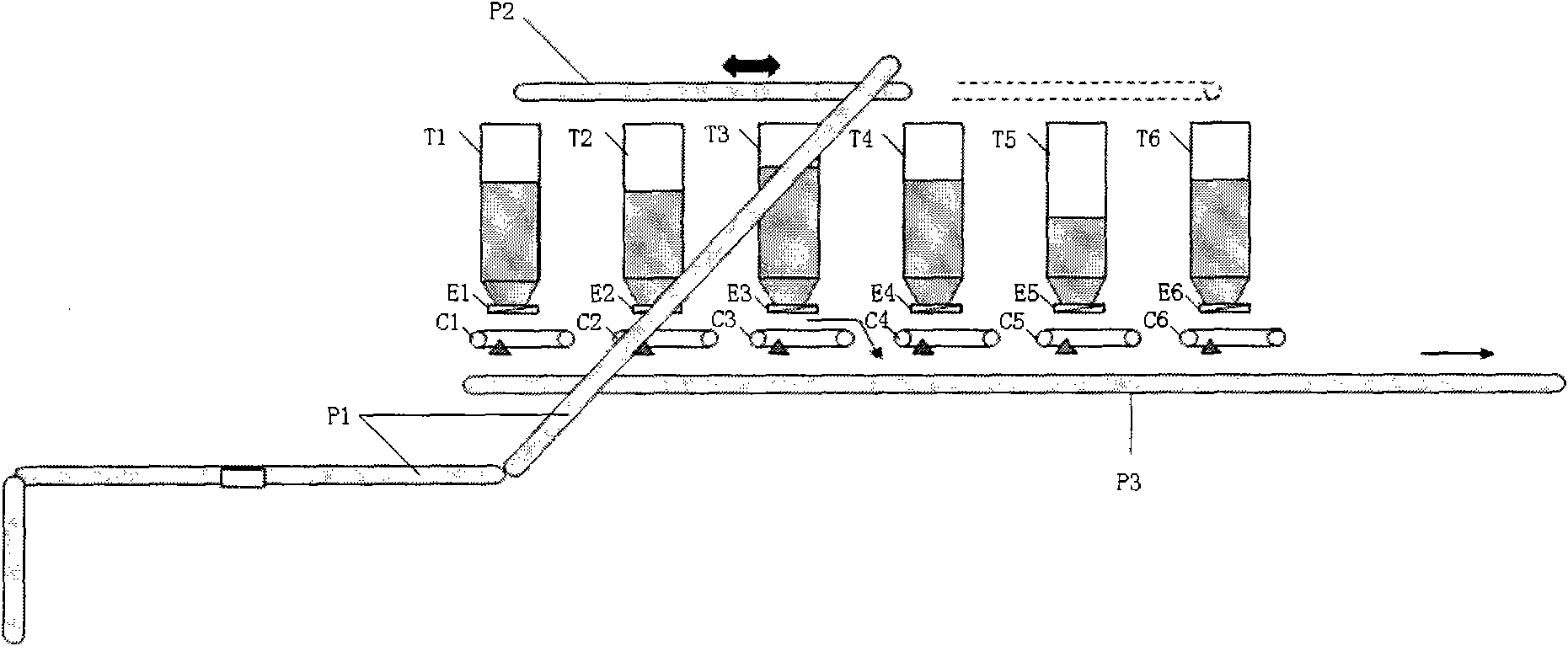

The invention relates to a PACT (powdered activated carbon treatment) process and an PACT process device. The activated carbon-microbial zoogloea culture method comprises the following steps: selecting activated sludge, and culturing until the activated sludge is mature; and adding powdered activated carbon to ensure that the powdered activated carbon serving as a core is wrapped by microorganisms to form activated carbon-microbial zoogloea floccules, and acclimating, thus increasing the specific gravity of the powdered activated carbon and enhancing the precipitability. In the PACT process device, a sludge return tank is added, and the powdered activated carbon is added into the sludge return tank, so that the powdered activated carbon and the microorganisms can form activated carbon-microbial zoogloeae in the sludge return tank, thereby prolonging the retention time of the powdered activated carbon in a water treatment system; and sludge in the sludge return tank is lifted into a sewage inlet at the front end of an aerobic tank through a lifting pump, so that the sludge and sewage can be better mixed, thereby prolonging the retention time of the powdered activated carbon in the aerobic tank and enhancing the treatment effect. On the basis of prolonging the water retention time of the aerobic tank, the invention does not need to increase the volume of the original aerobic tank, and is small in occupied area and easy to implement.

Owner:GUANGDONG XINDAYU ENVIRONMENTAL PROTECTION TECH CO LTD +1

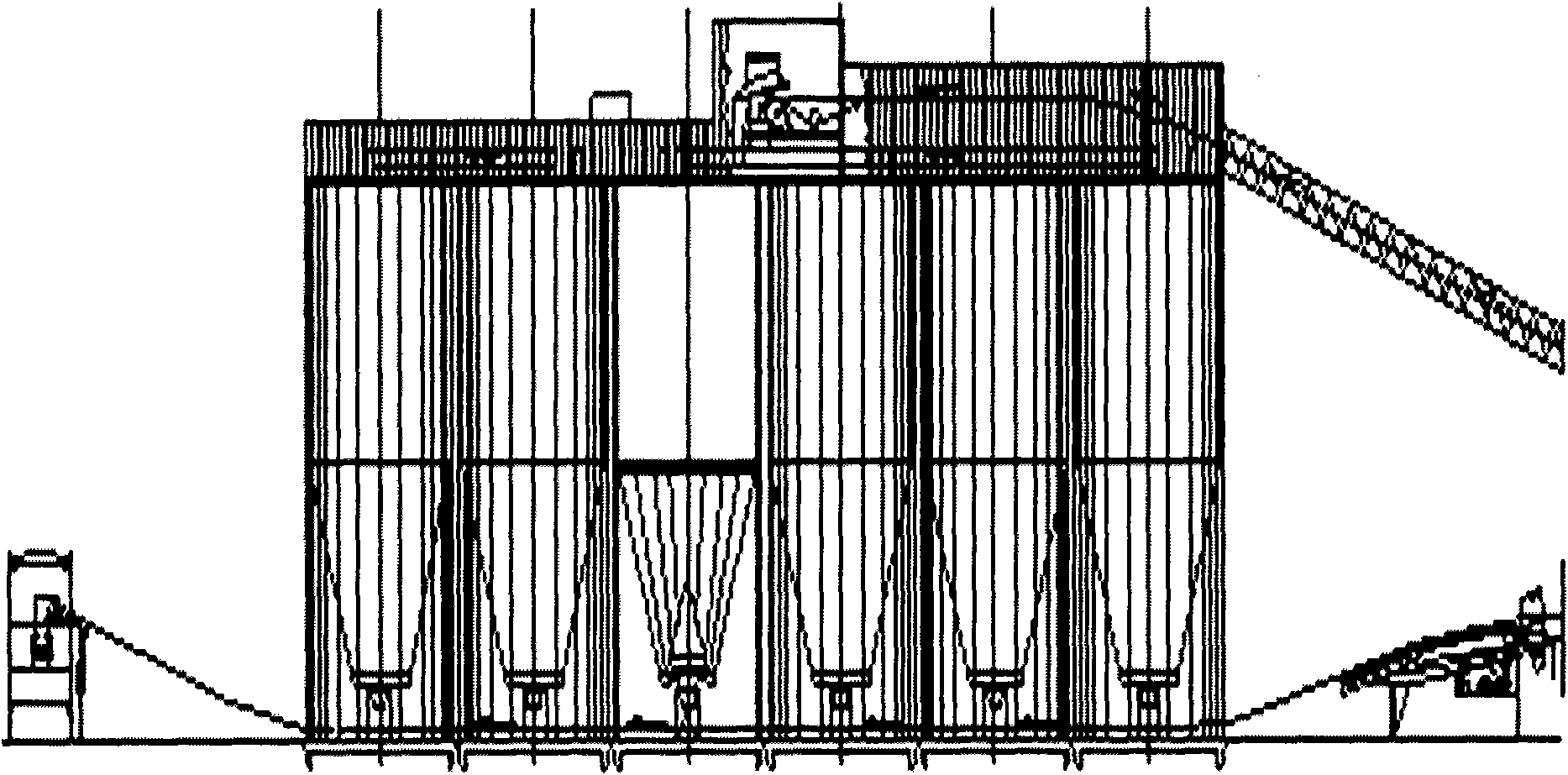

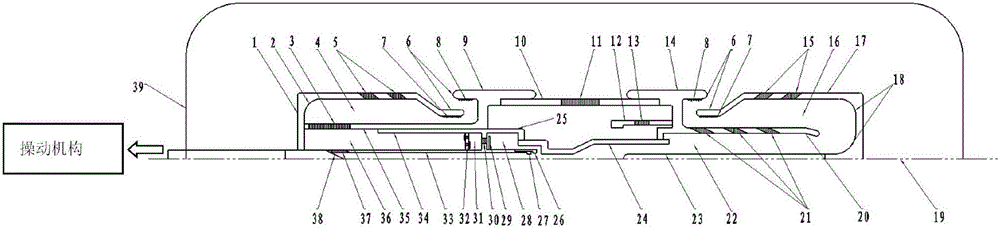

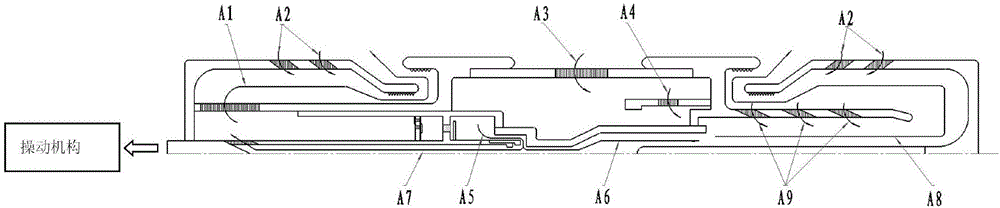

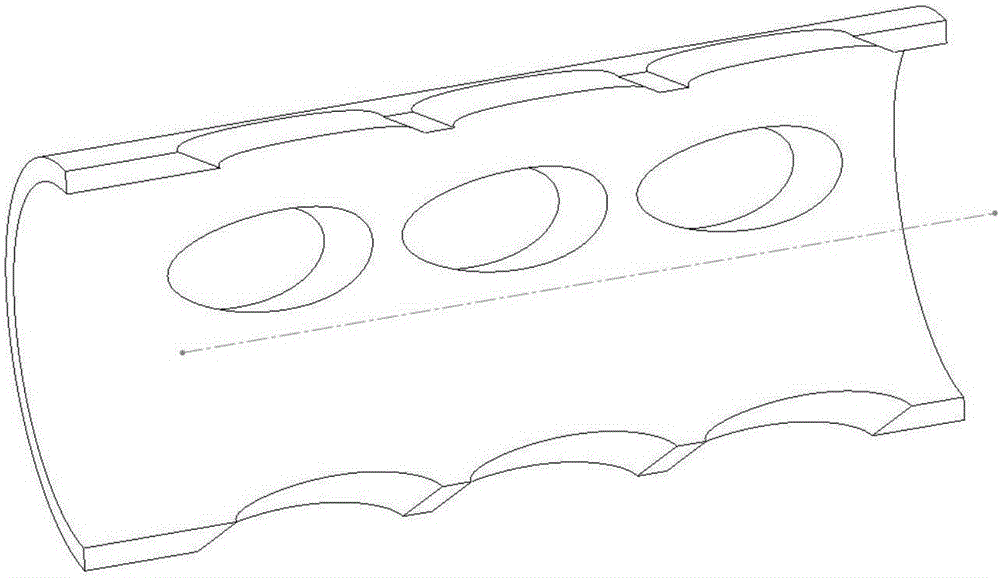

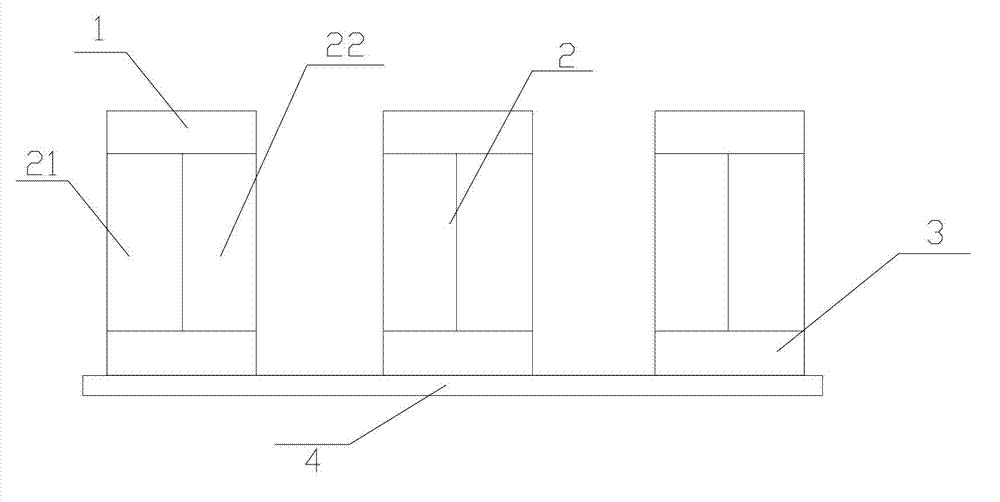

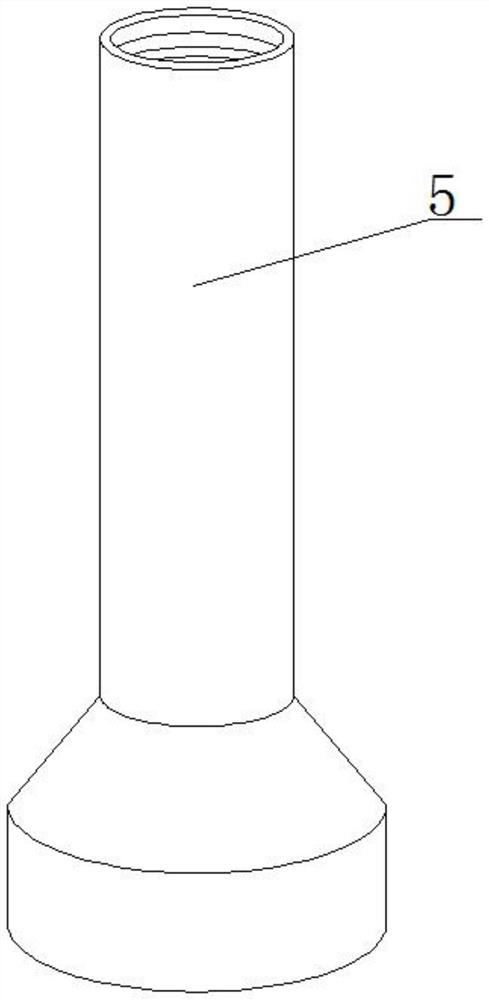

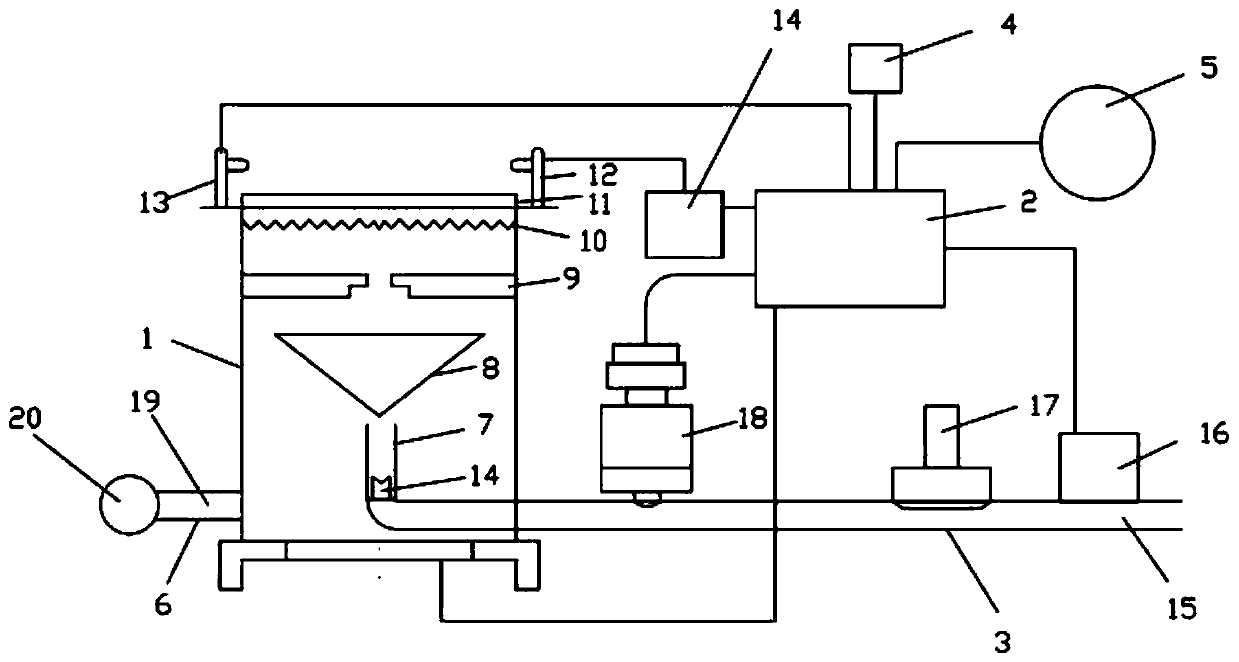

Coal distributing system and coal feeder used in same

ActiveCN102008920ACompact structureControl ratioMixer accessoriesLoading/unloadingCurve shapeDistributor

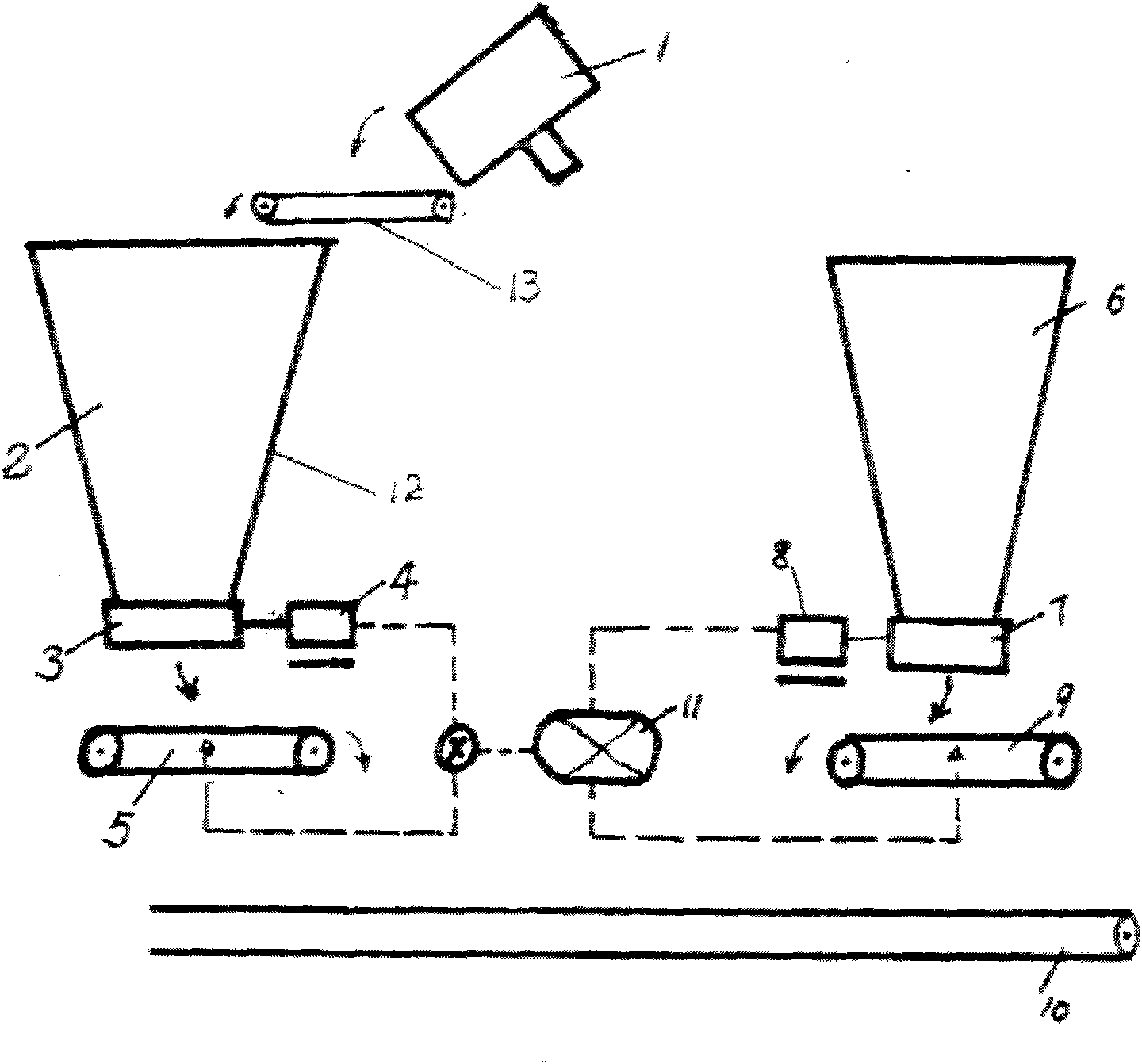

The invention relates to a coal distributing system which comprises a plurality of raw coal barrel bins, coal feeders, a barrel bin lower belt scale, a coal distribution conveying belt and a coal distributing control device, wherein the raw coal barrel bins are used for respectively storing different kinds of raw coal; and the coal feeders are arranged at the lower parts of all raw coal barrel bins along the axis directions of the raw coal barrel bins; each coal feeder is provided with a shell, a circular coal outlet, a coal distributor and a scraper; the shell is in an inverted cone platform shape, the upper part of the shell is opened, and the lower part is provided with a flat plate-shaped base plate; the circular coal outlet is arranged at the central part of the base plate; the coal distributor is conic and is arranged at the upper side of the coal feeder and arranged on a rod-shaped bracket which is fixedly installed on the shell so that the raw coal falling from the raw coal barrel bins uniformly slide to be near to the coal outlet along the conic surface; the scraper is in a curve shape extending along the flat-plate-shaped base plate and is arranged on a rotatable fixed bracket extending out from the coal outlet; and when the scraper rotates, the scraper is used for scraping the raw coal in the coal feeders into the coal outlet. According to the structure, the coal distributing system can realize precise coal distribution and has compact structure.

Owner:鹏发国际股份有限公司

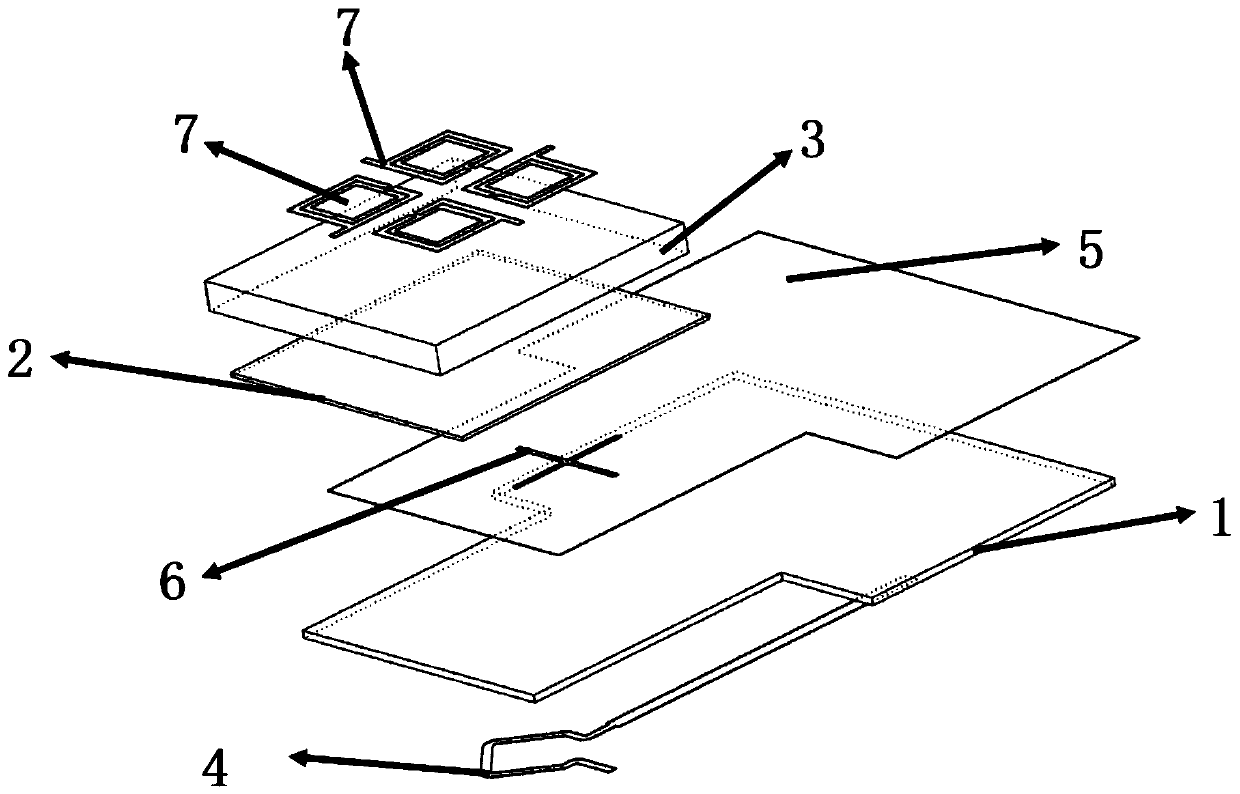

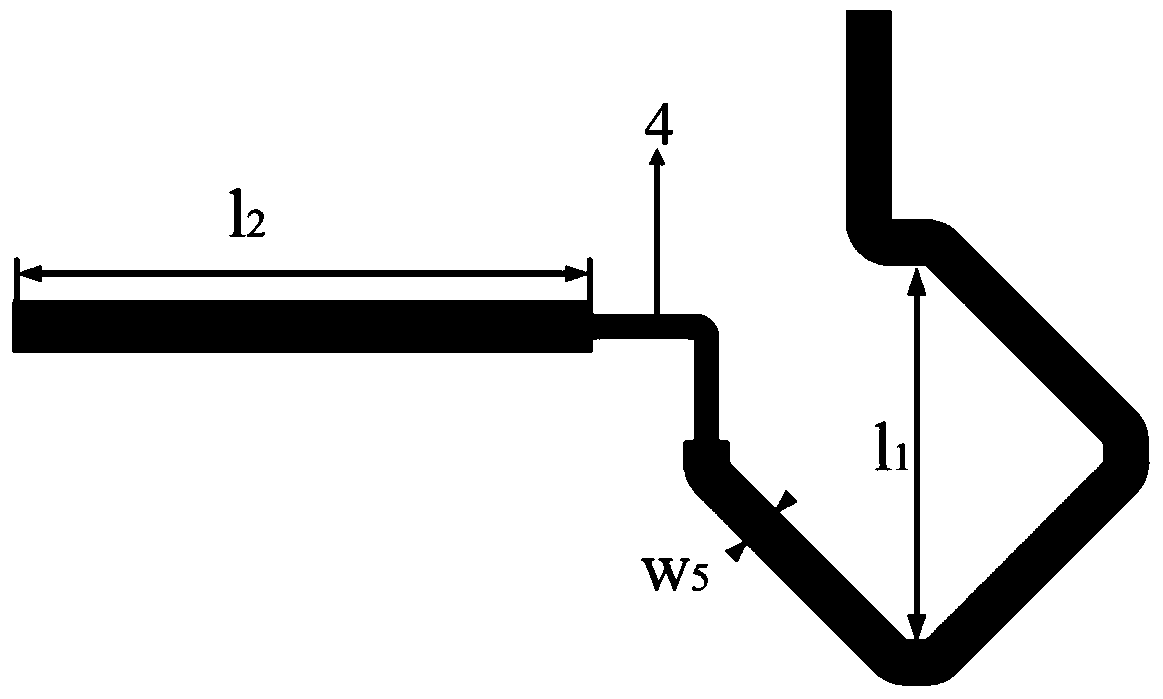

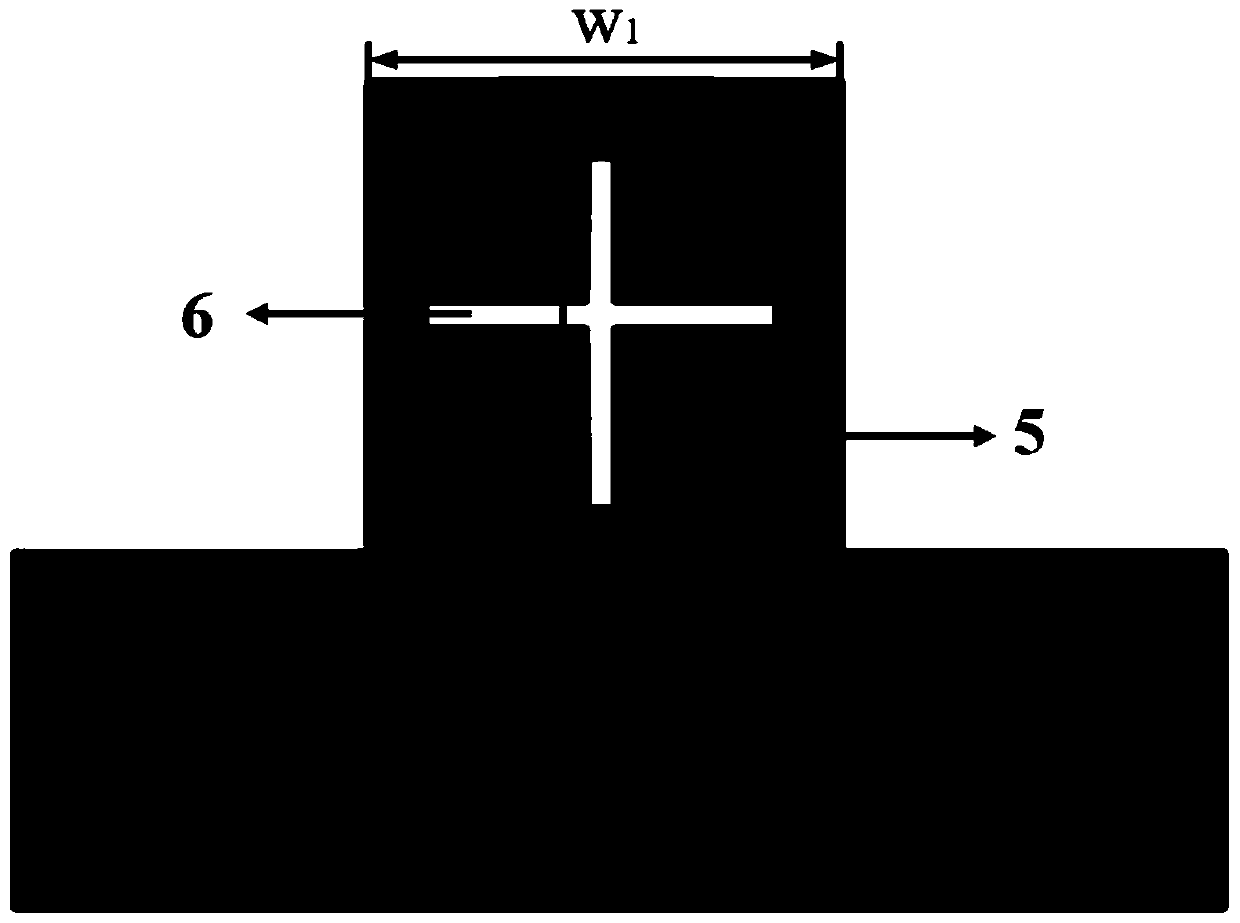

High-gain dual-frequency circularly polarized antenna based on metasurface

PendingCN110148833AImprove efficiencyNo need to increase the sizeRadiating elements structural formsAntennas earthing switches associationPhase differenceEnergy coupling

The invention discloses a high-gain dual-frequency circularly polarized antenna based on a metasurface. The working frequency bands are a K wave band and a Ka wave band. A metal layer of the antenna comprises a micro-strip ring feeder line, a grounding plane with a cross slot and a metasurface. The micro-strip ring feeder line at the lowest position is coupled with the slotted grounding plane at the middle position. The electromagnetic wave energy is coupled to the metasurface of the uppermost layer and is radiated out. The sequential rotation structure of the micro-strip ring feeder line cangenerate a phase difference of 90 degrees so as to excite circular polarization. According to the feed structure, a wide axial ratio bandwidth can be realized; the metasurface can influence the axialratio bandwidth and gain of high and low frequency bands; the gain of the antenna in two frequency bands is greater than 5dBic; and the single-port feed dual-frequency circularly polarized antenna hasgood radiation characteristics in two frequency band bands, and is compact in structure and easy to process, so that antenna has a good application prospect in a wireless communication system.

Owner:EAST CHINA NORMAL UNIV

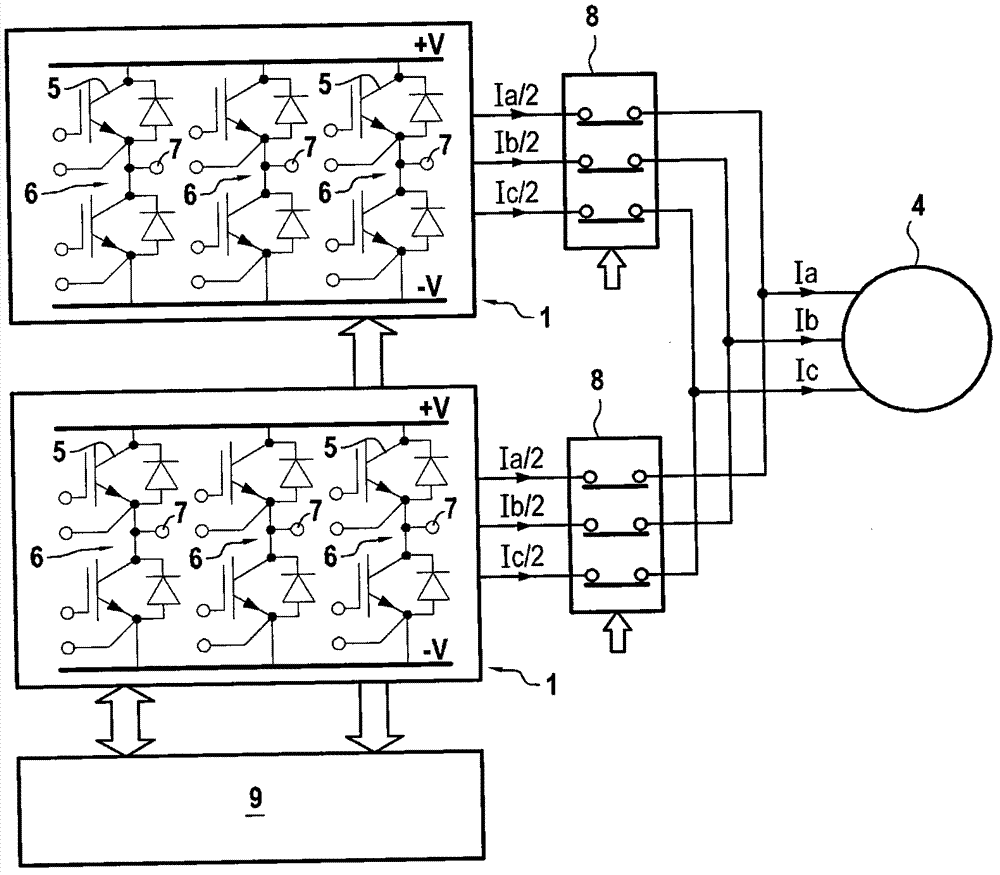

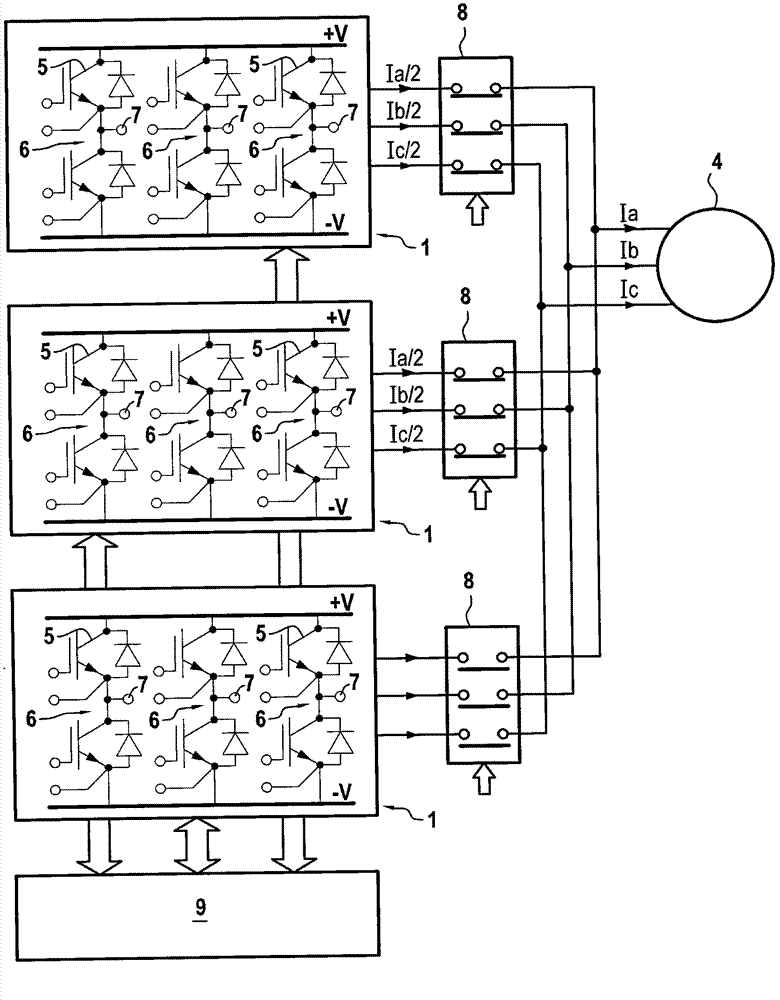

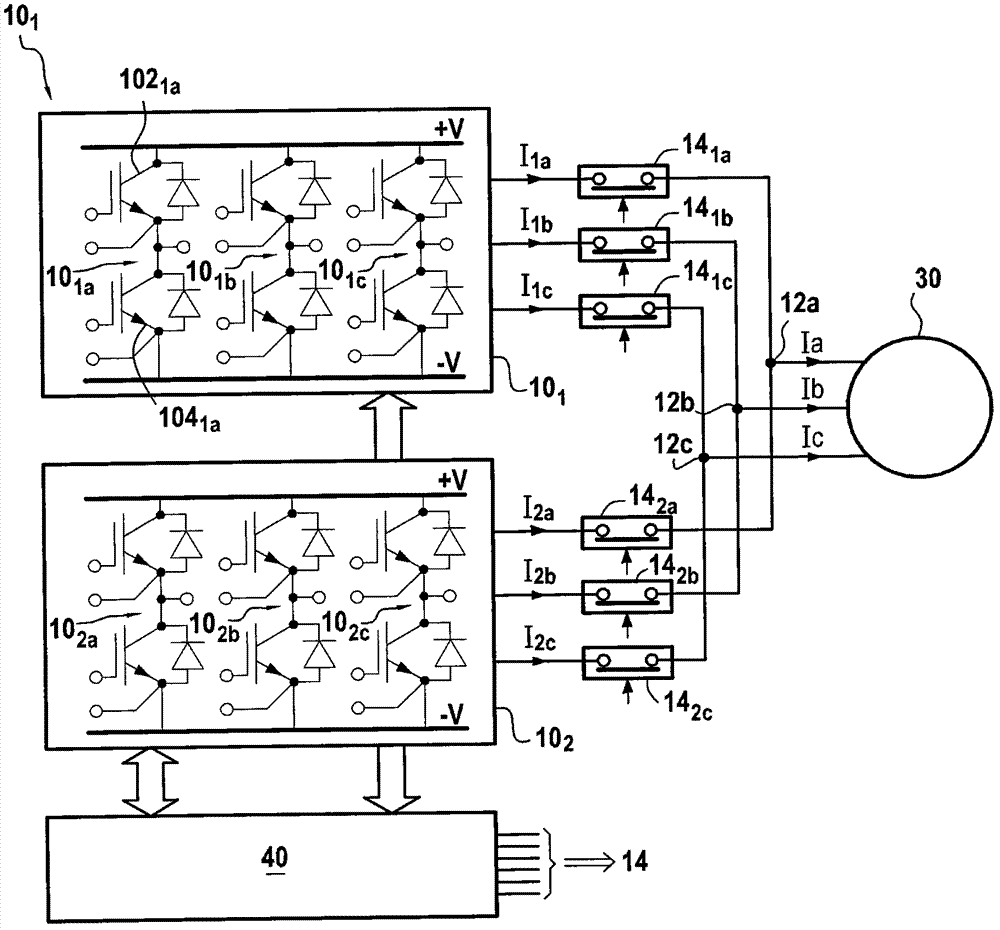

Method and device for controlling a polyphase electrical machine

ActiveCN102771042AConvey evenlyMitigationElectric motor controlAc-dc conversionPhase currentsSwitched current

The invention relates to a polyphase electrical machine (30), which is controlled by means of at least two inverters in parallel (101, 102), wherein each inverter has branches (101a, 101b, 101c, 102a, 102b, 102c), in a number equal to the number of phases of the machine, and is controlled by pulse width modulation (PWM). In response to the detection of a defective inverter branch (102a), the latter is isolated, and the phase in question is supplied with power by the or each other corresponding inverter branch (101a). The control by PWM is modified so as to make the power switches of said or each other branch (101a) consecutively conductive without switching when, in absolute value form, the strength of the current for the phase in question (1a) is greater than or equal to a threshold between 80% and 120% of (n-1) Imax / n, where n is the number of inverters and Imax is the maximum strength of the phase current. It is thus possible to maintain generation of substantially sine wave voltage over each phase while preventing overrated voltage in the power switches so that, in the event of a defect, said switches can switch currents with higher amplitudes than during normal operation.

Owner:LABINAL POWER SYST

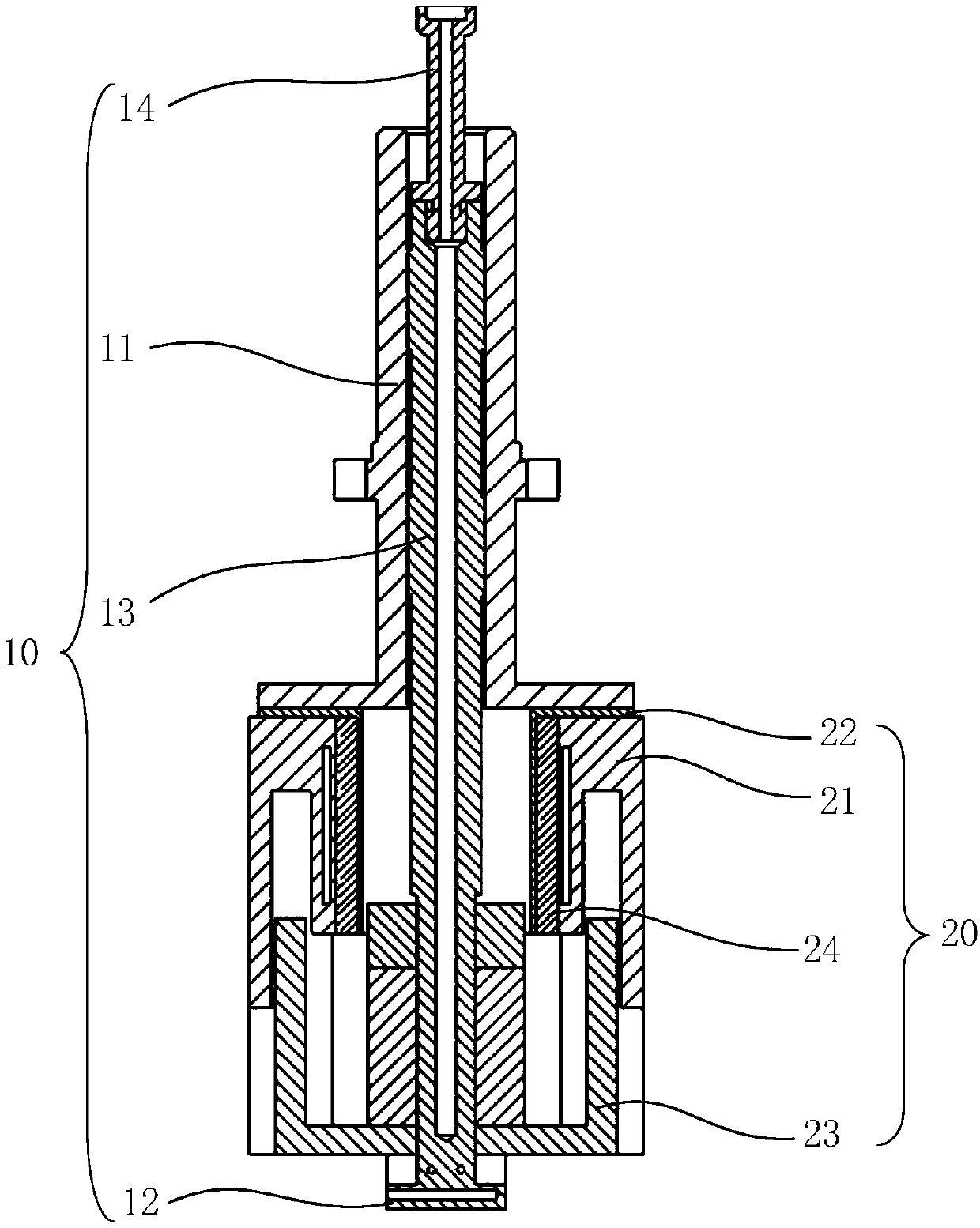

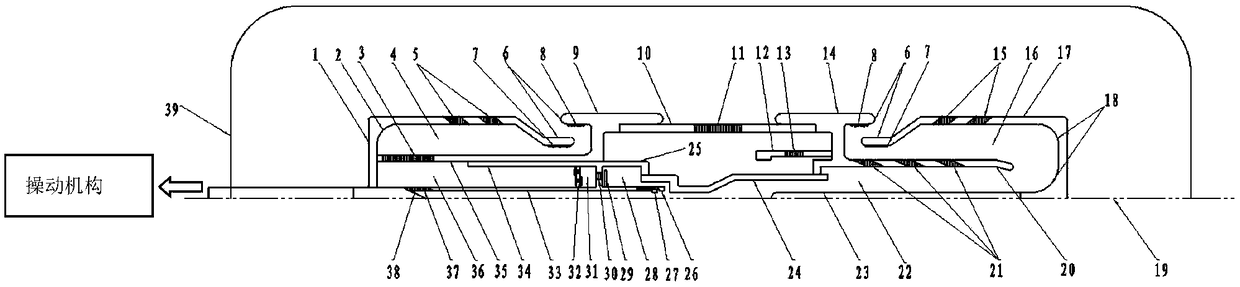

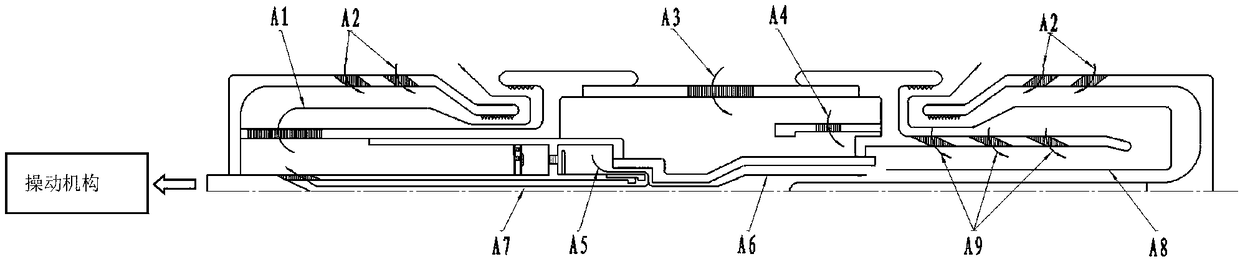

Gas circuit breaker with reinforced insulation recovery function

ActiveCN106710960AImprove insulation performanceSpeed up the insulation recovery rateHigh-tension/heavy-dress switchesAir-break switchesCore componentEngineering

The invention discloses a gas circuit breaker with a reinforced insulation recovery function. An expansion chamber, a compressed gas chamber, a main nozzle, an auxiliary nozzle, a moving side arc contact and a static side arc contact constitute an arc breaking core component. An arc extinguishing chamber is composed of an inner mixing area and an outer mixing area. Drainage holes of guide cylinders draw insulating gas in the outer mixing area of the arc extinguishing chamber into the inner mixing area of the arc extinguishing chamber, and the insulating gas and arc high-temperature gas are mixed at a first level and cooled in an area closest to a fracture. Drainage holes of a support base draw insulating gas outside the arc extinguishing chamber into the outer mixing area of the arc extinguishing chamber, and the insulating gas and arc gas are mixed at a second level and cooled. Spoilers at exhaust ports reduce the local velocity of high-temperature mixed gas exhausted. A pressure balance hole is arranged in a main contact shielding cover, which reduces the pressure difference between the two sides of the shielding cover. A pressure balance hole is arranged in an insulating cylinder, which reduces the fluctuation of gas pressure inside the insulating cylinder.

Owner:SHANGHAI SIEYUAN HIGH VOLTAGE SWITCHGEAR +1

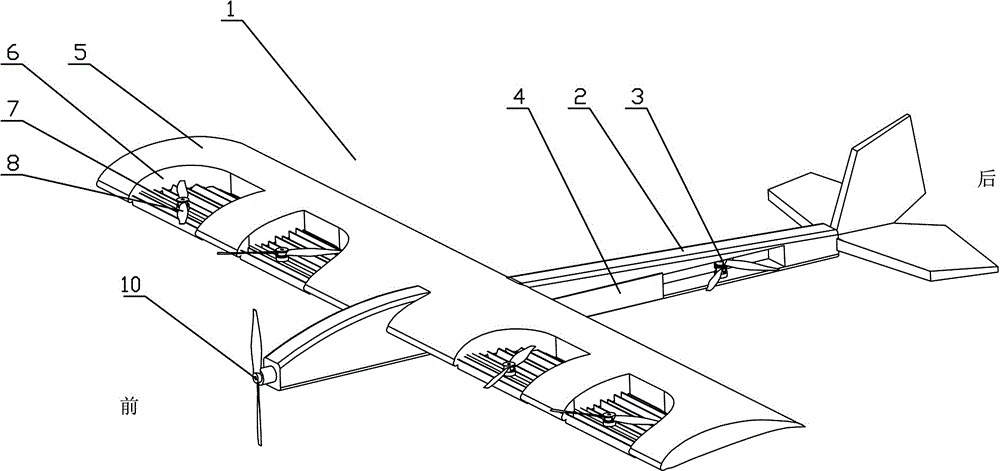

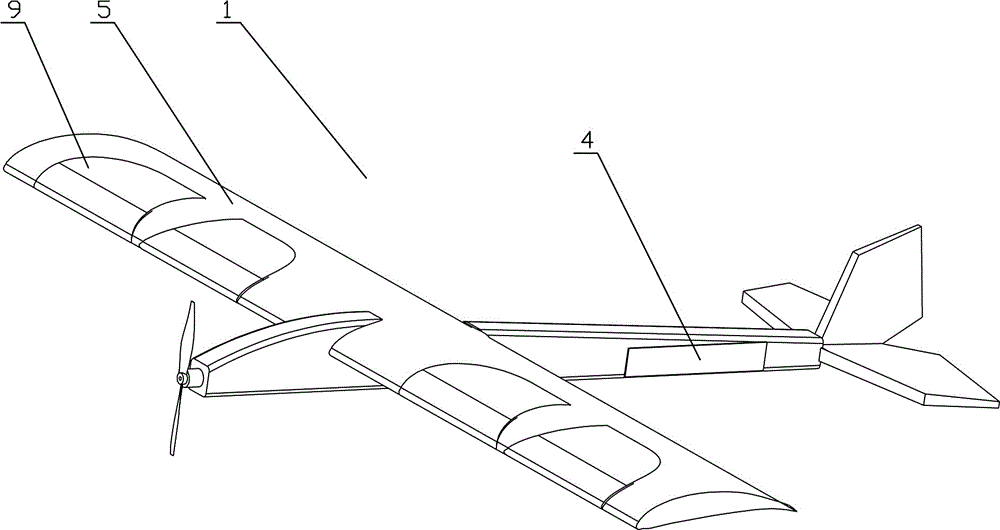

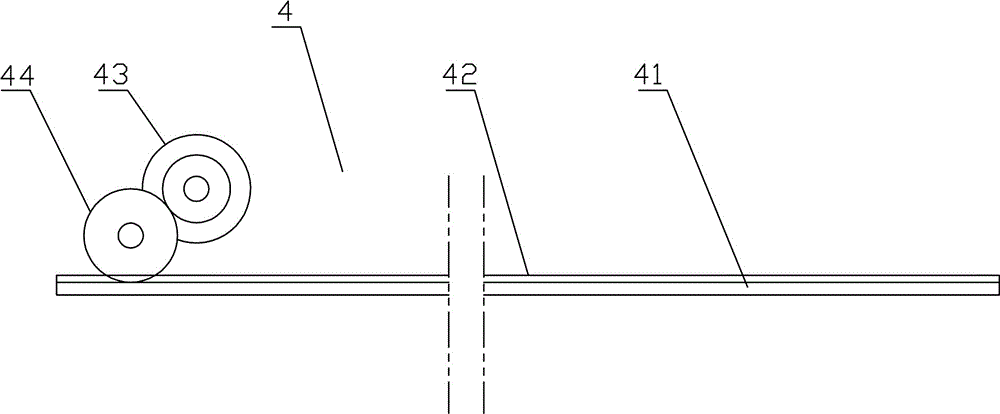

Vertical take-off and landing fixed-wing unmanned aerial vehicle

ActiveCN105905294AEasy to switchRealize switchingVertical landing/take-off aircraftsRotocraftSlide plateFixed wing

The invention provides a vertical take-off and landing fixed-wing unmanned aerial vehicle including a fuselage; wings are arranged at two sides of the fuselage; the fuselage is internally equipped with a foldable fuselage rotor wing; two sides of the fuselage rotor wing are equipped with fuselage slide plates; the wings are internally provided with a plurality of foldable wing rotor wings, and the top of each wing rotor wing is equipped with an openable-closable wing slide plate device. By adopting the structure, the unmanned aerial vehicle has the following beneficial effects that with adopting of forward driving and combination of the fuselage rotor wing and the wing rotor wings, switching between the vertical take-off and landing and fixed wing flight is convenient to realize. The unmanned aerial vehicle having the structure conveniently hovers at any time during task implementing, so that a camera can conveniently perform fixed-point observation, and at the same time, runways and ejection equipment are not required during take-off and landing. With the combination of the fuselage rotor wing and the wing rotor wings, the balance of the whole fuselage is convenient to control. With the use of the hidden type fuselage rotor wing and the hidden type wing rotor wings, no interference exists between the vertical take-off and landing mode and the fixed wing flight mode, and the size of the wings is not required to be increased. The lifting efficiency of air stream is high.

Owner:BEIJING CASRS INFORMATION TECH

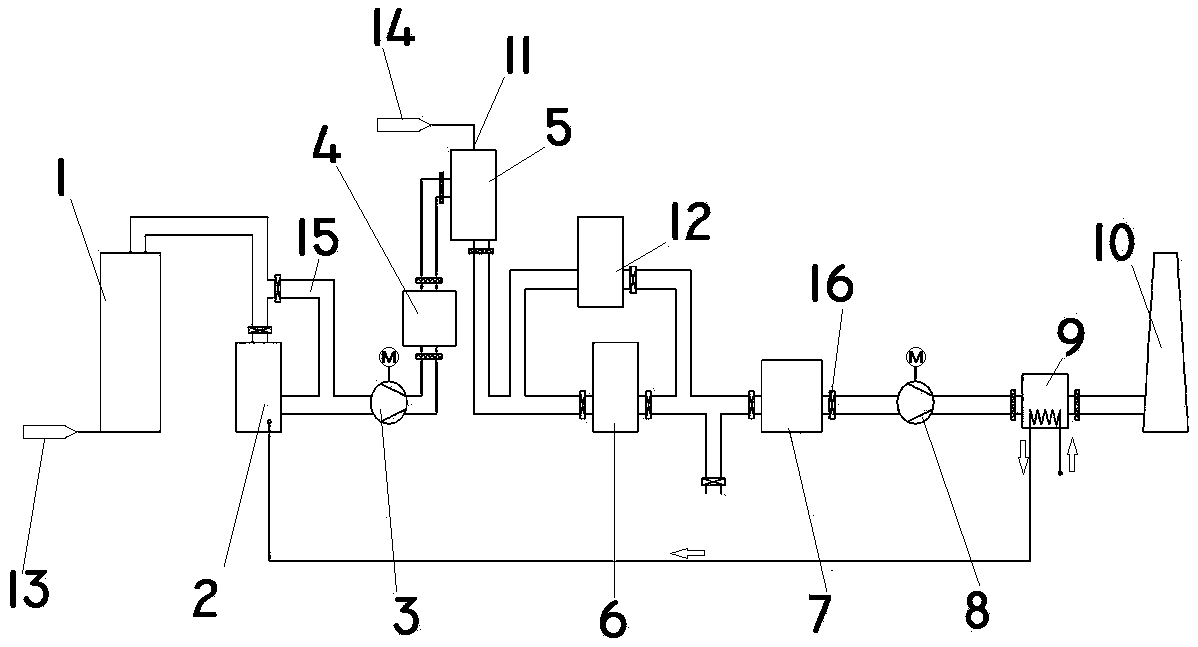

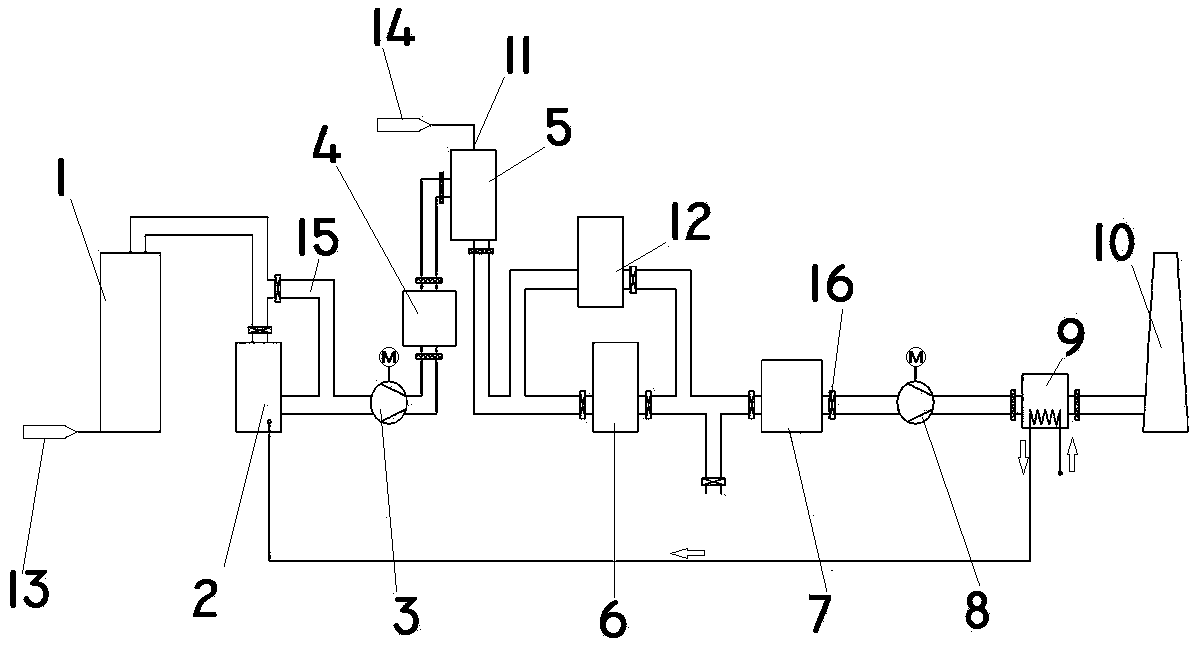

System, technology and method for de-nitrating flue gas of cement kiln and recovering waste heat of flue gas of cement kiln

PendingCN109966812AAchieve clean emissionsReduce contentCombination devicesGas treatmentFlue gasProcess engineering

The invention discloses a system, technology and method for de-nitrating flue gas of a cement kiln and recovering the waste heat of flue gas of a cement kiln. The system comprises a preheater, a wasteheat boiler, a highly hot air blower, a high temperature bag deduster, an SCR denitration reactor, a raw mill, a kiln tail deduster, an induced draft fan, a heat exchanger, and a chimney. A flue gasoutlet in the tail part of a rotary cement kiln is communicated with an inlet in the lower part of the preheater through a pipeline. The outlet in the top of the preheater is communicated with the inlet in the top of the waste heat boiler through a pipeline. The outlet in the lower part of the waste heat boiler is communicated with the inlet of the high temperature bag deduster through a pipeline.The outlet of the high temperature bag deduster is communicated with the inlet of the SCR denitration reactor through a pipeline. The outlet in the bottom of the SCR denitration reactor is communicated with the inlet of the raw mill through a pipeline. The outlet of the raw mill is communicated with the inlet of the kiln tail deduster through a pipeline. The ultralow temperature waste heat utilization and ultralow pollutant discharge are effectively co-researched. The content of NOx in flue gas of a cement kiln is efficiently reduced, the energy consumption is low, and finally discharged fluegas meets the discharge requirements.

Owner:BEIJING GUODIAN LONGYUAN ENVIRONMENTAL ENG

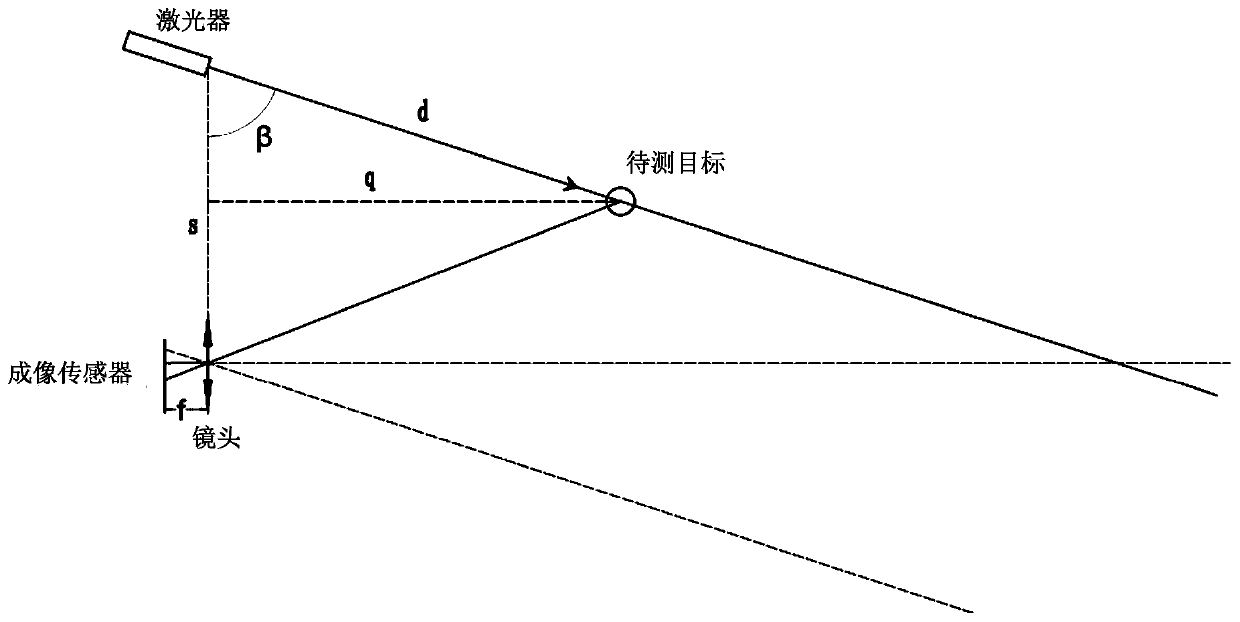

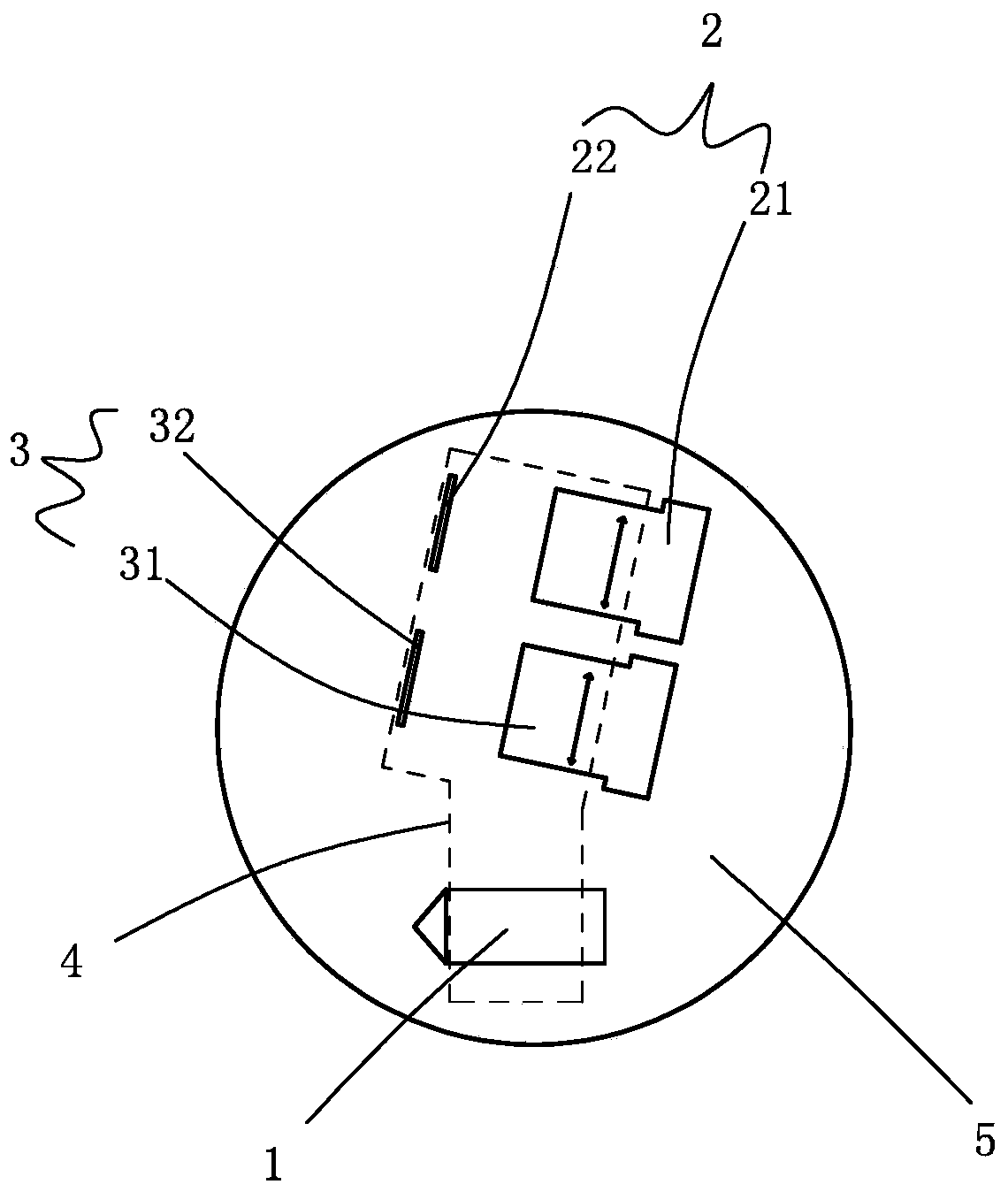

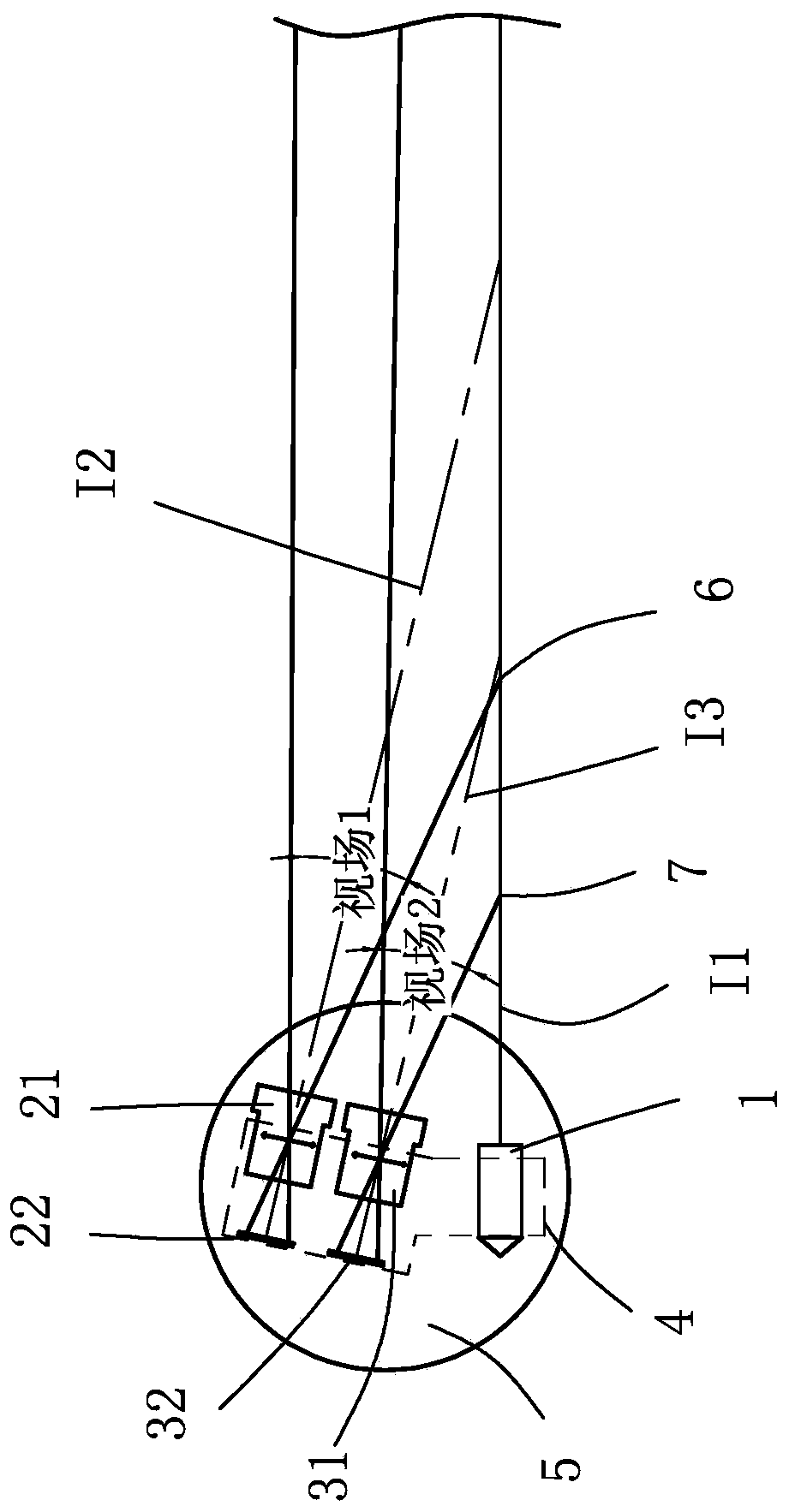

Laser radar

PendingCN110275176AMeet miniaturization requirementsMeet the precision requirementsOptical rangefindersElectromagnetic wave reradiationPhysicsOptoelectronics

The invention relates to the technical field of radar. The invention discloses laser radar. The laser radar comprises a laser and a receiving system, the laser is used for emitting a laser to a target to be detected, the receiving system is used for receiving a laser reflected by the target to be detected, the receiving system at least comprises a first receiving system and a second receiving system, the first receiving system and the laser are arranged at intervals, the second receiving system is arranged between the first receiving system and the laser, the first receiving system is used for receiving the laser reflected by the target to be detected in a range from a first near point to a first far point, the second receiving system is used for receiving a laser reflected by the target to be detected in a range from a second near point to a second far point, and the distance from the second near point to the laser is less than the distance from the first near point to the laser, is smaller than or equal to the distance from the second far point to the laser and is smaller than the distance from the first far point to the laser. The laser radar has an ultra-small blind area or even has no blind area and can meet the miniaturization requirement.

Owner:XIAMEN CITY YAPHA OPTOELECTRONICS TECH

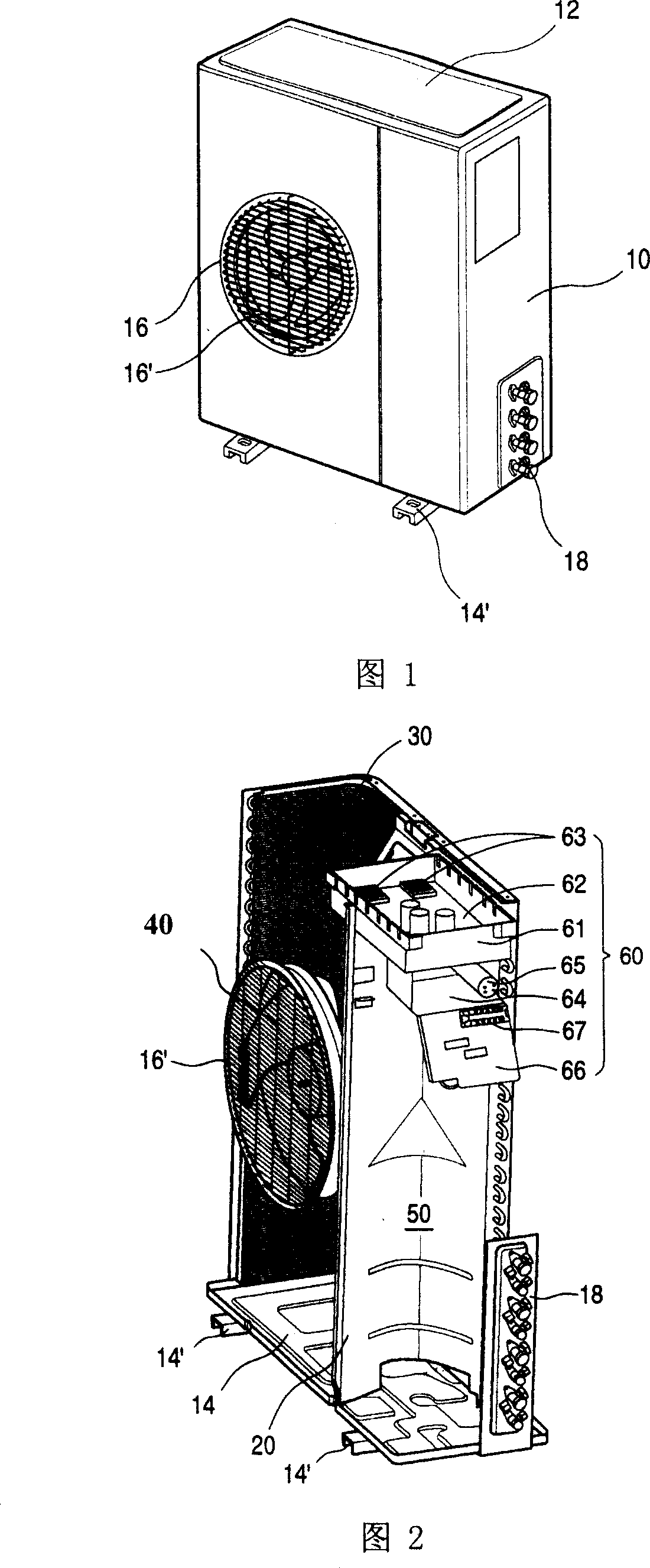

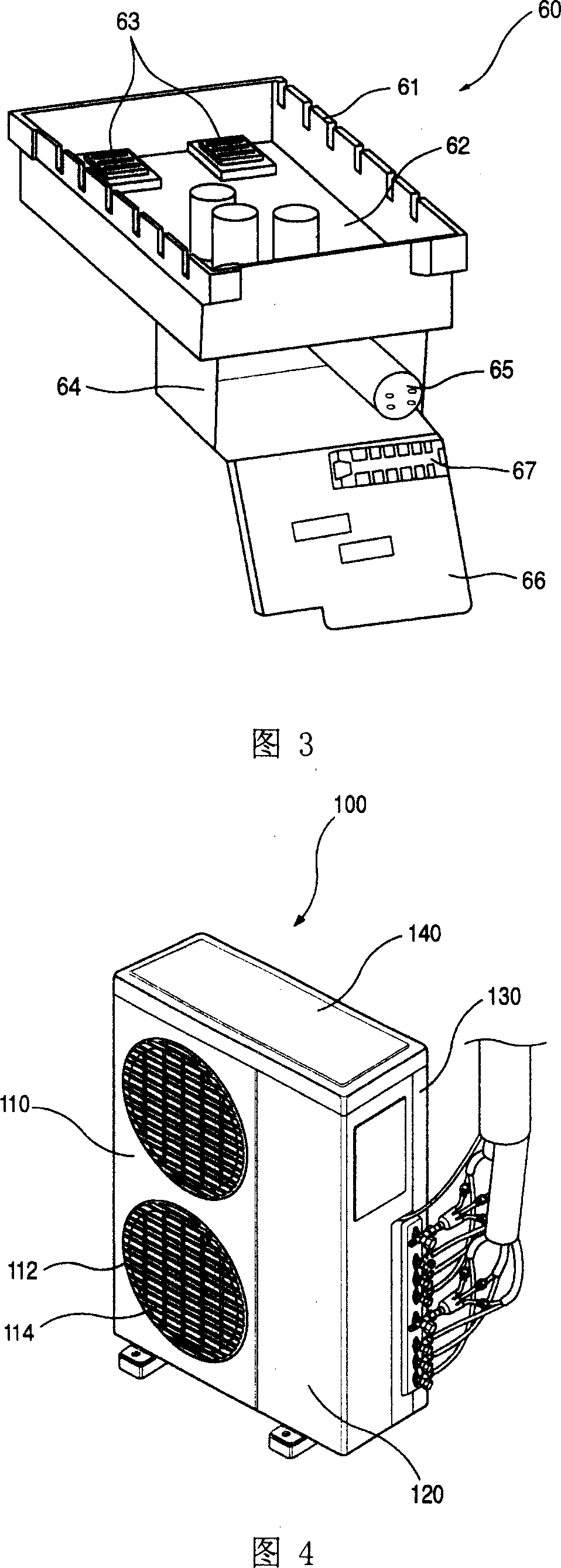

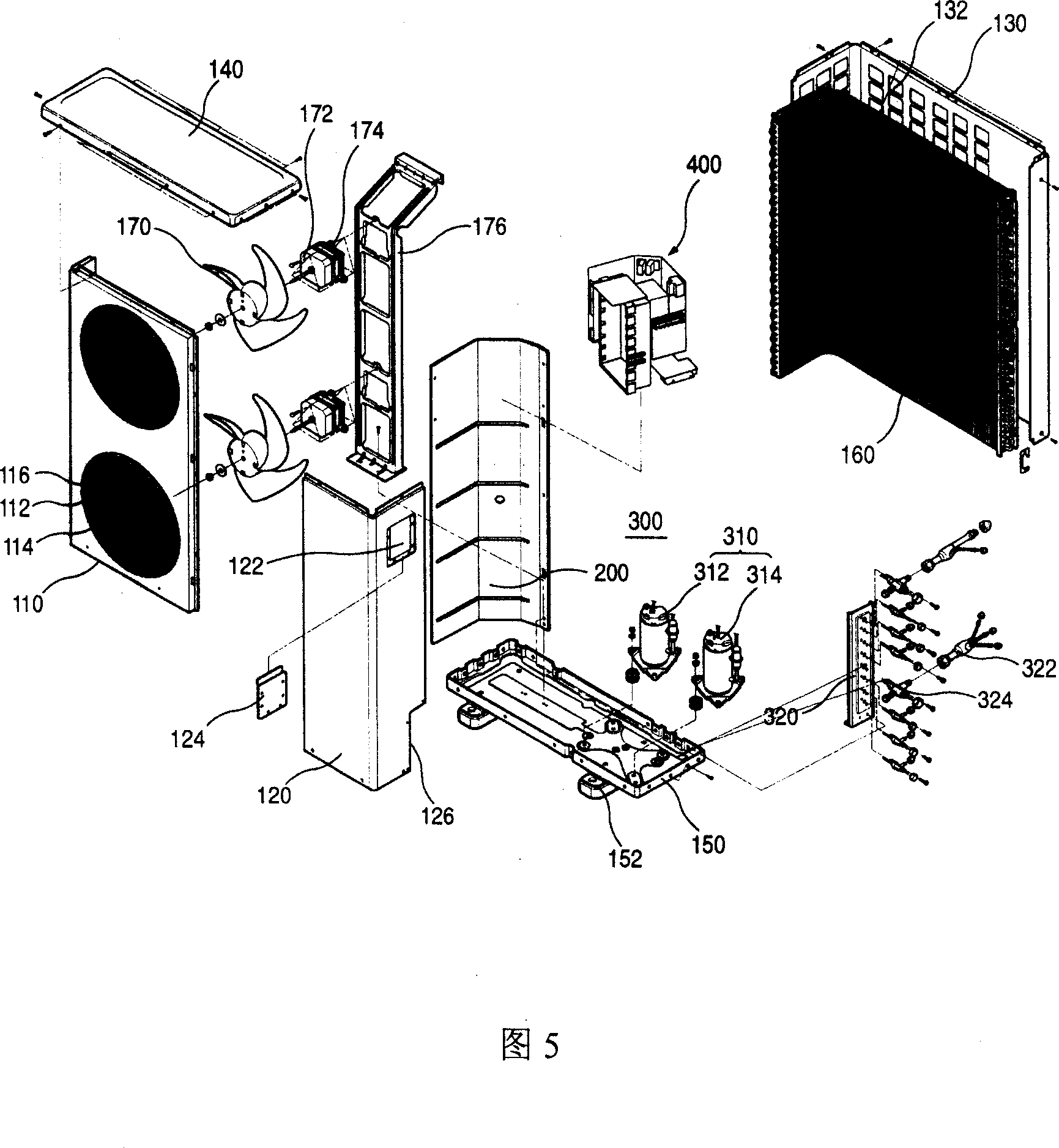

Outdoor set of air-conditioner

InactiveCN101086377AImprove space utilizationNo need to increase the sizeSpace heating and ventilation safety systemsLighting and heating apparatusThree-phaseEngineering

The invention discloses an air-conditioner outdoor set, which comprises the following parts: case, outdoor heat exchanger, baffle, fan, mechanic chamber and control part, wherein the control box is set on the control part to rotate, which is convenient to repair the electric appliance in the electric appliance chamber at the back of control box; the space of electric appliance chamber is used flexibly, which improves the utility of the space of outdoor set; the needed electronic part is assembled in the control part when using three-phase external power, which needn't increase entire bulk of outdoor set or making outdoor set individually according to the pattern of external power. The invention improves the manufacturing efficiency of the product, which reduces the making cost.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

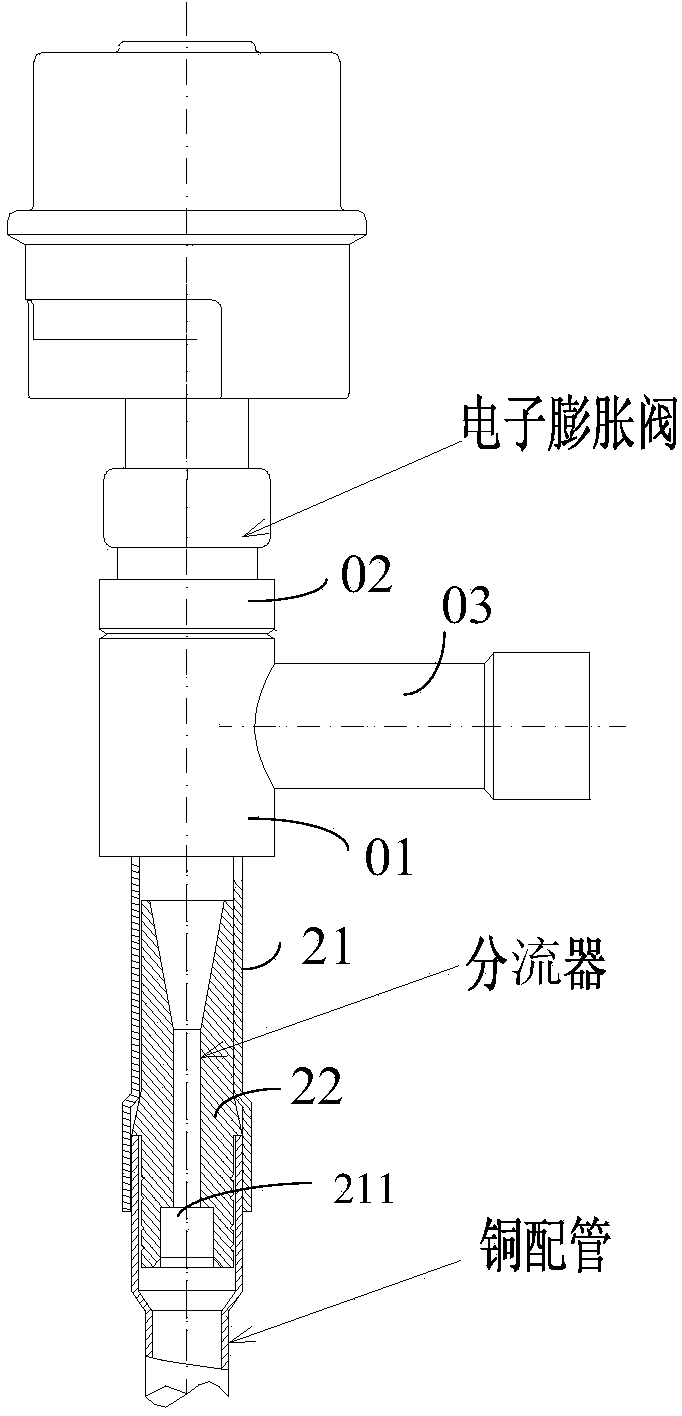

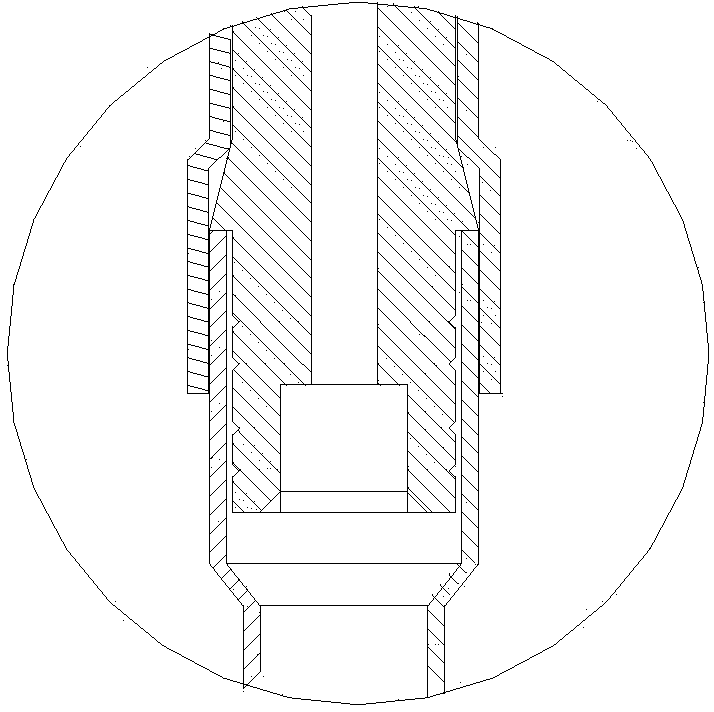

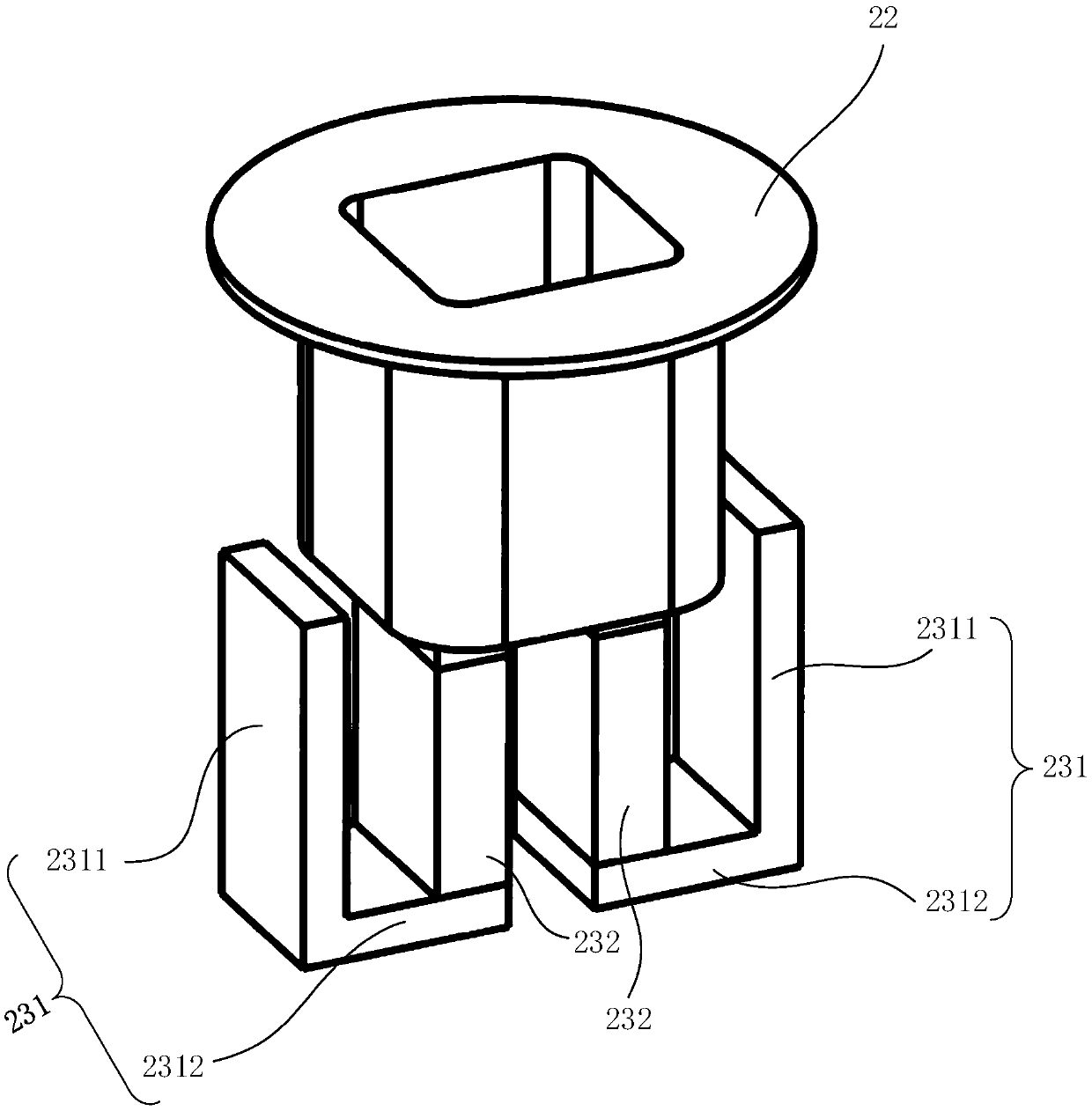

Noise reduction flow dividing device based on multi-connection air conditioning system

ActiveCN103471294ASimple structureEasy to installMechanical apparatusNoise suppressionShunt DeviceCoolant flow

The invention discloses a noise reduction flow dividing device based on a multi-connection air conditioning system. The flow dividing device comprises an electronic expansion valve and a divider. A step through hole accommodating a divider body is formed in a divider casing, the top end of the step through hole is communicated with the bottom end of an input unit, and the diameter of the step hole on the lower portion is larger than that of the step hole on the upper portion of the divider casing. A step through hole for conducting throttling and pressure reduction on coolant is formed in the divider body center along the coolant flowing direction. By means of the device, noise reduction cost can be reduced, and indoor space use rate can be improved.

Owner:QINGDAO HISENSE HITACHI AIR CONDITIONING SYST

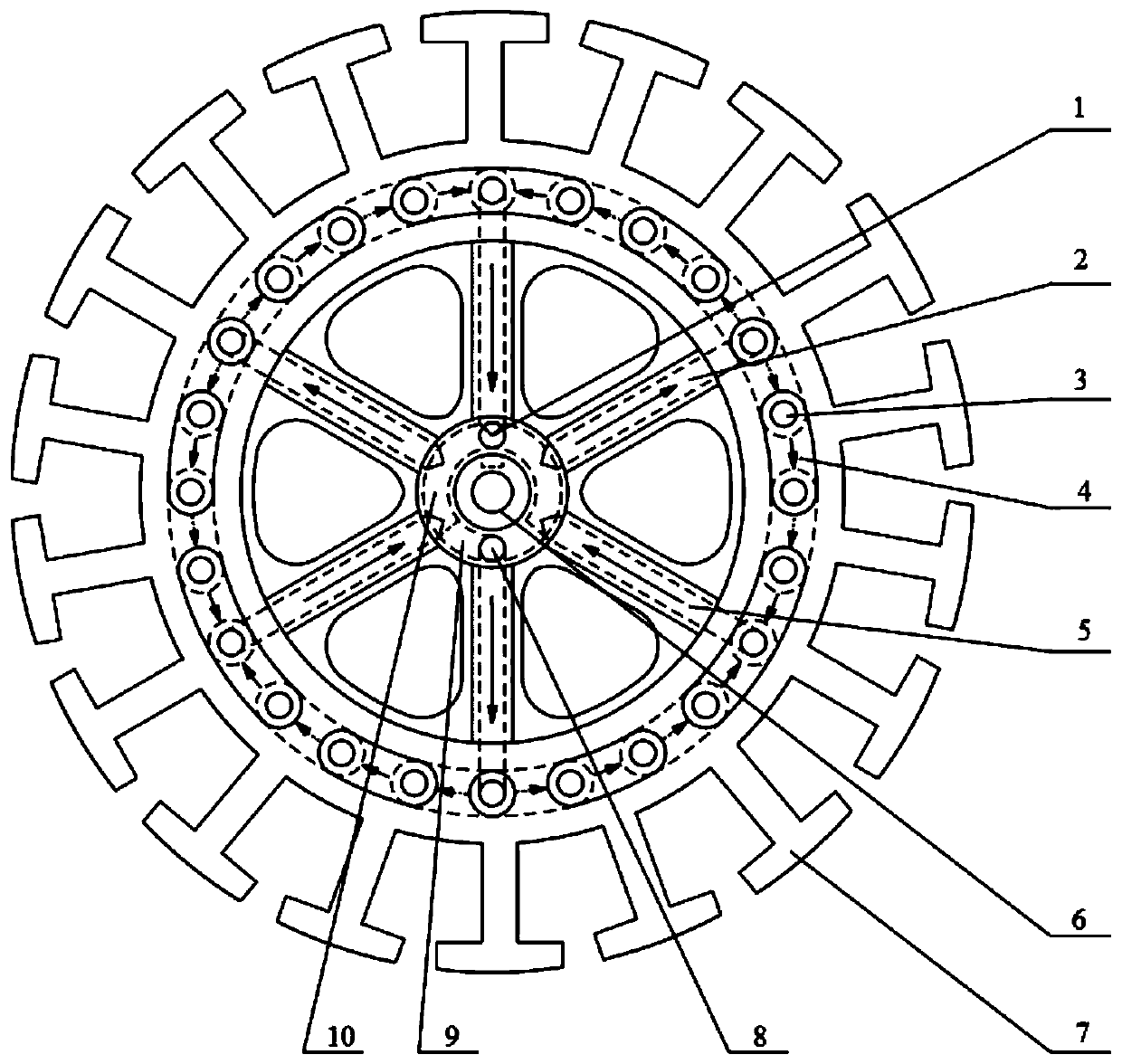

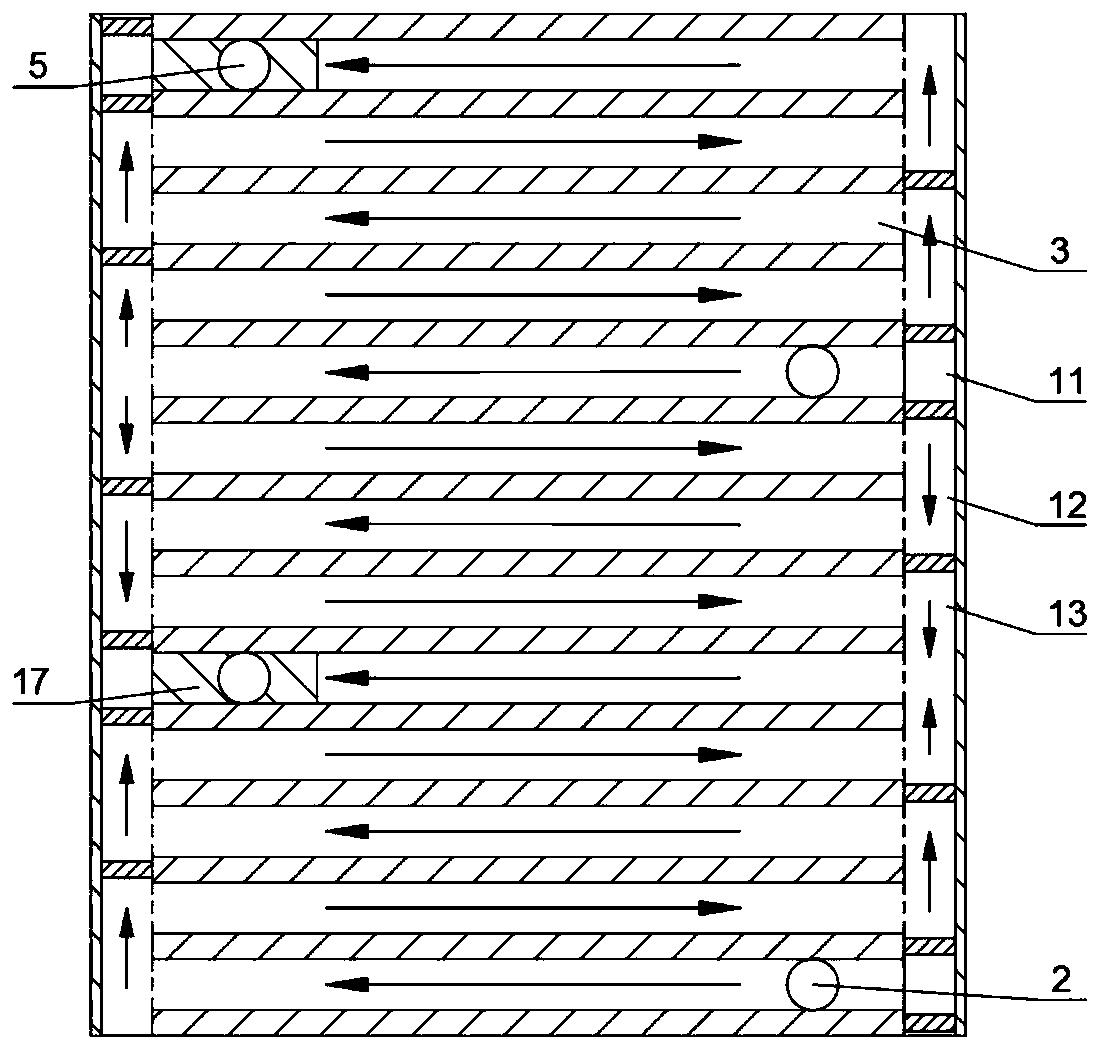

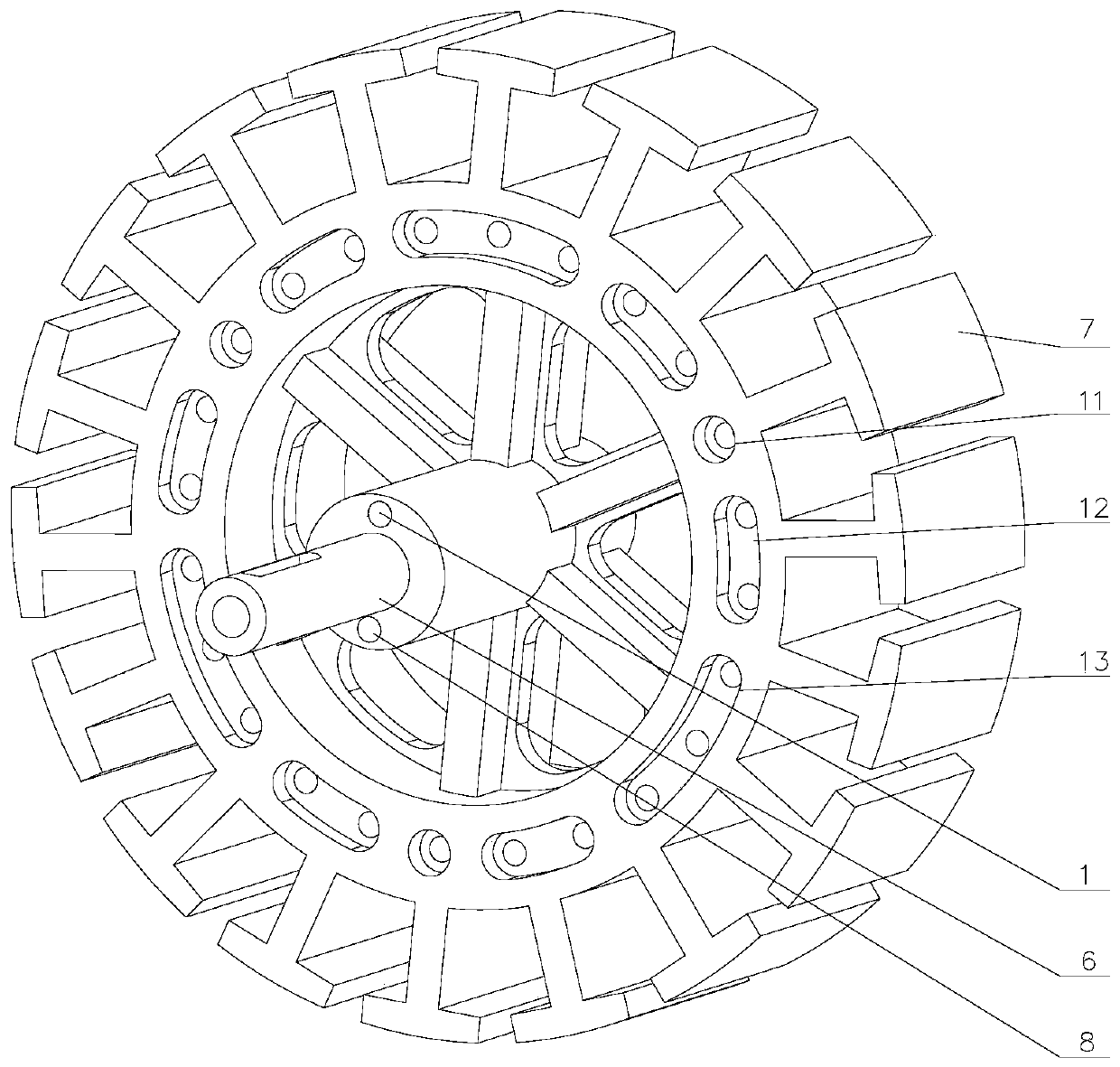

Hub motor stator water cooling structure for electric motor vehicle

ActiveCN110429727ASimple processLow manufacturing costElectric machinesMagnetic circuit stationary partsElectric vehicleCooling cycle

The invention discloses a hub motor stator water cooling structure for an electric motor vehicle. On the basis of maintaining the original structure of a motor, a cooling water path structure is arranged on the motor stator to achieve cooling and heat dissipation of the motor. The water cooling structure comprises a cooling liquid inlet channel, an outlet channel, a water inlet loop and a water outlet loop which are arranged at a motor stator shaft, and a cold water channel, a hot water channel, a cooling water channel, an arc groove and an arc groove cover which are arranged at a motor statoryoke. The cooling liquid flows in from the inlet channel, is split by the inlet channel to flow through the cold water channel, the cooling water channel and the hot water channel in order to converge through the water outlet loop, and finally flows out from the outlet channel. The water cooling structure has multiple groups of uniformly distributed cooling cycle branches, is provided with a thermostat valve to regulate the flow of each cooling liquid cycle branch to make cooling more uniform so as to avoid the temperature gradient of the motor, make the cooling effect better, reduce the volume of the motor and meet the demands of lightweight of the vehicle.

Owner:JIANGSU UNIV

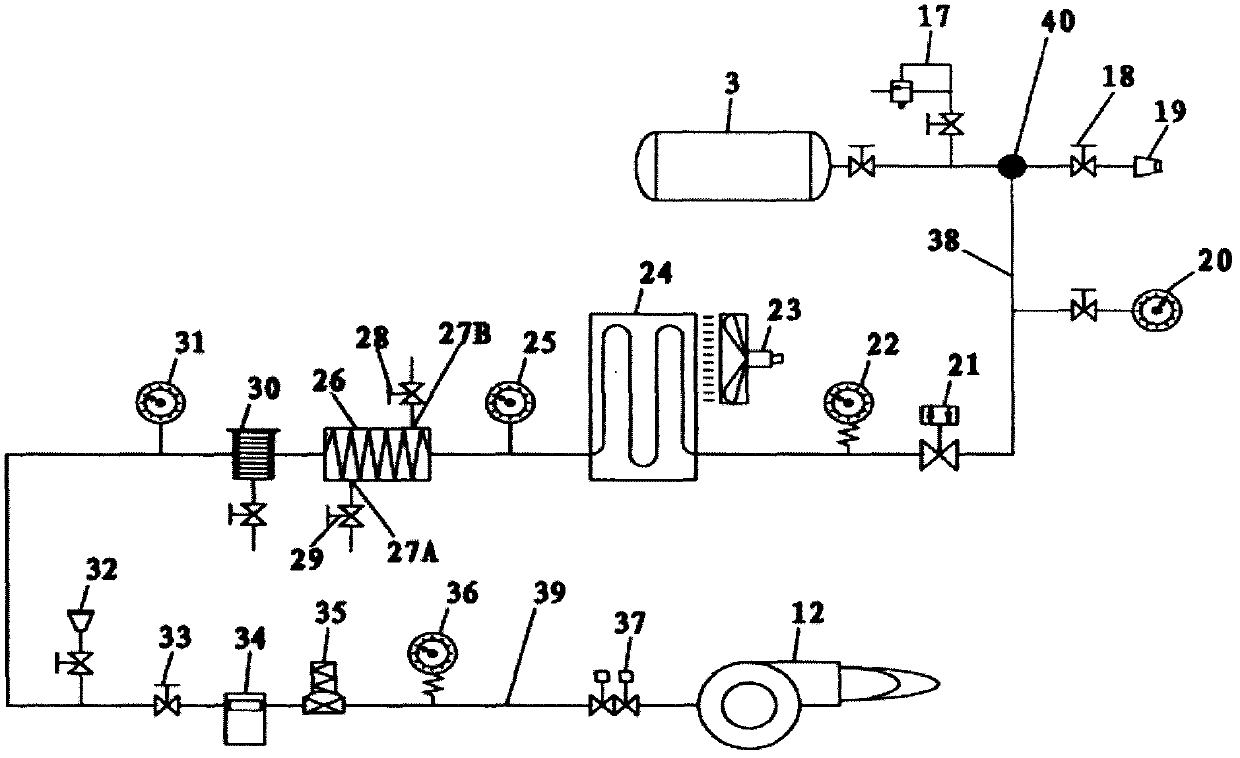

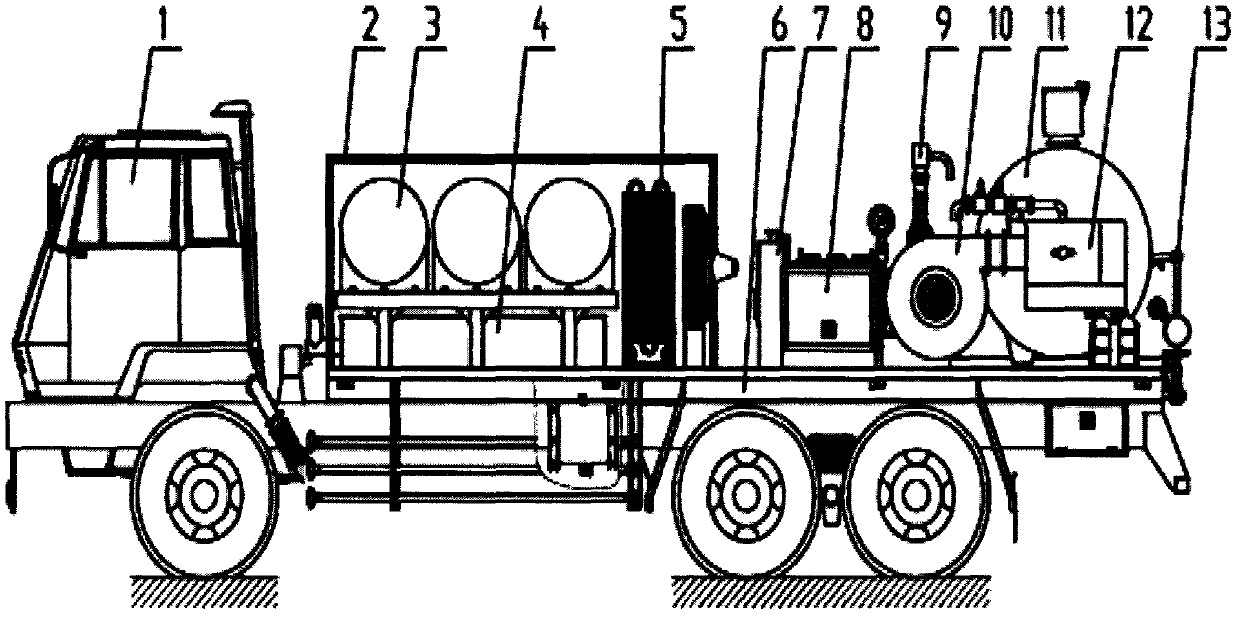

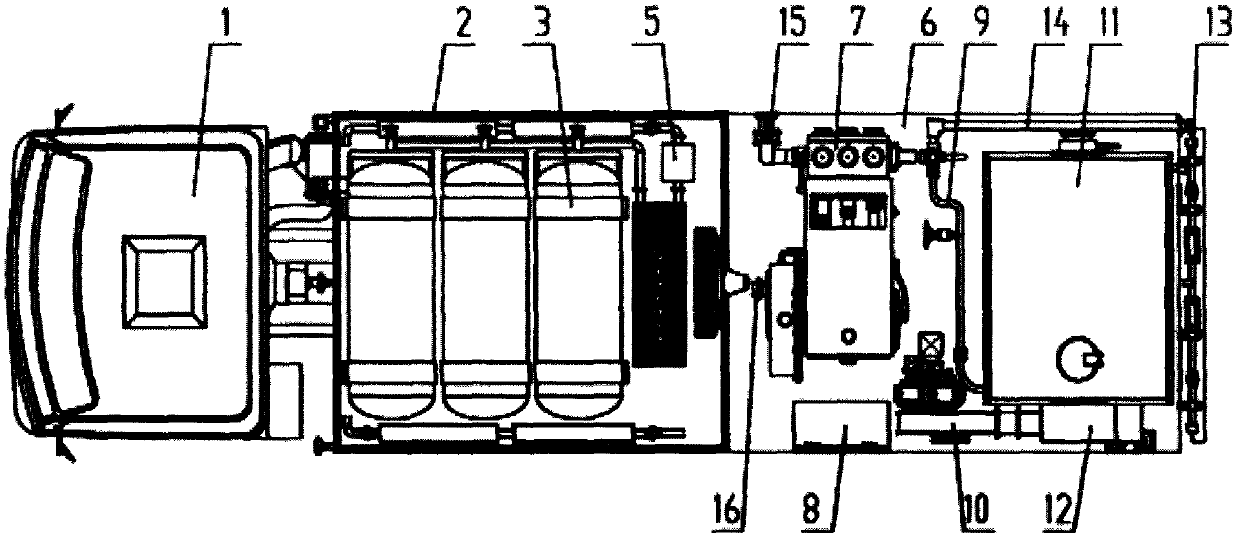

Fuel treating system and natural gas well-washing and wax-cleaning equipment

InactiveCN102635330AThe output temperature value increasesSolve quality problemsCleaning apparatusPressure vesselsWaxCombustion

The invention provides a fuel treating system and natural gas well-washing and wax-cleaning equipment. The fuel treating system disclosed by the invention comprises a fuel pipeline; the fuel pipeline comprises a gasification heat exchange pipeline and a decompression treatment pipeline which are sequentially communicated with each other along the flowing direction of fuel; the tail end of the decompression treatment pipeline is used for being connected with a combustion device and the initial end of the gasification heat exchange pipeline is used for being connected with an external fuel storage device; the gasification heat exchange pipeline is serially connected with a safety valve, an emergency cut-off valve, a gasifier and a heat exchanger; the heat exchanger is provided with a hot fluid inlet and a hot fluid outlet; the hot fluid inlet is used for being connecting with a hot water device and the hot fluid outlet is used for being connected with a water inlet pipeline of a water pump; and the decompression treatment pipeline is provided with a primary decompression valve. According to the invention, by arranging gasification heat exchange and primary decompression, liquefied natural gas with a pressure value and a temperature value which meet combustion requirements can be guaranteed to be output. The natural gas well-washing and wax-cleaning equipment using the fuel treating system disclosed by the invention uses the liquefied natural gas, reduces the quality and the volume of a whole vehicle and can effectively save the working cost.

Owner:ZYT GASOLINEEUM EQUIP

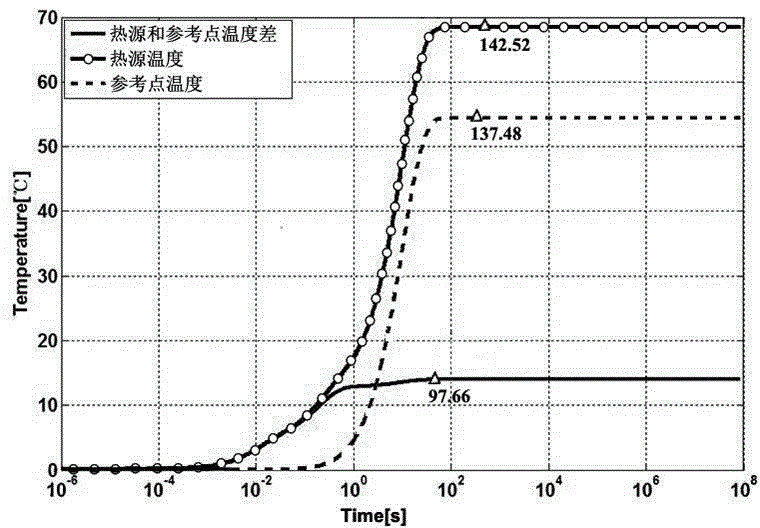

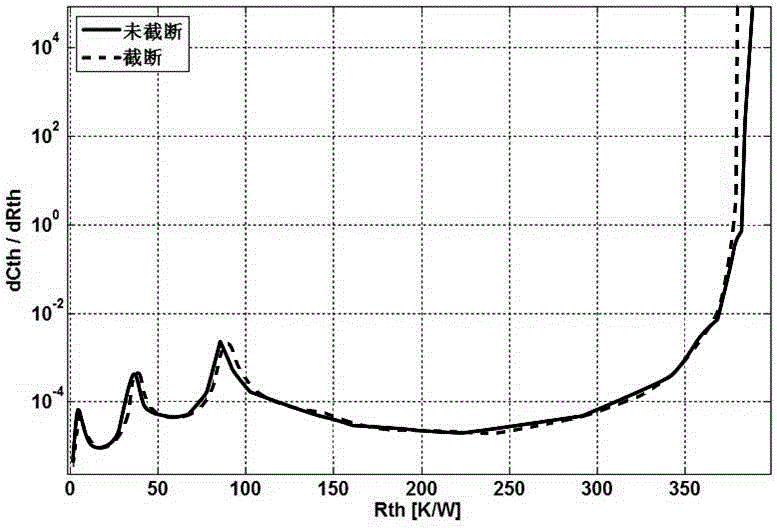

Thermal resistance analysis method

ActiveCN104950009AAccurate analysisShort analysis timeMaterial heat developmentImage resolutionThermal equilibrium state

The invention discloses a thermal resistance analysis method. The method comprises the following steps: synchronously monitoring the heat source temperature and reference point temperature of a high-power device, and introducing a quasi-thermal balance state judgment method with stable heat source and reference point temperature difference, so that accurate analysis of the thermal resistance information in a customized area of the high-power device can be realized, the reference point position can be accurately customized, and the resolution rate of the thermal resistance structure is effectively improved. The thermal resistance analysis method can be widely applied to accurate measurement of thermal characteristic tests of various high-power devices and has the characteristics of high efficiency, rapidness, wide application range and the like.

Owner:HANGZHOU EVERFINE PHOTO E INFO

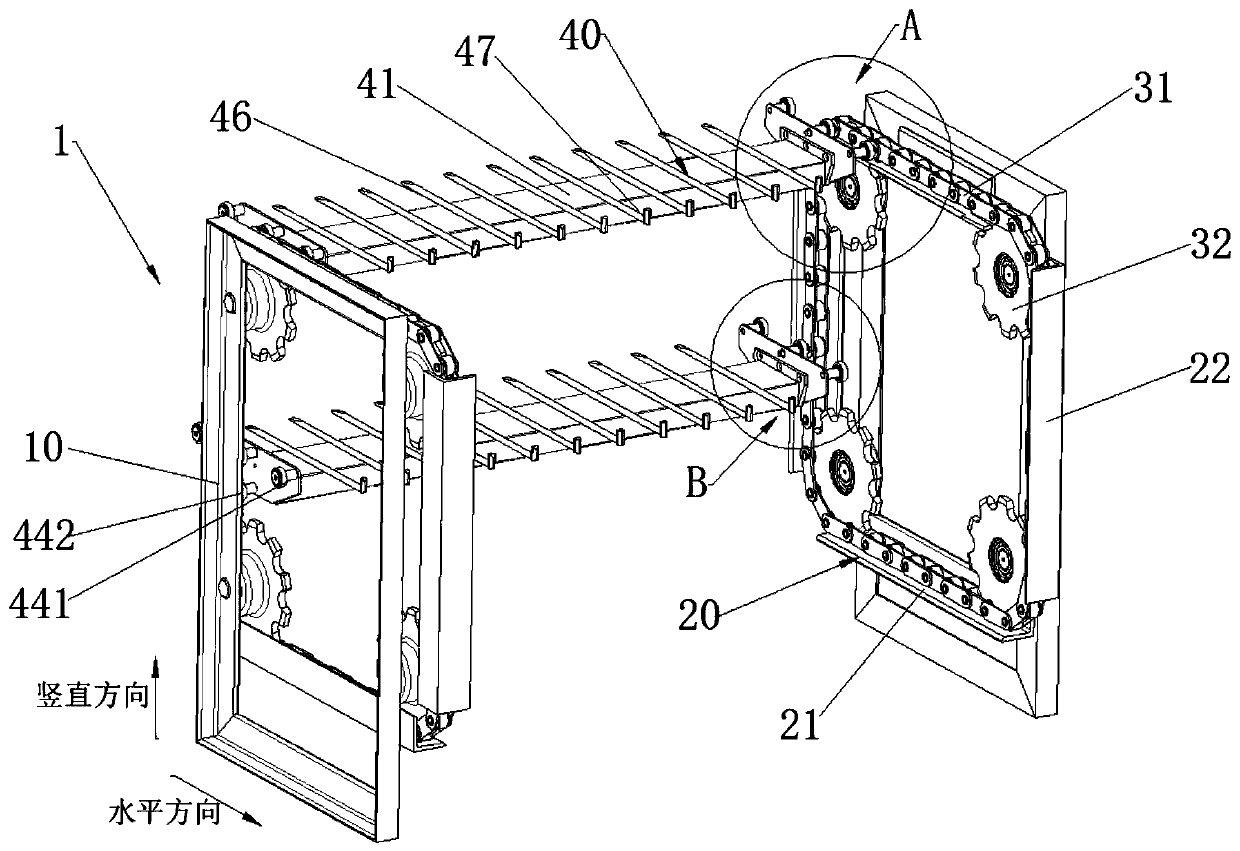

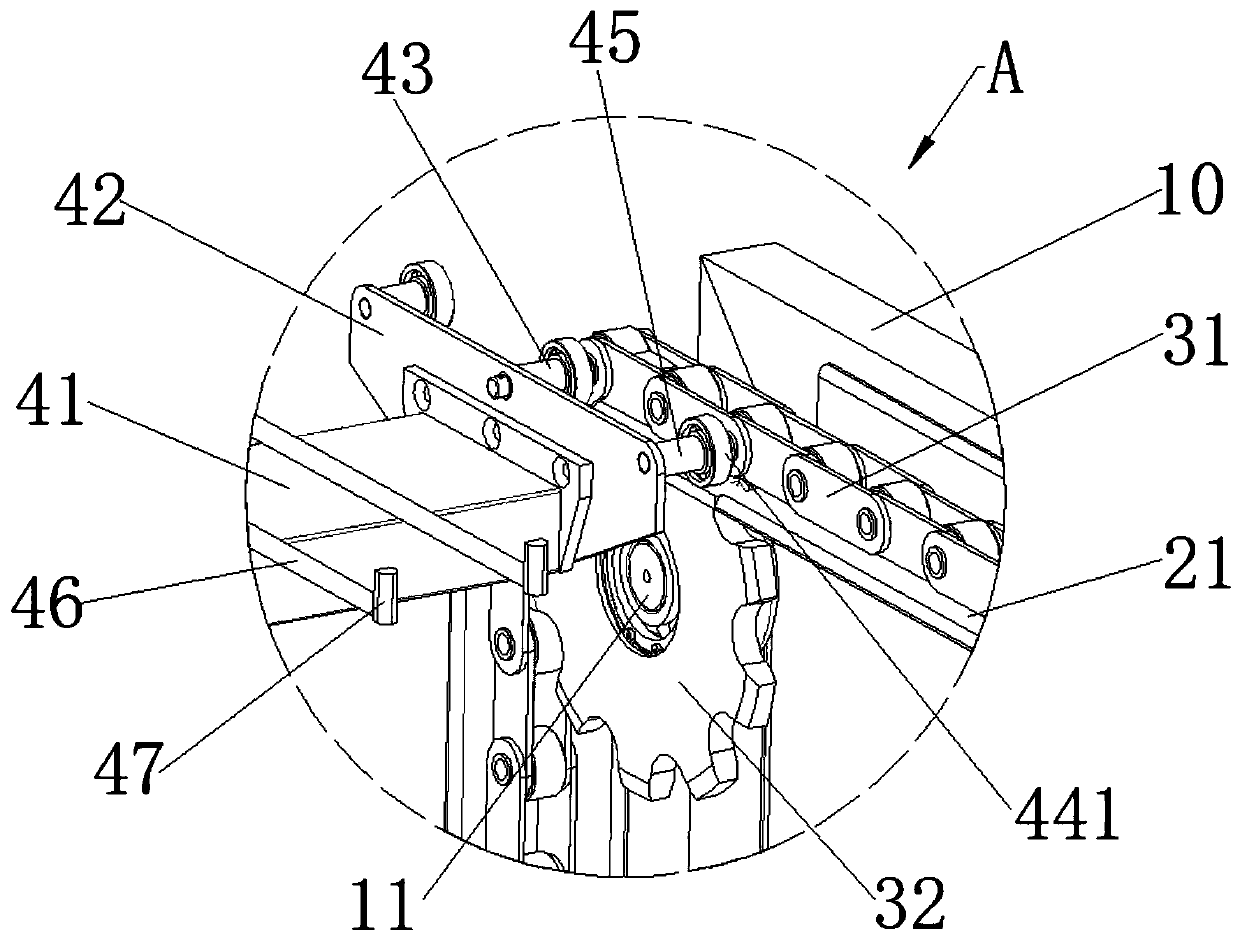

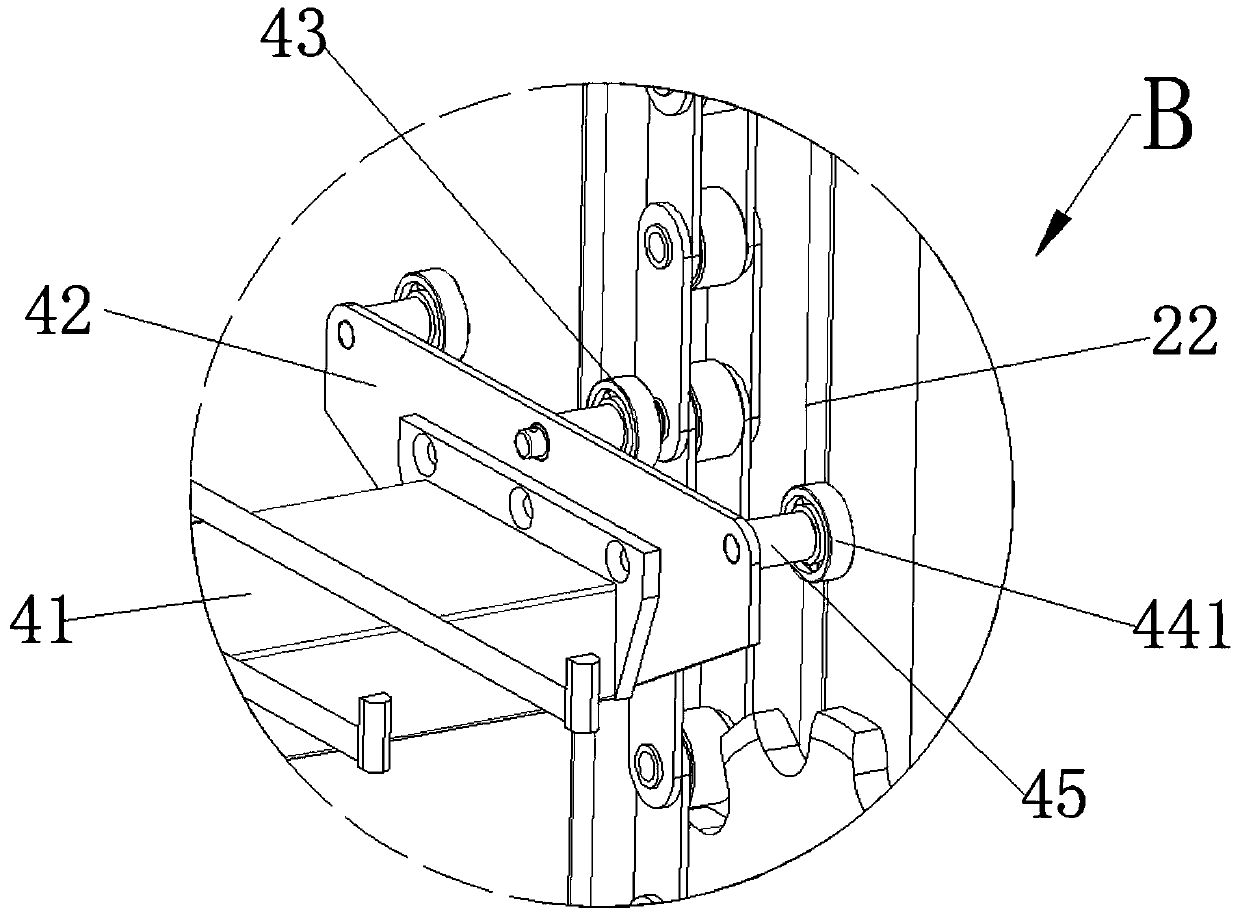

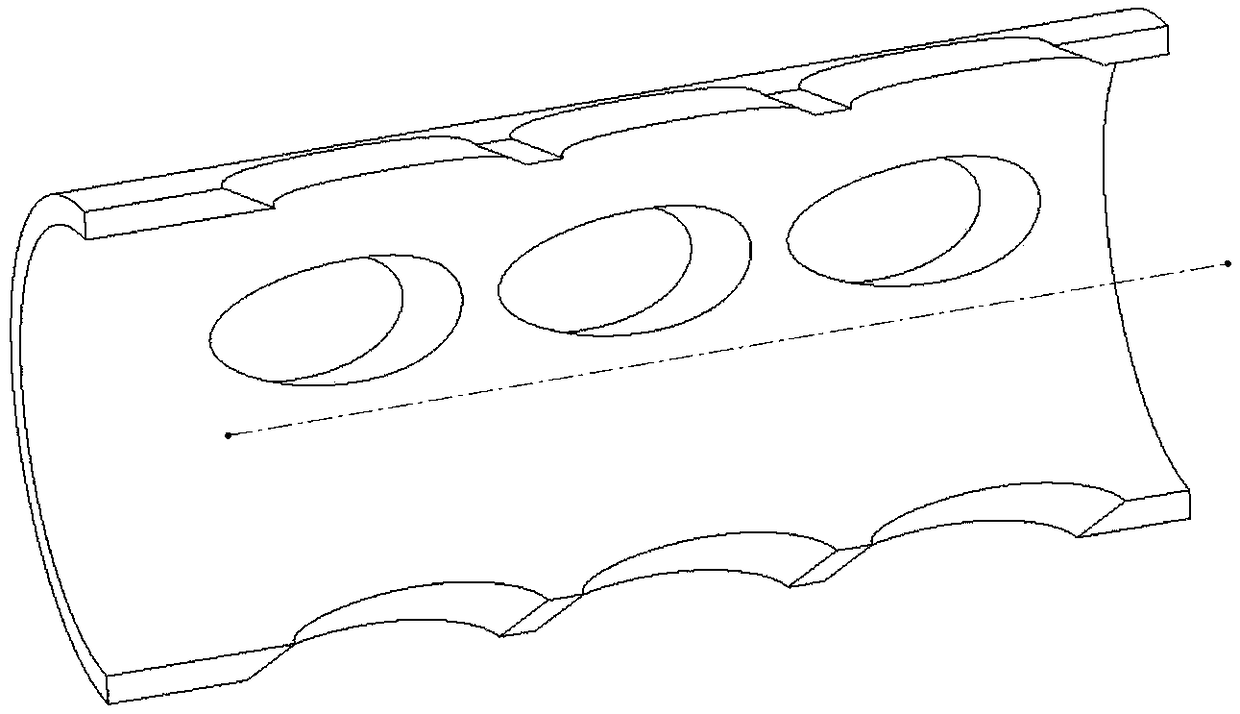

Turning motion structure and multi-layer food baking tunnel furnace

The invention provides a turning motion structure and a multi-layer food baking tunnel furnace. The turning motion structure comprises frames, guide rails, chains, support frames and chain wheels, wherein the guide rails are fixedly arranged on the frames and comprise horizontal guide rails and vertical guide rails; each chain wheel is rotatably connected with a rotating shaft fixedly arranged ona frame; a plurality of the chain wheels are arranged along the horizontal direction and the vertical direction of the frames correspondingly; the chains are in transmission connection with the chainwheels and are driven to move by rotation of the chain wheels; each support frame comprises a cross beam and supporting plates arranged at two ends of a cross beam; transmission rollers and guide rollers are arranged on supporting plates; the transmission rollers are fixedly connected with the chains; and the guide rollers can be propped against the guide rails. The turning motion structure provided by the invention has the following advantages: through transmission of the chain wheels and the chains, the support frames can be driven to move along a vertical or horizontal direction; through the guiding rollers, the support frames can move stably on the guide rails; thus, baking trays are prevented from tipping over; multi-layer baking of food in a vertical direction is realized; and the baking efficiency of a tunnel furnace is improved.

Owner:广州浩胜食品机械有限公司

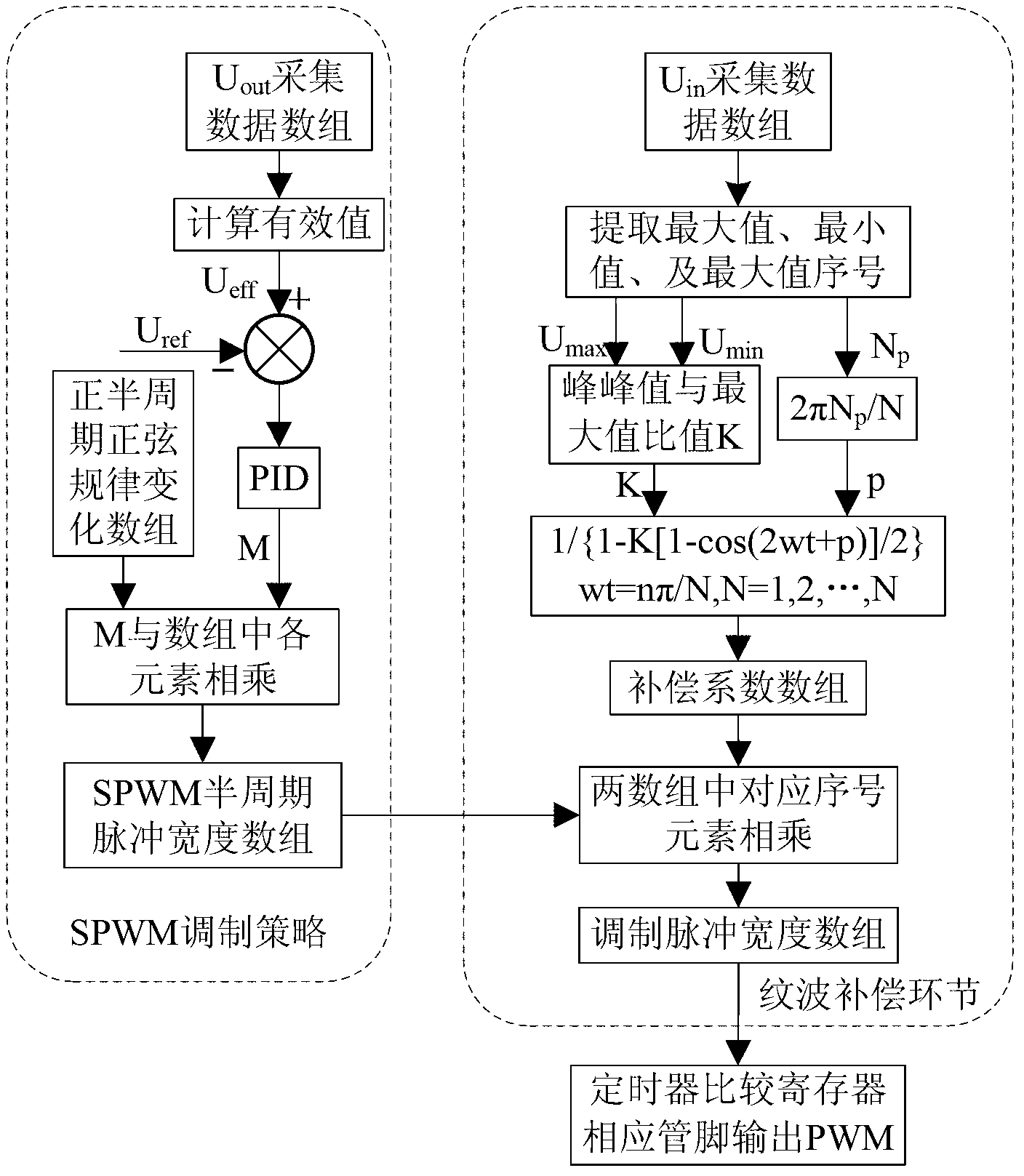

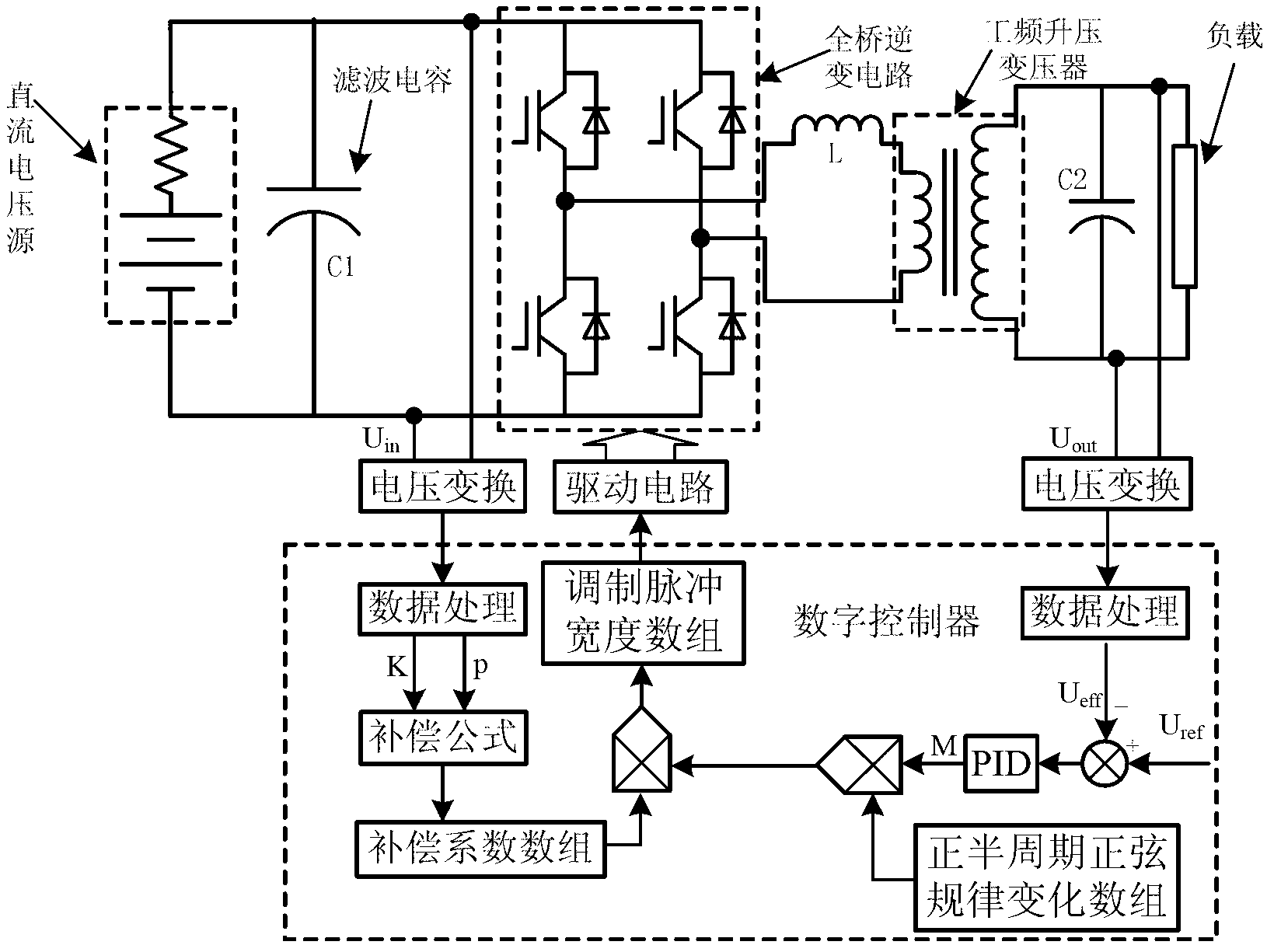

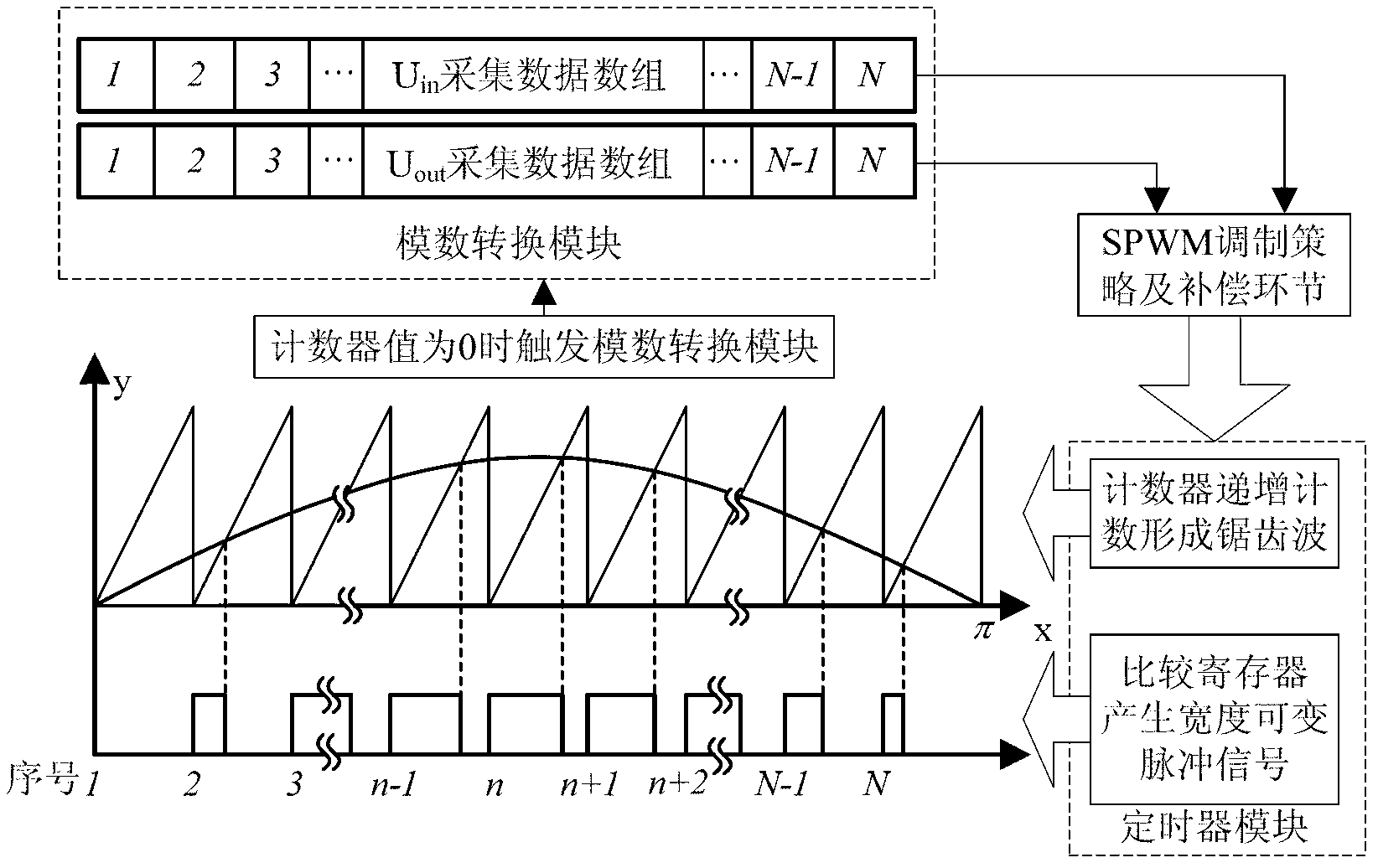

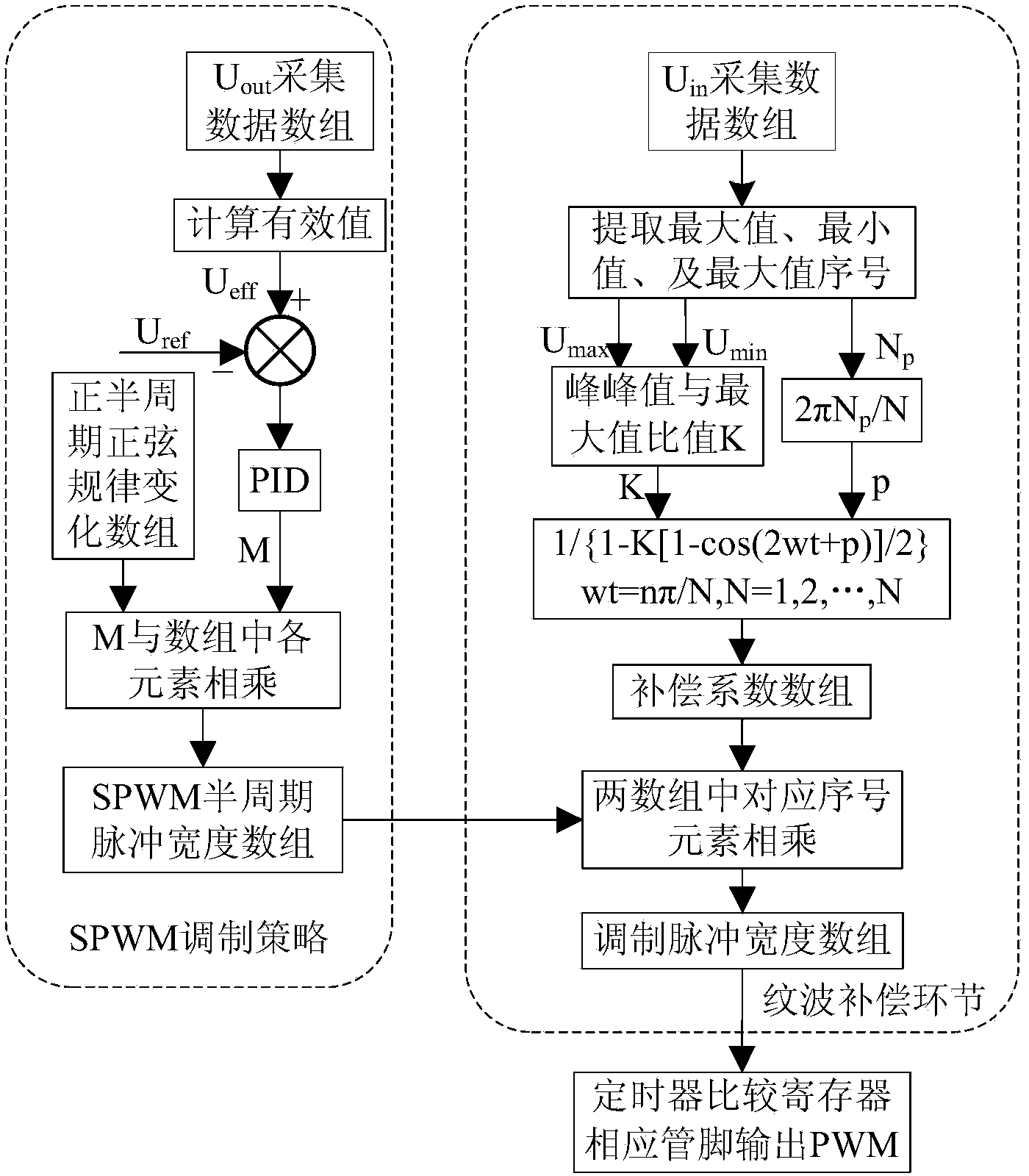

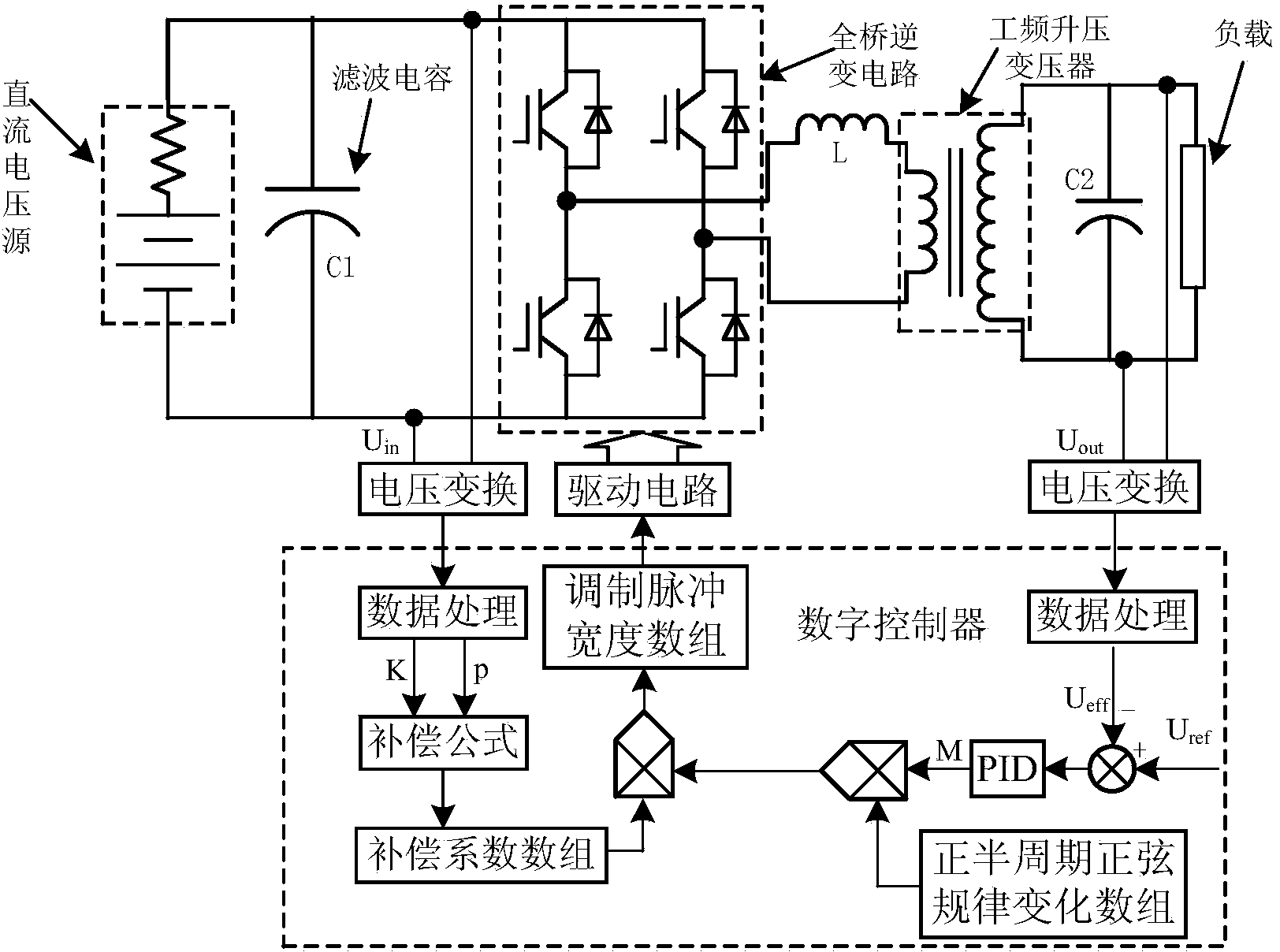

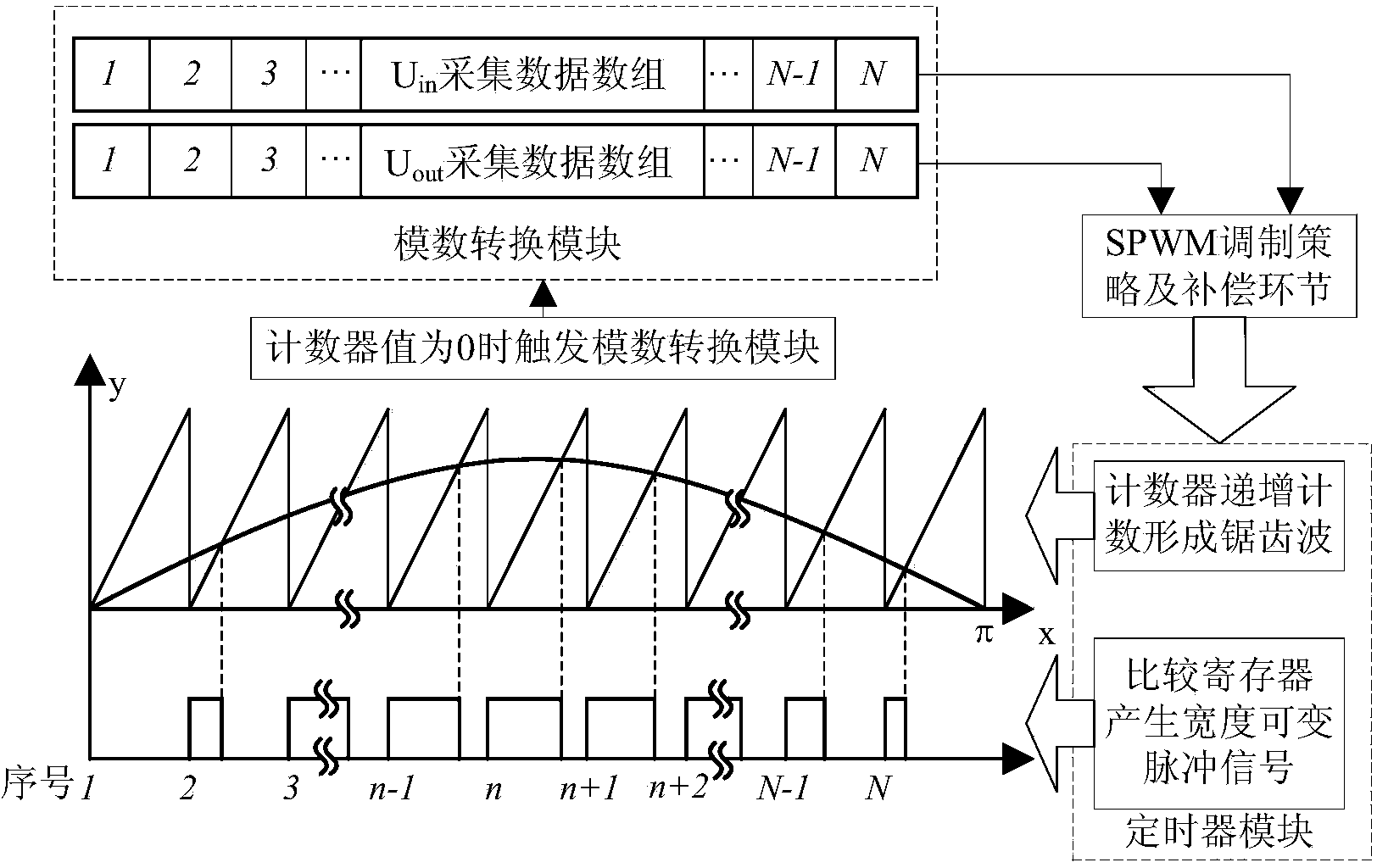

Ripple modulation compensation method for input voltage of single-phase inverter

InactiveCN103296871AIncrease costShorten control timePower conversion systemsSingle phaseVIT signals

A ripple modulation compensation method for input voltage of a single-phase inverter includes: inverter output voltage and full-bridge inverter circuit input voltage are collected while modulating pulse is output; SPWM (sinusoidal pulse width modulation) pulse signals are obtained by processing the inverter output voltage; ripple parameters are extracted from the full-bridge inverter circuit input voltage; according to pulse widths of the ripple parameter compensation SPWM signals, output voltage harmonic caused by ripples can be eliminated from compensated modulation. The method has the advantages that a modulation strategy is compensated only in software, so that hardware cost is saved; input voltage ripple parameters are compensated directly, so that ripple influence can be inhibited effectively and output quality of an inverter system is improved.

Owner:BEIJING EPSOLAR TECH

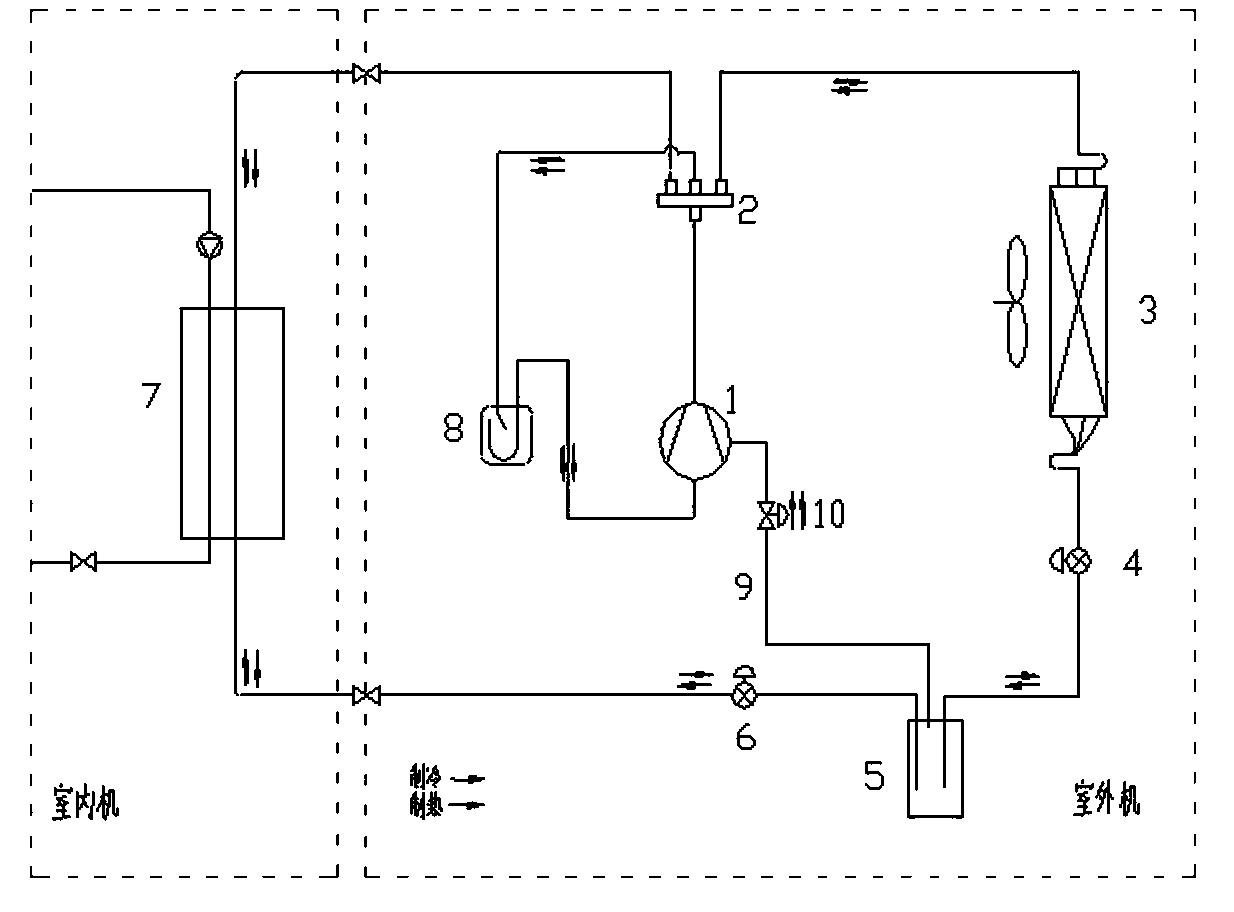

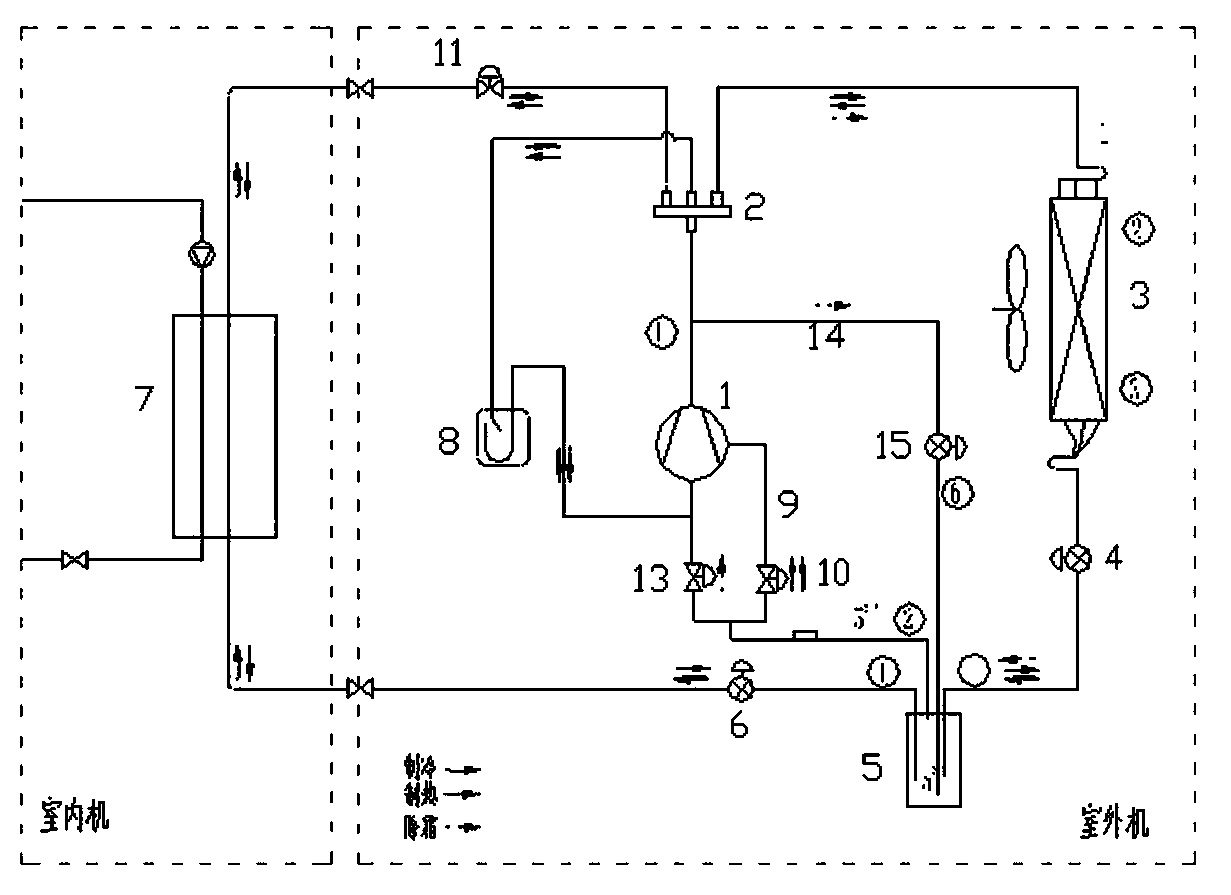

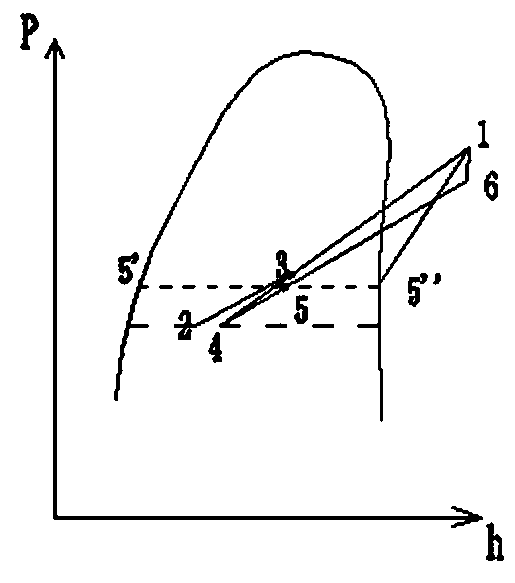

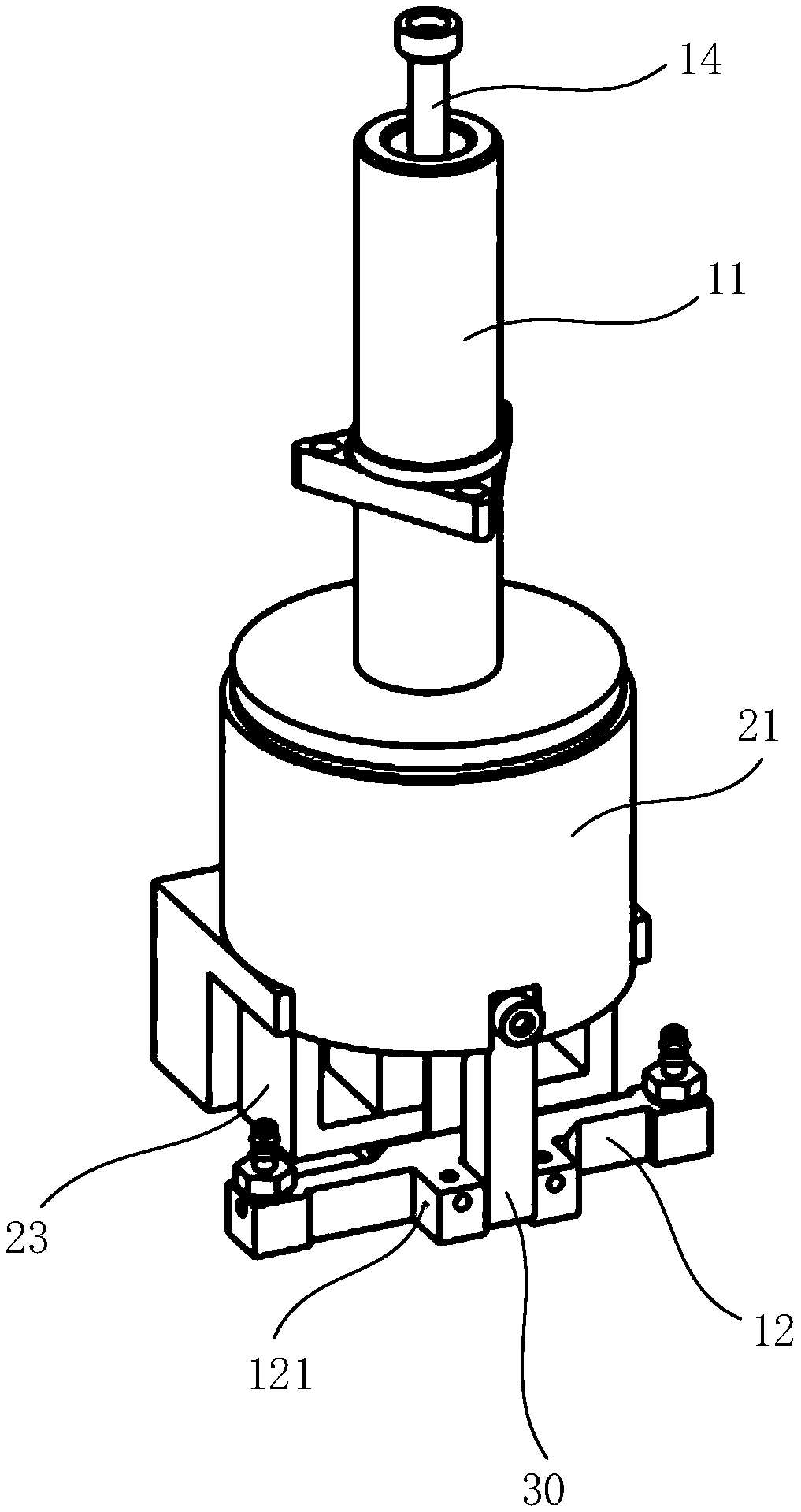

Heat pump circulating system with combined defrosting function and operation method

PendingCN108679890ANo need to increase the sizeSpeeds up the defrosting processCorrosion preventionRefrigeration componentsEngineeringElectromagnetic valve

The invention discloses a heat pump circulating system with a combined defrosting function and an operation method. The heat pump circulating system comprises a compressor, a four-way valve, an indoorheat exchanger and a flash evaporator, wherein an air supplementing pipeline is arranged between the flash evaporator and a compression cavity. A first electromagnetic valve (11) is arranged on a pipeline between the four-way valve (2) and the indoor heat exchanger (7), a branch is led out from the air supplementing pipeline (9), a second electromagnetic valve (13) is arranged on the branch, andthe other end of the branch is converged with an air inlet pipeline of the compressor. A bypass (14) communicating with the flash evaporator (5) is led out from an exhaust pipeline of the compressor,and a third expansion valve (15) is arranged on the bypass. A composite defrosting method combining reverse defrosting and hot air bypass defrosting is adopted, existing equipment of the system is directly used, the size of a vapor-liquid separator does not need to be increased, the defrosting process is accelerated, and the defrosting time is shortened.

Owner:GREE ELECTRIC APPLIANCES INC

Silicon wafer handover manipulator and silicon wafer handover device

ActiveCN110824850ANo need to increase the sizeImprove space utilizationGripping headsPhotomechanical exposure apparatusElectric machineStructural engineering

The invention discloses a silicon wafer handover manipulator, a silicon wafer handover device and a photoetching machine. The silicon wafer handover manipulator comprises an air floatation adsorptionassembly and a motor; the motor comprises a base, a coil framework and two magnet assemblies; a coil is wound on the coil framework; the coil framework is connected with the inner side of the base ina sleeving manner; the two magnet assemblies are arranged under the coil framework in a spaced mode; each of the magnet assemblies is in a U shape; a U-shaped groove is opposite to the coil framework;the air floatation adsorption assembly comprises a shaft sleeve, a shaft seat, an air floatation shaft and an adsorption rod; the shaft sleeve is connected with the coil framework; the shaft seat isconnected with the two magnet assemblies; one end of the air floatation shaft is connected with the shaft seat; the other end of the air floatation shaft penetrates through a gap between the two magnet assemblies and the coil framework to extend into the shaft sleeve; and the adsorption rod is connected with the shaft sleeve in a sleeving manner and connected with the air floatation shaft. The silicon wafer handover manipulator can improve the yield and exposure precision of a photoetching machine. The invention further provides a silicon wafer handover device with the silicon wafer handover manipulator.

Owner:SHANGHAI MICRO ELECTRONICS EQUIP (GRP) CO LTD

Resistance change memory and preparation method thereof

ActiveCN102881824AImprove storage densityNo need to increase the sizeElectrical apparatusElectrical resistance and conductanceStorage cell

The embodiment of the invention discloses a resistance change memory and a preparation method thereof. The resistance change memory comprises a substrate and a plurality of memory units at intervals on the substrate; each memory unit comprises a lower electrode, a resistance change layer and an upper electrode; the lower electrode is positioned on the substrate; the resistance change layer is positioned on the lower electrode; the upper electrode is positioned on the resistance change layer; and the resistance change layer comprises a resistance change material part and at least one doped resistance change part doped with elements for adjusting a resistance state. The invention also discloses a preparation method for the resistance change memory. According to the resistance change memory and the preparation method thereof, the resistance change layer is not made of a single resistance change material, and a plurality of resistance states can be generated according to different voltage in the set operation process of a resistance changer, so that the memory density of the resistance changer is increased; and meanwhile, the size of the resistance changer is not required to be increased.

Owner:PEKING UNIV

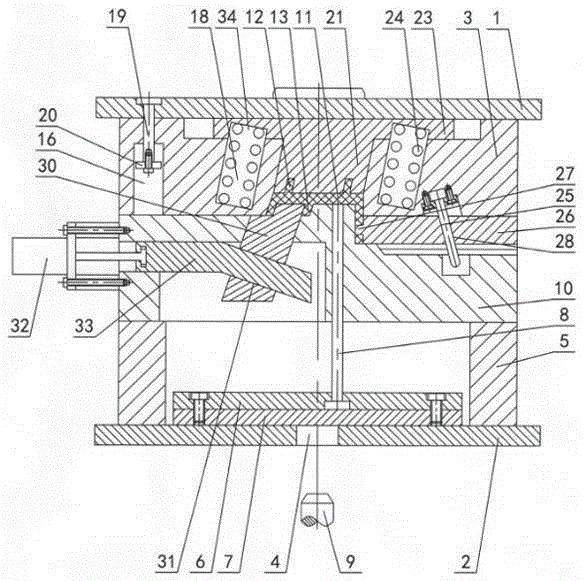

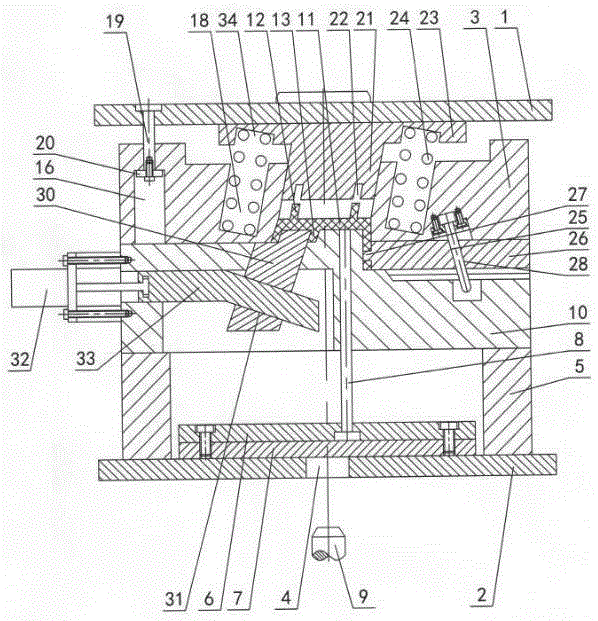

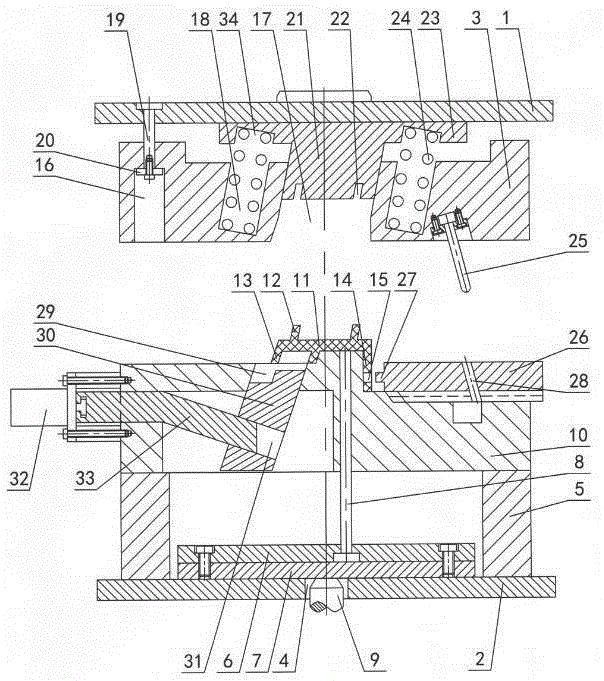

Three-way core-pulling mechanism of injection mold

Owner:ZHEJIANG KAIHUA MOLDS

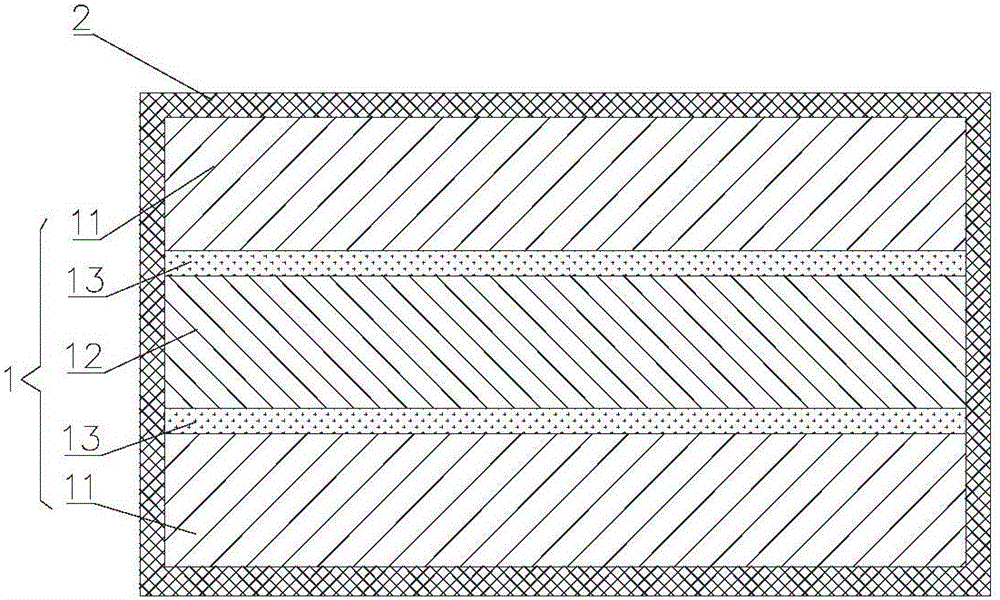

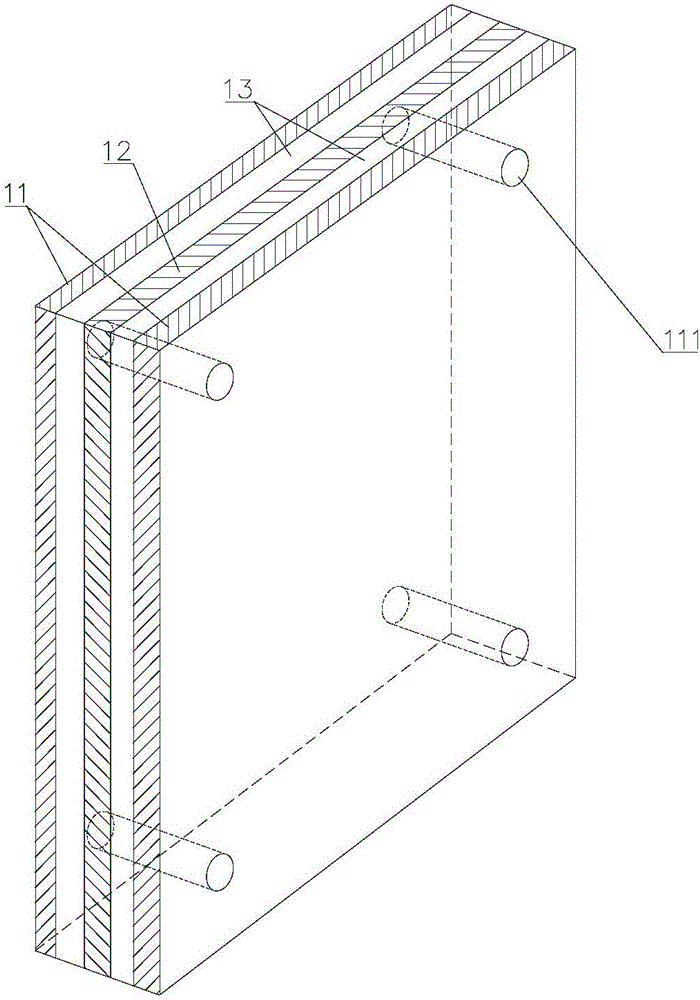

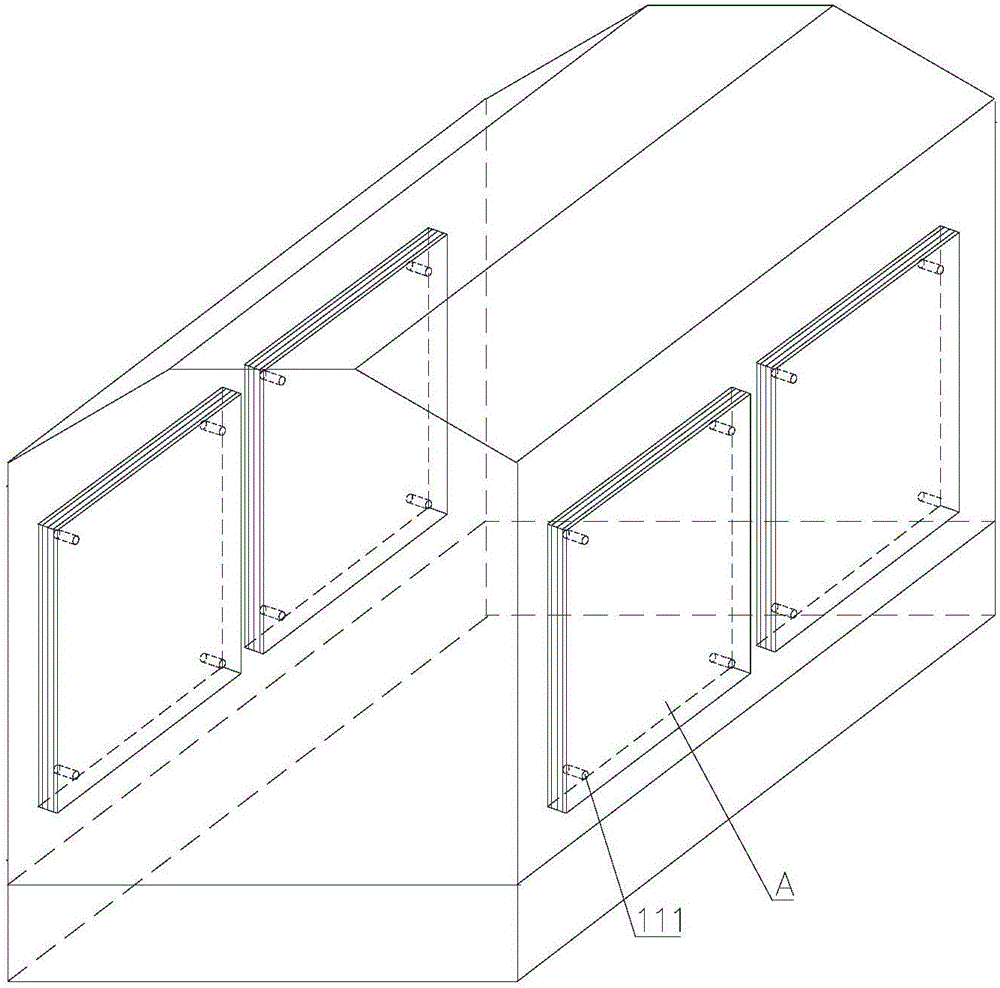

Noise reduction apparatus for transformer, transformer oil tank and transformer

InactiveCN105810419APlay a protective effectLow costTransformers/inductances coolingTransformers/inductances noise dampingFuel tankPaperboard

The invention discloses a noise reduction device for a transformer, a transformer oil tank and a transformer. The noise reduction device includes: a noise reduction board, and an insulating layer covering the surface of the noise reduction board; the noise reduction board includes: at least two cardboard layers, and a metal sheet layer arranged between adjacent cardboard layers; Moreover, the topmost layer and the bottommost layer of the noise reduction board are both cardboard layers. The noise reduction device has the advantages of low cost and good noise reduction effect. Moreover, since the noise reduction device can be arranged in the idle space in the transformer oil tank, there is no need to avoid the line, and it is not necessary to increase the volume of the transformer. At the same time, the straight inner wall of the transformer is also conducive to simplifying the structure of the noise reduction device, making it easy to process and realize industrial production.

Owner:CHINA ELECTRIC POWER RES INST +2

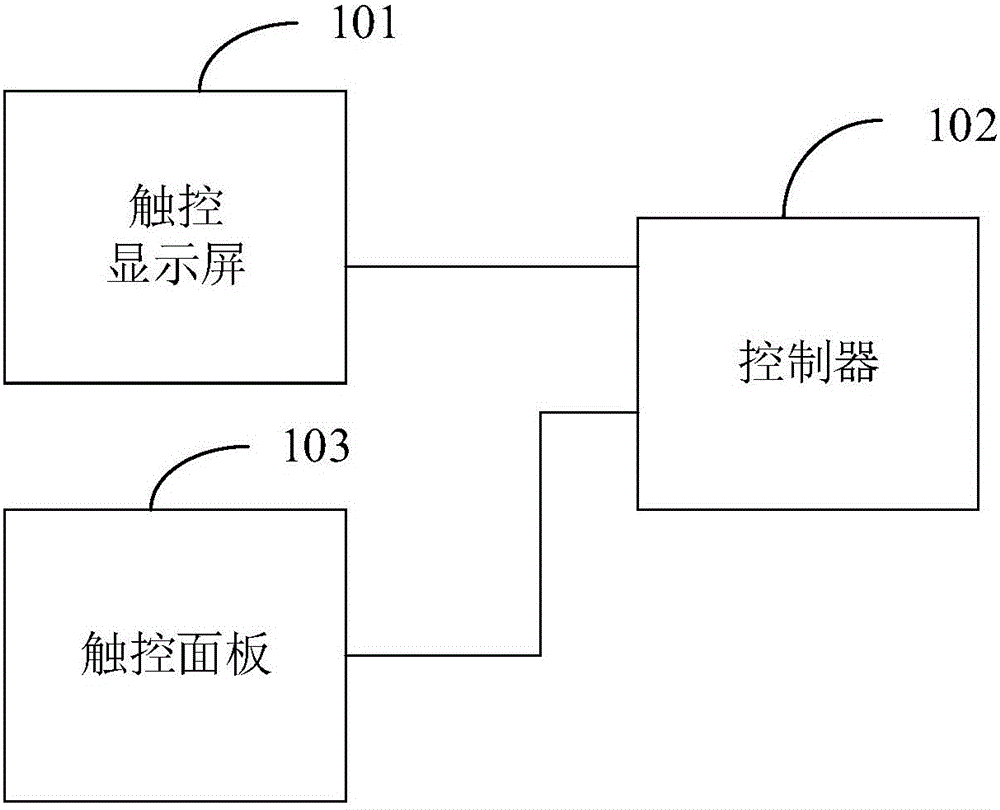

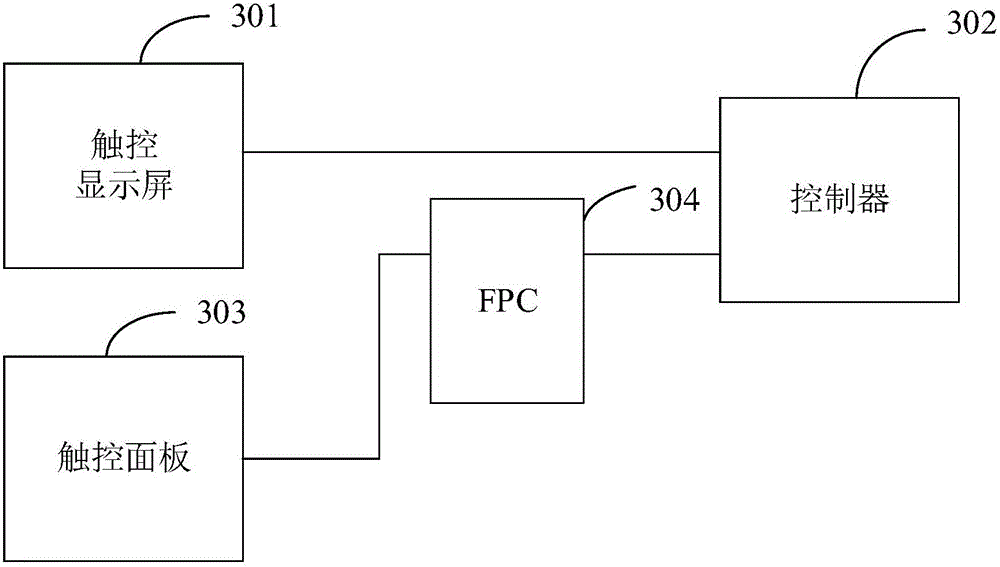

Intelligent terminal and control method therefor

InactiveCN106020349AVersatileNo need to increase the sizeDigital data processing detailsInput/output processes for data processingElectricityTouch panel

The invention discloses an intelligent terminal and a control method therefor. The intelligent terminal comprises a touch display screen, a controller and a touch panel, wherein the controller is electrically connected with the touch display screen and the touch panel; and the touch panel is integrated in a camera accessory of the intelligent terminal. Existing components of the intelligent terminal are reasonably utilized without additionally increasing costs, so that the intelligent terminal is richer in function, the convenience is provided for users, and the user experience is improved. Moreover, holes do not need to be additionally formed in other parts of a back housing of the intelligent terminal for mounting the touch panel, and the intelligent terminal can be more attractive without increasing the original volume of the intelligent terminal.

Owner:SHENZHEN TINNO WIRELESS TECH

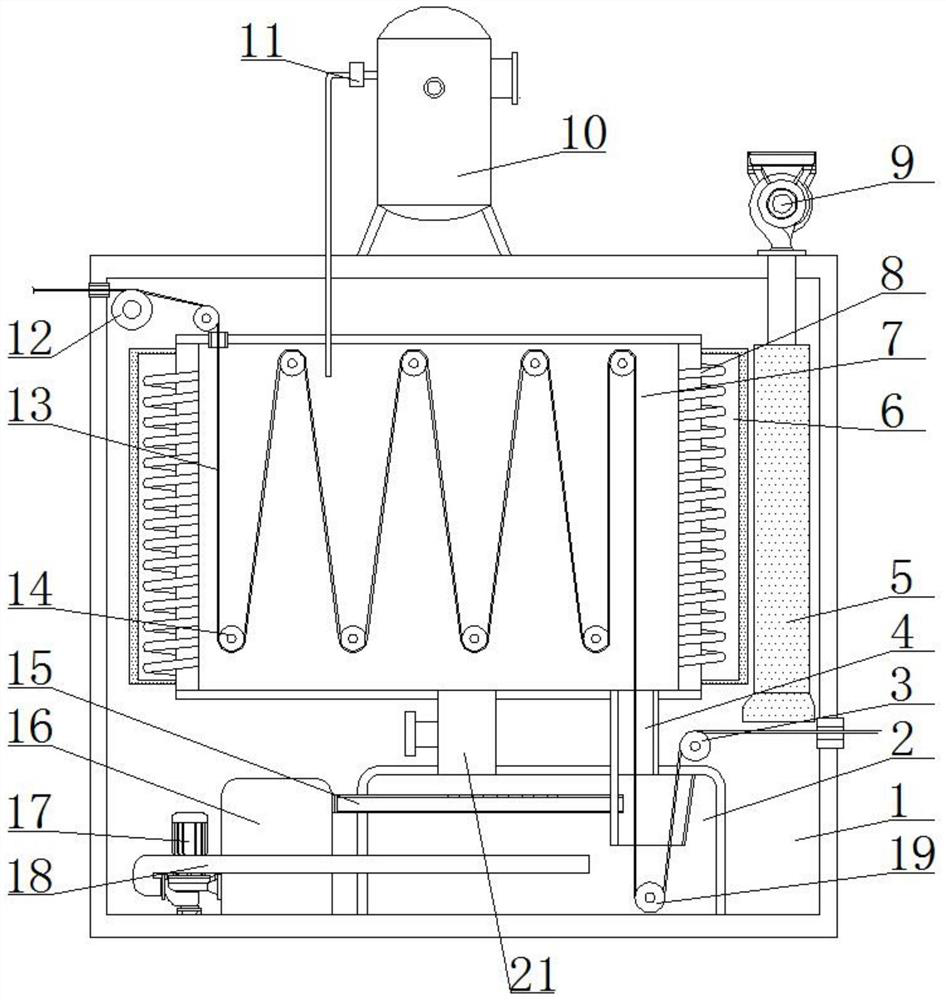

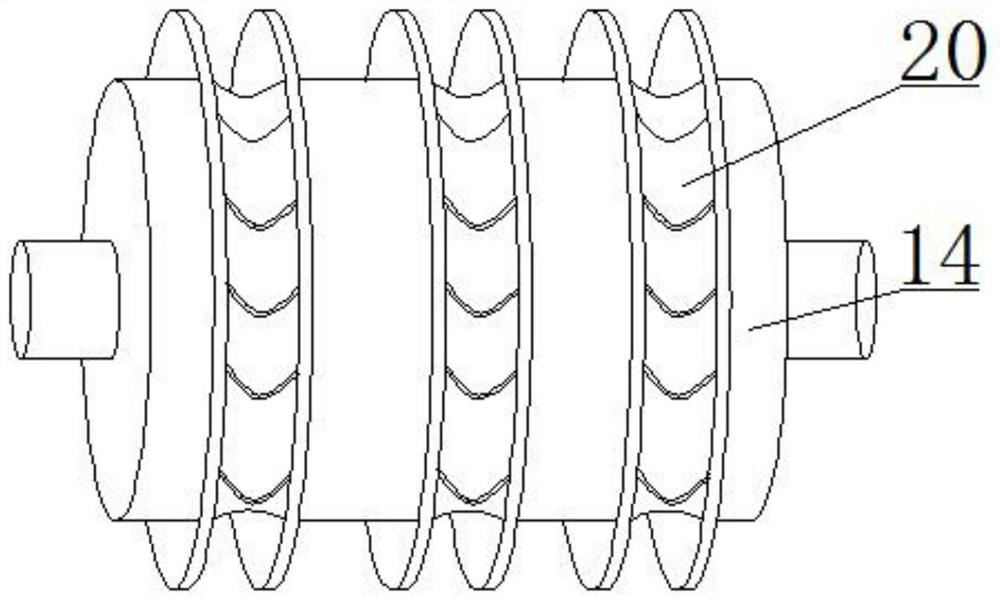

Annealing furnace for enamelled wire production

PendingCN111996361ANo need to increase the sizeNo need to increase powerFurnace typesIncreasing energy efficiencyMetallurgyCirculating pump

The invention relates to the technical field of enamelled wire production, and discloses an annealing furnace for enamelled wire production. The annealing furnace comprises an annealing furnace shell,a cooling water tank is fixedly installed at the bottom of an inner cavity of the annealing furnace shell, a first winding roller is movably installed inside the cooling water tank, a grease separation box is fixedly installed on a position, located on the left side of the cooling water tank, at the bottom of the inner cavity of the annealing furnace shell, a circulating pump is fixedly installedon the position, located on the left side of the grease separation box, at the bottom of the inner cavity of the annealing furnace shell, and the input end of the circulating pump fixedly communicates with the left side face of the grease separation box. According to the annealing furnace for enamelled wire production, an original electric heating pipe type annealing furnace is changed into an existing electromagnetic induction type annealing device, annealing operation can be carried out on a plurality of enamelled wires at the same time, meanwhile, the power of the annealing device does notneed to be increased; and and through the arranged multiple internal wire rollers, the length of the annealed enameled wires located inside can be increased, and the size of the annealing furnace does not need to be increased, so that a large amount of space is saved.

Owner:白建生

A gas circuit breaker with enhanced insulation recovery function

InactiveCN106710960BImprove insulation performanceSpeed up the insulation recovery rateHigh-tension/heavy-dress switchesAir-break switchesCore componentEngineering

Owner:SHANGHAI SIEYUAN HIGH VOLTAGE SWITCHGEAR +1

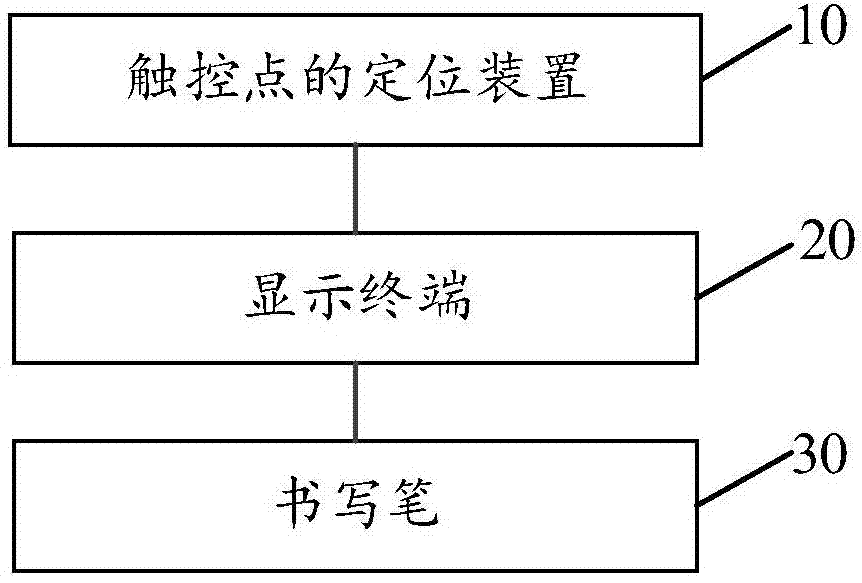

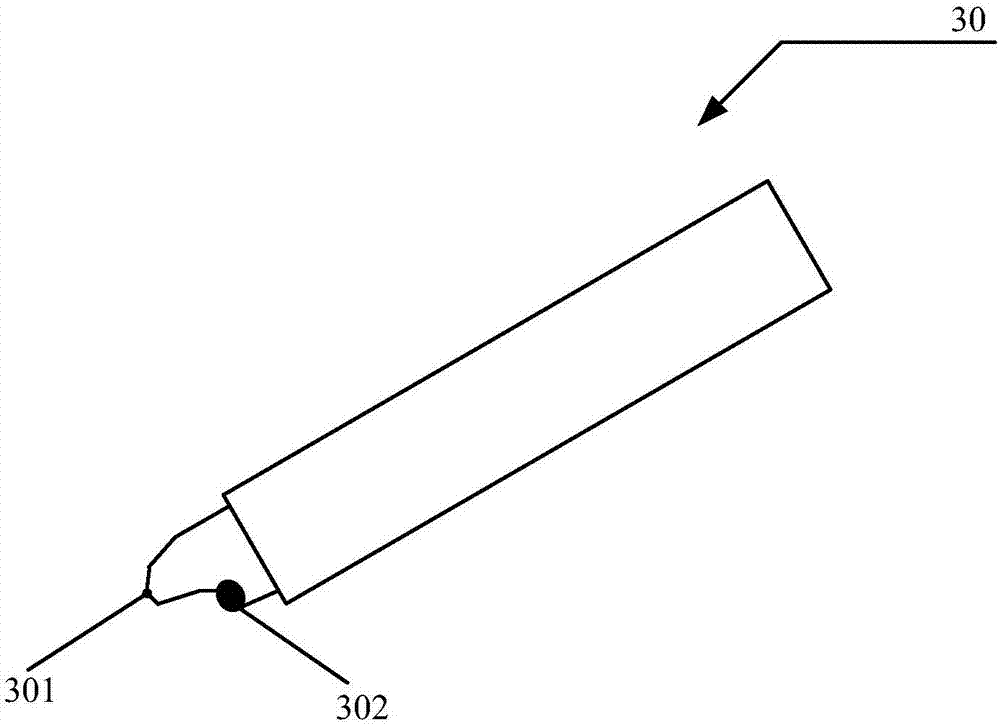

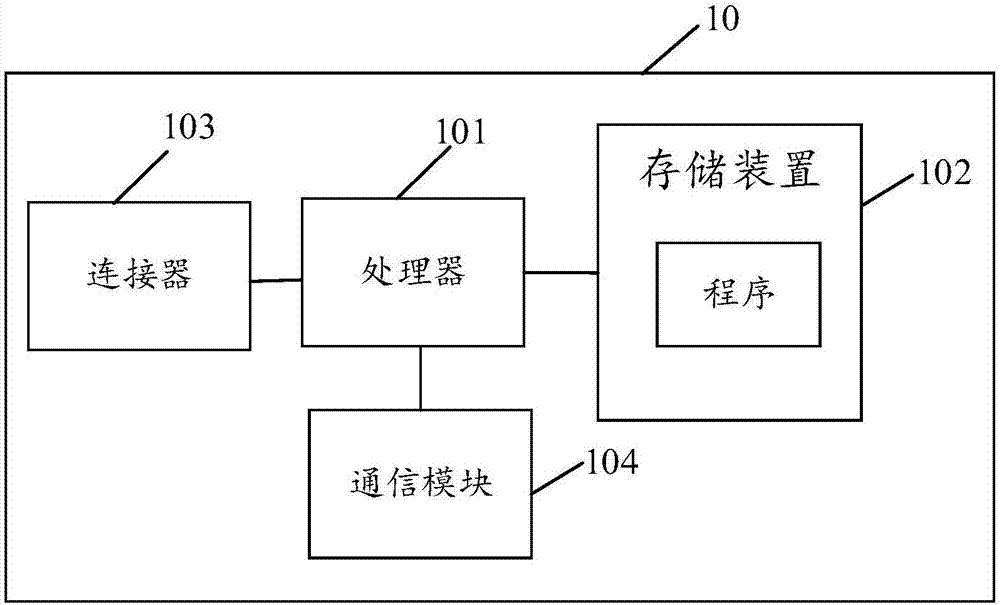

Method, device and system for positioning of touch control point, display terminal and writing pen

InactiveCN107479729AAchieve positioningNo need to increase the sizeInput/output processes for data processingComputer terminalComputer engineering

The invention discloses a method, device and system for positioning of a touch control point. The method comprises the steps that a positioning image with position encoding information is sent to a display terminal under a set frequency, so the positioning image is displayed by the display terminal; further, a touch control image which is sent by a writing pen and is shot and obtained when the writing pen conducts a touch control operation on the display terminal with the displayed positioning image is received; then, the position encoding information in the touch control image is extracted; and the position of a touch control point in the positioning image is determined according to the extracted position encoding information, so a touch control position of the writing pen on the display terminal can be positioned. According to the invention, on the premise that cost is low and the size of display terminal is not increased, the touch control point on the display terminal can be positioned, so cost is saved; and the display terminal with a touch control point positioning function is lighter, thinner and nicer, so user's experience is improved effectively.

Owner:GUANGZHOU SHIYUAN ELECTRONICS CO LTD +1

Integrated power combustion device

PendingCN111486454AEmission reductionNo need to increase the sizeFuel supply regulationDirect carbon-dioxide mitigationNitrogen oxidesMetallic materials

The invention discloses an integrated power combustion device. The integrated power combustion device comprises a power combustor, a single-chip microcomputer, a gas device, a power adapter and an operation interface; an aerodynamic gas device is arranged on one side of the power combustor, and the other side of the power combustor is connected with the gas device; a fuel gas injection pipe, a gasinverted-cone-shaped fluid director, a mixed gas gathering device, a wave-shaped net, a fire spraying cover, an ignition device and a flame detection device are arranged in the power combustor; and the fuel gas device comprises a fuel gas pipeline, a fuel gas electromagnetic valve, a fuel gas pressure stabilizing valve and a fuel gas pressure sensor. Compared with the prior art, the integrated power combustion device has the advantages that the pressure of gas entering a house can be stabilized and balanced, flame is in a thin transparent sharp corner shape during burning, combustion productsof carbon monoxide, nitric oxide and carbon dioxide can be greatly reduced at the same time, the burning speed is high, the burning intensity and heat explosive power are high, time is saved, the energy-saving and low carbon effect is remarkable, the combustor is small in size, the requirement for high-heat-load firepower can be met, and the manufacturing cost of metal materials is saved.

Owner:武汉净燃科技有限公司

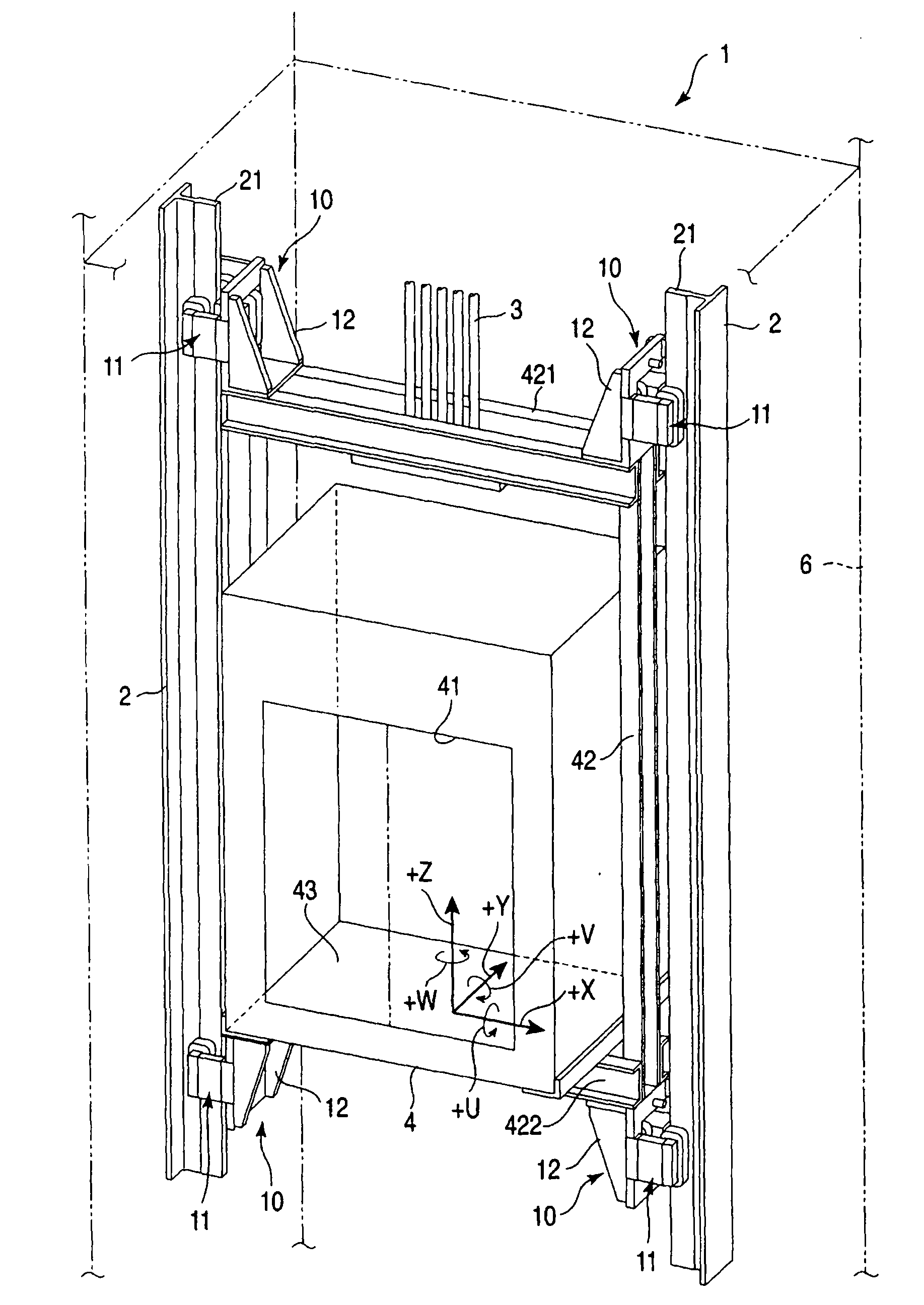

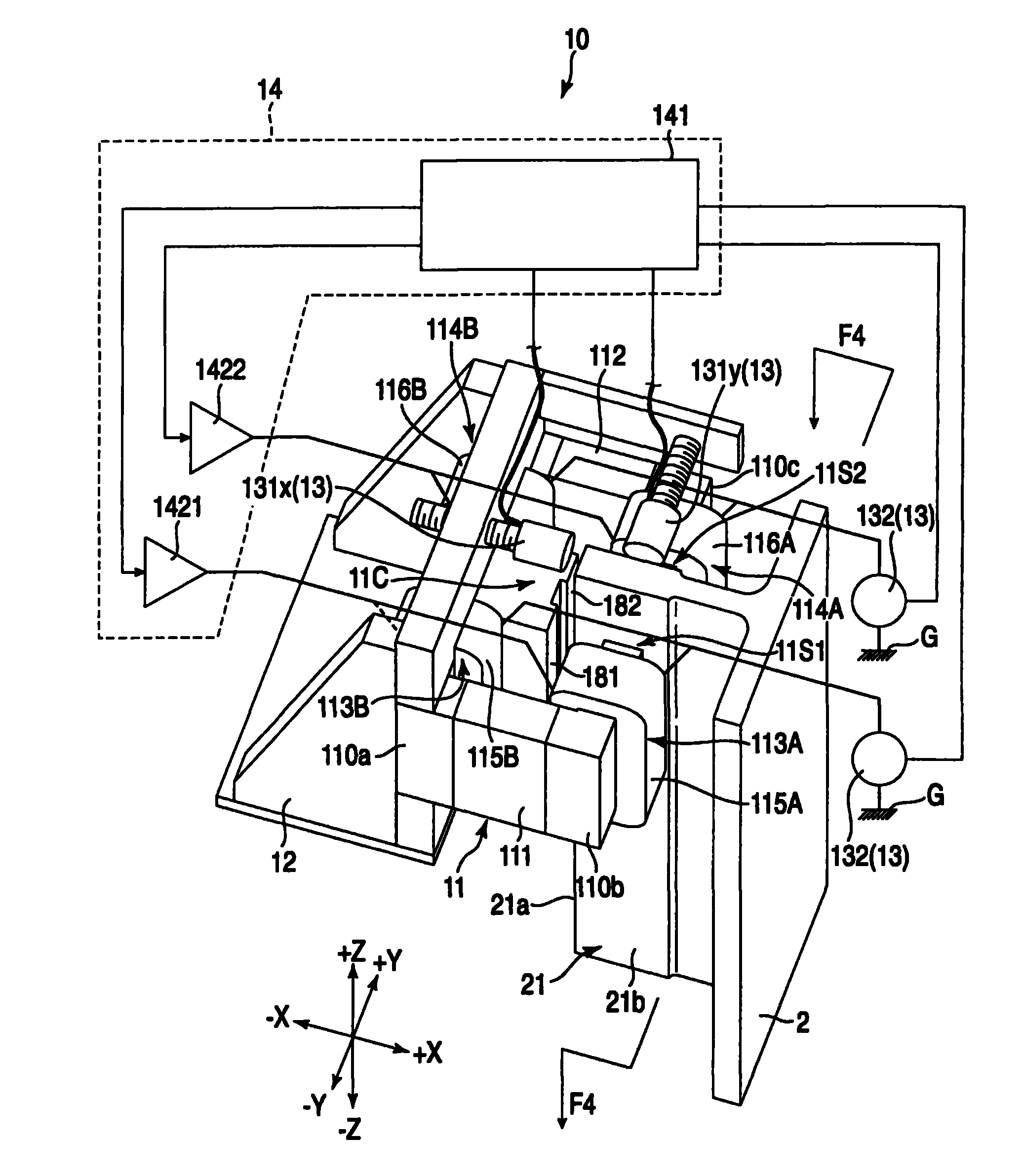

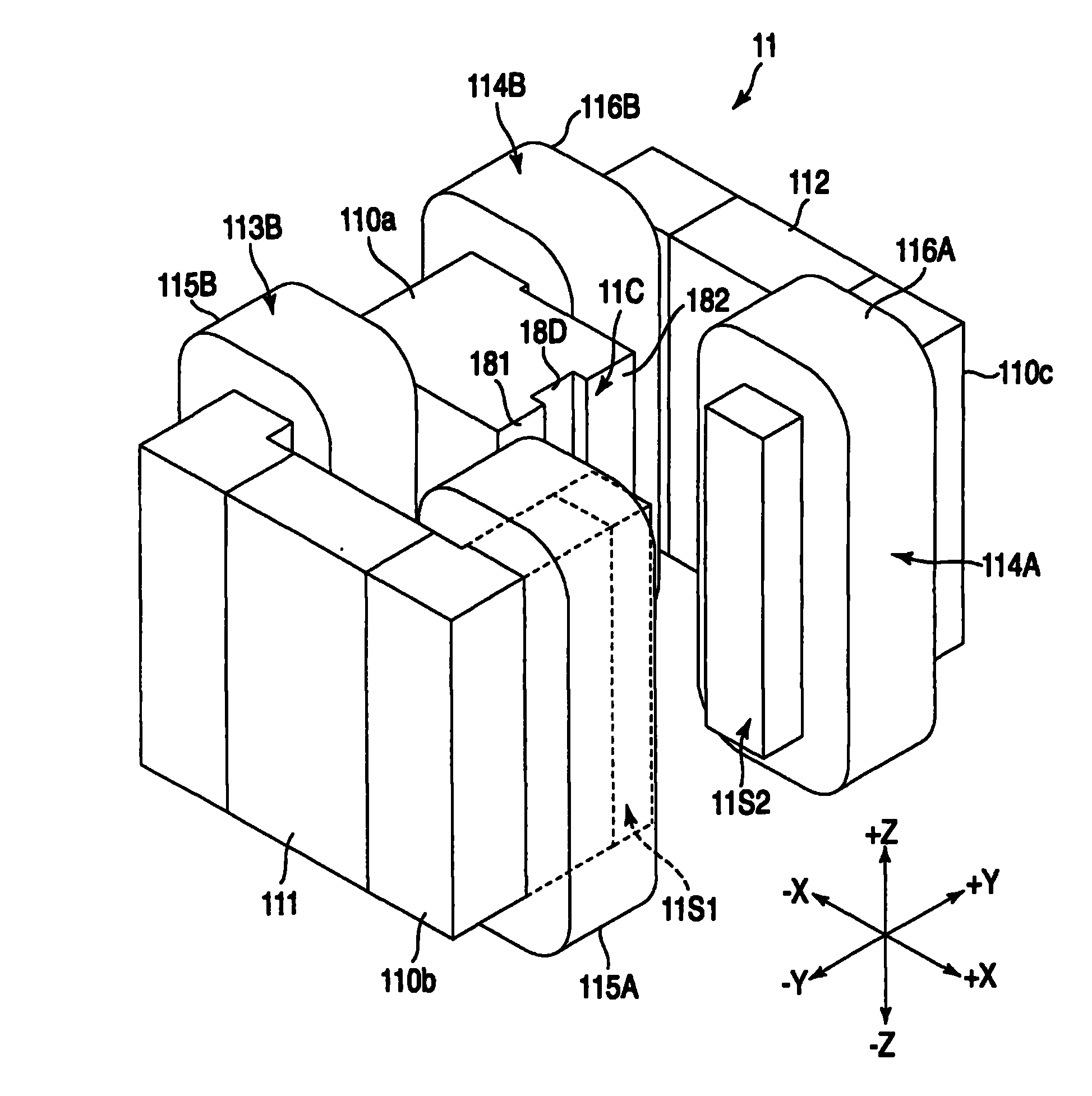

Magnetic guiding apparatus of elevator

InactiveCN102009894AEnhanced magnetic forceNo need to increase the sizeElevatorsMagnetic polesControl unit

A guide apparatus includes a pair of guide rails (2), magnet units (11), pedestals (12), a sensor unit (13), a magnetic guide control apparatus as a control unit (14), and projected parts (181, 182). The magnet unit (11) includes electromagnets (113A, 113B, 114A, 114B) and permanent magnets (111, 112) and magnetic poles (11C, 11S1, 11S2) thereof are opposed to a blade (21) of the guide rail (2) from three directions with a gap. The projected parts (181, 182) are formed with side parts of a tip part of a central magnetic pole (11C) opposite to a tip surface (21a) of the blade (21) of the guide rail (2) among the magnetic poles of the magnet unit (11) being brought closer to the guide rail than a center section thereof.

Owner:TOSHIBA ELEVATOR KK

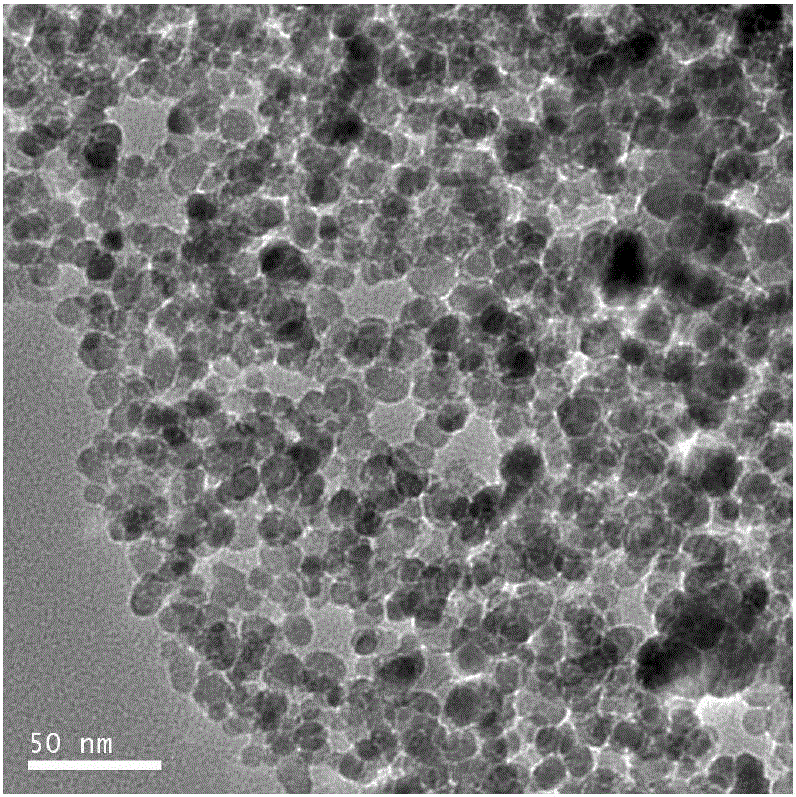

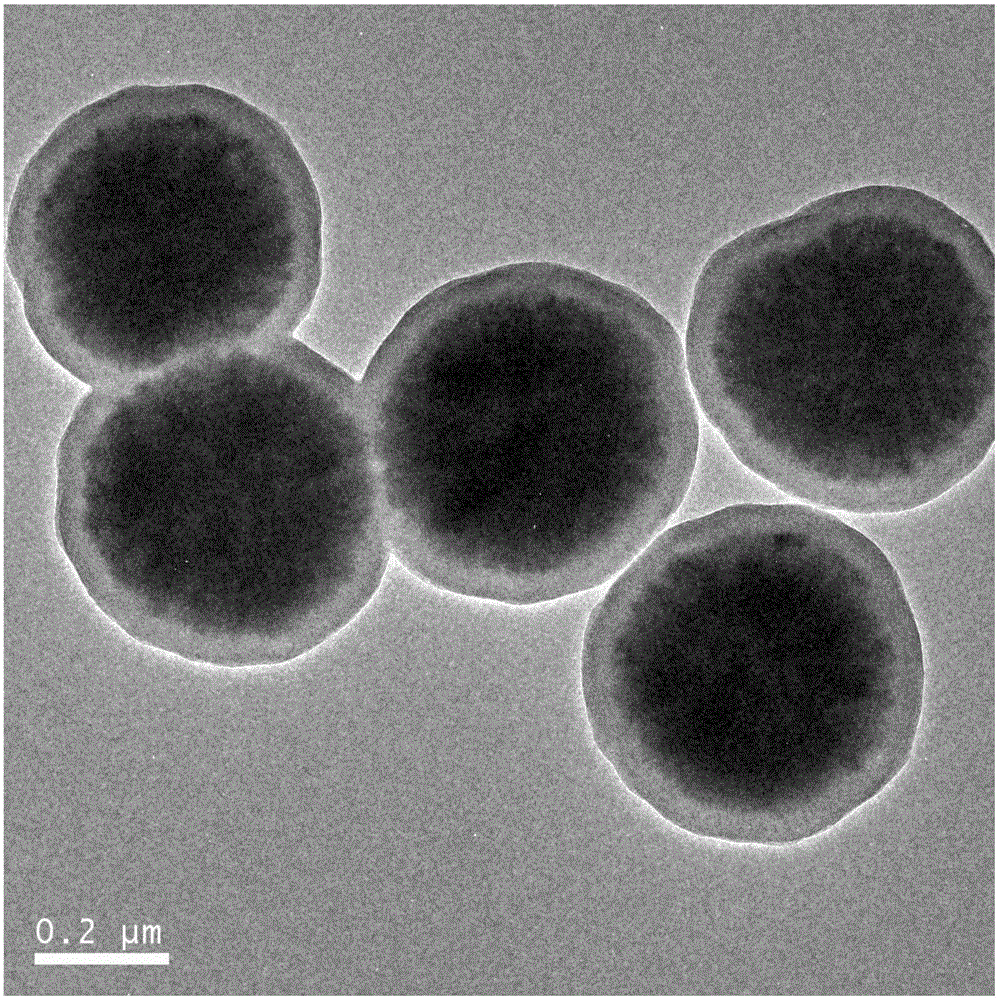

Monodisperse strong-magnetism immunologic nanoparticles and preparation method thereof

ActiveCN105869813AHave independent claimsDetailed Independent ClaimsInorganic material magnetismInductances/transformers/magnets manufactureDispersityMicrosphere

The invention discloses monodisperse strong-magnetism immunologic nanoparticles. The particle size of the monodisperse strong-magnetism immunologic nanoparticles ranges from 5 nm to 5 microns. The invention further discloses a preparation method of the monodisperse strong-magnetism immunologic nanoparticles. The method includes the following steps that firstly, ferroferric oxide nanoparticles are prepared; secondly, monodisperse silicon hydroxyl magnetic nanoparticles are prepared; thirdly, monodisperse amination magnetic nanoparticles are prepared; fourthly, the monodisperse strong-magnetism immunologic nanoparticles are prepared. The monodisperse strong-magnetism immunologic nanoparticles and the preparation method thereof have the advantages that superparamagnetism is good, the magnetic content is high, dispersity is good, the agglomeration phenomenon dose not exist, the appearance is regular and standard, the particle size is unified and controllable, and functional modification is easy.

Owner:杭州卓立纳米科技有限公司

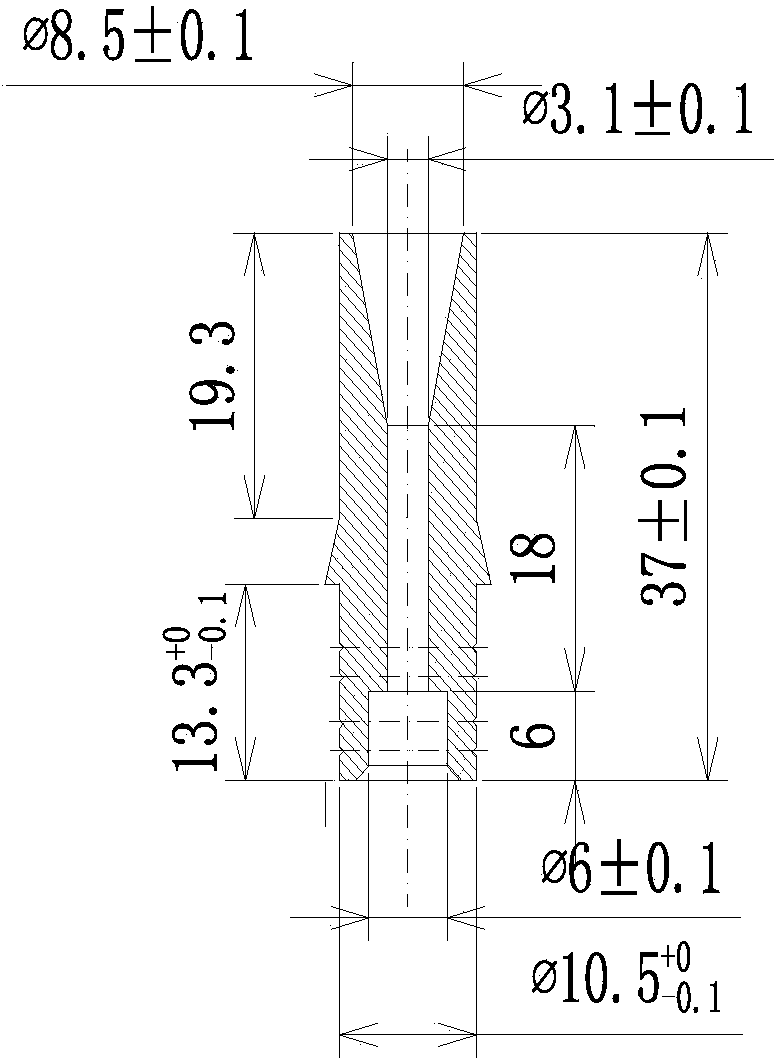

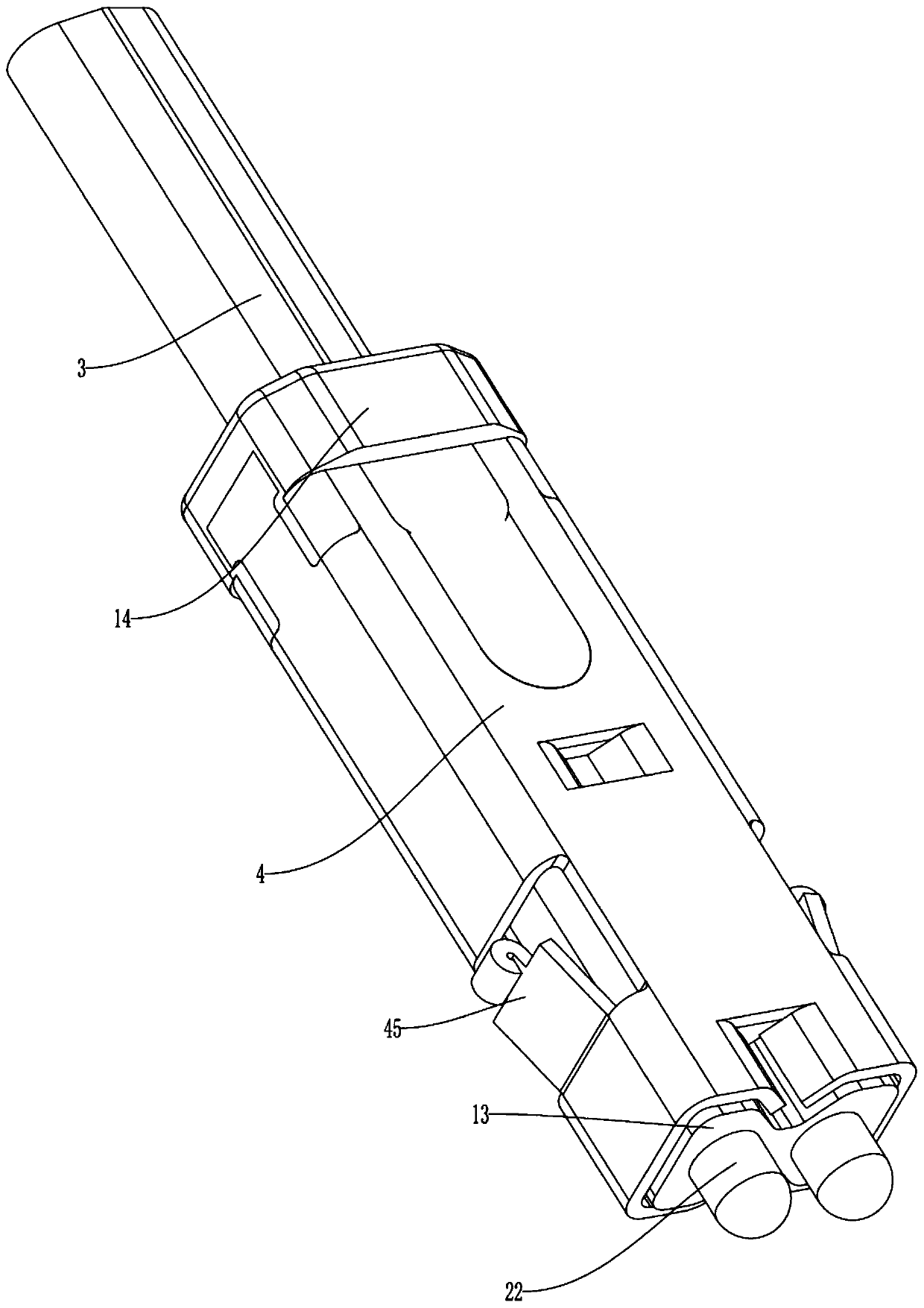

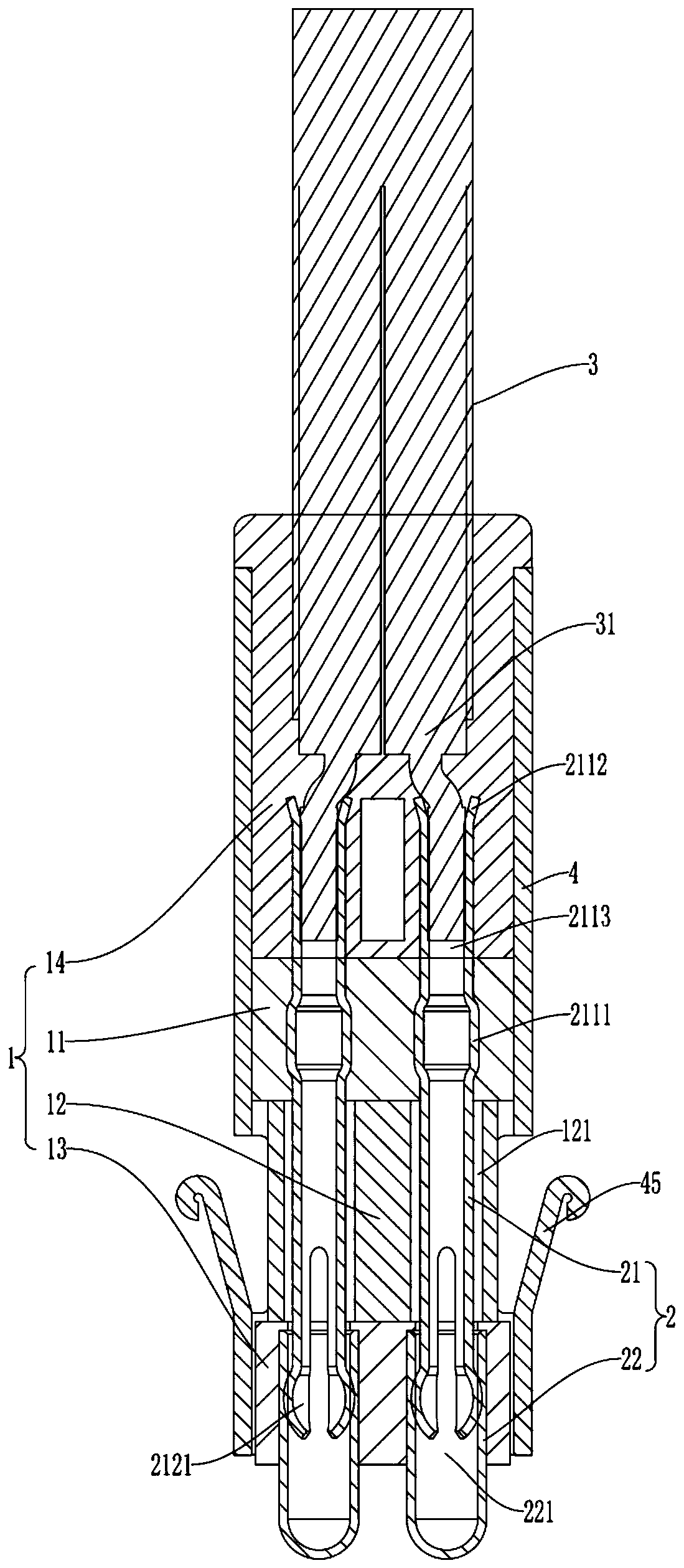

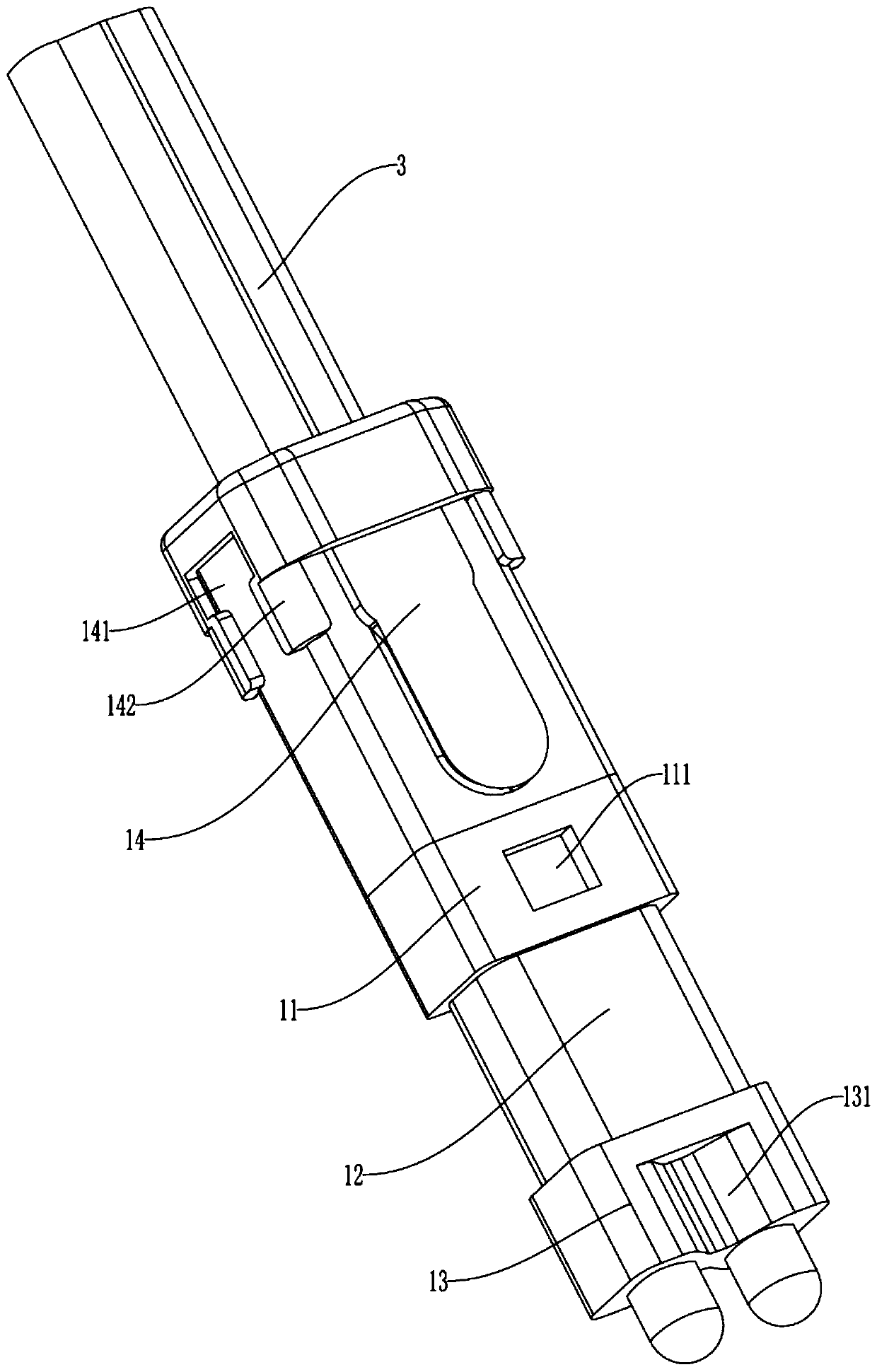

Connector

ActiveCN111509440ANo need to increase the sizeMeet the needs of miniaturization developmentSecuring/insulating coupling contact membersCoupling contact membersMiniaturizationStructural engineering

The invention relates to the technical field of connectors and discloses a connector which comprises an insulating body assembly and a plurality of terminal assemblies arranged side by side, each terminal assembly comprises a connecting terminal and a contact terminal; the connecting terminals are arranged in the insulating body assembly, the front ends of the contact terminals are exposed out ofthe insulating body assembly, tail parts of the contact terminals are provided with accommodating holes, the contact terminals sleeve the front ends of the connecting terminals, the sleeving length isadjustable, and the front ends of the connecting terminals are in elastic contact with inner walls of the accommodating holes. The contact terminals are contracted in a manner of moving towards the direction of the connecting terminals and are not contracted in a bending manner by elastic deformation. Therefore, the part exposed out of the insulating body assembly does not need to be bent, the space occupied by the contact terminals can be reduced, more terminal assemblies can be arranged in the limited space of the connector without increasing the volume of the connector, and the requirementof miniaturization development of the connector is met.

Owner:DONGGUAN LUXSHARE TECH CO LTD

Single-phase inverter input voltage ripple modulation compensation method

ActiveCN103683878AInhibition effectNo need to increase the sizePower conversion systemsHarmonicEngineering

Provided is a single-phase inverter input voltage ripple modulation compensation method which comprises the following steps: when a modulation pulse is outputted, an inverter output voltage and a full-bridge inverter circuit input voltage are acquired; the inverter output voltage is processed so that an SPWM modulation pulse signal is acquired; a ripple parameter is extracted from the full-bridge inverter circuit input voltage; and output voltage harmonic waves brought by ripples can be eliminated from the modulation effect after compensation according to each pulse width of the SPWM modulation pulse signal compensated by the ripple parameter. A modulation strategy is compensated only in software so that hardware cost is saved. Besides, the input voltage ripple parameter is compensated directly so that influence of the ripples can be effectively inhibited and output quality of an inverter system is enhanced.

Owner:惠州汇能精电科技有限公司

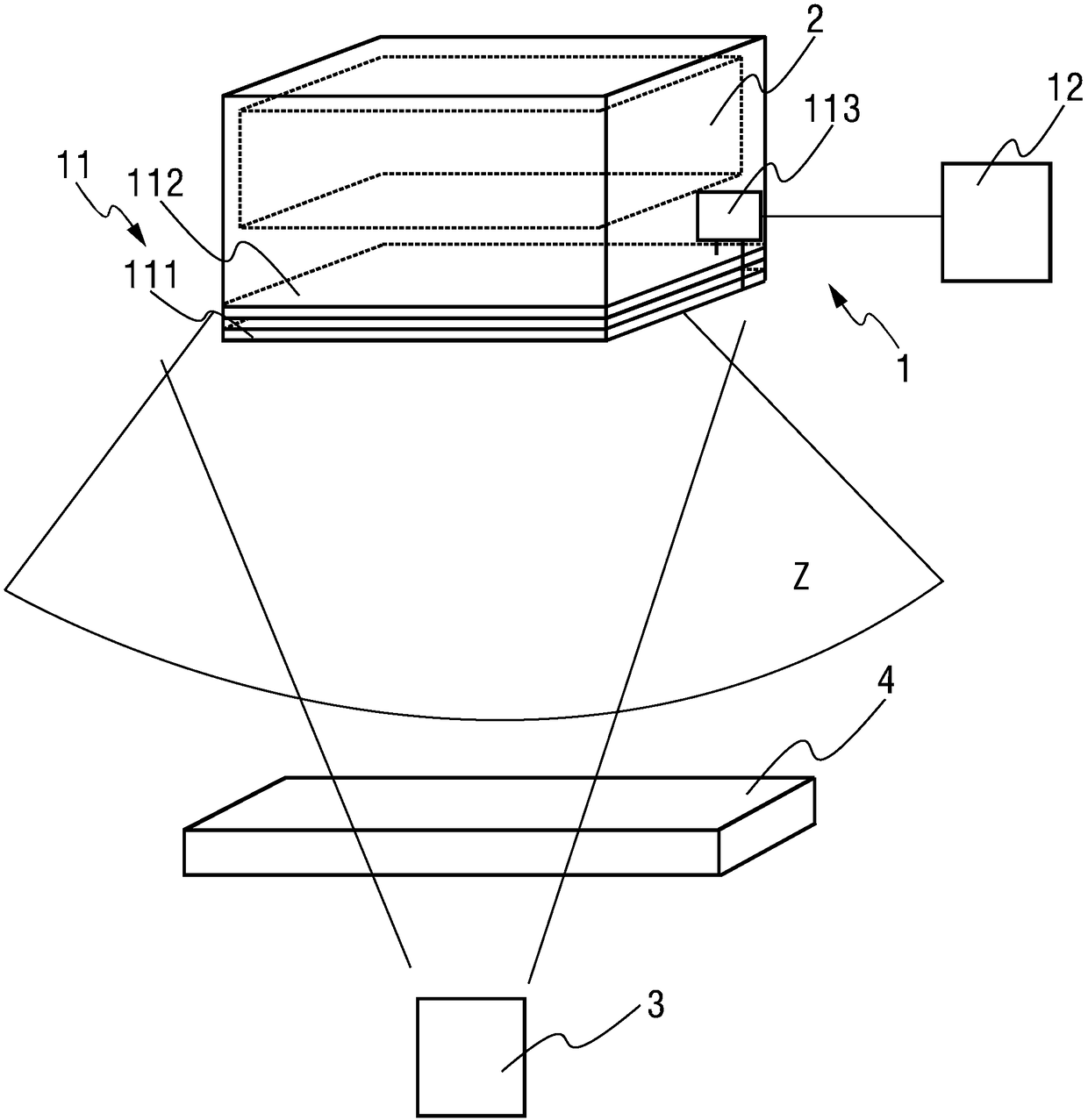

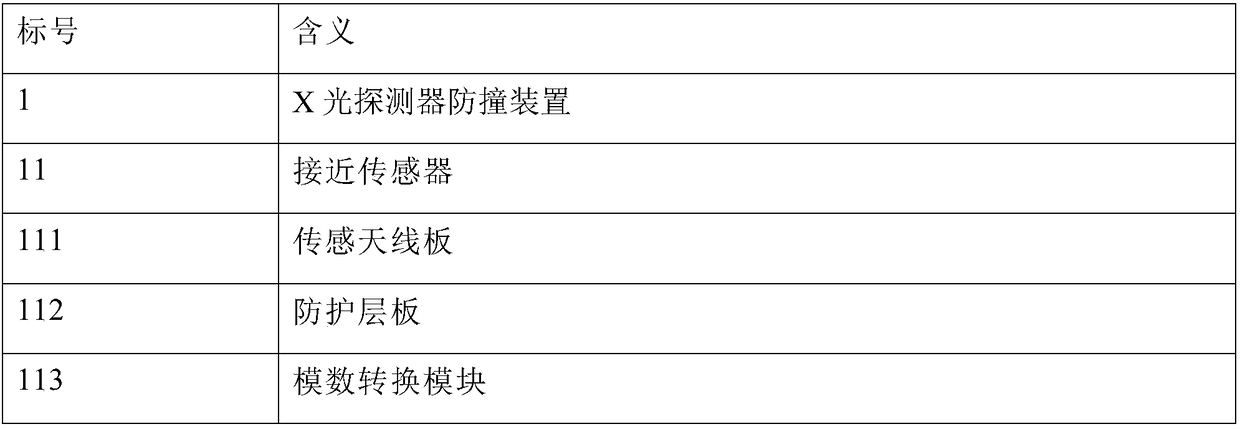

X-ray detector anti-collision device, method and proximity sensor thereof

InactiveCN108201448AAchieving crash protectionMake up for the shortcomingsRadiation safety meansElectric/magnetic detectionElectricityCapacitance

The invention discloses an X-ray detector anti-collision device, method and proximity sensor thereof. The proximity sensor comprises a sensing antenna plate which is made of X-ray transmissive material and is positioned at one side, where X-ray signals are received, of the X-ray detector, for detecting the capacitance signals in a detected area; and an analog-to-digital conversion module which iselectrically connected with the sensing antenna plate and is used for converting the capacitance signals into digital capacitance values from analog quantity. The technical solution in the invention can realize the anti-collision protection of the X-ray detector.

Owner:SIEMENS SHENZHEN MAGNETIC RESONANCE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com